Understanding the components of large transport systems is crucial for maintaining and enhancing their functionality. Each piece plays a specific role in ensuring the smooth and efficient operation of these machines, making it important to familiarize oneself with their arrangement and function.

The framework of such equipment is made up of numerous intricate elements. These mechanisms work together to provide the durability, strength, and versatility required for various types of heavy-duty transport. Knowing how these systems are organized can help with troubleshooting, maintenance, and optimization.

This article will provide an overview of the core sections and their connections, helping you better understand how the overall system operates. We will dive into the details of different elements and explain their significance within the larger context of the machinery’s performance.

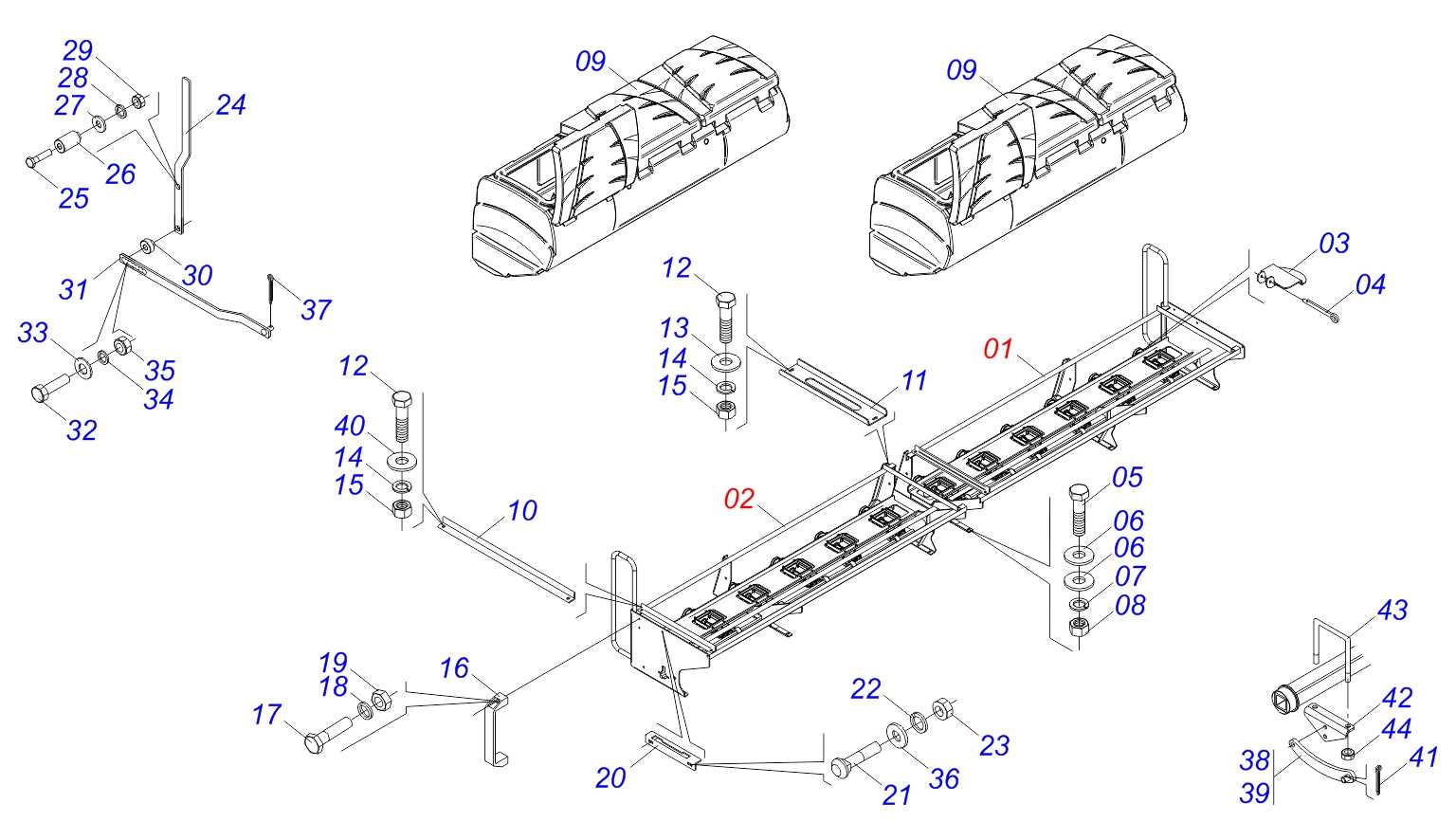

Understanding the Structure of Grain Trailers

The design of cargo transporters used for bulk agricultural products is an intricate balance between functionality and durability. These vehicles are engineered to handle substantial loads while maintaining stability and ease of unloading. By understanding the key elements involved in their construction, one can better appreciate how they serve their purpose efficiently in the agricultural industry.

Frame and Foundation

The core of these transporters lies in their robust foundation. Built to endure heavy usage, the frame provides the necessary support to keep the entire structure intact, even when subjected to rough conditions. Reinforced materials are often used to ensure long-lasting performance, minimizing wear and tear over time.

Compartmentalization and Access

A crucial feature of these vehicles is their compartmentalization, which allows for the organized storage of materials. Strategically placed access points enhance functionality, enabling efficient loading and unloading processes. These design choices are

Key Components in Grain Haulers

Transport vehicles designed for moving bulk goods rely on a variety of critical elements to ensure efficient and safe operation. These systems work together to provide stability, proper weight distribution, and reliable performance under heavy loads. Understanding the primary elements involved is essential for maintaining and optimizing the vehicle’s functionality.

Frame and Structure

The core framework of bulk transport vehicles must be sturdy and well-engineered to handle constant stress from heavy cargo. The structure includes reinforced beams and materials designed to support not only the weight of the load but also external forces encountered during transport.

Loading and Unloading Systems

Efficient mechanisms for loading and discharging bulk materials are critical. These systems include hydraulic lifts, doors, and adjustable chutes, allowing operators to manage the flow of goods smoothly. Proper maintenance of these elements ensures durability and reduces downtime during operations.

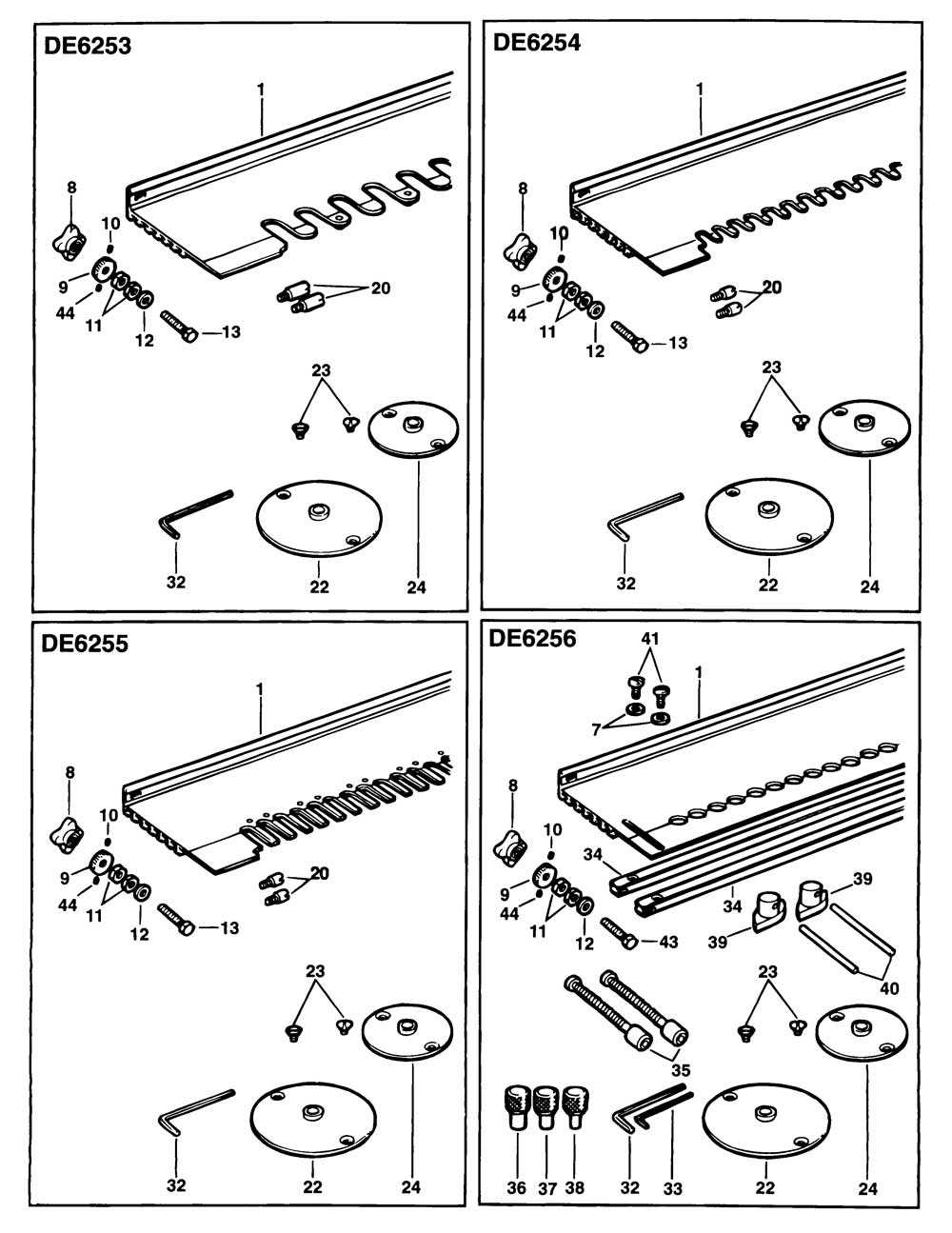

Frame and Chassis Overview

The foundation of any transport unit relies on its structural integrity and durability. A robust framework combined with a well-engineered base ensures both stability and long-term performance under various operational conditions. The overall design directly influences load distribution, weight capacity, and handling, all of which are essential for maintaining efficiency and safety on the road.

Key Structural Components

The main elements of the structure include longitudinal beams and cross members. These parts form the backbone, supporting the entire body and ensuring resistance to external forces. The quality of materials and construction methods used in these components directly impacts the longevity of the unit.

Load-Bearing Capacity

The chassis design is optimized to distribute weight evenly, minimizing stress points and maximizing durability. Reinforcements in critical areas help prevent damage from uneven terrain and heavy loads, ensuring a longer lifespan for the vehicle.

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Frame | Provides overall structural support and houses key components. | ||||||||||

| Cross Members | Enhances stability by connecting the sides of the structure. | ||||||||||

| Reinforcement Plates | Wheel Assembly and Suspension Systems

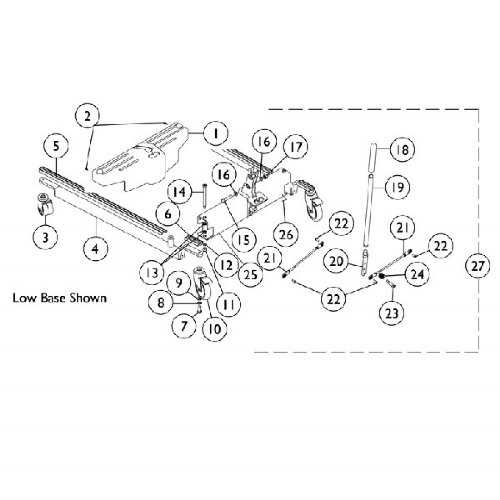

In this section, we delve into the intricate mechanisms that govern the movement and stability of the trailer’s wheels. Understanding these systems is crucial for maintaining optimal performance and safety during transport. Key Components Overview

Functionality and MaintenanceThese systems work synergistically to absorb shocks, maintain balance, and facilitate controlled movements across different surfaces. Regular inspection and maintenance are imperative to prolong the lifespan and reliability of these critical components. Hydraulic Systems for Efficient DumpingEfficient dumping mechanisms rely heavily on advanced hydraulic systems. These systems enable controlled movement and precise positioning of the dumping components, optimizing the unloading process. By harnessing hydraulic power, operators can smoothly elevate and tilt the cargo bed, facilitating quick and reliable discharge of materials. Key Components and Functions

Key components in these hydraulic setups include actuators, valves, and fluid reservoirs. Actuators convert hydraulic energy into mechanical force, driving the lifting and tilting motions essential for dumping. Valves regulate the flow and pressure of hydraulic fluid, ensuring smooth operation without overload or jerky movements. Fluid reservoirs store the hydraulic fluid, maintaining proper levels for consistent performance. This integration of hydraulic technology enhances the operational efficiency of dumping systems, offering robust capabilities for handling various loads with precision and reliability. Exploring Brake and Safety MechanismsEnsuring the proper functioning of stopping systems and protection features is crucial for any heavy-duty Lighting and Electrical System SetupProper installation of the lighting and electrical network is crucial for safe and efficient operation. A well-designed setup ensures visibility in low-light conditions and supports other essential functions powered by electricity. It’s important to pay attention to wiring connections and the choice of components to avoid future malfunctions. Wiring Layout: Organizing the cables is a vital step in the process. Clear and labeled connections help reduce confusion and simplify maintenance. Proper insulation and routing are necessary to protect wires from external damage. Lighting Components: Selecting the right lights ensures maximum visibility. Bright and energy-efficient solutions are recommended to enhance both safety and functionality. Testing the lights after installation helps verify that everything operates as intended. Power Distribution: A balanced distribution of electrical power prevents overloads and ensures smooth functioning Loading and Unloading MechanismsThe efficiency of transporting bulk materials largely depends on the mechanisms employed for loading and unloading. These systems are designed to streamline the process, ensuring quick and safe transfer of contents, thus maximizing productivity. In modern transport solutions, various approaches are utilized to facilitate this task. Hydraulic systems are particularly popular due to their ability to exert significant force with minimal effort. These systems often work in conjunction with conveyor belts and augers, which transport materials smoothly from one point to another. Additionally, gravity-fed mechanisms are commonly employed in unloading scenarios, where the natural force aids in the swift removal of contents. These methods are not only efficient but also reduce the risk of spillage and wastage. Understanding the different types of loading and unloading systems is essential for maintaining optimal performance and ensuring the longevity of the transport equipment. Regular inspections and timely maintenance of these components will further enhance their reliability and efficiency. Proper Maintenance of Trailer PartsMaintaining components of a transport vehicle is crucial for ensuring optimal performance and longevity. Regular attention to these elements can prevent costly repairs and enhance safety during operation. By adhering to a systematic upkeep routine, operators can identify potential issues early and implement necessary corrective measures. Key Maintenance Practices

Safety Considerations

Implementing these practices will not only prolong the life of the vehicle but also contribute to a safer operating environment. Prioritizing maintenance is an investment in reliability and efficiency. Common Wear and Tear PointsIn the context of transporting bulk materials, certain components of the hauling equipment experience significant stress over time. Understanding these areas prone to deterioration is crucial for maintaining optimal functionality and ensuring safety during operations. Regular inspections and timely replacements can greatly enhance the lifespan of the entire system. Key Areas of Concern

Maintenance Tips

Best Practices for Replacement Parts

Ensuring the longevity and optimal performance of machinery requires careful consideration when selecting and installing new components. Adhering to effective strategies can significantly enhance functionality and reduce the risk of malfunctions. Understanding these best practices is crucial for maintaining operational efficiency and safety. Selection CriteriaChoosing the right components involves evaluating several factors. Quality, compatibility, and reliability should guide your decision-making process. Opting for original equipment or high-quality aftermarket options can prevent premature wear and maintain peak performance. Additionally, checking specifications to ensure a proper fit is vital for seamless integration. Installation TechniquesProper installation techniques can further extend the lifespan of new components. Following manufacturer guidelines and utilizing the correct tools are essential for achieving a secure fit. Regular maintenance checks after installation can identify potential issues early, allowing for timely adjustments and ensuring smooth operation.

Choosing the Right Upgrades

When considering enhancements for your transport equipment, it’s essential to focus on components that can significantly improve functionality and efficiency. Selecting the appropriate modifications can lead to a more effective operation and prolonged lifespan of the vehicle. Begin by evaluating the specific needs of your machinery. Assessing performance metrics such as load capacity, speed, and durability will help identify areas that require improvement. Consulting with industry experts can provide insights into which upgrades offer the best return on investment. In addition, prioritize upgrades that enhance safety features. Options like improved braking systems or advanced lighting can contribute to safer operations, especially in challenging environments. By focusing on high-quality components, you ensure that your vehicle meets modern standards and enhances overall productivity. Finally, consider the compatibility of new components with existing systems. Upgrading parts that work seamlessly together minimizes operational disruptions and ensures a smoother transition. Investing in the right enhancements will ultimately lead to a more efficient and reliable machine. |