When maintaining or repairing large transport equipment, it’s essential to comprehend how different mechanical elements connect and function together. Identifying the right components and their roles ensures smooth operation and helps avoid downtime due to unexpected failures. This knowledge provides a solid foundation for efficient repairs and upgrades.

Exploring the various mechanical segments of these units can offer a clearer view of how everything works in harmony. Recognizing how these elements interrelate is vital for anyone involved in upkeep or modification, enabling a better understanding of their overall system.

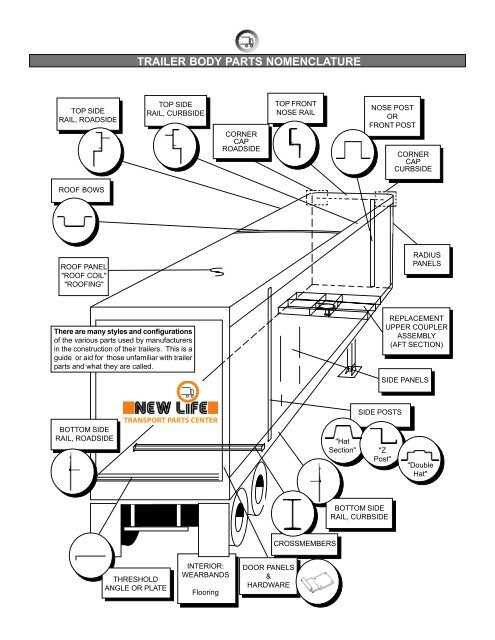

Detailed visual guides play a critical role in simplifying complex setups. These illustrations help locate essential elements swiftly, ensuring an accurate and smooth maintenance process. With well

Understanding Wabash Trailer Components

Transport equipment relies on numerous interconnected elements to ensure safe and efficient operation. By comprehending the key features of these systems, you can maintain and repair them more effectively, maximizing durability and performance. The arrangement of these elements plays a vital role in their functionality, requiring regular checks and understanding of how each part interacts with others.

Core Structural Elements

The framework consists of multiple sections that work together to provide stability and support. These sections are often made of strong materials designed to handle the load and external forces during operation.

- Main frame: This is the backbone that supports the entire structure and distributes weight evenly.

- Axles: These components bear the

Key Elements of Wabash Trailers

Understanding the core features of modern transport units is essential for maximizing their efficiency. These transport solutions are designed with a range of components that contribute to their strength, reliability, and adaptability, ensuring they can meet the demands of various industries. Below is an overview of the most important aspects that define these versatile cargo carriers.

Feature Description Structural Integrity Built with high-grade materials to ensure durability and support for heavy loads during extended use. Aerodynamic Design Exploring the Structure of Trailer Axles

The core component responsible for supporting the load and maintaining balance during transportation is the axle system. Understanding its structure is crucial for efficient and safe operation. These systems consist of several interconnected elements that work together to distribute weight evenly, ensure smooth motion, and provide necessary stability under various conditions.

Key Components of the Axle System

An axle consists of multiple integral parts, each playing a vital role in overall performance. The main shaft connects to the wheels, transferring the force needed for movement. Bearings within the assembly reduce friction, allowing the axle to rotate freely while supporting significant loads.

The Role of Suspension in Axle Function

The suspension system, attached to the axle,

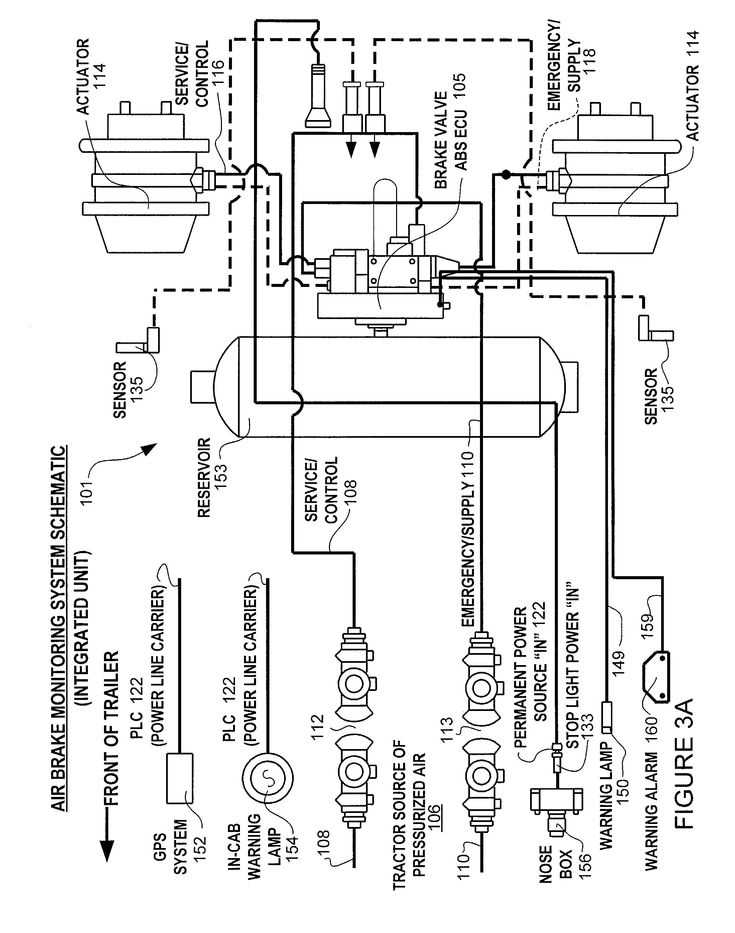

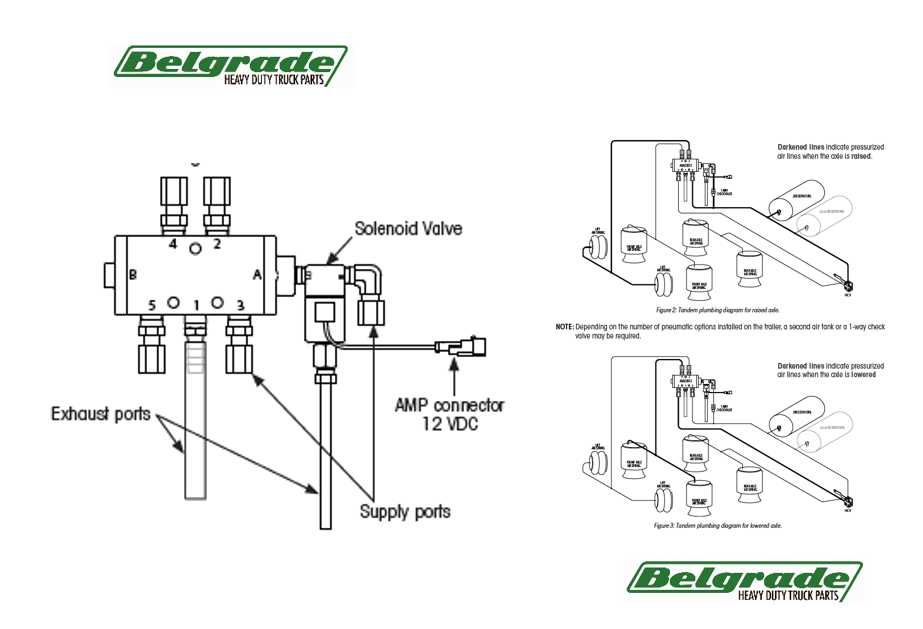

Braking Systems in Wabash Trailers

The braking mechanism in modern transport units is a critical safety feature designed to ensure control and stability during travel. These systems are engineered to deliver responsive and reliable deceleration, especially under varying load conditions. Whether operating in challenging environments or on smooth highways, the effectiveness of the braking components directly impacts the overall handling and safety of the vehicle.

Air brake systems are commonly utilized, relying on compressed air to function. This type of system offers robust performance and is well-suited for heavy loads. The components work together to distribute braking force evenly, minimizing wear and ensuring smooth stopping power.

Additionally, electronic braking advancements have introduced more precision and control. These innovations help improve response times, allowing for better management of the vehicle’s speed. Regular maintenance of the braking systems is essential to ensure optimal performance and prevent potential malfunctions.

Suspension Parts for Improved Stability

Ensuring stability in any transport system is crucial for safe and smooth operation. A well-functioning suspension system plays a vital role in maintaining balance, distributing weight evenly, and absorbing shocks from uneven surfaces. Understanding the key components involved in this system can help achieve enhanced performance and longevity.

- Shock absorbers: These devices help minimize the impact of bumps and uneven terrain, providing a smoother ride by reducing the amount of movement between the wheels and the frame.

- Leaf springs: Essential for distributing weight across the vehicle, these elements improve balance and ensure a consistent response to various loads.

- Control arms: These elements connect the wheel assemblies to the chassis, allowing controlled movement while maintaining alignment and reducing sway during motion.

- Resistance to Moisture: Flooring that can repel water is essential to prevent warping and decay.

- Load-Bearing Capacity: The ability to support heavy loads without bending or breaking is vital for maintaining integrity.

- Surface Grip: A textured surface can reduce the risk of slips and accidents, enhancing safety.

- Perform routine inspections to identify wear and damage.

- Clean the surface regularly to remove debris and contaminants.

- Apply protective coatings to enhance resistance to elements.

- Visual Check: Look for any visible damage such as cuts, cracks, or bulges on the tire surface.

- Tread Depth: Measure the tread depth to ensure it meets the legal standards and provides sufficient traction.

- Pressure Levels: Check tire pressure regularly to avoid under-inflation or over-inflation, which can affect performance and safety.

- Wheel Condition: Inspect the wheel for signs of rust, corrosion, or deformation that may compromise its integrity.

- Fasteners: Ensure that all bolts and nuts are secure and not exhibiting any signs of wear or loosening.

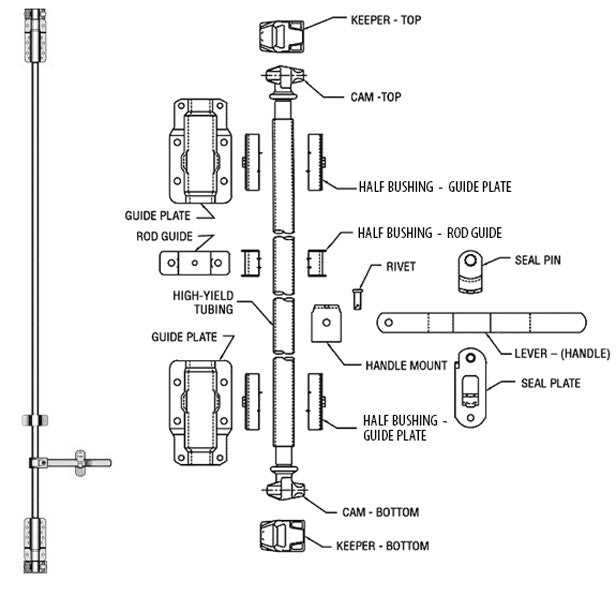

- Locks: Secure the door, preventing unauthorized access.

- Hinges: Allow smooth opening and closing of the door.

- Seals: Provide insulation and protect against weather conditions.

- Handles: Facilitate easy operation of the door.

- Regularly check for rust or corrosion on metal components.

- Lubricate hinges and locks to ensure smooth operation.

- Inspect seals for wear and replace them as needed.

- Ensure handles are secure and functioning properly.

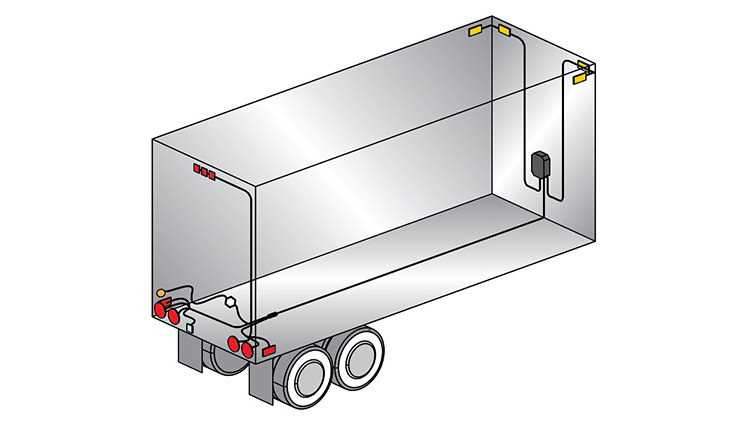

Lighting and Electrical Connections Overview

The functionality of lighting and electrical systems is crucial for ensuring visibility and safety in various types of vehicles. This section will provide an overview of how these systems work together to maintain effective communication between the towing vehicle and the connected equipment. Proper understanding of electrical connections is key to avoiding malfunctions, ensuring a smooth and safe journey.

Component Function Wiring Harness Distributes electrical power to various lights and devices. Connectors Ensure proper linking between the vehicle and attached equipment for smooth signal transmission. Lighting System Includes brake Importance of Trailer Coupling Mechanisms

Coupling mechanisms play a critical role in ensuring the safe and efficient connection between a towing vehicle and its load. The reliability of these systems directly impacts stability, maneuverability, and overall performance during transport. Well-designed couplings help prevent accidents by securely locking the components together, minimizing the risk of disconnection or imbalance on the road.

In addition, high-quality coupling devices can improve fuel efficiency and extend the lifespan of both vehicles and loads. Proper maintenance and attention to the condition of these systems are crucial to achieving safe and smooth operation in various driving conditions.

Sidewall and Roof Panels of Trailers

The structural elements that form the external surfaces of cargo containers are essential for ensuring durability and protection from external factors. These components are designed to withstand various stresses, including weather conditions, impacts, and the general wear of long journeys. Their role is crucial in maintaining the integrity and safety of the transported goods.

Construction and Materials

The side and top coverings of these vehicles are often crafted from lightweight but sturdy materials. Common choices include composite layers, aluminum, or reinforced steel, which offer the right balance between strength and flexibility. Their design ensures protection from environmental factors like rain, wind, and UV exposure, while also resisting punctures or dents from external impacts.

Insulation and Noise Reduction

Another important

How Trailer Flooring Affects Durability

The choice of flooring material plays a crucial role in determining the longevity and strength of a transport unit. Various options are available, each with unique characteristics that can significantly influence overall performance under varying conditions.

Impact of Material Quality

The durability of the flooring is primarily dictated by the quality of the material used. High-grade substances can withstand wear and tear, while lower-quality alternatives may deteriorate quickly. Key factors include:

Maintenance Requirements

The upkeep of flooring is another aspect that affects durability. Regular maintenance can prolong the life of the surface, while neglect can lead to rapid deterioration. Consider the following:

Inspecting Tire and Wheel Assemblies

Regular examination of tire and wheel systems is essential for ensuring optimal performance and safety. These components play a critical role in maintaining stability and handling, making their inspection a vital part of routine maintenance.

During an inspection, focus on the following aspects:

By adhering to these inspection guidelines, you can enhance the lifespan of tire and wheel systems and promote safe operation.

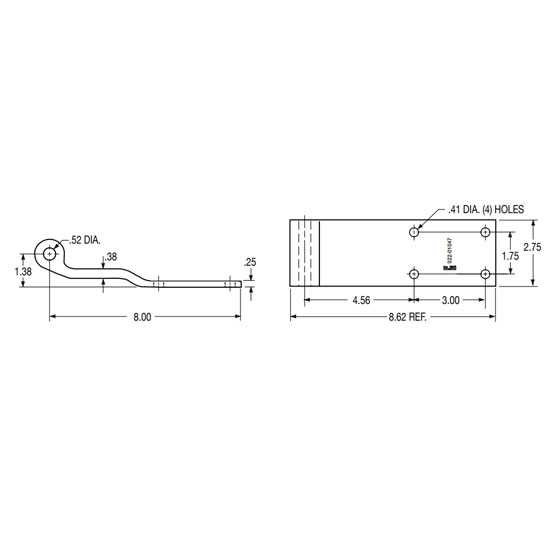

Trailer Door Systems and Hardware

Understanding the mechanisms that facilitate access to cargo compartments is essential for ensuring efficient operation and safety. Various components play a vital role in the functionality and reliability of these systems, contributing to the overall performance of transportation vehicles.

Key Components

Maintenance Tips

Understanding Wabash Trailer Safety Features

Ensuring the highest level of protection during transportation is crucial for every vehicle equipped for heavy loads. Various mechanisms and systems are integrated to enhance safety, reduce risks, and provide peace of mind for users. Recognizing the essential elements that contribute to secure operations can significantly improve overall performance and reliability.

One vital aspect includes advanced braking systems that respond effectively under different conditions. These systems are designed to minimize stopping distances and enhance control, particularly in emergency situations. Additionally, reflective materials and lighting play a key role in improving visibility, making it easier for other drivers to notice vehicles on the road.

Another critical feature involves structural integrity, where materials and design elements are optimized for durability and strength. This ensures that the load remains stable, reducing the chances of accidents caused by shifting cargo. Furthermore, regular maintenance and inspections are recommended to keep all safety systems functioning correctly, ensuring long-lasting reliability and performance.

Incorporating these safety features not only adheres to regulatory standards but also fosters a culture of responsibility among operators. By prioritizing secure operations, users can ensure safer journeys and contribute to the overall well-being of everyone on the road.