The intricate machinery responsible for powering vehicles is a fascinating system of interconnected components. Each element within this system plays a vital role in ensuring smooth and efficient operation, contributing to the overall performance and reliability of the engine. Grasping how these components function together is essential for those aiming to maintain or enhance their vehicle’s performance.

In this article, we will delve into the various elements of the mechanism, breaking down their roles and relationships. Whether you’re interested in improving efficiency or troubleshooting issues, a clear understanding of the internal connections can offer valuable insights into optimizing your vehicle’s operation.

By exploring the specific functionalities of these elements, you can gain a deeper appreciation for the complexity of the system. This knowledge will not only aid in repairs and upgrades but also in making informed decisions when it comes to vehicle maintenance.

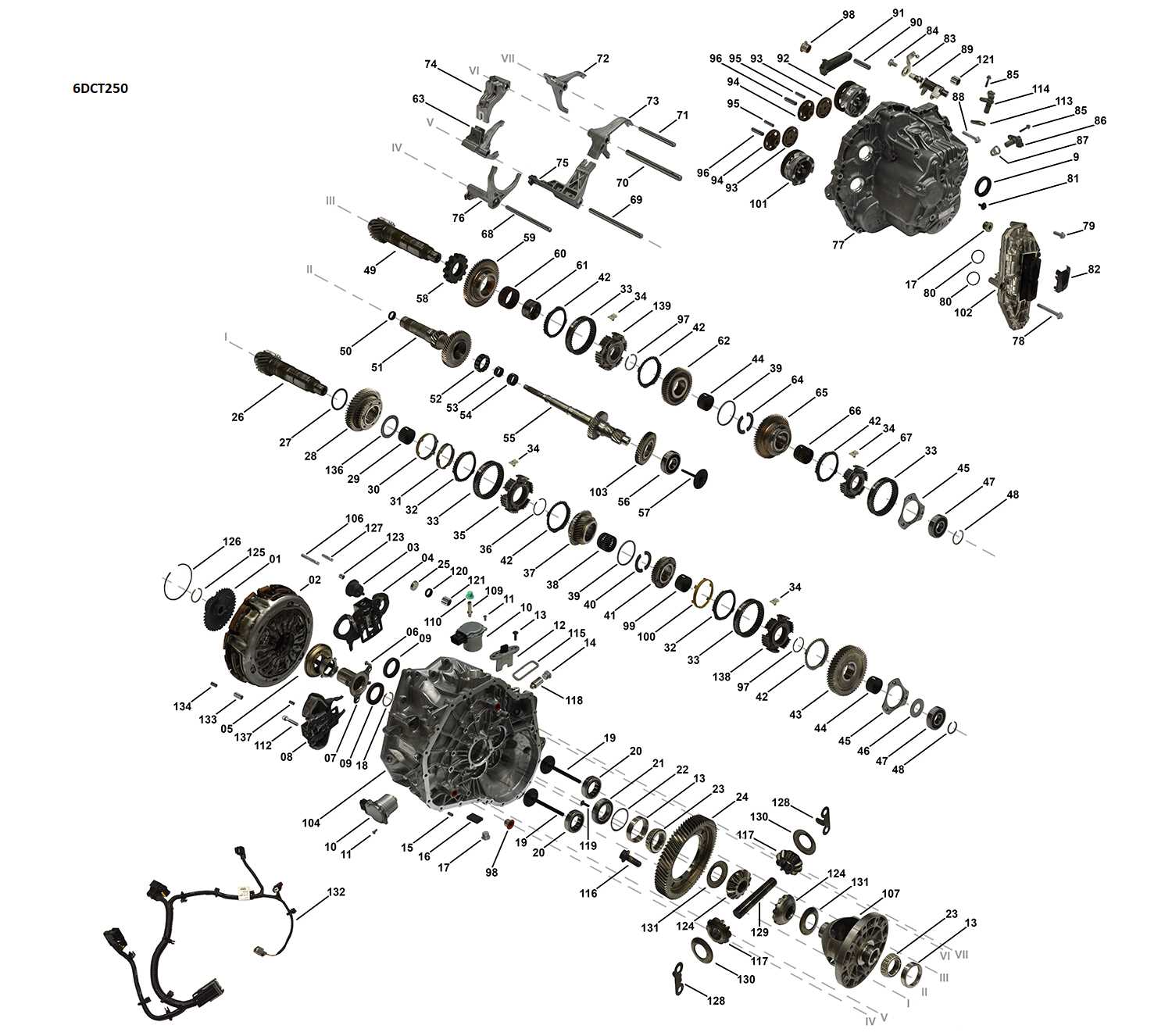

47RE Transmission Parts Diagram Overview

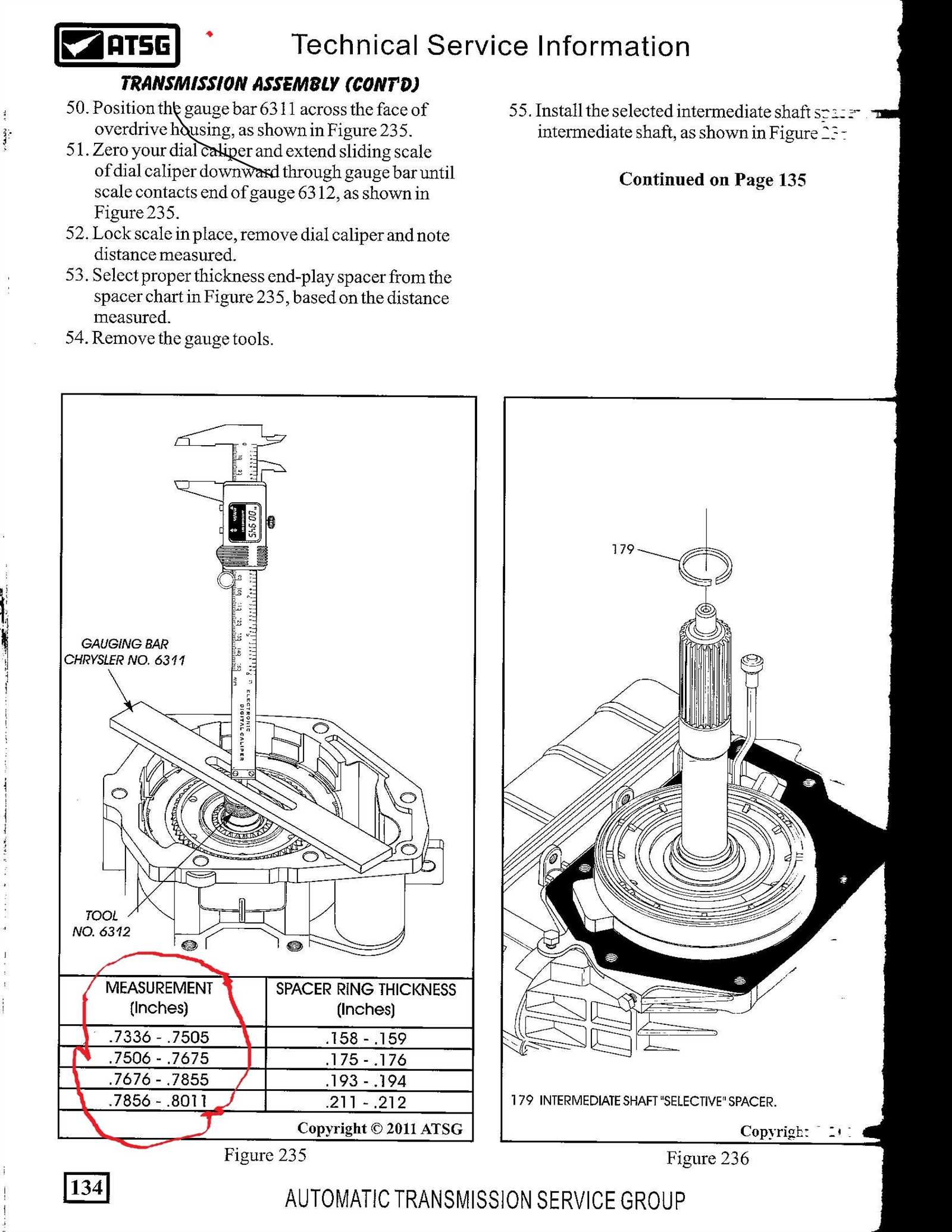

In complex mechanical systems, understanding how different components interact is key to ensuring optimal performance. Each element plays a role in maintaining the integrity and functionality of the entire setup, making it essential to grasp how they connect and contribute to overall efficiency. A clear layout of these elements can help in visualizing their placement and role.

Detailed illustrations provide a comprehensive view of the various internal mechanisms, allowing for easier identification and analysis of each section. By examining these connections closely, one can better understand the flow of operations within the system, ultimately aiding in repairs and maintenance.

The organized layout simplifies the identification of key sections and highlights how individual elements work together to form a cohesive unit. This approach enhances troubleshooting and helps pinpoint potential issues, providing valuable insight into the workings of these intricate systems.

Main Components of the 47RE Gearbox

The system responsible for managing power flow within the vehicle relies on several key elements working together. Each of these elements serves a specific purpose in ensuring that energy is efficiently transferred from the engine to the wheels, enabling smooth performance during operation.

One essential element is the control unit, which oversees the flow of energy and ensures precise timing between different stages of power delivery. Another critical part is the converter, which adjusts energy levels to optimize performance, allowing the vehicle to

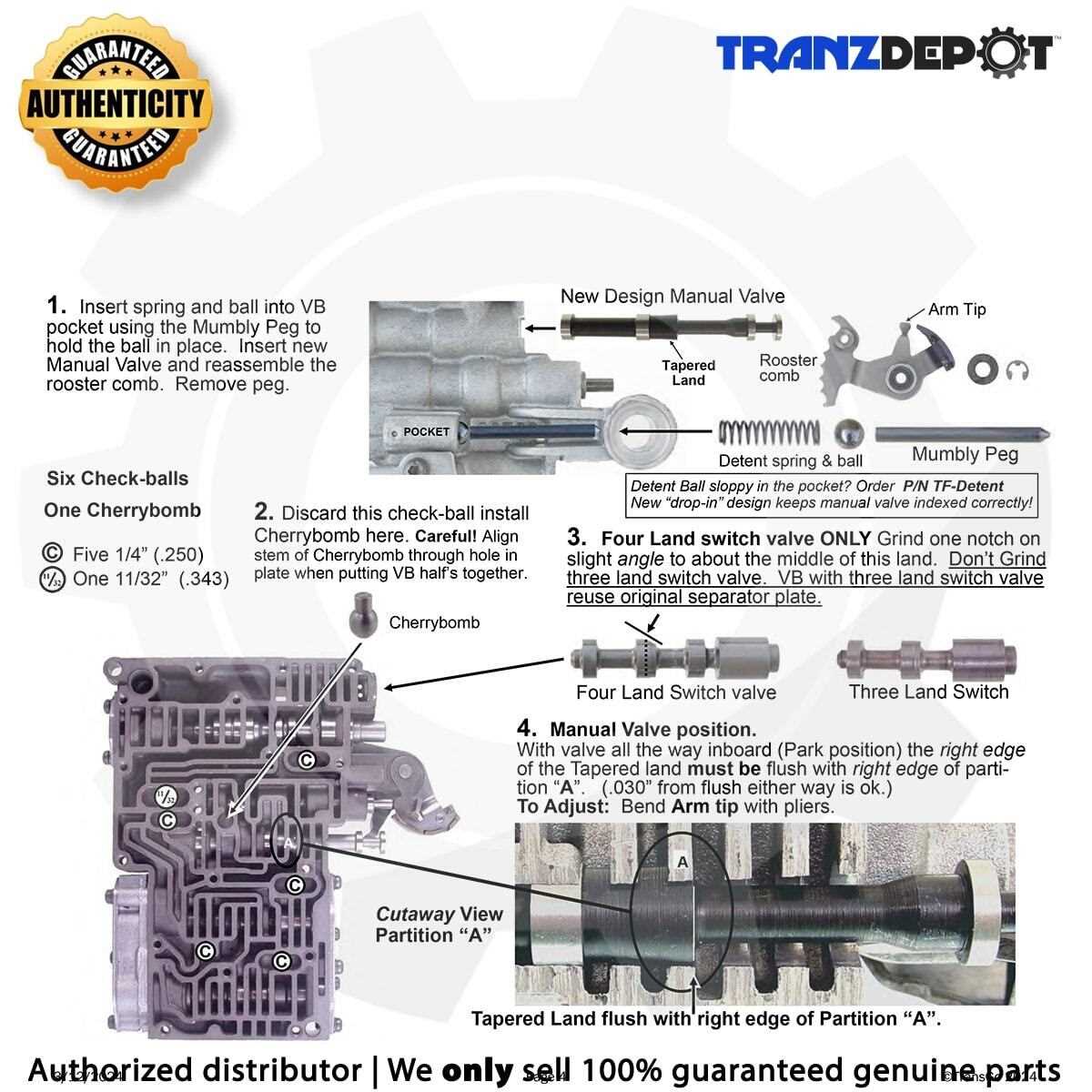

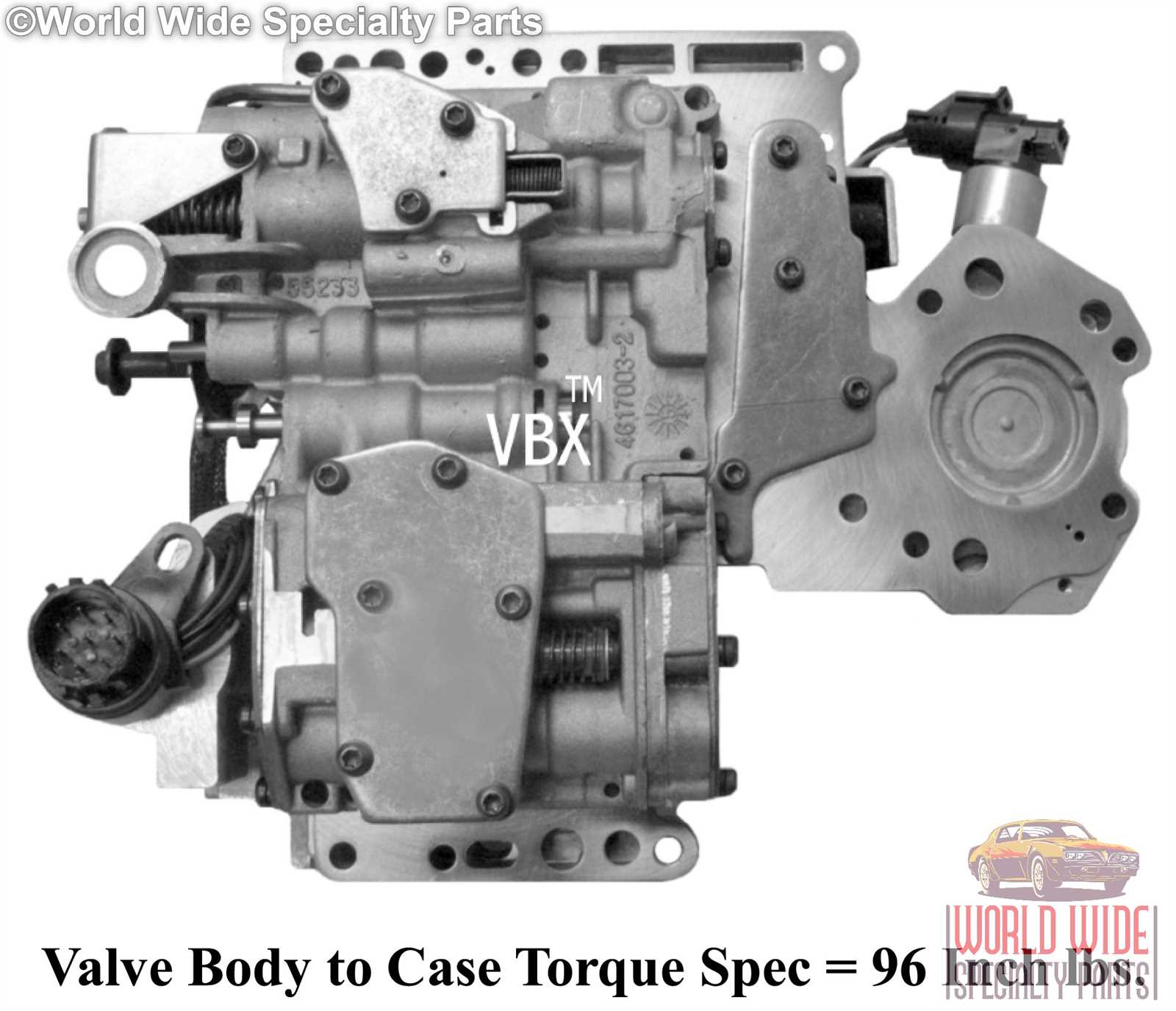

Understanding the Valve Body Assembly

The valve body assembly plays a pivotal role in controlling the flow of hydraulic fluid within complex mechanical systems. It is responsible for directing pressure to various components, ensuring smooth operation and precise performance. This intricate network of channels and valves manages key functions, making it essential for proper system regulation.

Each passage within the assembly is designed to handle specific tasks, activating or deactivating elements as needed. The coordinated movement of these valves ensures efficient control, helping to maintain stability and performance in various operational conditions.

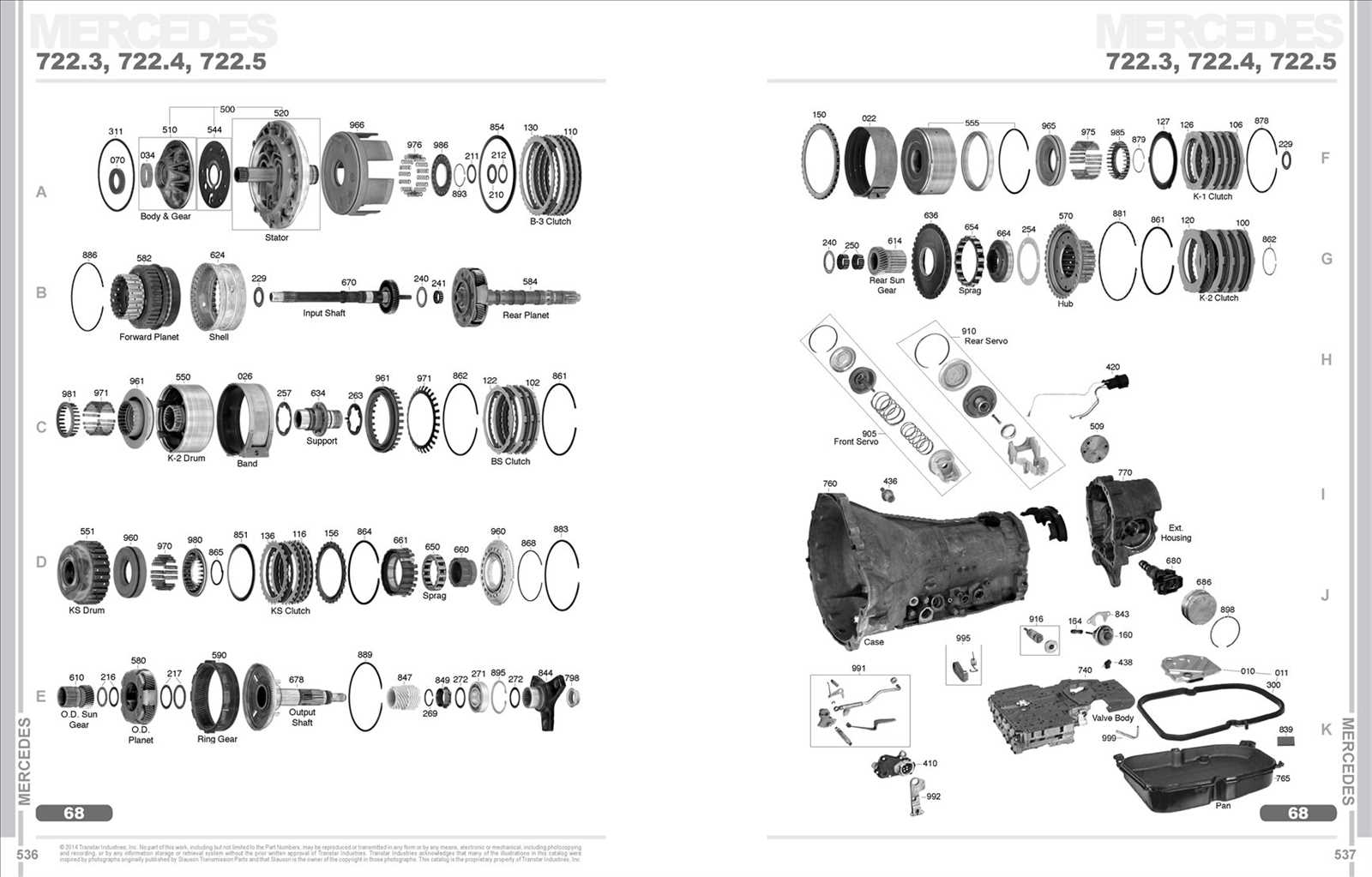

Clutch Pack and Band Placement

The arrangement of internal friction elements is essential for the smooth operation of mechanical systems that rely on controlled motion and force distribution. Understanding where these components are located and how they interact with other elements is critical for maintaining efficiency and preventing wear over time.

Positioning of the Clutch Pack

The stack of friction discs, known as the clutch pack, is strategically positioned to engage or disengage rotating elements. This precise alignment ensures that power can be transferred effectively when needed, while also allowing for smooth disengagement during shifts. Proper placement is vital to avoid overheating or excessive wear.

Role of Bands in the Mechanism

Metal bands play a pivotal role by tightening around specific drums to halt or regulate movement. Their placement directly affects the overall control of the system, as they are responsible for locking or releasing rotating assemblies. Correct positioning is key to ensuring the seamless operation of the entire

Torque Converter Function and Layout

The torque converter plays a crucial role in transmitting power from the engine to the vehicle’s mechanical system. It allows for a smooth transfer of rotational energy, enabling the system to engage and disengage efficiently. Understanding its internal structure and function helps optimize overall performance and ensures proper mechanical interaction between components.

Main Components of the Torque Converter

To better understand how the torque converter operates, it is essential to explore its key elements. These include a pump, turbine, stator, and a clutch mechanism, each of which contributes to the smooth flow of power and the regulation of mechanical engagement.

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pump | Draws fluid from the system to generate

Exploring the Governor System in 47RE

The governor mechanism plays a crucial role in regulating the performance of automatic gear-shifting assemblies. By monitoring the speed of the system, it ensures optimal functionality, enhancing the overall driving experience. Understanding its operation and components is essential for both maintenance and performance tuning. Key Functions of the Governor AssemblyThis assembly is designed to manage hydraulic pressure and adjust the shifting points based on the vehicle’s speed. The following key functions are integral to its operation:

Components of the Governor MechanismThe efficiency of the governor assembly depends on its various components, each contributing to its overall functionality. Below is a table summarizing the main elements involved:

Oil Pump and Fluid CirculationThe efficiency of any mechanical system relies heavily on the proper management of lubricant flow and pressure. Within this context, the role of the oil pump becomes crucial, ensuring that the necessary fluid reaches all essential components. This process not only facilitates smooth operation but also enhances the overall longevity of the system. Function of the Oil PumpThe oil pump serves as the heart of the lubrication system, drawing fluid from the reservoir and distributing it throughout the intricate network of gears and moving parts. By maintaining optimal pressure, the pump prevents wear and tear on critical components, safeguarding them from damage caused by friction and heat. The design and efficiency of this pump are paramount for achieving reliable performance. Fluid Circulation Mechanism

Fluid circulation is a continuous process that ensures every part receives adequate lubrication. As the oil circulates, it absorbs heat and contaminants, which are then directed back to the reservoir for filtration. This cycle not only lubricates moving parts but also helps in cooling, ensuring that the entire mechanism operates smoothly under various conditions. Proper fluid management is vital for optimal functionality and durability. Electronic Sensors and Control ModulesIn modern automotive systems, the integration of electronic components plays a crucial role in optimizing vehicle performance and reliability. These devices are essential for monitoring various functions and facilitating communication between different systems within the vehicle. Their accurate operation ensures smooth functionality and enhances the overall driving experience. Electronic sensors are responsible for collecting vital data from the vehicle’s environment and internal mechanisms. This information is transmitted to control modules, which process the data and make real-time adjustments to maintain optimal performance. Some key functions include:

These components work together seamlessly, allowing for effective management of power delivery and enhancing fuel efficiency. The precise interaction between sensors and control units is vital for achieving the desired operational characteristics of the vehicle. In summary, the synergy between electronic sensors and control modules is foundational to modern automotive technology. Their collaboration enables vehicles to adapt to varying driving conditions while ensuring safety and performance. Cooling System and Transmission LinesThe efficiency of any vehicle’s operation greatly depends on the proper functioning of its cooling system and the pathways that facilitate fluid movement. These elements play a crucial role in maintaining optimal temperatures, thereby ensuring smooth performance. By effectively managing heat, they prevent potential damage to vital components and contribute to the overall longevity of the system. Importance of Cooling Mechanisms

A well-designed cooling mechanism is essential for regulating the temperature within the assembly. It circulates a cooling fluid that absorbs excess heat generated during operation. This process not only safeguards various elements from overheating but also enhances the efficiency of power delivery. Regular maintenance of this system is imperative to avoid overheating issues, which could lead to catastrophic failures. Fluid Pathways and Their Role

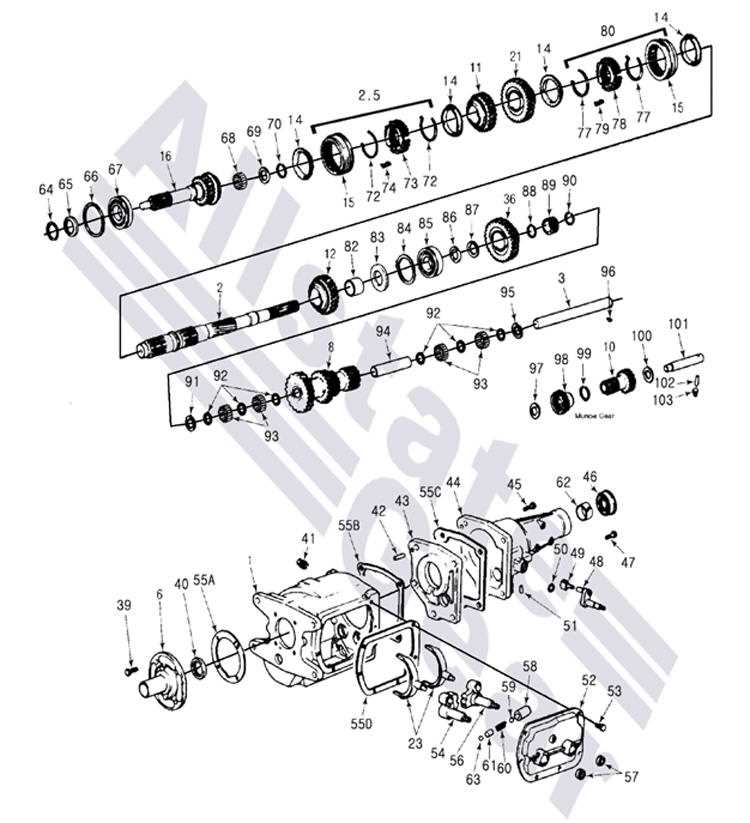

The routes through which the cooling fluid travels are integral to the entire operation. These pathways must be clear and properly connected to ensure effective flow. Any blockage or leakage can severely disrupt the cooling process, leading to increased temperatures and potential breakdowns. Monitoring these lines for wear and tear is vital to prevent any operational issues and maintain the performance integrity of the assembly. Shift Mechanism and Linkage Breakdown

The process of shifting gears in an automatic system involves a series of interconnected components that work harmoniously to ensure smooth transitions between different operational modes. Understanding how these mechanisms interact is essential for diagnosing issues and enhancing overall performance. At the core of this system lies the linkage assembly, which facilitates the communication between the control lever and the internal mechanisms. This assembly consists of various rods, levers, and joints, each playing a pivotal role in translating the driver’s inputs into mechanical actions. When these elements become worn or misaligned, it can lead to sluggish shifts or even complete failure to change gears. Regular inspection of the shift mechanism is crucial. Signs of wear may include unusual noises, difficulty in shifting, or a noticeable delay between inputs and responses. By identifying these issues early, proper maintenance can be implemented to prolong the lifespan of the assembly and improve overall functionality. |