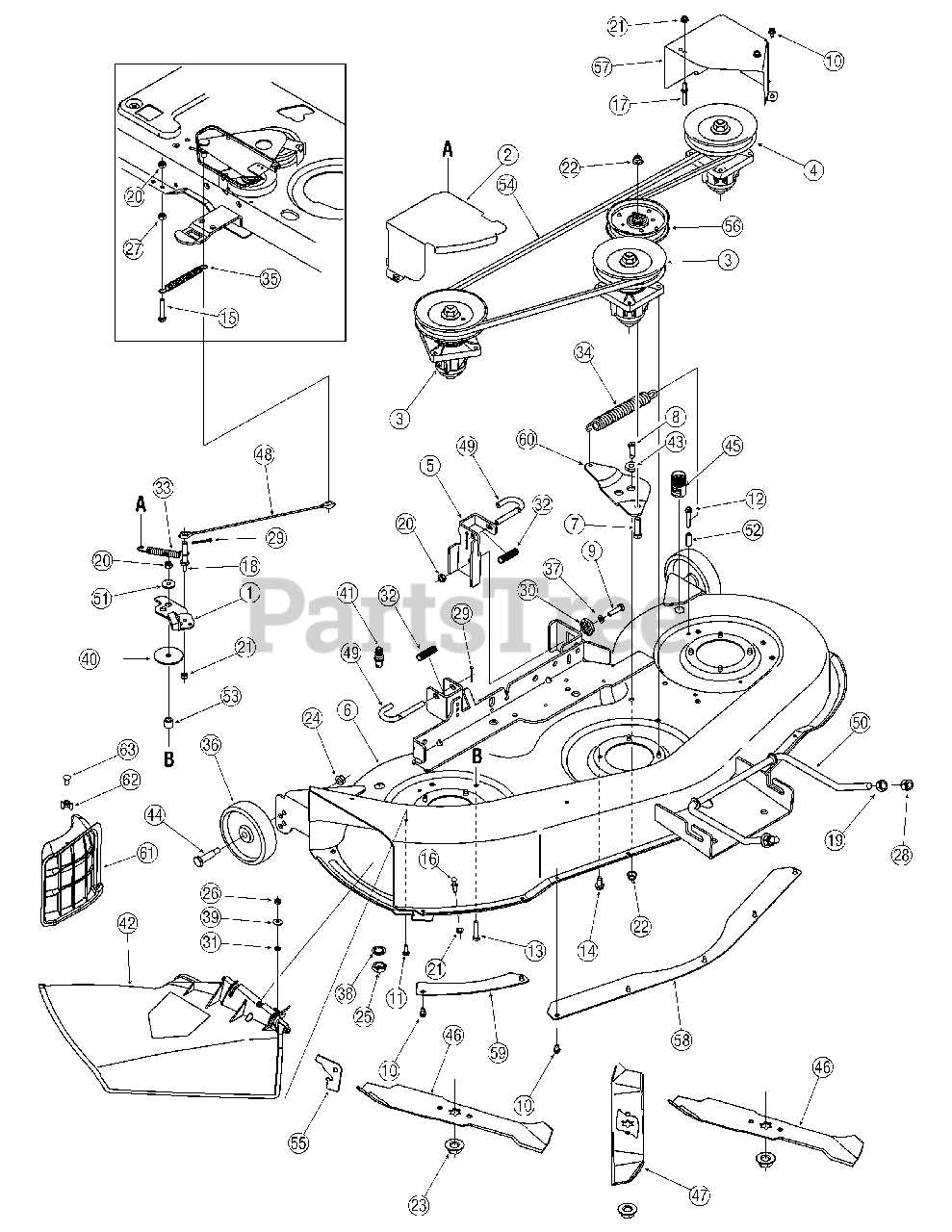

When dealing with intricate machinery, knowing the internal structure of each component is essential for maintenance and repairs. Understanding how different elements connect and interact helps ensure smooth operation and extends the lifespan of the equipment. A detailed overview of the connections and mechanisms can greatly assist in troubleshooting and servicing.

For those working with complex mechanical systems, having a visual reference to the arrangement of key components is invaluable. Whether you’re replacing individual elements or conducting a full system overhaul, understanding the positioning and relationships between parts is crucial. This information not only simplifies repairs but also enhances overall efficiency and performance.

By familiarizing yourself with the layout and relationships of various mechanical elements, you can more easily identify issues, ensure proper function, and maintain a high level of performance. A clear understanding of how different parts fit together can save time and prevent costly mistakes during maintenance or repairs.

Understanding Key Components of White Tractor

To ensure the smooth operation of any agricultural machinery, it’s essential to be familiar with its fundamental systems. This knowledge aids in regular maintenance and efficient troubleshooting, contributing to optimal performance and longevity. Below, we will explore the primary elements that make up this type of equipment, shedding light on their functions and interdependencies.

Core Mechanical Structures

The primary framework of this machinery consists of several key structural components. These elements provide support and stability, enabling the equipment to handle various types of terrain and loads. The essential systems are designed to withstand stress and ensure that the machinery can operate effectively, even in demanding conditions.

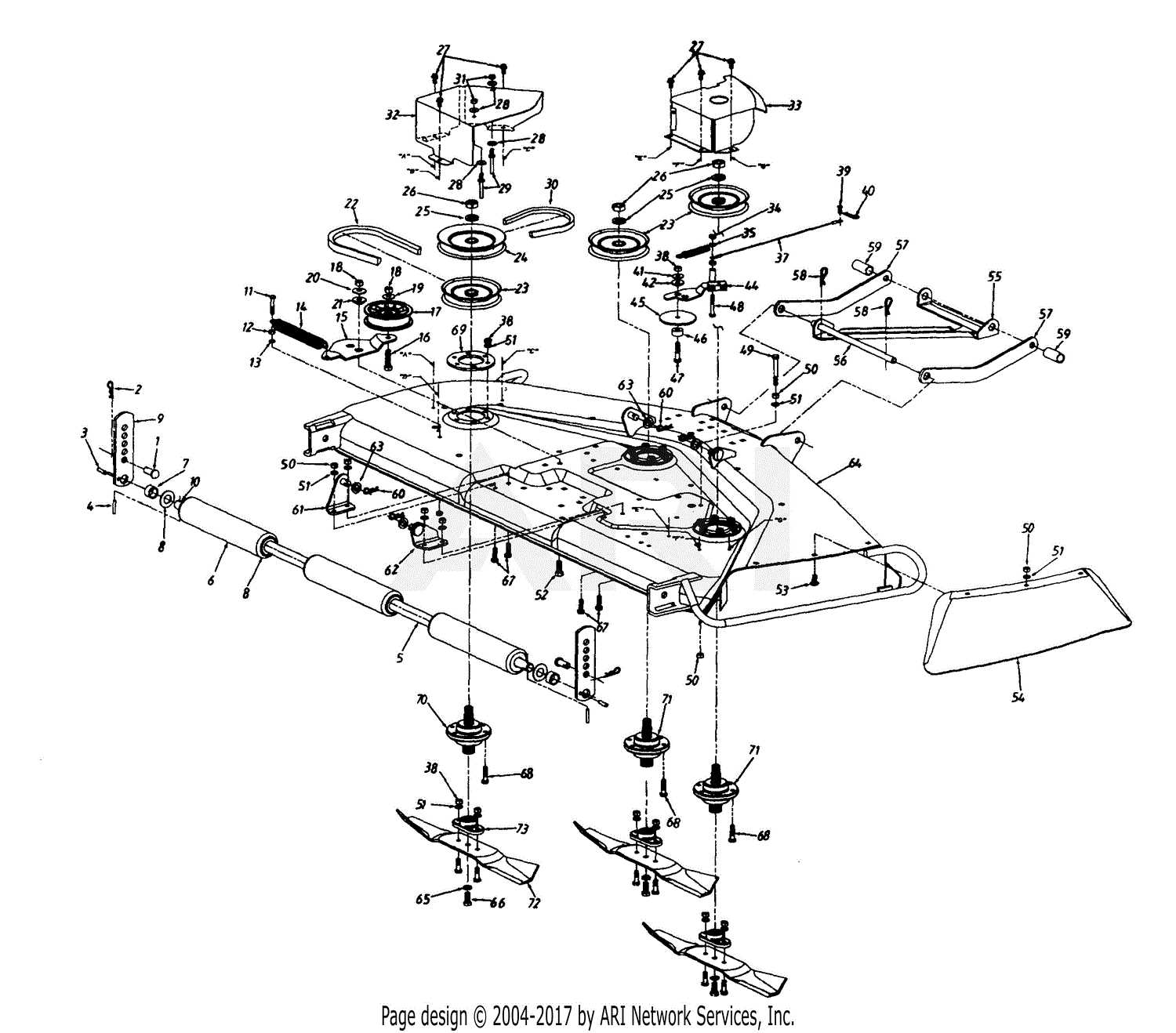

Powertrain and Transmission System

At the heart of the machinery’s operation is the powertrain, which transfers energy from the engine to the wheels. The transmission system, a crucial component within this setup, allows the operator to adjust speeds and maintain control over the equipment. Understanding how

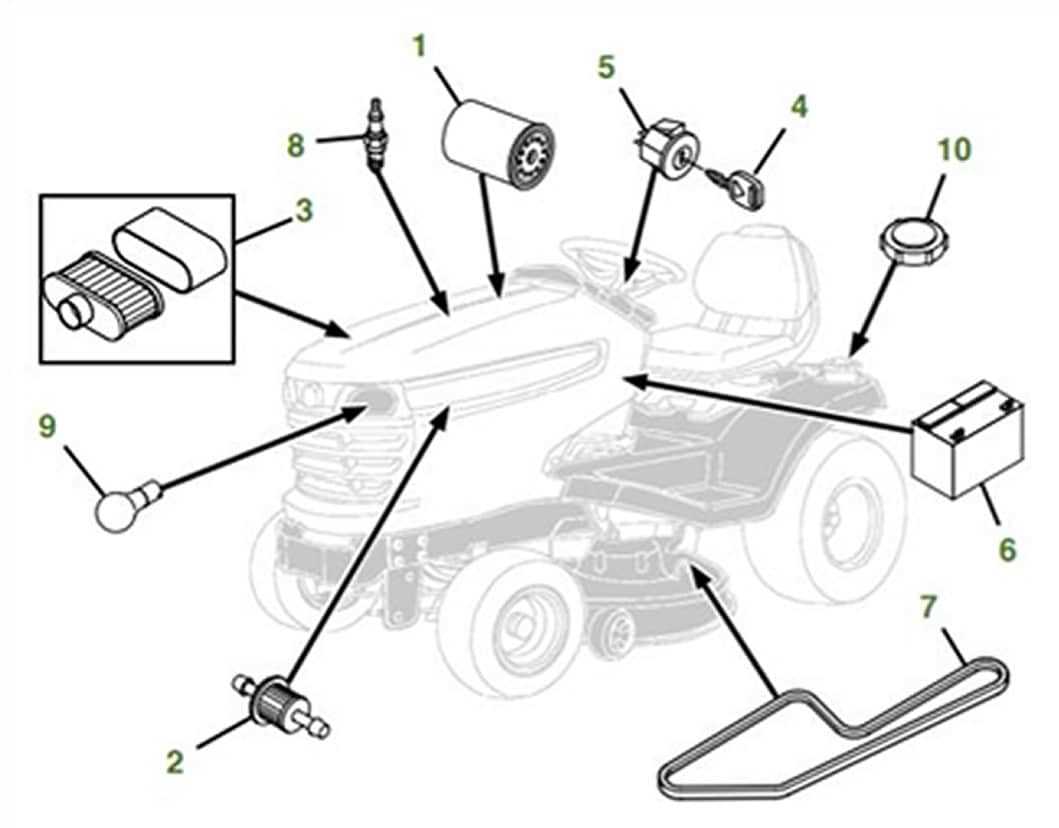

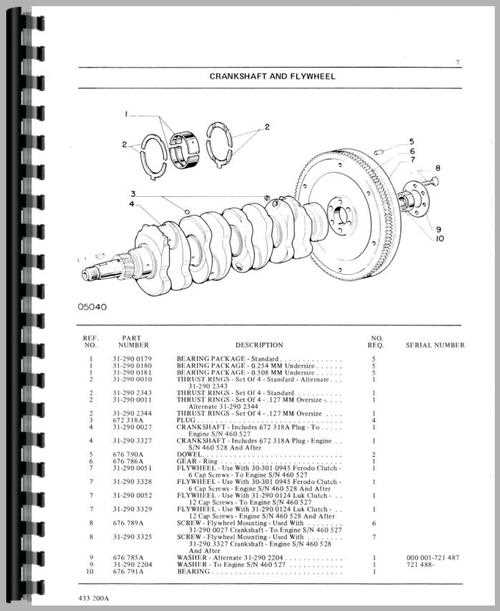

Identifying Engine Parts and Their Functions

Understanding the key elements of an engine and their specific roles is crucial for maintaining performance and diagnosing potential issues. Each component plays a vital role in ensuring smooth operation, from the internal mechanisms to the systems that support power generation and efficiency. In this section, we’ll explore the main components and their functions in detail.

Major Engine Components

The engine is composed of several essential elements, each with a distinct purpose. Below is an overview of the most common components found in modern engines:

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Piston | Converts fuel combustion into mechanical motion to drive the crankshaft. | ||||||||||||

| Crankshaft | Transforms the pistons’ up-and-down motion into rotational motion for the drivetrain. | ||||||||||||

| Cylinder Head |

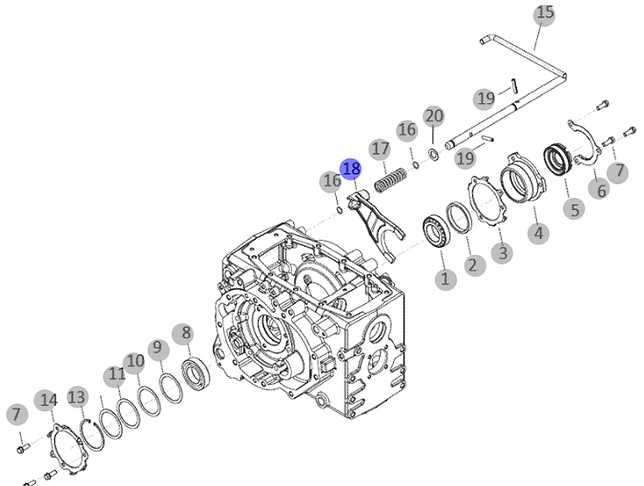

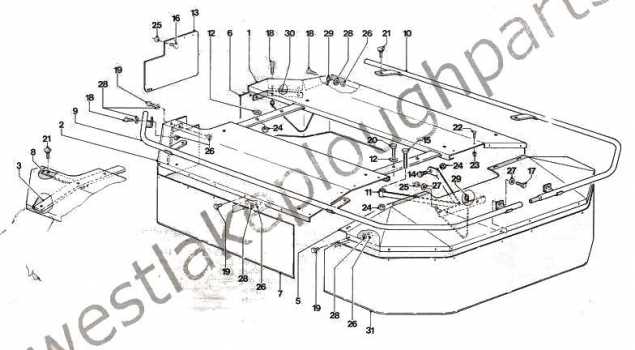

Transmission System Breakdown for White TractorThe transmission system plays a crucial role in the overall operation of the machine, ensuring efficient power delivery and control. This section provides an in-depth look at the key elements that make up this system, highlighting how each component contributes to smooth and reliable performance. Understanding these components is vital for maintaining operational effectiveness and diagnosing potential issues. Core Components of the Transmission

How the Transmission Operates

The transmission works by transferring energy from the engine to the wheels. This energy conversion is controlled through a combination of gears, hydraulic elements, and clutches, allowing the operator to adjust speed and torque Hydraulic System Overview and Component Layout

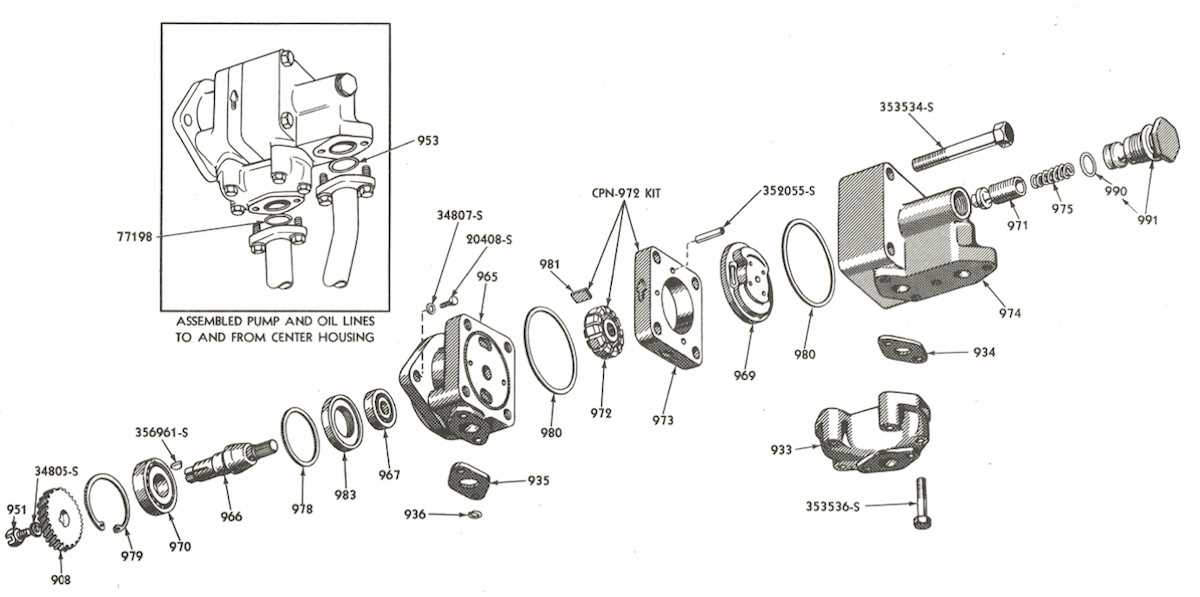

The hydraulic system serves as a key mechanism in the functioning of various equipment, enabling smooth and efficient movement through the controlled transfer of fluids. Understanding the core components and their arrangement is essential for maintaining optimal performance. The system operates through a combination of pressure, flow, and direction to deliver precise force where it’s needed. Main Hydraulic Components

At the heart of the system is the pump, which generates the necessary pressure to drive the entire operation. Connected to this is a network of hoses and valves that regulate the flow and direction of the fluid. These elements work together to ensure the accurate delivery of hydraulic power to the actuators. Layout and Flow PathThe layout of the system follows a logical flow, starting with the reservoir that holds the fluid, feeding it into the pump. From there, the fluid travels through various channels and control Exploring the Electrical Wiring ConnectionsUnderstanding the layout of electrical wiring is essential for ensuring proper operation and maintenance of complex machinery. This section will delve into the various connections, examining how components are linked together to ensure seamless functionality. Proper knowledge of these connections can prevent issues and ensure the efficient handling of electrical systems. Each wire serves a specific purpose, often color-coded for easy identification. Whether it’s powering a system or facilitating communication between parts, recognizing the role of each connection is crucial. By paying attention to wiring details, one can ensure that all electrical components operate harmoniously and effectively. Furthermore, it’s important to regularly inspect and maintain these connections, as wear and environmental factors can affect their integrity. Proper handling, including securing loose wires and replacing damaged ones, contributes to the long-term reliability of the system. Knowing how to navigate the wiring layout helps streamline troubleshooting and maintenance tasks. Fuel System Configuration and Key PartsThe functionality of any agricultural machinery heavily relies on the efficiency of its energy delivery mechanism. A well-organized fuel system is essential for optimal operation, ensuring that the engine receives a consistent supply of energy for performance. This section delves into the configuration and crucial components that facilitate effective energy transfer, highlighting their significance in maintaining machinery efficiency. Essential Components of the Energy Delivery MechanismAt the heart of the energy delivery system are several vital components that work in harmony to ensure smooth operation. The fuel tank serves as the storage unit, while the fuel pump is responsible for transporting the liquid to the engine. Filters are also critical, as they remove impurities that could hinder performance. Additionally, fuel injectors play a pivotal role by atomizing the liquid for optimal combustion, enhancing overall efficiency. Configuration for Optimal PerformanceProper arrangement of these elements is crucial for achieving peak functionality. The placement of the fuel tank relative to the engine affects the pressure and flow rate, influencing how effectively energy is supplied. Moreover, regular maintenance of filters and injectors ensures that the system operates without interruptions, thus prolonging the life of the machinery and improving productivity in the field. Examining the Cooling System LayoutThe efficiency of any heavy-duty machinery significantly relies on its thermal management. This section delves into the intricacies of the thermal regulation framework, which is essential for optimal performance and longevity. Understanding the components and their arrangement can enhance maintenance practices and improve operational reliability. Key Components of the Thermal Regulation Framework

Functionality and Maintenance Considerations

Each element in the thermal management setup serves a vital role in sustaining the operational temperature. Regular inspections and timely replacements can prevent overheating and mechanical failures. Key maintenance tasks include:

Brake System Components and Diagram Explanation

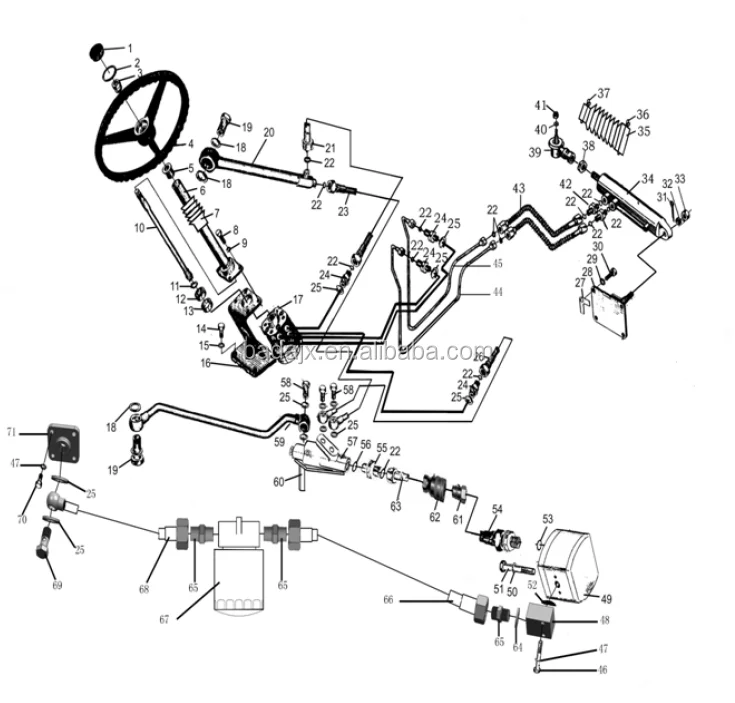

The braking mechanism is a critical aspect of any vehicle, ensuring safety and control during operation. Understanding its various elements and their interconnections provides insight into how effective stopping power is achieved. Key elements of this system include the brake pedal, which initiates the braking process, and the master cylinder, responsible for generating hydraulic pressure. This pressure is transmitted through brake lines to the brake calipers, where it engages the friction material against the discs or drums to halt motion. Additionally, components such as the brake booster enhance the force applied to the pedal, making the braking action more efficient. Regular maintenance and inspection of these elements are essential to ensure optimal performance and safety on the road. By examining a schematic representation of this assembly, one can appreciate the intricate relationships among these components, highlighting how each plays a pivotal role in the overall functionality of the braking system. Steering Mechanism and Its Main Parts

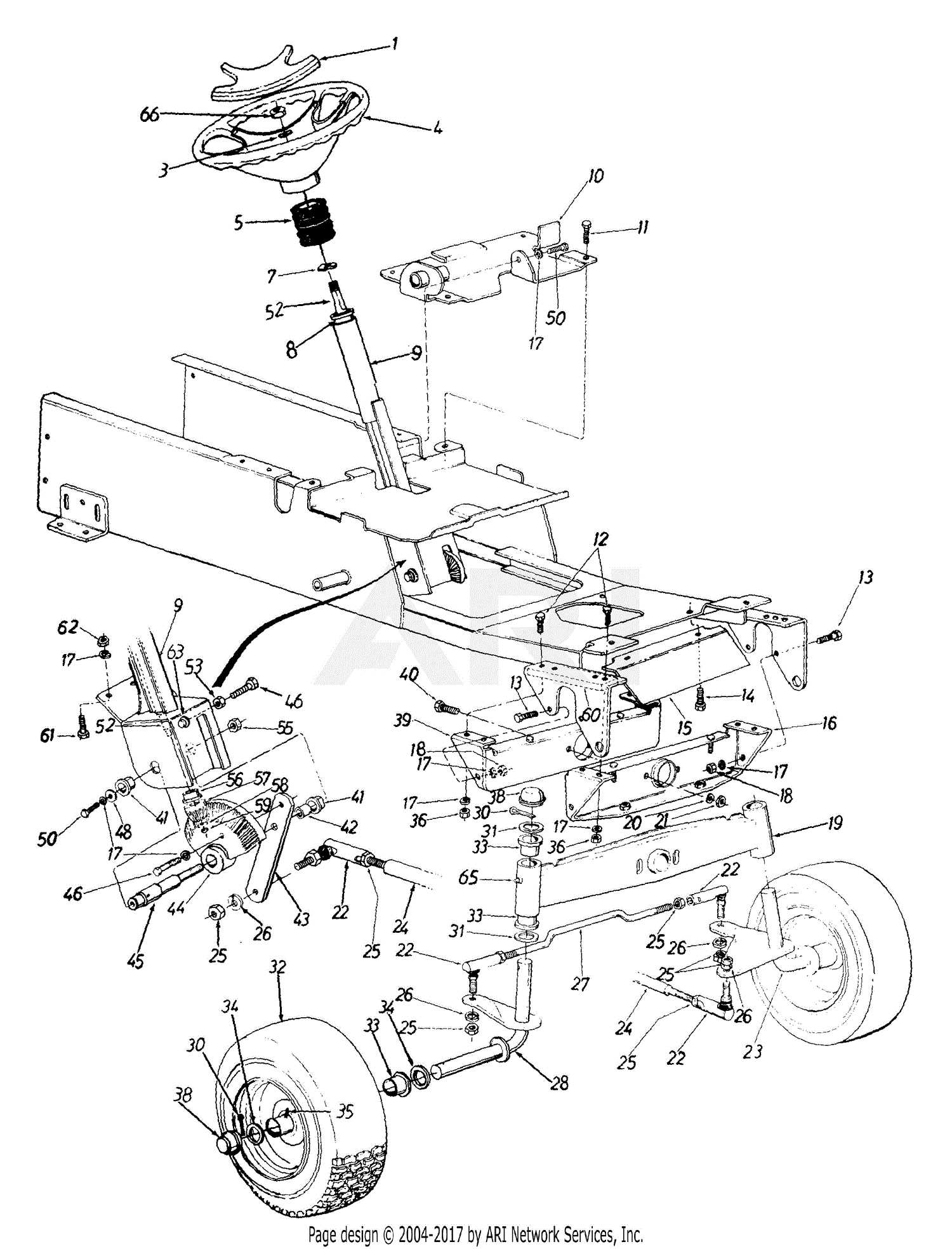

The steering system is crucial for the precise control of vehicle navigation, enabling the operator to maneuver effectively. Understanding its components can enhance maintenance and functionality, ensuring optimal performance during operation. Key Components of the Steering SystemThis system comprises several integral components that work in harmony to provide steering control. Each element plays a vital role in the overall mechanism, contributing to the vehicle’s handling and stability.

Maintenance Tips

Regular inspection and maintenance of the steering system components are essential for safe operation. Ensuring that each part is in good condition helps prevent steering failures and prolongs the life of the vehicle. Analyzing the Suspension and Axle Components

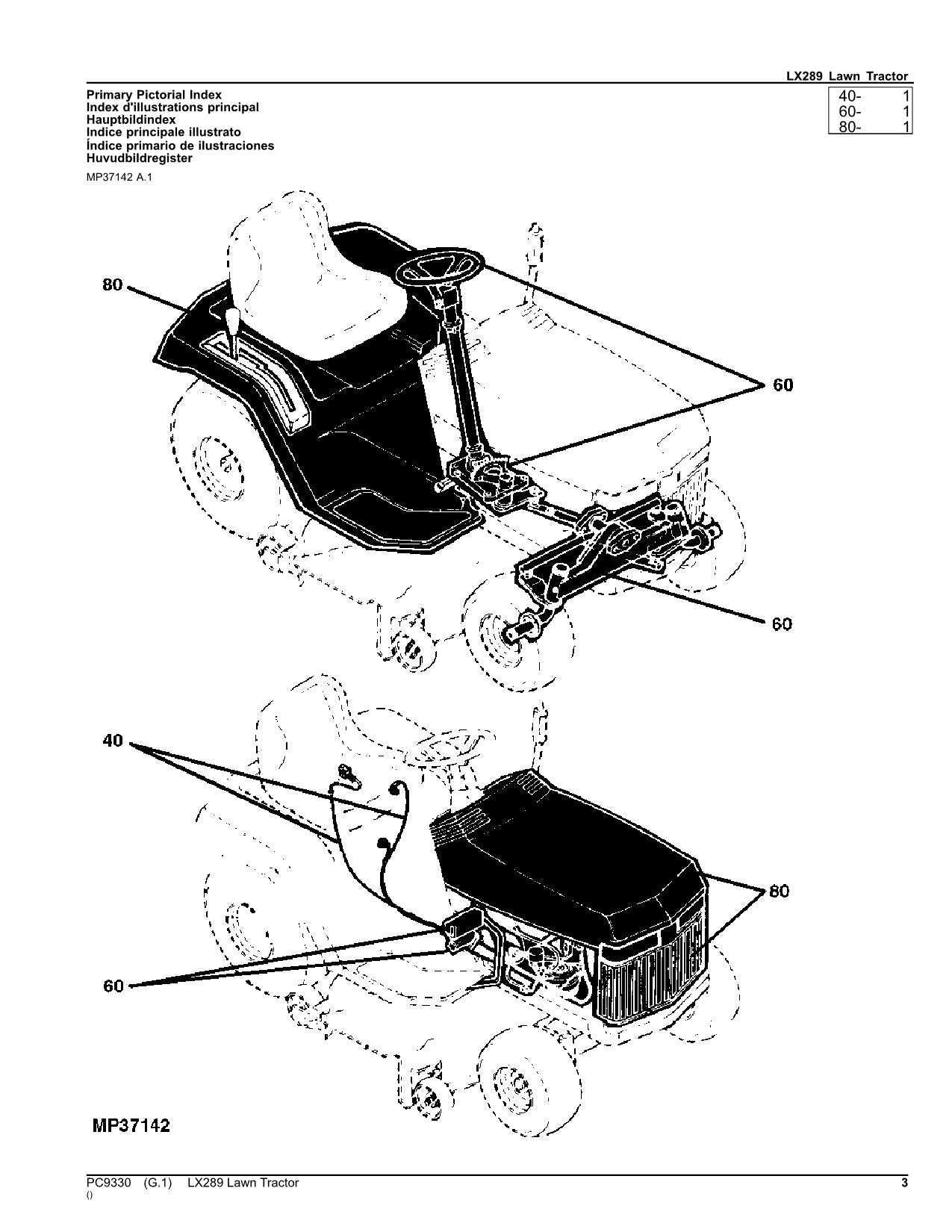

The suspension system and axle elements play a crucial role in the overall performance and stability of heavy machinery. Understanding their functions and interconnections is vital for ensuring optimal operation and longevity of the vehicle. Suspension systems are designed to absorb shocks and provide a smooth ride by allowing for relative movement between the chassis and the wheels. This component not only enhances comfort but also maintains tire contact with the ground, which is essential for effective steering and braking. On the other hand, axle assemblies are fundamental in transferring power from the engine to the wheels, enabling mobility. They must be robust enough to handle heavy loads while also allowing for smooth rotation. The integration of these elements significantly affects the overall efficiency and safety of the vehicle. In summary, a comprehensive analysis of the suspension and axle components is essential for identifying potential issues and implementing necessary maintenance practices. Understanding how these systems work together can lead to improved performance and reduced operational costs. Cabin Controls and Instrumentation Layout

The organization of controls and instrumentation within the cabin is essential for ensuring operational efficiency and user comfort. A well-designed layout allows for intuitive access to vital functions, facilitating smooth interactions during various tasks. This section delves into the critical components that contribute to an optimal working environment, enhancing the overall experience for operators. Control ArrangementStrategically positioned controls provide easy reach and usability. Typically, these include levers, switches, and buttons, each designated for specific functionalities. An ergonomic arrangement minimizes physical strain while maximizing accessibility, allowing users to maintain focus on their tasks. Instrument Cluster Overview

The instrument cluster serves as the central hub for monitoring performance and operational metrics. Displaying essential information such as speed, fuel level, and temperature, it enables operators to make informed decisions swiftly. Clear labeling and intuitive layout further enhance usability, ensuring that critical data is readily available when needed. |