When it comes to maintaining and operating heavy farming equipment, having a comprehensive understanding of the various elements that contribute to its functionality is essential. This section aims to provide a detailed overview of the intricate assembly of these machines, highlighting their critical components and their respective roles. Familiarity with these elements not only enhances operational efficiency but also facilitates troubleshooting and repairs.

Throughout this guide, we will explore the intricacies involved in the design and arrangement of different components that work in unison to ensure optimal performance. Each piece serves a specific purpose, contributing to the overall effectiveness of the equipment. By examining the layout and connections, users can gain valuable insights into how to properly maintain and service their machinery.

Additionally, understanding the structure of these components allows operators to make informed decisions when it comes to repairs and replacements. Recognizing which parts are interchangeable or require specific attention can significantly reduce downtime and improve productivity. Engaging with this knowledge empowers users to optimize their equipment’s performance and longevity.

Understanding New Holland Tractors

The machinery produced by this renowned brand has become synonymous with reliability and efficiency in agricultural and construction applications. These robust machines are designed to tackle a variety of tasks, ranging from fieldwork to heavy lifting. Their exceptional engineering ensures durability and ease of use, making them a preferred choice among professionals and enthusiasts alike.

Recognizing the key components of these machines is essential for optimal performance and maintenance. Each element is intricately designed to work harmoniously, contributing to the overall functionality of the equipment. Familiarity with the layout and design of these components empowers operators to make informed decisions regarding service and repairs.

Additionally, understanding how these machines operate can greatly enhance their efficiency. Operators equipped with knowledge about the various systems can ensure proper handling, leading to improved productivity and longevity of the equipment. Regular maintenance, based on a solid comprehension of the inner workings, is crucial for sustaining performance over time.

Essential Components of Tractors

Understanding the fundamental elements of agricultural machinery is crucial for efficient operation and maintenance. Each unit plays a vital role in enhancing productivity and ensuring reliability during farming activities. A comprehensive grasp of these key components can lead to better decision-making regarding repairs, upgrades, and overall management.

Key Elements

- Engine: The powerhouse of the machinery, responsible for generating the necessary energy to perform various tasks.

- Transmission: This system transfers power from the engine to the wheels, enabling movement and control over speed.

- Hydraulics: Essential for lifting and maneuvering attachments, allowing for versatile functionality in different applications.

- Chassis: The framework that supports all other components, providing structural integrity and stability.

- Electrical System: Powers lights, controls, and other electronic devices necessary for modern operations.

Attachments and Implements

In addition to core systems, various accessories enhance functionality:

- Plows: Used for turning over soil and preparing fields for planting.

- Seeders: Essential for evenly distributing seeds across prepared land.

- Harvesters: Designed to efficiently collect mature crops, streamlining the harvesting process.

- Tillage Tools: Important for soil cultivation, helping to improve aeration and nutrient availability.

Recognizing these components fosters a deeper appreciation for their roles and contributes to effective equipment management in agricultural settings.

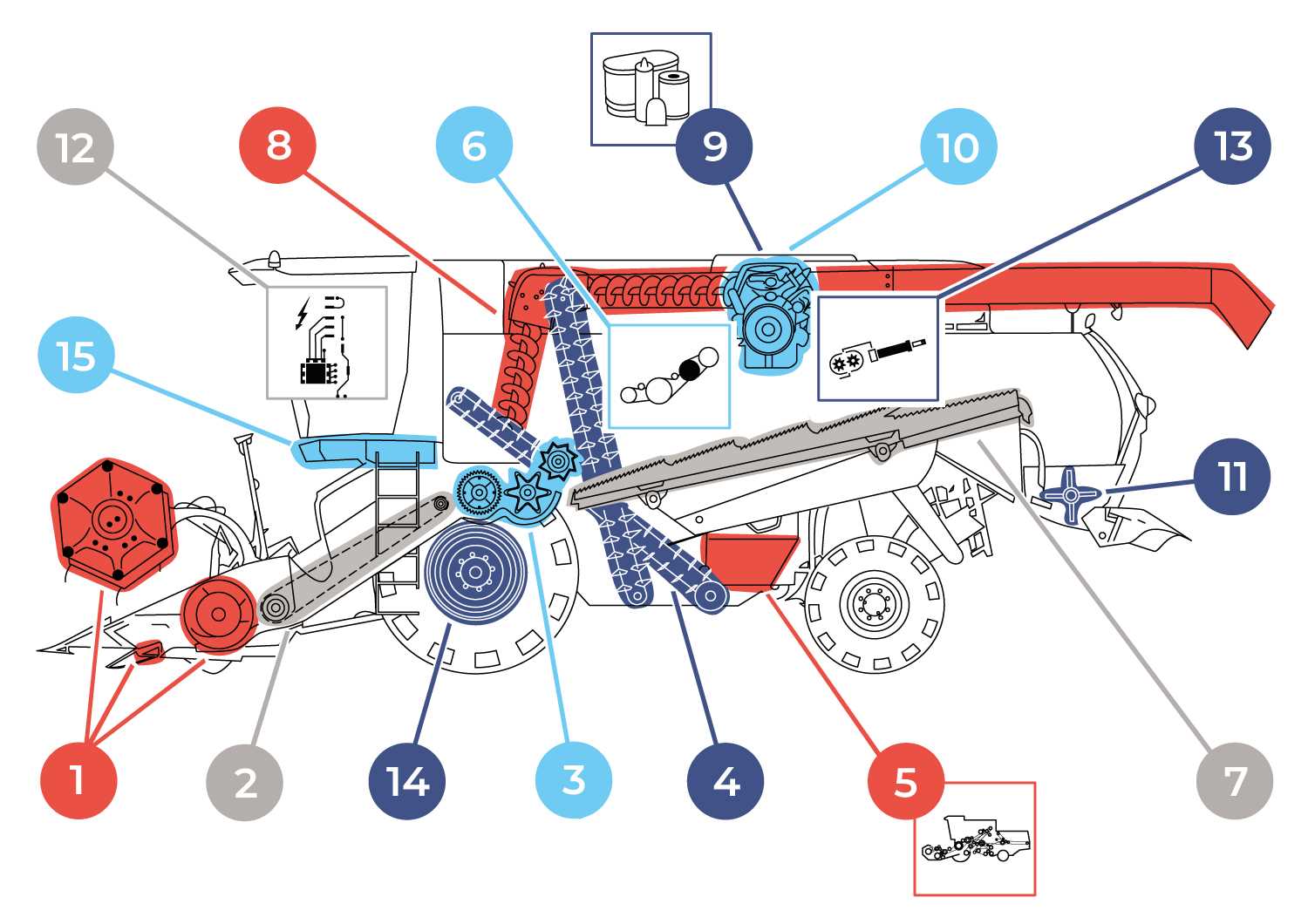

Identifying Key Parts and Functions

Understanding the essential components of agricultural machinery is crucial for efficient operation and maintenance. Recognizing these elements enables users to troubleshoot issues effectively and ensures optimal performance during various tasks. Each component plays a significant role, contributing to the overall functionality of the equipment.

Main Components Overview

The following table highlights some of the primary elements commonly found in such machinery, along with their respective functions:

| Component | Function |

|---|---|

| Engine | Provides power to operate various systems. |

| Transmission | Transfers power from the engine to the wheels, allowing for speed adjustments. |

| Hydraulic System | Facilitates lifting and controlling attachments through fluid pressure. |

| Cooling System | Maintains optimal operating temperature to prevent overheating. |

| Chassis | Serves as the frame, supporting various components and providing stability. |

Understanding Functions

Each listed element is vital for the overall efficiency of the machinery. The engine’s power output must be effectively managed by the transmission, while the hydraulic system enhances versatility. Proper cooling ensures reliability, and the chassis provides the necessary structure for durability and stability during operation.

Common Issues with Tractor Parts

Maintaining machinery can present various challenges that affect its overall performance. Understanding the typical problems associated with components is essential for effective troubleshooting and ensuring operational efficiency. This section outlines common difficulties encountered with mechanical elements, highlighting key areas that require attention.

Frequent Mechanical Challenges

- Wear and Tear: Over time, components can degrade due to prolonged use, leading to diminished performance.

- Improper Installation: Incorrectly fitted elements can cause malfunctions and result in significant damage.

- Lack of Maintenance: Neglecting regular upkeep can lead to failures and costly repairs.

Signs of Malfunction

- Unusual Noises: Sounds such as grinding or squeaking may indicate internal issues.

- Decreased Efficiency: A noticeable drop in productivity can signal problems with specific components.

- Fluid Leaks: Puddles or stains beneath the machinery often suggest a leaking component.

Identifying these issues early on can save time and resources, ensuring that the machinery operates smoothly and reliably.

Maintenance Tips for Longevity

To ensure the extended life of your machinery, regular upkeep and attention to detail are essential. Proper maintenance not only enhances performance but also minimizes the likelihood of unexpected breakdowns. Implementing a consistent maintenance routine can lead to significant savings in repair costs and downtime.

Regular Inspections

Frequent evaluations of various components are crucial. Check for wear and tear on essential parts, including belts, hoses, and filters. Identifying issues early can prevent more significant problems in the future.

Fluid Management

Keeping fluids at the appropriate levels is vital for optimal operation. Regularly change the engine oil and coolant, and ensure that hydraulic fluids are clean and at the correct levels. This practice promotes efficient performance and reduces the risk of overheating.

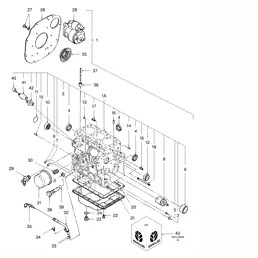

Parts Replacement Procedures Explained

Understanding the methods for replacing components is essential for maintaining equipment efficiency and longevity. This section outlines effective strategies for ensuring that each replacement is conducted smoothly and safely.

Here are the general steps to follow when replacing a component:

- Preparation: Gather all necessary tools and new components before beginning the replacement process.

- Safety Precautions: Ensure the equipment is powered off and take necessary safety measures to prevent accidents.

- Access the Component: Remove any coverings or obstructions that prevent access to the component needing replacement.

- Remove the Old Component: Carefully detach the faulty item, taking note of how it is connected for easy reassembly.

- Install the New Component: Position the new item correctly and secure it in place, ensuring all connections are tight and properly aligned.

- Reassemble the Equipment: Replace any covers or parts that were removed, ensuring everything is returned to its original state.

- Testing: Power on the equipment and conduct a test run to verify that the new component is functioning correctly.

Following these procedures will enhance the efficiency of your machinery and reduce the likelihood of future issues. Regular maintenance and timely replacements are key to optimal performance.

Tools Required for Repairs

Performing maintenance and repairs on agricultural machinery necessitates a variety of specialized instruments. These tools are essential for ensuring that each task is completed efficiently and effectively, allowing for optimal functionality and longevity of the equipment. Understanding the specific tools needed can streamline the repair process and minimize downtime.

Essential Hand Tools

Having the right hand tools at your disposal is crucial for addressing minor repairs and adjustments. Common instruments include wrenches, screwdrivers, and pliers. Each of these plays a significant role in loosening or tightening components, as well as in disassembling various sections of the machinery for thorough inspection.

Power Tools for Efficiency

In addition to hand tools, power tools can significantly enhance the efficiency of repair tasks. Drills and impact wrenches are particularly useful for handling stubborn fasteners and making quick work of assembly or disassembly. Utilizing these tools can save valuable time, allowing for quicker returns to field operations.

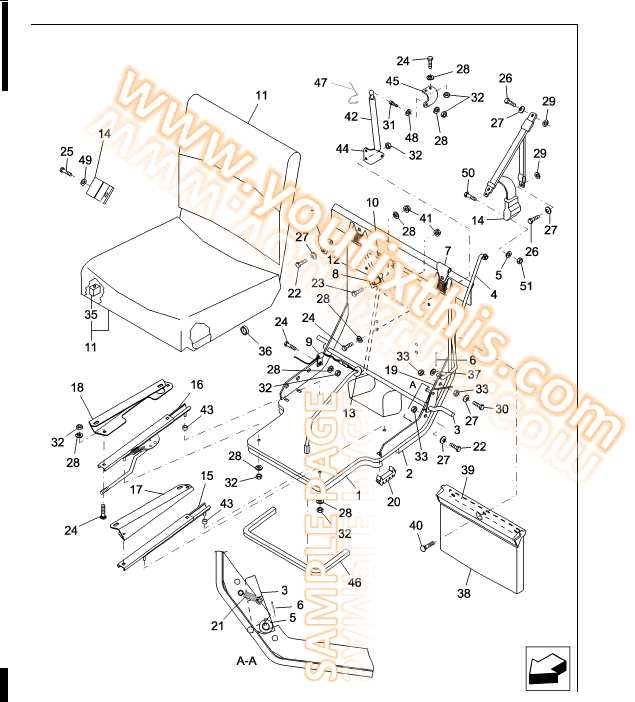

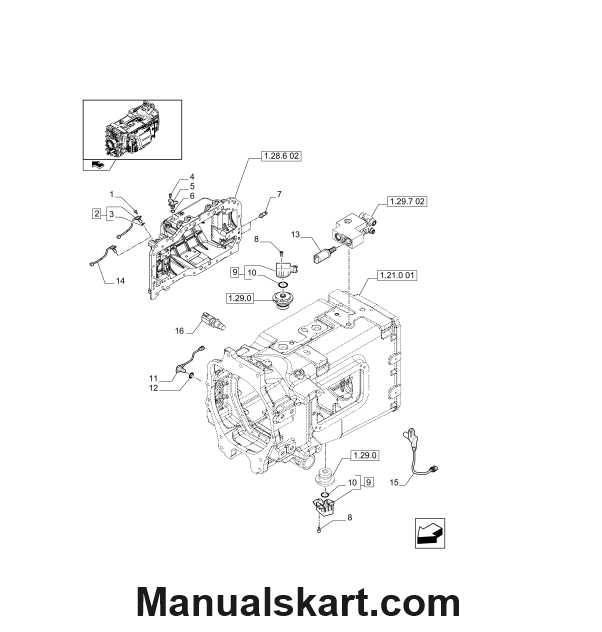

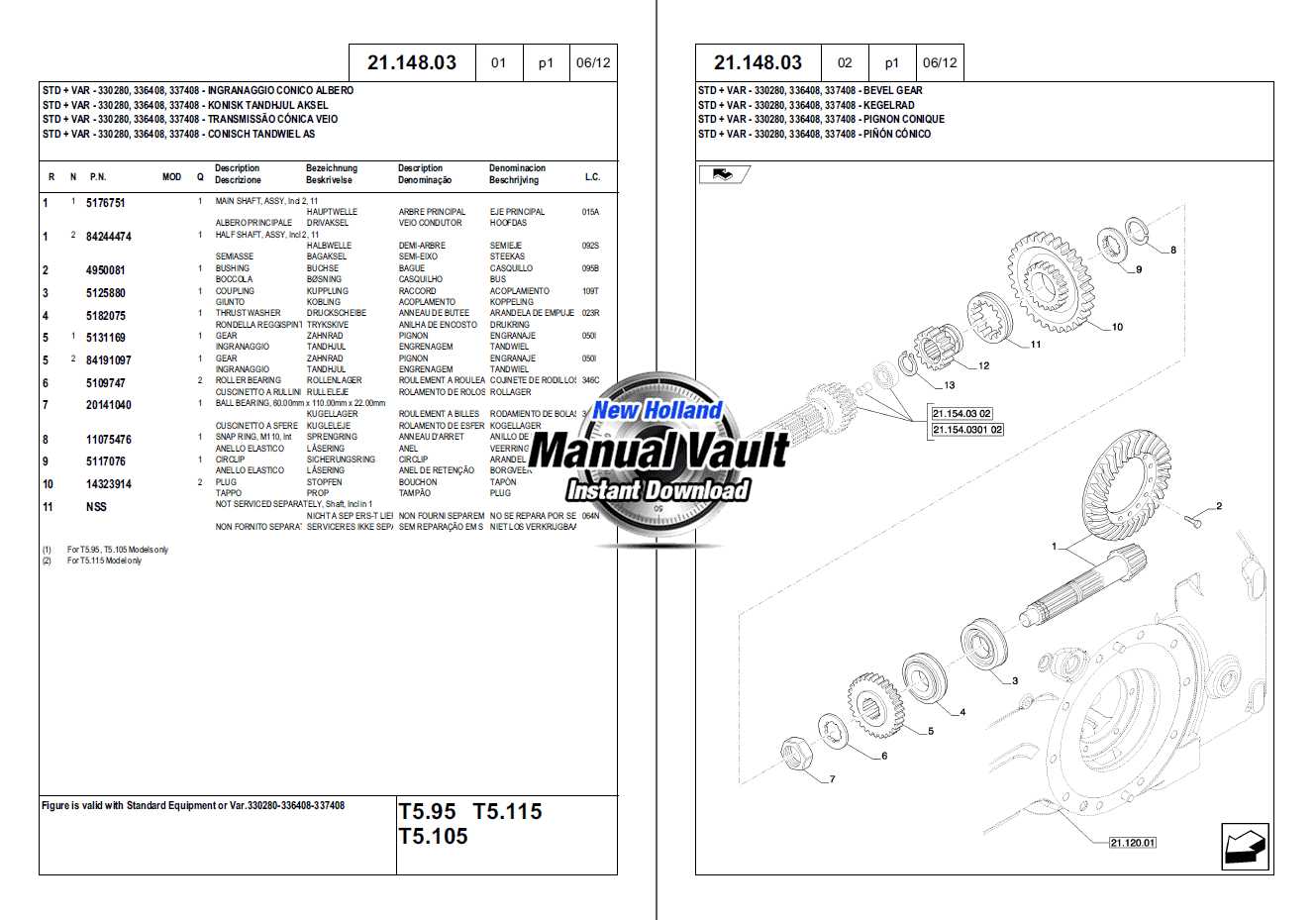

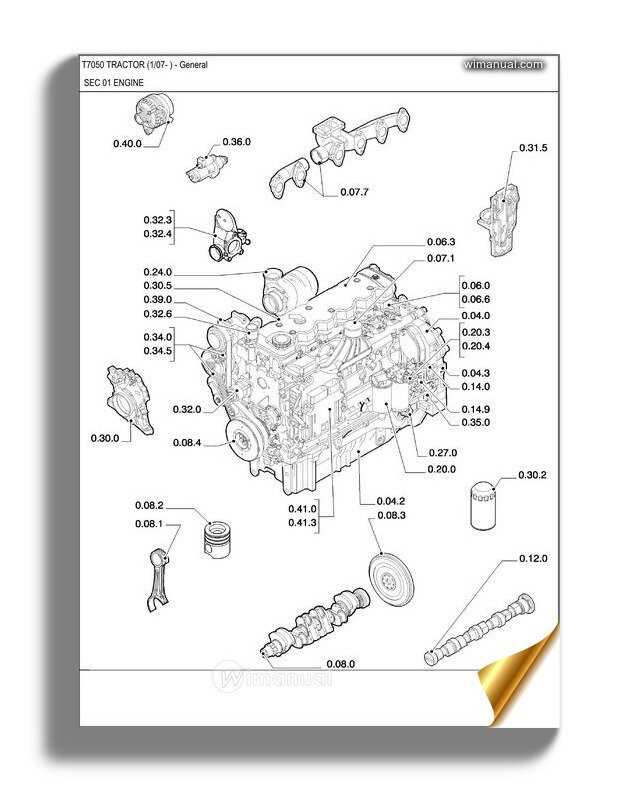

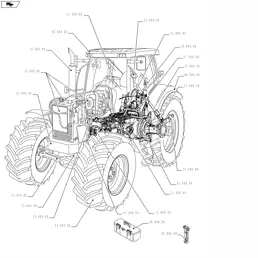

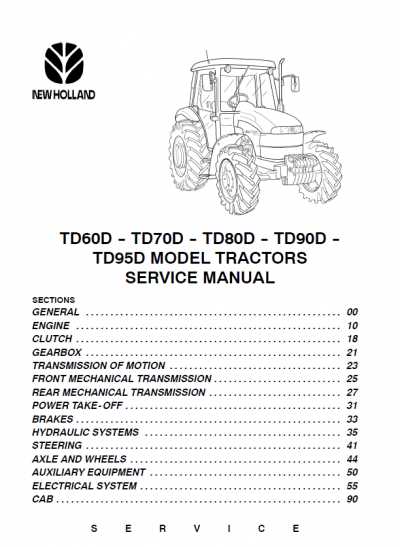

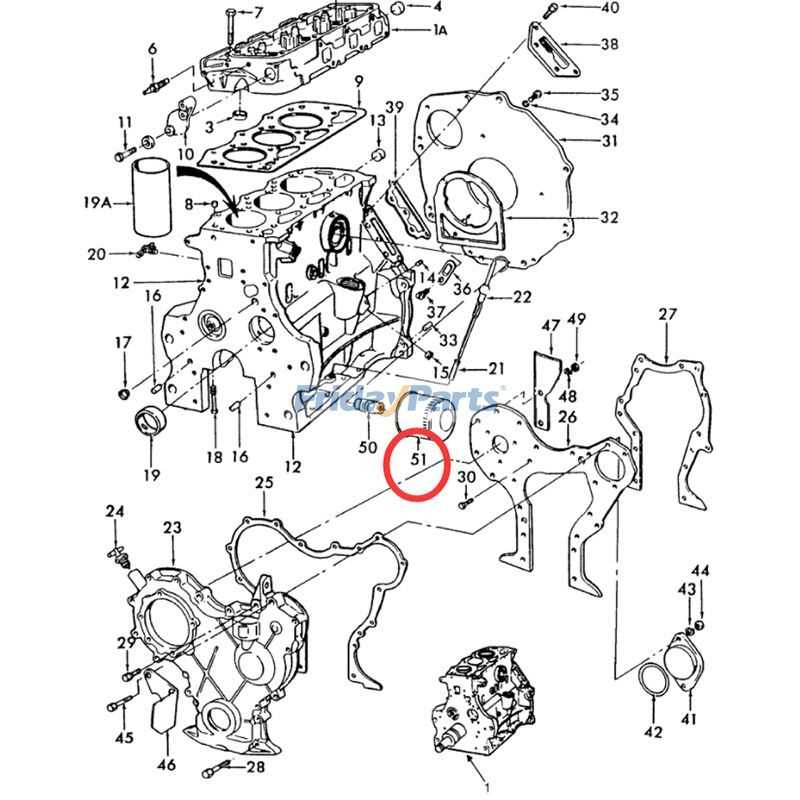

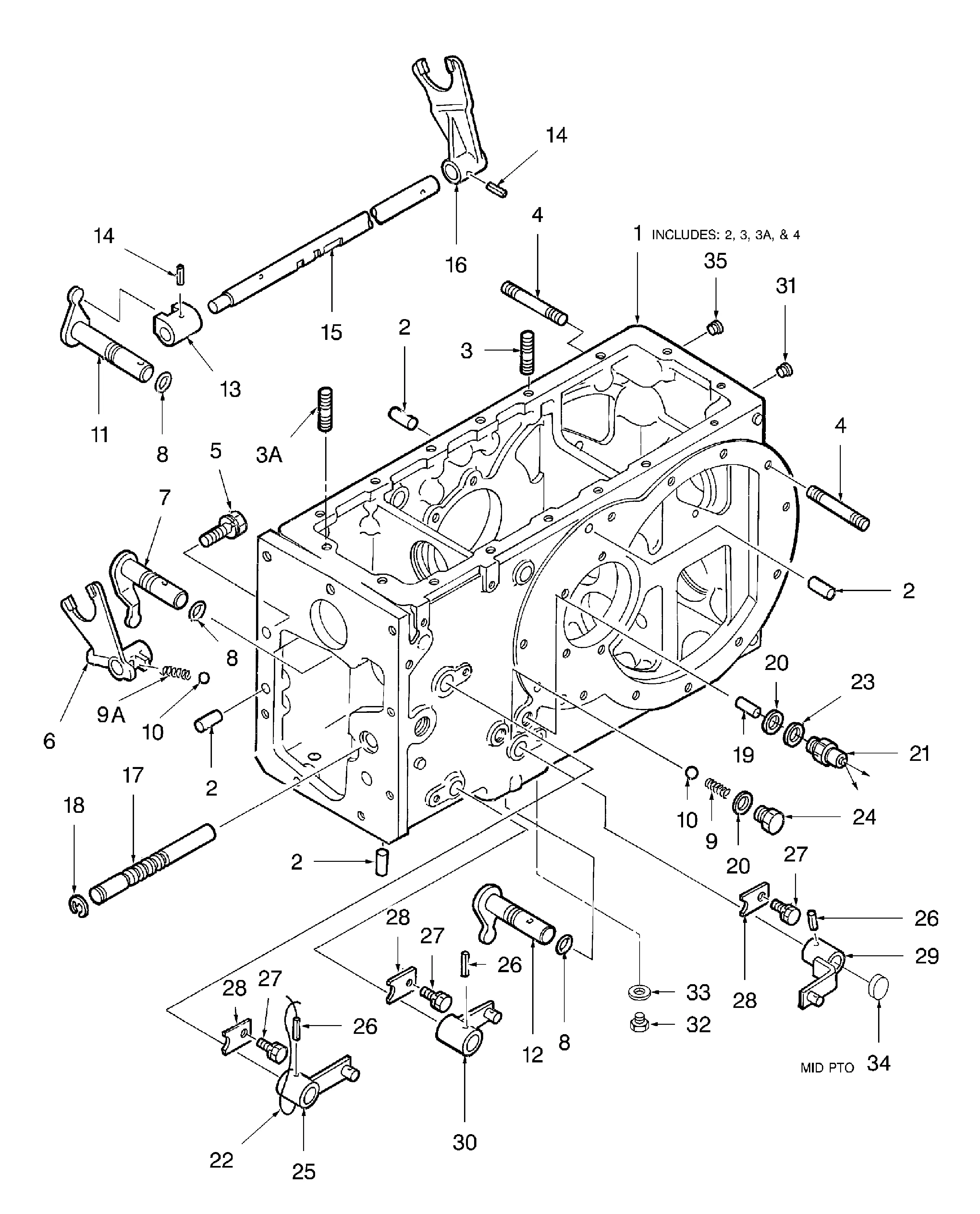

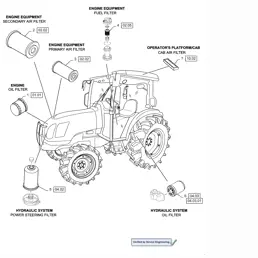

Diagram Interpretation and Usage

Understanding visual representations is essential for efficient maintenance and repair of machinery. These illustrations serve as valuable resources, offering insights into the components and their interconnections. By deciphering these visuals, operators can effectively troubleshoot issues and enhance the overall functionality of their equipment.

When approaching these representations, it’s crucial to familiarize oneself with the symbols and notations used. Each element signifies a specific component or connection, providing a clear understanding of the system’s layout. Proper interpretation not only aids in identifying potential faults but also facilitates informed decision-making during repairs.

Utilizing these visuals allows for a systematic approach to maintenance. By referencing the illustrations, technicians can efficiently locate parts and follow correct procedures, minimizing downtime. Moreover, this practice encourages a proactive maintenance strategy, ensuring that machinery operates optimally over time.

In summary, mastering the interpretation of these illustrations is key to enhancing operational efficiency. Engaging with these resources enables individuals to perform tasks confidently and accurately, ultimately contributing to the longevity of the equipment.

Aftermarket Parts vs. Original Equipment

The choice between replacement components from independent manufacturers and those supplied by the original manufacturer is a significant consideration for many equipment owners. Each option has its own set of advantages and disadvantages that can impact performance, reliability, and cost-effectiveness.

Advantages of Aftermarket Components

- Cost Savings: Independent products often come at a lower price point, making them an attractive choice for budget-conscious consumers.

- Variety: There is a broader selection available, allowing for customization and improved performance tailored to specific needs.

- Availability: These components are typically easier to source, with many suppliers offering fast shipping and local availability.

Benefits of Original Manufacturer Components

- Quality Assurance: Components from the original maker are designed specifically for compatibility, ensuring optimal performance and durability.

- Warranty Protection: Using genuine products often helps maintain warranty coverage, providing peace of mind for users.

- Technical Support: Original suppliers typically offer dedicated customer service, which can be valuable in troubleshooting and installation.

Ultimately, the decision should be guided by individual priorities, including budget, performance needs, and long-term maintenance considerations.

Ordering Parts Efficiently Online

When it comes to acquiring components for your agricultural machinery, navigating the online marketplace can be a straightforward yet crucial task. Understanding how to streamline the ordering process not only saves time but also ensures that you receive the correct items needed for maintenance or repair. This section will explore practical strategies to enhance your purchasing experience, making it as efficient as possible.

Identifying Reliable Suppliers

Choosing a reputable source is essential for obtaining quality items. Look for websites that provide detailed product descriptions, customer reviews, and reliable shipping options. Ensure that the supplier offers a clear return policy and customer support to address any potential issues.

Utilizing Search Tools Effectively

Most online platforms feature advanced search tools that allow you to filter results based on specific criteria. Utilize these features to narrow down your options by specifications, compatibility, or price range. This approach minimizes time spent browsing and increases the likelihood of finding the exact component required.

Additionally, consider creating an account on the supplier’s website. This can streamline future orders, as your shipping information and preferences will be saved, making reordering seamless. Always verify the part numbers and specifications before completing your purchase to avoid any discrepancies.

By following these guidelines, you can make the online ordering process efficient and effective, ensuring your machinery remains in optimal condition.

Safety Guidelines During Repairs

Ensuring safety while conducting maintenance is crucial for preventing accidents and injuries. Adhering to established protocols helps create a secure working environment, allowing for efficient repairs and minimizing risks. Proper preparation and awareness of surroundings contribute significantly to overall safety during the process.

1. Wear Appropriate Personal Protective Equipment (PPE): Always equip yourself with suitable gear, including gloves, safety goggles, and steel-toed boots. This protective clothing safeguards against potential hazards and reduces the risk of injury.

2. Disconnect Power Sources: Before initiating any work, ensure that all power sources are disconnected. This includes removing batteries and unplugging electrical connections to prevent accidental activation.

3. Utilize Proper Tools: Use the right tools for each task, ensuring they are in good condition. This not only enhances efficiency but also minimizes the likelihood of accidents caused by tool malfunctions.

4. Maintain a Clean Workspace: A tidy area helps prevent tripping hazards and allows for easier access to equipment. Regularly clean up any spills and remove unnecessary items from the workspace.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions and guidelines for specific procedures. Adhering to these recommendations ensures that repairs are performed correctly and safely.

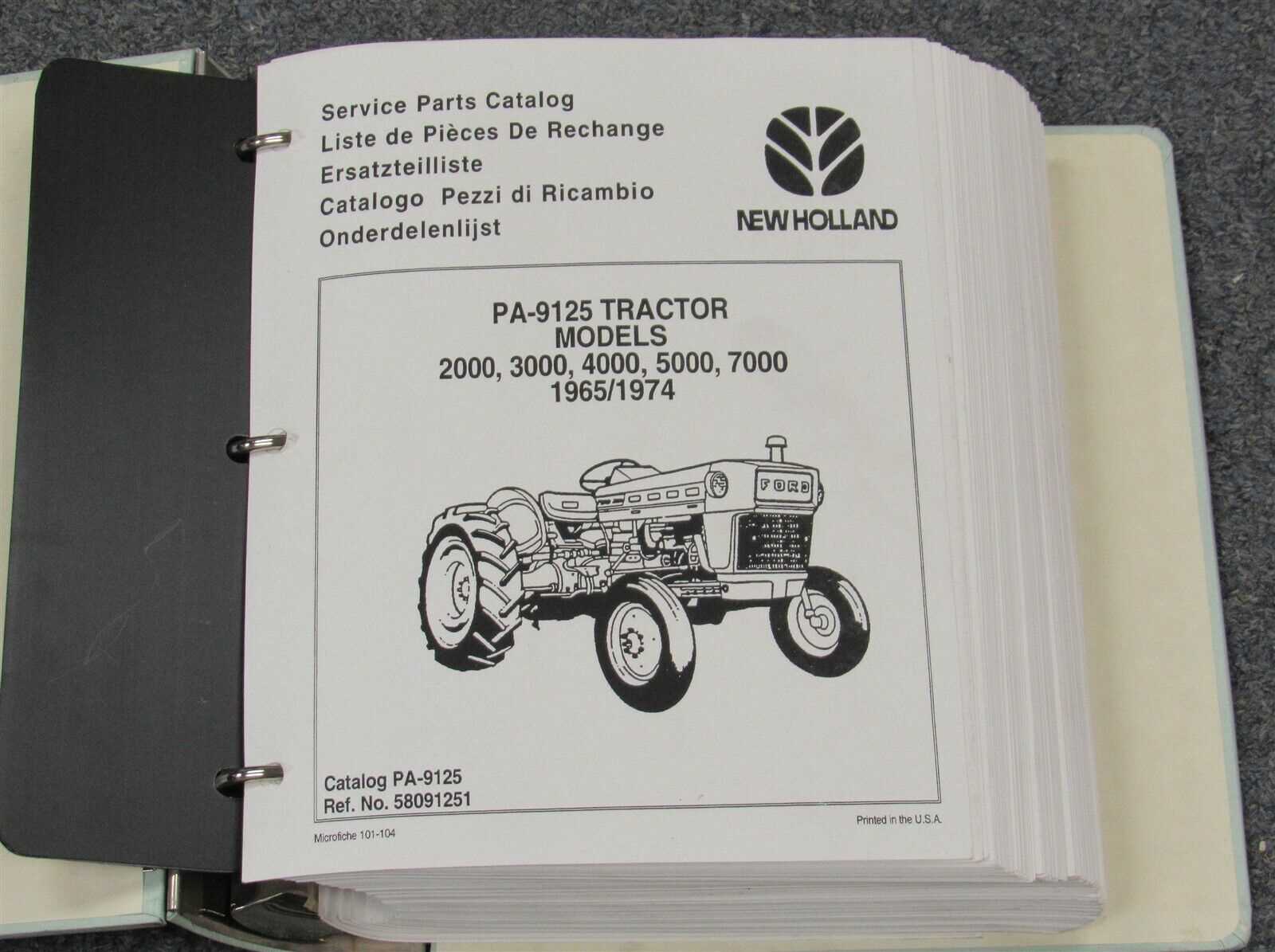

Tractor Parts Resources and References

This section provides valuable information and sources for identifying and acquiring components related to agricultural machinery. Having access to accurate references is essential for maintenance, repairs, and upgrades, ensuring optimal functionality of the equipment. Various resources offer detailed insights, including manuals, online databases, and specialized forums.

Online Databases and Retailers

Numerous websites cater to enthusiasts and professionals seeking information on components. Online retailers often have extensive catalogs that include images, specifications, and compatibility details, making it easier to find the right items for specific machines. Additionally, some platforms feature user reviews that can guide purchasing decisions.

Manufacturer Support and Communities

Reaching out to manufacturers can yield official documentation, troubleshooting tips, and parts availability. Online communities and forums provide a space for users to share experiences and solutions, fostering collaboration and knowledge exchange among those who work with similar machinery.