In the realm of advanced machinery, a thorough comprehension of the intricate mechanisms at play is crucial. This section aims to explore the essential elements that contribute to the seamless operation of robust systems, enhancing efficiency and performance.

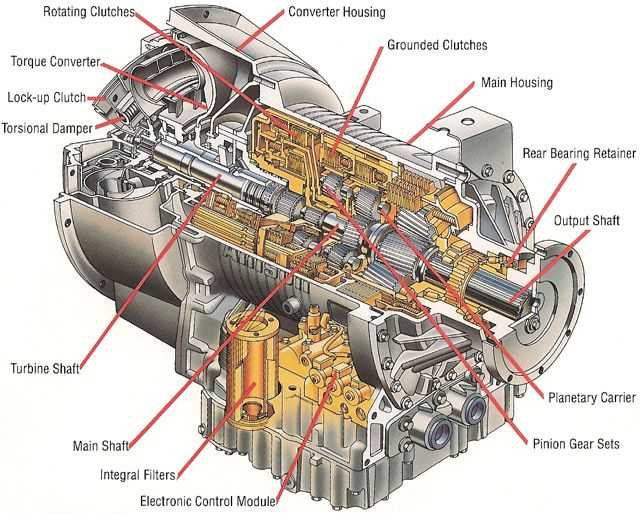

By examining the layout and interrelationships of these components, one can gain valuable insights into their functionality and maintenance. The visual representation serves as a guide to navigate through the complex assembly, providing clarity and understanding.

Whether you are a technician seeking to deepen your knowledge or an enthusiast curious about heavy-duty equipment, this exploration will delve into the ultimate intricacies of each unit. Discovering how these elements work together not only fosters appreciation but also aids in effective troubleshooting and repair.

Understanding Allison Transmission 3000 Series

The design and functionality of automatic shifting mechanisms play a crucial role in modern vehicles, especially in heavy-duty applications. This section delves into the features and components that contribute to the efficiency and reliability of these systems, enabling seamless operation and enhanced performance in demanding environments.

At the core of these mechanisms is a sophisticated arrangement of gears and hydraulic controls that work together to facilitate smooth gear transitions. The integration of advanced technology not only optimizes power delivery but also improves fuel efficiency, making it an essential aspect for fleet operators and vehicle manufacturers.

Key components include various sensors and actuators that monitor performance metrics, ensuring real-time adjustments to meet operational demands. This adaptability is vital in maintaining optimal performance under varying load conditions.

Furthermore, maintenance plays a significant role in prolonging the lifespan of these assemblies. Regular inspections and timely replacements of wear components can prevent costly downtimes and enhance overall vehicle reliability. Understanding the internal workings of these systems is essential for technicians and operators alike.

In summary, the complexity and engineering excellence behind these automatic shifting mechanisms underscore their importance in today’s transportation landscape. Knowledge of their function and upkeep is paramount for anyone involved in heavy-duty vehicle management.

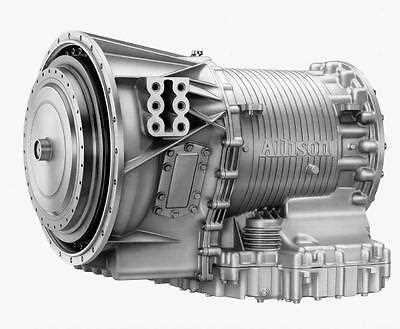

Key Components of Allison 3000

This section explores the essential elements that constitute a sophisticated automatic gear system used in various heavy-duty vehicles. Understanding these components is crucial for grasping how the entire assembly functions seamlessly to deliver optimal performance and efficiency.

One of the primary elements is the hydraulic system, which facilitates fluid movement to enable gear shifts. This system relies on a series of pumps, valves, and fluid reservoirs to maintain pressure and ensure smooth transitions between gears.

Another vital component is the electronic control unit, which governs the operation of the entire mechanism. This sophisticated device utilizes sensors to monitor vehicle performance, adjusting shifting patterns and optimizing power delivery based on real-time conditions.

The clutch assembly also plays a significant role, allowing for the engagement and disengagement of gears. This assembly must withstand considerable stress and heat, requiring durable materials and precise engineering to function effectively over time.

Additionally, the gearing system itself is a critical aspect, comprising a series of gears that transmit power from the engine to the wheels. The design of these gears influences the overall efficiency and responsiveness of the vehicle.

Finally, the cooling system is essential to prevent overheating, ensuring that all components operate within safe temperature ranges. Proper cooling extends the lifespan of the entire assembly and maintains optimal performance under heavy loads.

Importance of Transmission Diagrams

Visual representations of mechanical systems serve as essential tools for understanding complex structures. They provide a clear roadmap, enabling technicians and enthusiasts alike to navigate the intricacies of assembly and disassembly effectively.

Benefits of Visual Guides

- Enhances comprehension of component relationships.

- Facilitates efficient troubleshooting processes.

- Aids in accurate reassembly after maintenance.

Applications in Maintenance

- Streamlines repair procedures.

- Improves safety by reducing errors.

- Promotes knowledge sharing among professionals.

Common Issues with Allison 3000 Parts

The complexity of automatic gear systems can lead to a variety of challenges, often stemming from specific components within the assembly. Understanding these common problems can aid in effective maintenance and prolong the lifespan of the system. Identifying and addressing these issues early is crucial for ensuring optimal performance.

Fluid Leaks: One of the most frequent issues involves leakage of hydraulic fluid. This can result from worn seals or gaskets, leading to low fluid levels and impaired functionality. Regular inspections can help detect leaks before they cause significant damage.

Overheating: Excessive temperatures can negatively impact performance and durability. This may be caused by insufficient fluid levels, debris in the cooling system, or malfunctioning cooling components. Monitoring temperature levels is essential for preventing overheating.

Shifting Problems: Difficulty in shifting gears can be attributed to a range of factors, including low fluid pressure, faulty sensors, or issues with electronic controls. Diagnosing these problems promptly can prevent more severe complications.

Noises and Vibrations: Unusual sounds or vibrations during operation often indicate internal wear or damage. These symptoms should not be ignored, as they can lead to catastrophic failures if left unaddressed.

Sensor Failures: Modern systems rely on various sensors for optimal operation. Malfunctioning sensors can lead to inaccurate readings, affecting performance and efficiency. Regular testing of electronic components can help maintain reliability.

Maintenance Tips for Allison Transmissions

Proper upkeep is essential for ensuring the longevity and reliability of automatic gear systems. Regular checks and maintenance can prevent costly repairs and enhance performance. Below are some valuable tips to keep in mind for optimal care of these systems.

Firstly, it is crucial to monitor fluid levels and quality. Regularly check for leaks and ensure that the fluid is clean and at the appropriate level. Old or contaminated fluid can lead to inefficiencies and damage.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Change | Every 30,000 miles | Replace old fluid to maintain optimal performance. |

| Filter Inspection | Every 15,000 miles | Check and replace filters to prevent blockages. |

| Leak Check | Monthly | Inspect for any signs of fluid leaks underneath the vehicle. |

| Visual Inspection | Monthly | Look for any signs of wear and tear or unusual noises. |

Additionally, avoid heavy towing unless the system is specifically designed for it. Excessive strain can lead to premature wear. Finally, always follow the manufacturer’s guidelines for any specific maintenance recommendations.

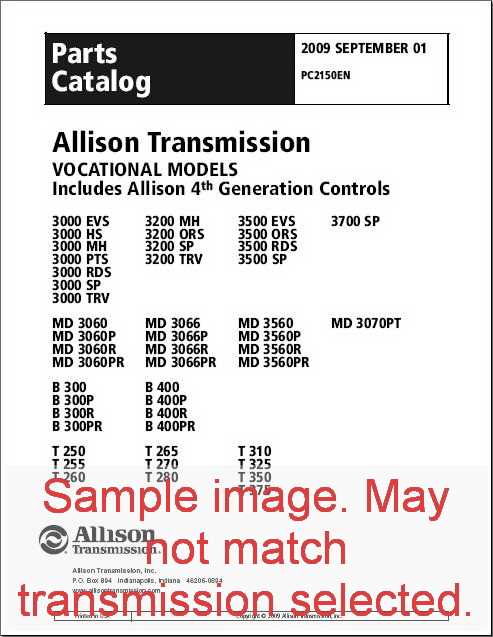

How to Read a Parts Diagram

Understanding a visual representation of components is essential for efficient maintenance and repair tasks. This guide aims to simplify the process, allowing you to quickly identify and locate essential elements.

Here are some key points to consider:

- Legend and Symbols: Familiarize yourself with the legend, which explains the symbols used in the illustration.

- Component Groups: Identify clusters of related elements, often grouped for easier reference.

- Numbering System: Pay attention to the numbering, as it usually corresponds to a list or catalog of items.

By following these steps, you’ll be better equipped to navigate through complex illustrations with confidence.

Replacement Parts for Allison 3000

Maintaining optimal performance of heavy-duty machinery relies on the availability of quality components. Ensuring that each element is in top condition is vital for longevity and efficiency.

- Seals and Gaskets

- Filters

- Valves

- Clutches

- Electronic Control Units

Identifying and sourcing reliable substitutes can significantly impact functionality. Here are some essential categories to consider:

- Fluid Management: Ensure proper flow and cleanliness.

- Wear Components: Regular replacement can prevent larger issues.

- Monitoring Systems: Keep track of performance metrics for proactive maintenance.

Investing in high-quality replacements enhances reliability and ultimately extends the service life of your equipment.

Benefits of Using Genuine Parts

Utilizing authentic components for vehicle repairs ensures optimal performance and longevity. Genuine products are crafted to meet specific standards, providing reliability that aftermarket alternatives often cannot match.

| Advantage | Description |

|---|---|

| Quality Assurance | Manufactured to precise specifications, ensuring durability and efficiency. |

| Compatibility | Designed to fit seamlessly, reducing the risk of malfunction or damage. |

| Warranty Coverage | Often accompanied by comprehensive warranties, providing peace of mind. |

| Resale Value | Maintaining genuine components can enhance the vehicle’s overall worth. |

Tools Required for Transmission Repairs

Performing maintenance on complex machinery necessitates a range of specialized instruments. Having the right tools on hand not only simplifies the process but also ensures that repairs are conducted safely and effectively. Understanding the essential equipment will prepare you for any challenges that may arise during the service.

Essential Tools

To carry out efficient repairs, certain tools are indispensable. Below is a table outlining the primary instruments needed for this type of work:

| Tool | Description |

|---|---|

| Socket Set | Variety of sizes to fit different bolts and nuts. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Seal Puller | Assists in removing seals without damage. |

| Fluid Pump | Used for draining and refilling lubricants. |

| Impact Wrench | Delivers high torque for loosening stubborn fasteners. |

Safety Equipment

In addition to repair tools, safety gear is crucial to protect the technician. This includes gloves, goggles, and steel-toed boots, which help prevent injuries during the repair process.

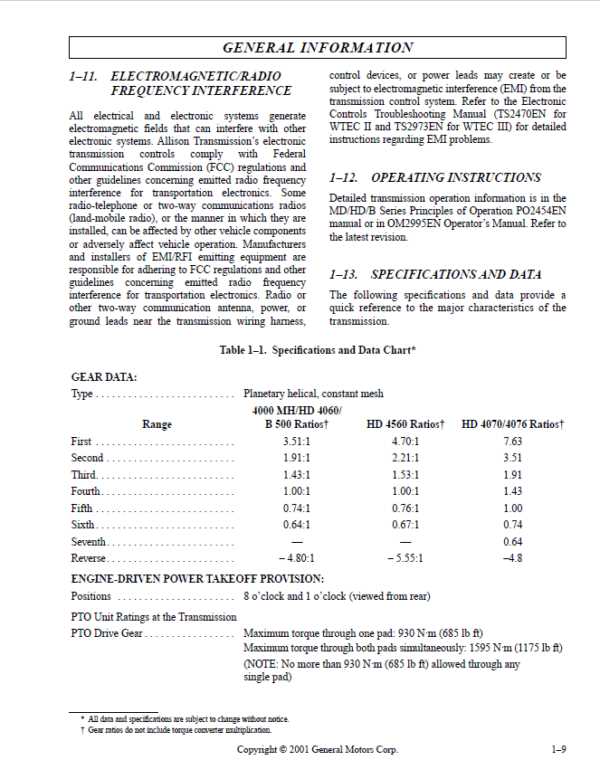

Comparing Allison 3000 to Other Models

This section explores the distinctions between a specific series of automatic gear systems and their counterparts, highlighting key features, performance metrics, and design innovations. Understanding these differences aids in selecting the optimal solution for various applications.

Performance and Efficiency

When examining various systems, one notable aspect is their efficiency in power transfer and fuel consumption. Some models offer advanced electronic controls, enhancing overall performance while maintaining lower operational costs. Moreover, specific configurations may provide superior torque handling, essential for demanding tasks.

Durability and Maintenance

Another critical factor is the longevity and upkeep of the units. Certain alternatives boast enhanced materials that resist wear and tear, leading to extended service intervals. Additionally, simpler designs in some models can facilitate easier maintenance, which is crucial for minimizing downtime.

Expert Insights on Transmission Performance

Understanding the mechanics behind automatic gear systems is crucial for achieving optimal efficiency and longevity. Insights from industry specialists reveal how critical components interact, influencing overall functionality and responsiveness.

Key Factors Influencing Performance

Several elements play a significant role in the efficiency of these systems. Fluid quality and temperature regulation are paramount; they ensure smooth operation and reduce wear. Regular maintenance and timely fluid changes are essential for sustaining high performance.

Advanced Technologies and Innovations

Recent advancements have introduced smart diagnostics and enhanced materials that boost durability and performance. These innovations allow for real-time monitoring, providing users with valuable data to prevent potential failures and optimize usage.

Finding Quality Service for Repairs

Identifying reliable assistance for mechanical issues is essential for maintaining the performance and longevity of your vehicle. The right professionals can ensure that any necessary work is conducted efficiently and effectively, providing peace of mind to the owner.

Key Considerations

- Experience and Expertise: Look for technicians with extensive backgrounds in similar systems.

- Reputation: Research reviews and testimonials to gauge customer satisfaction.

- Warranty and Guarantees: Ensure the service provider offers warranties on their work and parts.

- Certifications: Verify that the technicians hold relevant certifications to perform repairs.

Steps to Find Quality Service

- Ask for Recommendations: Seek referrals from friends or family who have had similar repairs.

- Research Online: Utilize forums and review sites to gather information on local service providers.

- Visit Service Centers: Inspect facilities and speak with staff to assess their professionalism.

- Request Quotes: Compare estimates to understand the market rates and services offered.