Understanding the intricate design of gear systems is essential for grasping their functionality and maintenance. This section will explore the various elements involved in these mechanisms, shedding light on how each contributes to overall performance.

By examining the arrangement and relationship between different components, one can appreciate the engineering involved. Such insights are vital for anyone looking to enhance their knowledge or undertake repairs, ensuring efficient operation and longevity.

In this exploration, we will highlight significant features and interactions within the assembly, providing a clearer picture of how these units operate cohesively. Knowledge of these components is crucial for effective troubleshooting and optimization.

Understanding Transmission Components

In the realm of machinery, grasping the various elements that contribute to the functionality of power transfer systems is essential. Each component plays a pivotal role in ensuring smooth operation and efficient performance.

Key Elements of Power Transfer

These mechanisms typically comprise several crucial elements, each designed to fulfill specific functions. Understanding their roles aids in diagnosing issues and improving overall efficiency.

| Component | Function |

|---|---|

| Gear Set | Facilitates the adjustment of speed and torque. |

| Clutch | Enables the connection and disconnection of power flow. |

| Shaft | Transfers rotational force between components. |

| Housing | Protects internal elements and supports structure. |

Importance of Maintenance

Regular inspection and upkeep of these elements are vital for prolonging the lifespan and efficiency of the entire system. Identifying wear or damage early can prevent more extensive repairs and ensure optimal performance.

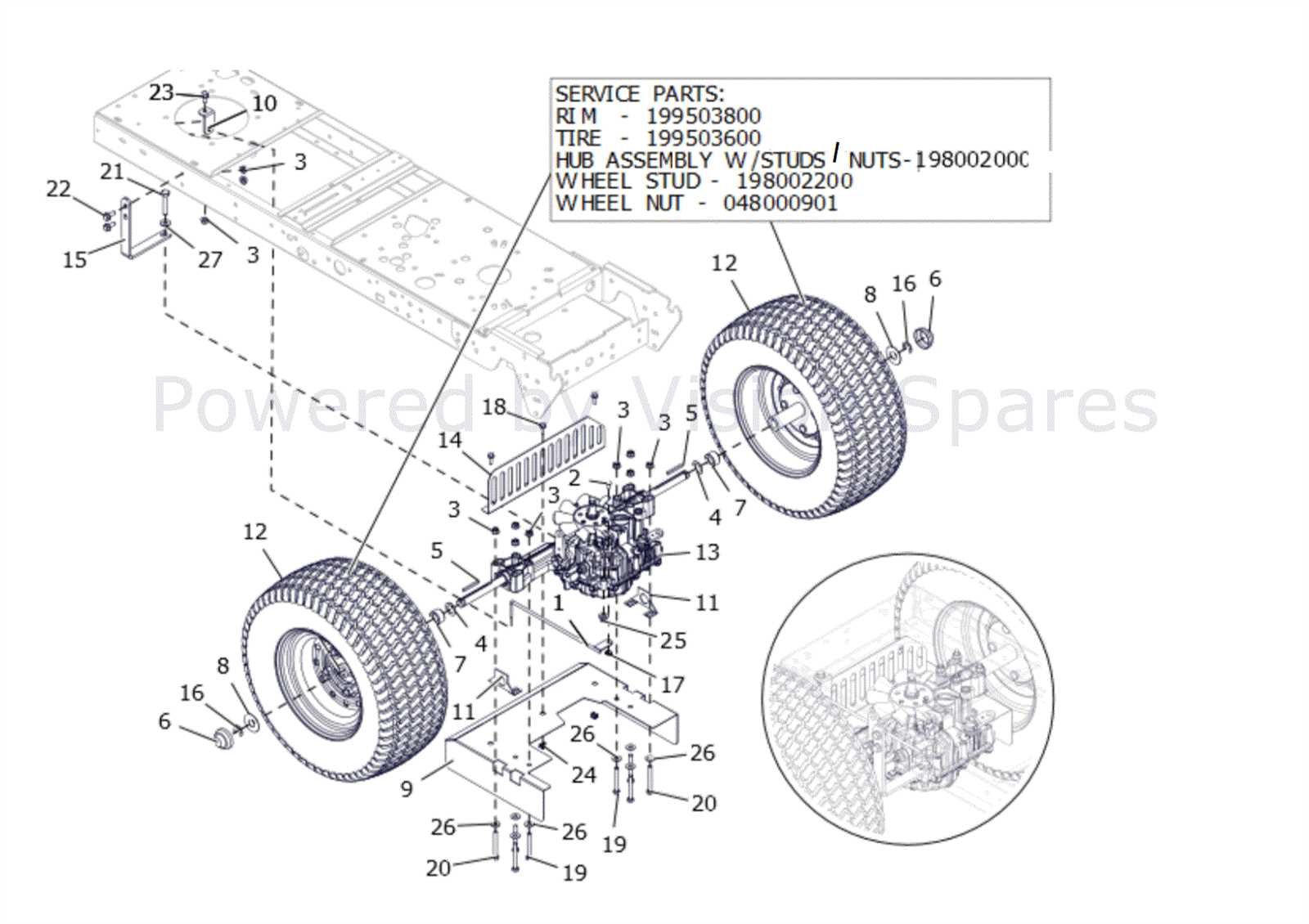

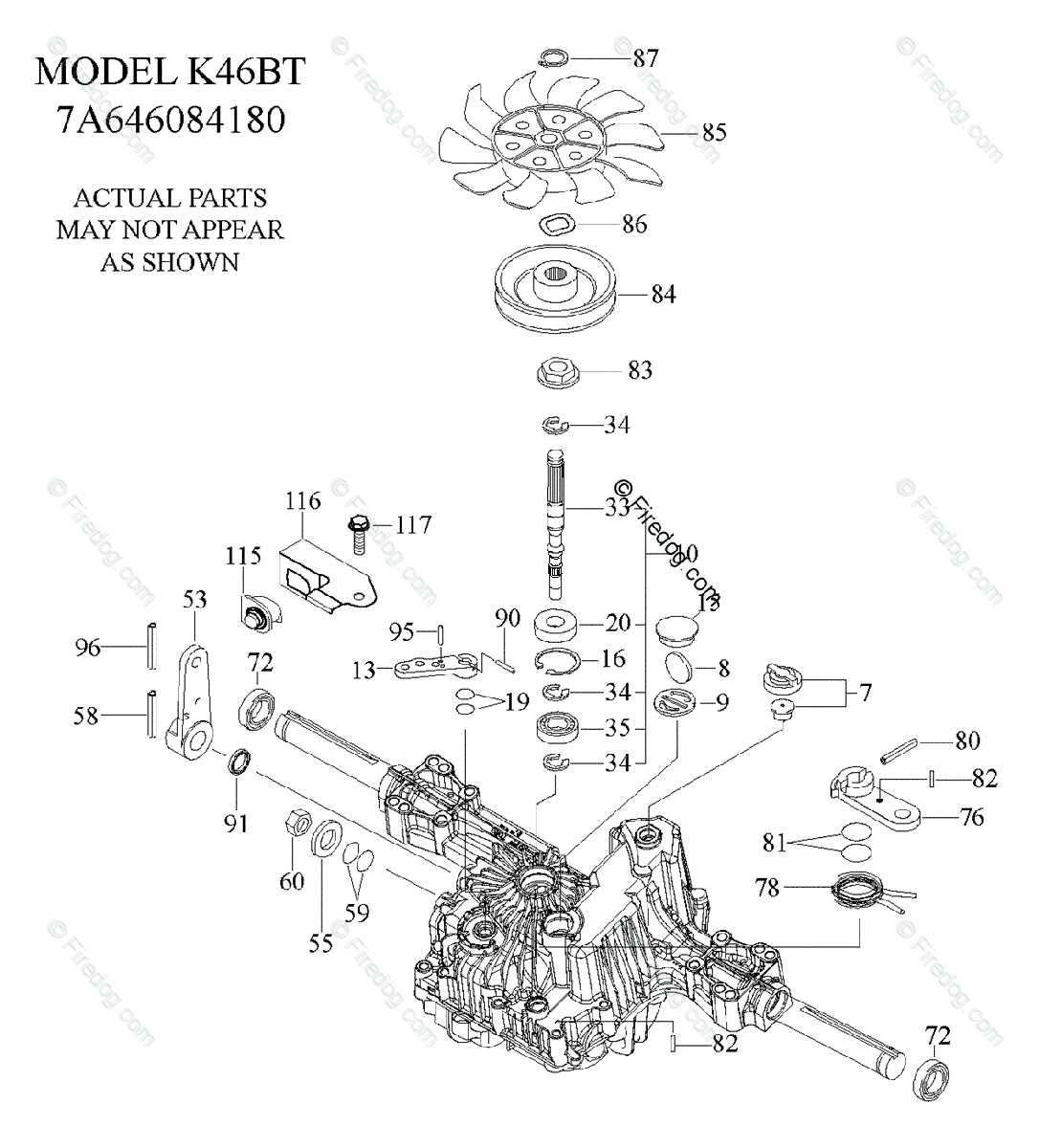

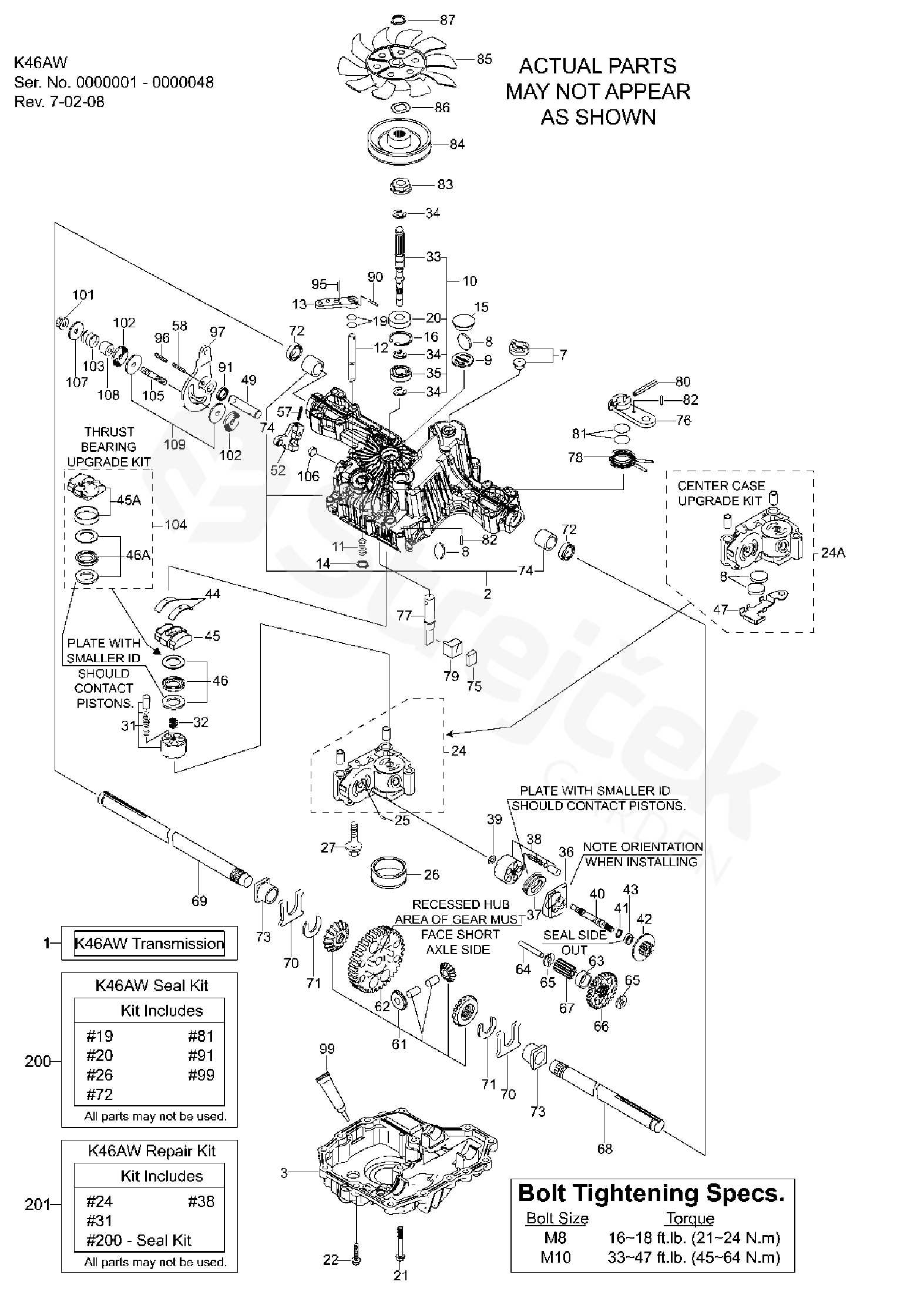

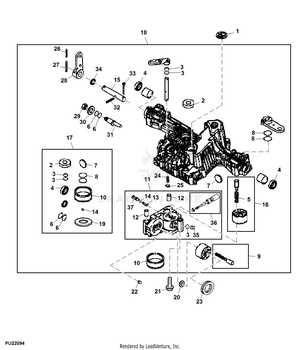

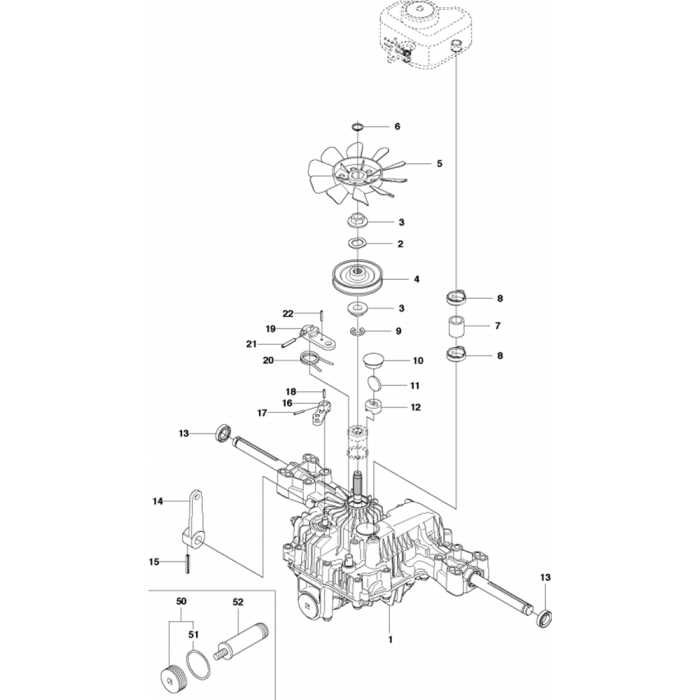

Key Parts of the K46 System

The fundamental components of this mechanism play a crucial role in ensuring smooth operation and efficiency. Understanding these elements can enhance maintenance and troubleshooting processes.

Central Housing: This structure serves as the core unit, providing support and housing for various essential elements.

Drive Gear: Vital for transferring motion, this element ensures effective engagement and disengagement during operation.

Linkage System: This network connects different sections, allowing for coordinated movement and functionality.

Fluid Reservoir: Critical for lubrication and cooling, this component helps maintain optimal performance and longevity.

Control Mechanism: Responsible for regulating functions, it allows for precise adjustments and control over the entire system.

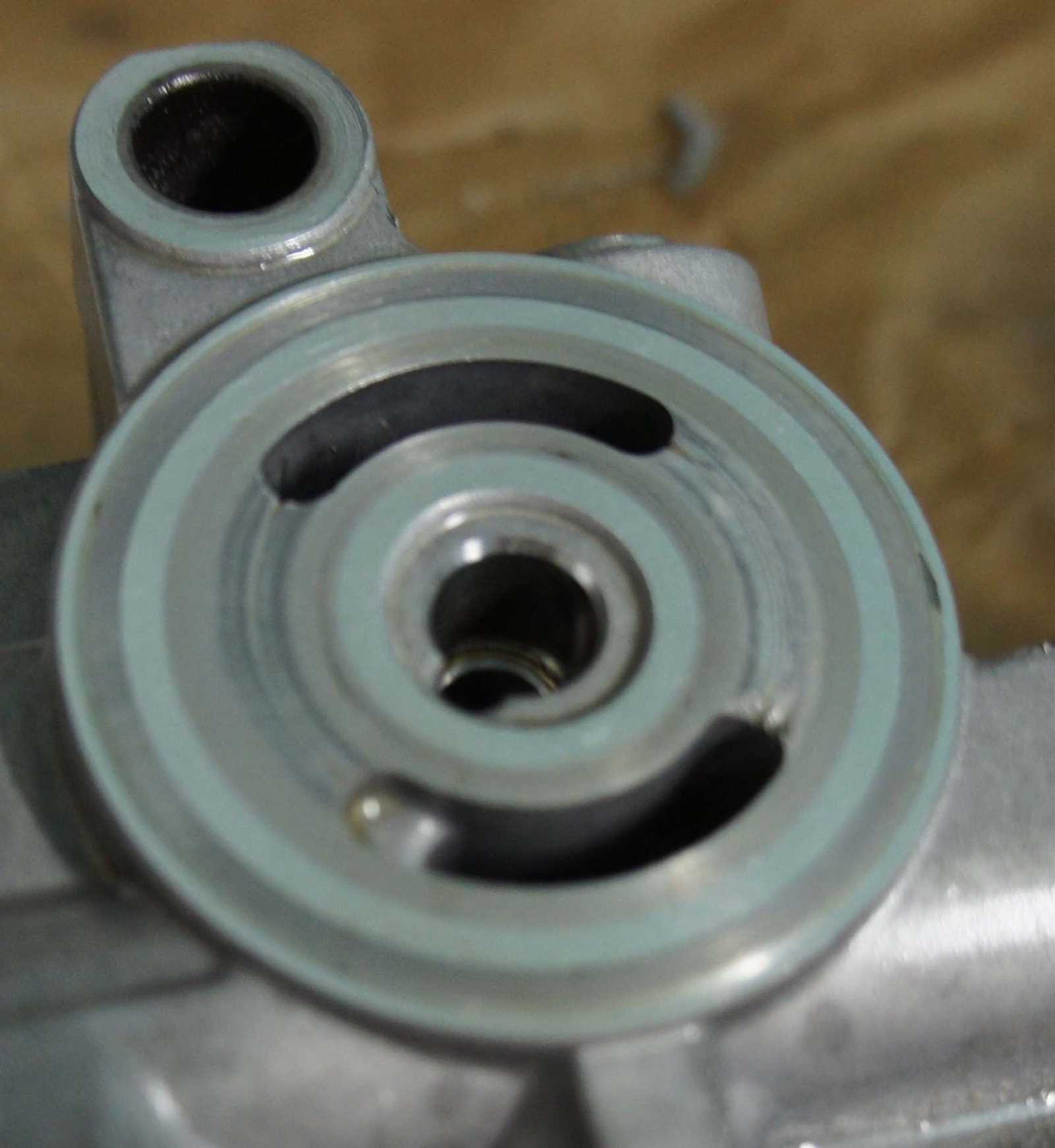

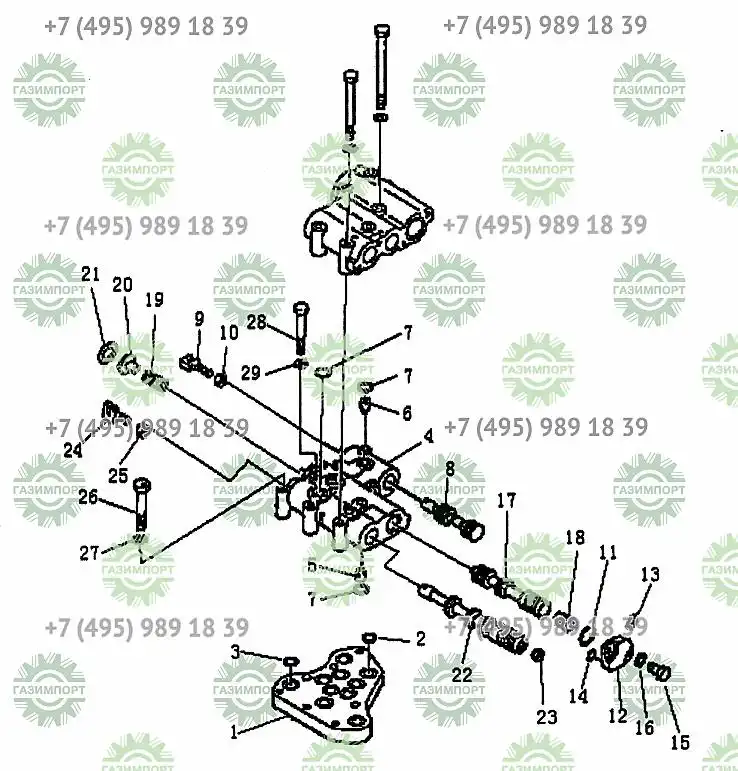

Functionality of Major Elements

This section delves into the roles and interactions of key components within a specific mechanical system, highlighting their significance in overall performance. Understanding how these elements work together is essential for optimizing functionality and ensuring reliability in operation.

Core Mechanisms

The primary mechanisms serve as the backbone of the system, facilitating the transfer of motion and power. Each mechanism plays a distinct role, from initiating movement to maintaining balance and efficiency. Their precise coordination is crucial for seamless operation, allowing the system to respond effectively to varying demands.

Supporting Components

In addition to core mechanisms, supporting components enhance stability and durability. These elements contribute to the overall robustness of the system, ensuring that it can withstand external pressures and maintain optimal functionality over time. Regular maintenance and understanding of their roles can greatly extend the lifespan of the entire assembly.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for enhancing the lifespan of mechanical components. By implementing effective maintenance strategies, you can ensure smooth functionality and reduce the likelihood of costly repairs.

Regular Inspections

Conducting routine examinations helps identify potential issues before they escalate. Check for wear and tear, and ensure all components are functioning correctly.

Lubrication and Cleaning

Keeping parts clean and well-lubricated is crucial. Use appropriate lubricants and remove debris to maintain optimal performance.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Lubrication | Every 500 hours |

| Cleaning | As needed |

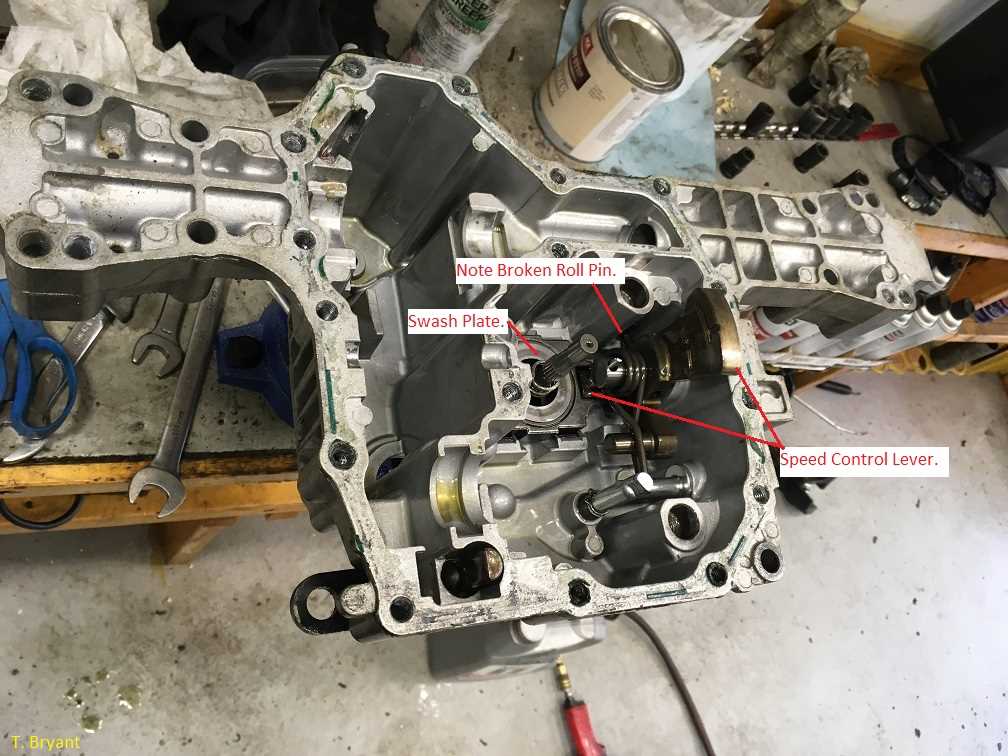

Common Issues and Solutions

In the realm of mechanical systems, certain challenges frequently arise, impacting efficiency and performance. Addressing these common problems effectively can enhance functionality and prolong the lifespan of the equipment.

Frequent Malfunctions

One prevalent issue is the irregular shifting behavior, which can stem from various factors such as fluid quality or misalignment. Regular maintenance checks can help identify and rectify these concerns promptly.

Performance Enhancements

Another common difficulty involves overheating, which may be mitigated by ensuring proper lubrication and cooling systems are functioning optimally. Implementing these solutions can significantly improve overall performance.

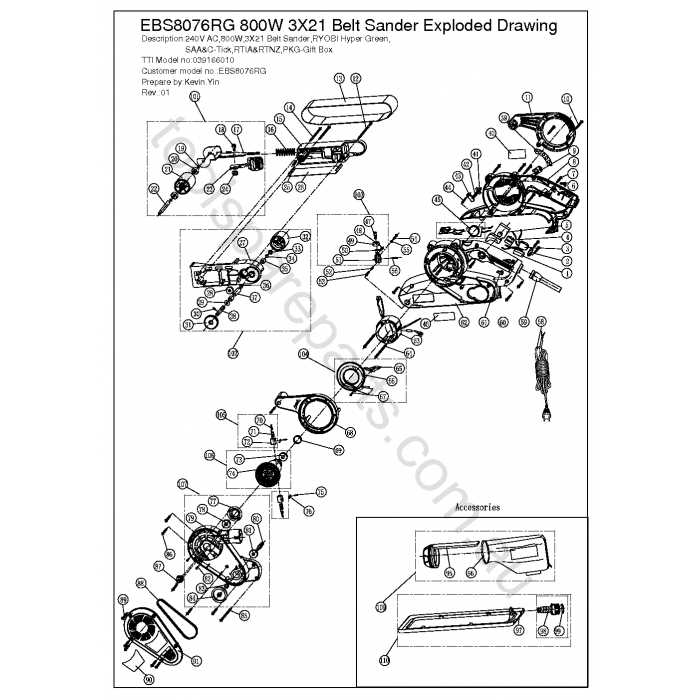

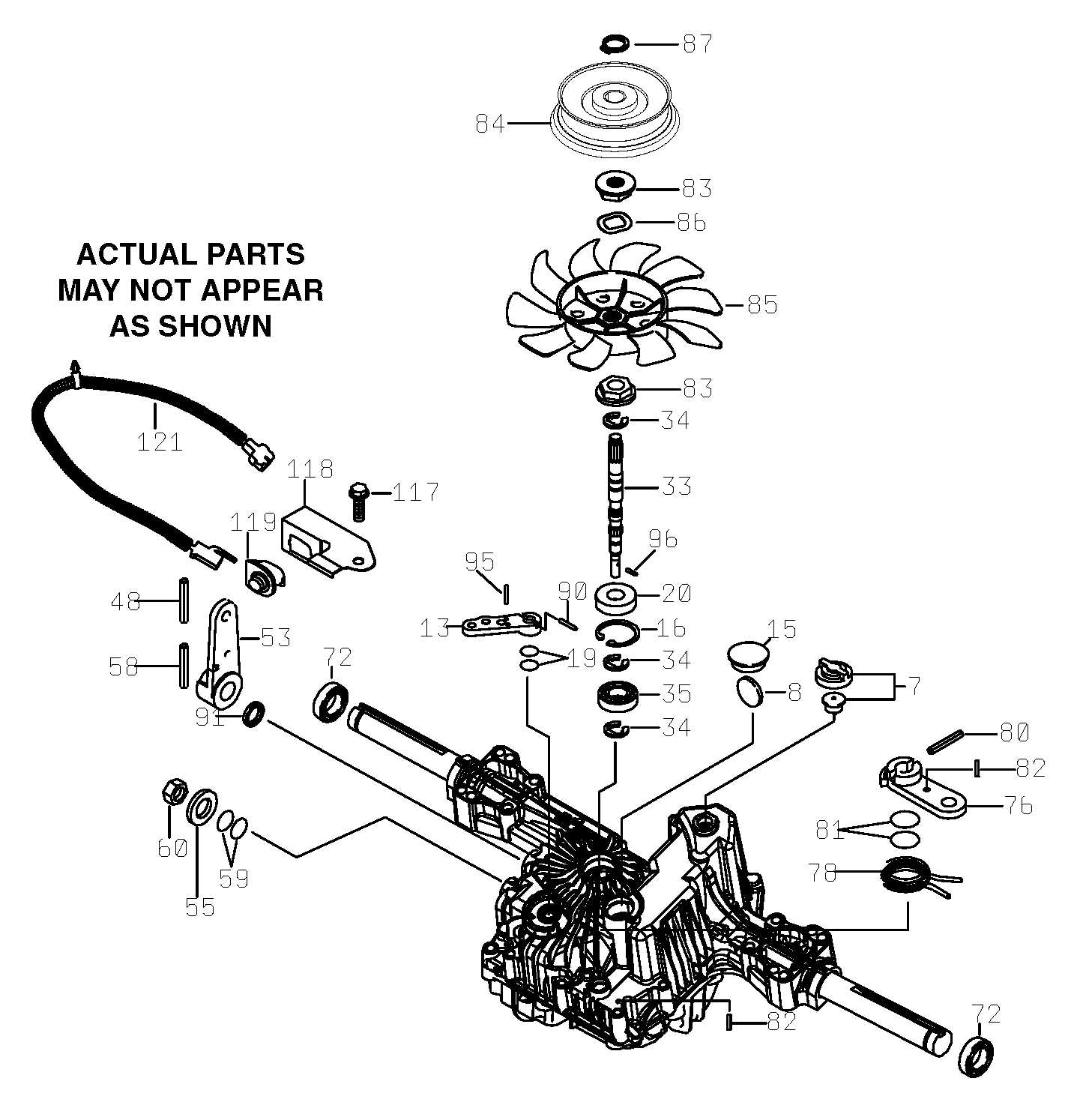

Visual Guide to K46 Parts

This section offers an illustrative overview of essential components within a specific mechanical system, providing clarity on their functions and interrelationships. By understanding the layout and characteristics of each element, users can enhance their comprehension and maintenance skills.

Component Overview

The primary elements play crucial roles in ensuring smooth operation. Familiarity with these components aids in effective troubleshooting and repair. Each item contributes uniquely to the overall functionality, making it important to recognize their significance.

Identification and Functionality

Recognizing each unit’s purpose is vital for efficient handling. Various segments are designed for specific tasks, ranging from power transfer to stability enhancement. Detailed visuals and descriptions can facilitate a deeper understanding of how these units collaborate.

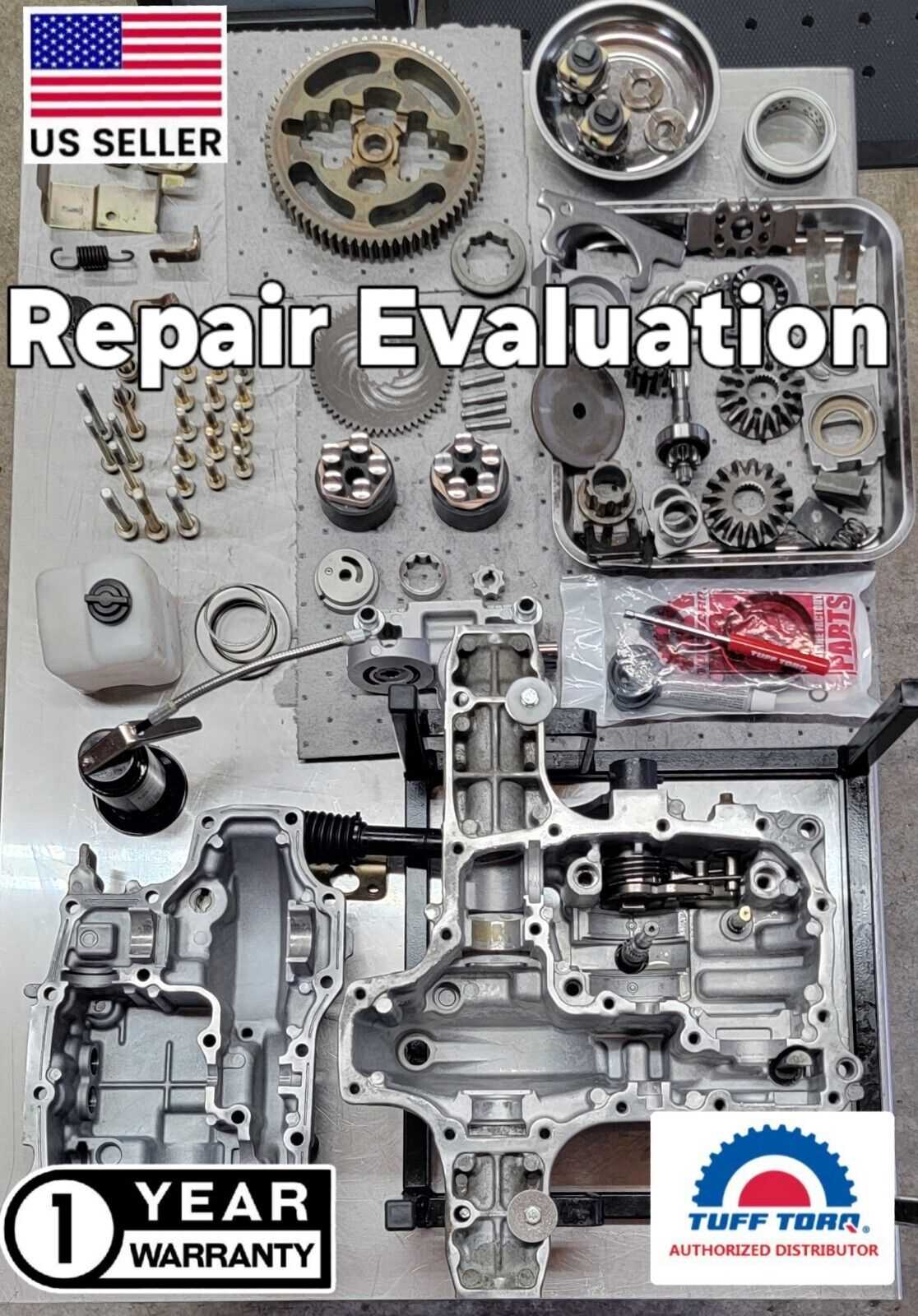

Assembly Process Explained

This section provides an overview of the assembly method for essential mechanical components, focusing on the systematic approach to ensure optimal functionality. Each phase is critical for achieving reliable operation, emphasizing precision and attention to detail.

| Step | Description |

|---|---|

| 1 | Gather all necessary components, ensuring they are clean and undamaged. |

| 2 | Begin with the foundation assembly, aligning elements accurately for stability. |

| 3 | Integrate secondary elements, following the prescribed sequence to maintain coherence. |

| 4 | Secure all fasteners appropriately to prevent any movement during operation. |

| 5 | Conduct a thorough inspection, checking for alignment and overall integrity. |

Comparative Analysis with Other Transmissions

This section explores the distinctions and similarities between various systems used in vehicles. By examining different mechanisms, we can better understand their unique characteristics and operational efficiencies.

Key Features of Alternative Mechanisms

Alternative systems offer diverse functionalities that cater to specific performance needs. Each design presents unique advantages, whether in speed, durability, or ease of maintenance.

| Feature | System A | System B | System C |

|---|---|---|---|

| Efficiency | High | Medium | Low |

| Durability | Moderate | High | Medium |

| Maintenance Cost | Low | High | Medium |

Performance Comparison

When assessing performance, different designs can significantly impact vehicle handling and response. Understanding these nuances aids in selecting the most suitable option for specific driving conditions.

Upgrades and Modifications

Enhancing the performance and durability of your vehicle’s mechanical components can significantly improve its efficiency and overall functionality. By implementing various enhancements, you can achieve better responsiveness, increased power output, and greater longevity.

One common approach involves upgrading the internal mechanisms to optimize their performance. This can include replacing stock elements with high-quality alternatives that offer improved strength and reduced wear. Additionally, incorporating advanced lubricants can further enhance the smooth operation of these mechanisms.

Another modification that many enthusiasts consider is the adjustment of ratios within the system. This can lead to a more tailored driving experience, allowing for quicker acceleration or improved fuel efficiency, depending on your specific goals. Moreover, custom tuning of the electronic controls can yield significant benefits, ensuring that the engine and other systems work in perfect harmony.

Key benefits of these enhancements include:

- Improved acceleration

- Enhanced fuel efficiency

- Increased overall reliability

By carefully selecting the right upgrades, you can transform your machine into a more capable and enjoyable vehicle that meets your performance expectations.

Resources for Further Learning

For those looking to deepen their understanding of mechanical components, a variety of valuable resources are available. Engaging with literature, online platforms, and community forums can significantly enhance knowledge and skills in this field.

Books and Manuals

Comprehensive guides often provide detailed insights into mechanisms and their functioning. Explore technical manuals that focus on various systems, ensuring to select ones that cater to your specific interests.

Online Courses and Tutorials

Digital platforms offer numerous courses that cover theoretical and practical aspects. Many of these resources include video tutorials, which can be particularly helpful for visual learners seeking to grasp complex concepts.

Expert Opinions on K46 Parts

In the realm of mechanical systems, insights from seasoned professionals provide valuable perspectives on the components that ensure optimal performance. Discussions often revolve around the reliability and functionality of these essential elements, shedding light on their roles in enhancing overall efficiency.

Many specialists emphasize the importance of selecting high-quality alternatives, as they significantly impact longevity and operational success. Regular maintenance and timely replacements are key factors highlighted by experts, who advocate for a proactive approach to avoid potential failures.

Furthermore, experienced technicians often recommend consulting technical manuals and resources for detailed guidance. This practice not only aids in informed decision-making but also fosters a deeper understanding of how each component interacts within the system.