The T5 gear system is a complex mechanical assembly that plays a vital role in the smooth operation of many vehicles. It consists of multiple interconnected elements that work together to transfer power efficiently. To truly appreciate its functionality, it’s essential to explore the various components and their interrelations.

Each element within the T5 system serves a specific purpose, from the smallest gear to the largest casing. By examining how these elements interact, we can gain valuable insight into the system’s overall efficiency and performance. Proper knowledge of these mechanisms can aid in maintenance and troubleshooting, ensuring a longer lifespan for the machinery.

In this section, we will delve deeper into the different components that make up the system, outlining their roles and how they contribute to the seamless operation of the whole unit. This understanding is crucial for anyone looking to optimize their vehicle’s mechanical performance or perform repairs with confidence.

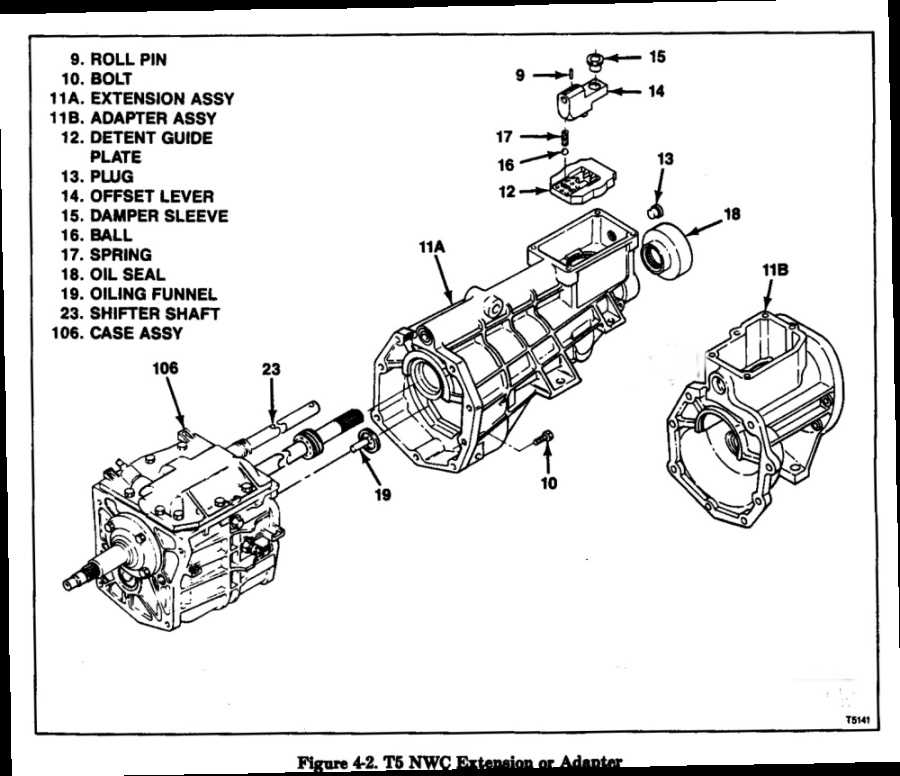

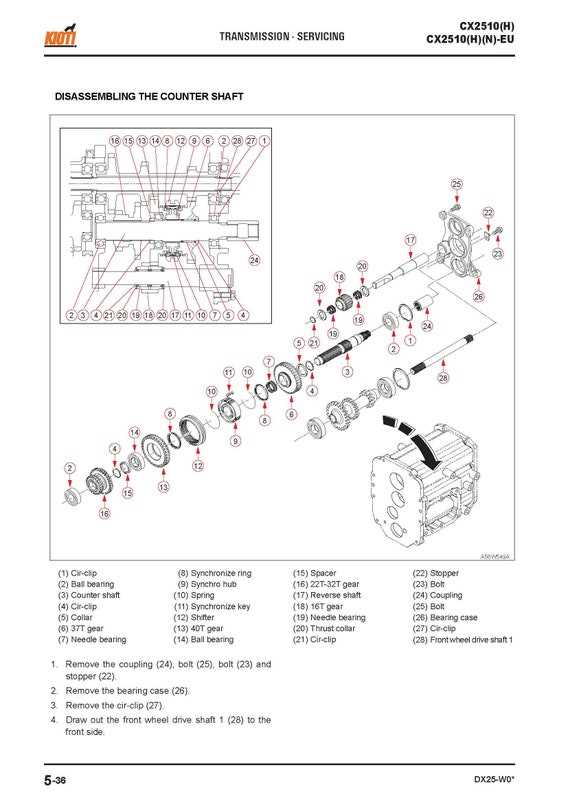

Understanding Labeled T5 Transmission Components

When examining the structure of a T5 unit, it’s important to break down the individual sections that work together to create a seamless operation. Each element has a specific function, contributing to the overall performance of the system. This knowledge allows for a clearer insight into the internal workings and enhances the ability to identify issues or make necessary adjustments.

By recognizing the role of each component, from the housing to the gears and shafts, one can gain a deeper appreciation for how they interact. These mechanical elements are designed to synchronize smoothly, ensuring the system operates with precision under varying conditions. Knowing these key sections helps improve maintenance practices and ensures longevity in performance.

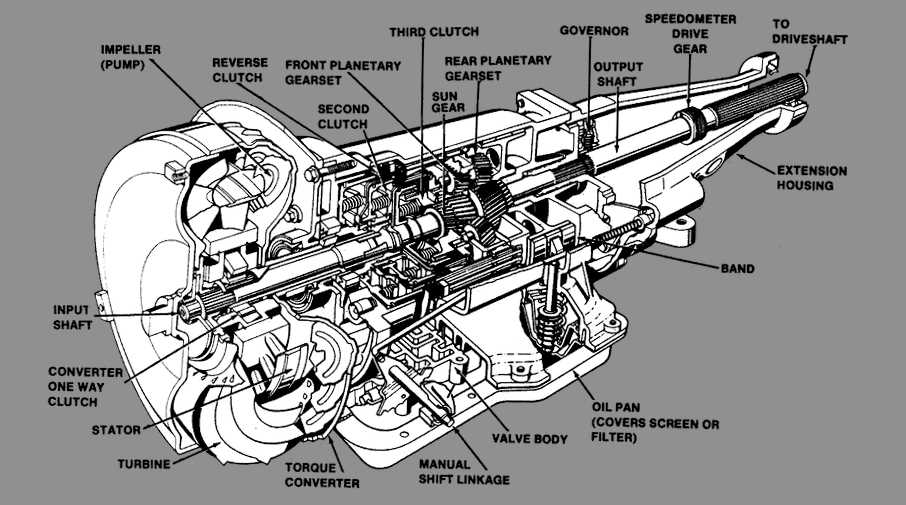

Exploring T5 Gearbox Internal Mechanisms

The T5 gearbox is known for its robust design and versatility across various applications. In this section, we will delve into the internal workings of this mechanical system, exploring how different components interact to ensure smooth operation. By understanding the key elements and their functions, it becomes easier to grasp how the entire system operates efficiently under various conditions.

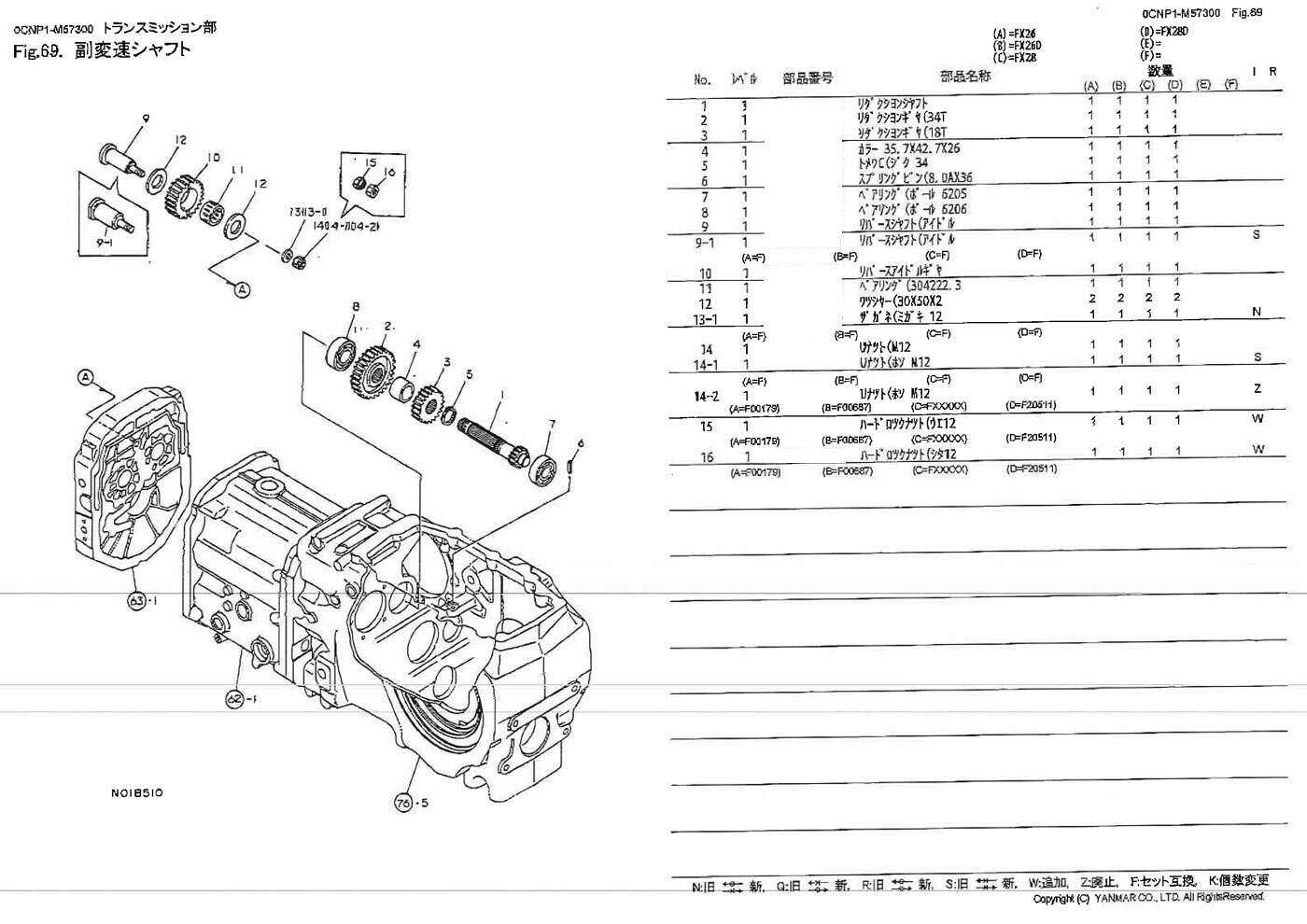

Key Components of the T5 Gearbox

Within the gearbox, several crucial parts work in unison to regulate power and speed. These elements include the synchronizers, which manage the engagement of different gears, and the gears themselves, which vary in size and function to control torque distribution. The shafts, both input and output, play a critical role in transferring power from the engine to the wheels, ensuring the vehicle moves as intended.

How the Gears Interact

The interaction between the gears and synchronizers is essential for seamless shifting. When a gear change is initiated, the synchronizers help align the rotating speeds of the gears to ensure smooth engagement. This process

Key Parts of a T5 Transmission Explained

The T5 gearbox is a complex mechanism that relies on several components working together to deliver smooth operation and efficient power transfer. Understanding these elements can provide insights into how the system functions and the role each piece plays in ensuring durability and performance. Below is an overview of the essential elements that make this device operate effectively.

Main Gears and Their Purpose

The primary gears are at the heart of the system, responsible for determining the speed and torque distribution. These gears come in various sizes and arrangements, each contributing to the overall functionality. Input and output gears interact with one another to synchronize movement and provide a seamless driving experience.

Synchronizers and Their Role

Synchronizers are crucial for smooth shifting between speeds. They help match the speed of the gears to reduce friction and wear during transitions. By doing so, synchronizers ensure a quieter and more comfortable ride, while also extending the lifespan of the mechanism.

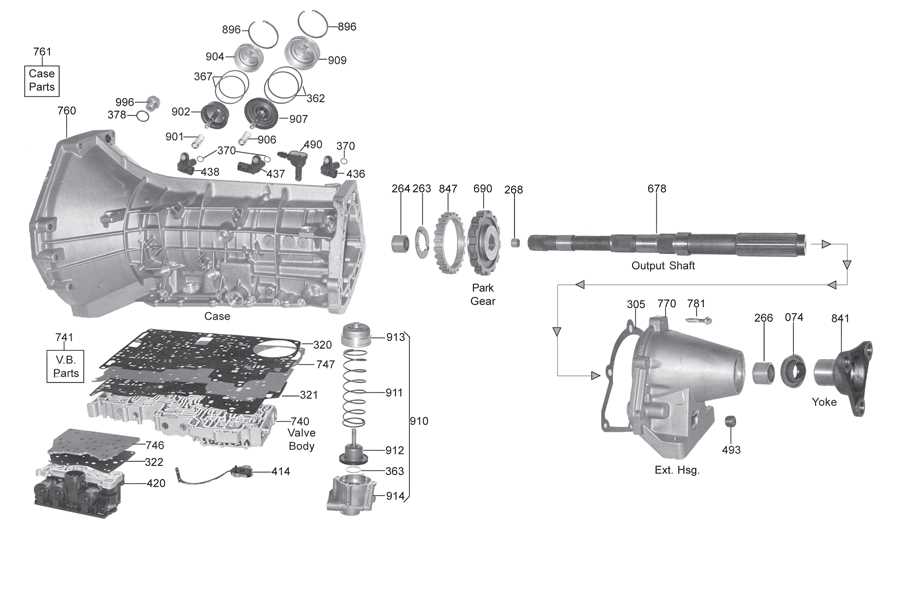

Illustrated Breakdown of T5 Transmission Gears

The following section provides an in-depth visual analysis of the various gears found within the T5 system. By exploring their arrangement and function, you can gain a clear understanding of how each gear contributes to the overall performance and smooth operation. Each component works together to create a cohesive mechanical flow, allowing for efficient power transfer and gear shifts.

First Gear: This gear is designed for maximum torque, enabling strong initial acceleration. It is the largest gear in the set and plays a crucial role in launching the vehicle from a standstill.

Second Gear: Positioned to offer a balance between power and speed, this gear allows for smoother transitions from lower to higher speeds. It helps reduce engine strain as the vehicle gains momentum.

Third Gear: Acting as a middle point in the gear sequence, third gear supports consistent speed while maintaining efficient fuel consumption. It is critical for mid-range acceleration.

Fourth Gear: Often known for optimal cruising efficiency, this gear facilitates steady driving at higher speeds. It plays a significant part in reducing engine noise and improving fuel economy.

Fifth Gear: The highest gear in the system, this component is primarily used for highway driving. It minimizes engine revolutions per minute (RPM), providing a smooth and quiet experience during long trips.

Each gear in the T5 system is carefully engineered to deliver specific performance benefits at different driving conditions, making the system versatile and efficient for a wide range of applications.

Identifying Essential T5 Transmission Elements

The core components within the T5 system play a crucial role in ensuring smooth operation and optimal performance. These key elements work together to transfer power efficiently, making them integral to the overall functionality. Understanding how these elements interact can help in maintaining and optimizing the system’s performance.

| Component | Description | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input Shaft | Responsible for transferring power from the engine to the internal mechanisms. | |||||||||||||||||||

| Output Shaft | Transfers power to the wheels, completing the cycle of energy transfer. | |||||||||||||||||||

| Synchronizers | Ensure smooth gear shifts by matching gear speeds during engagement. | |||||||||||||||||||

| Gear Set | Comprised of various gear ratios that control the speed and torque applied to the drive system. | |||||||||||||||||||

| Bearings |

| Part | Function |

|---|---|

| Synchro Ring | Matches the speed of the gears during a shift |

| Blocking Ring | Prevents the gears from clashing by stopping rotation until speeds are aligned |

| Shift Fork | Engages and disengages gears by moving the synchros |

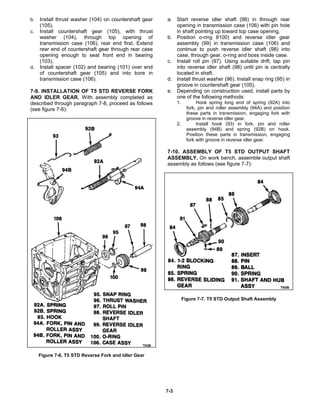

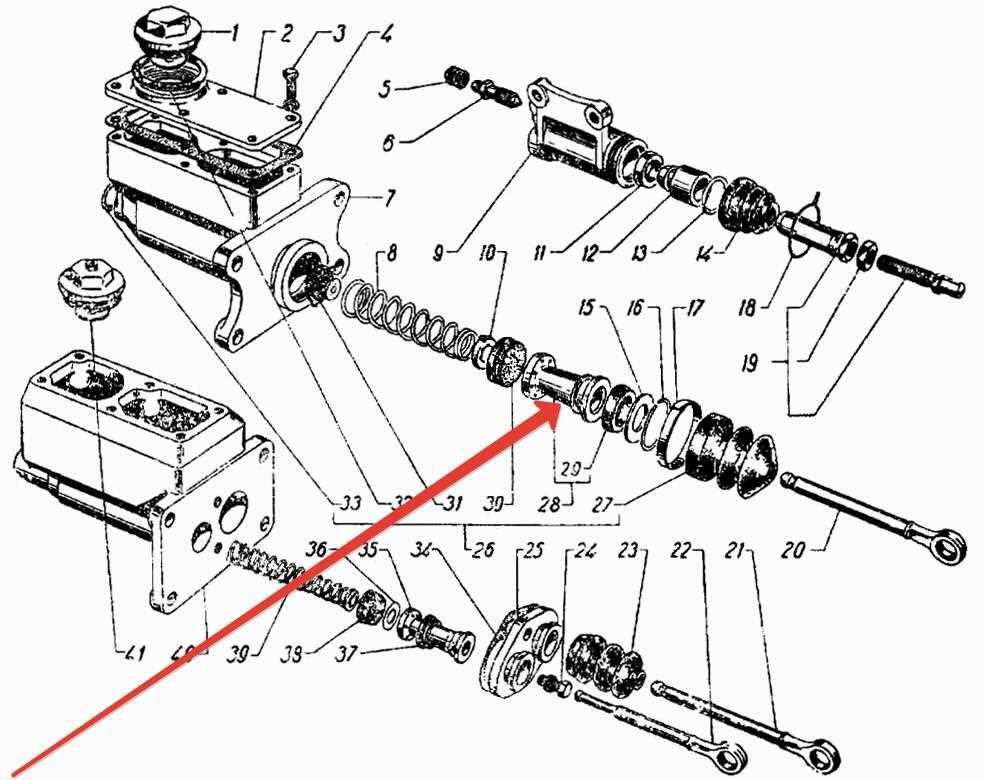

Analyzing the T5 Shifter Components

The T5 shifter mechanism is a crucial element in ensuring smooth gear engagement and overall driving performance. Understanding its structure and functionality can help in improving the precision and reliability of the gear shifting experience. In this section, we will explore the key components that make up the shifter system, examining how each piece contributes to the overall operation and what to look for in terms of maintenance and optimization.

Shifter Mechanism and Linkage

The shifter mechanism works as the interface between the driver and the gearbox. It converts the driver’s input into a mechanical movement that shifts the gears inside the system. The linkage, which connects the shifter to the internal components, plays a critical role in ensuring that the correct gear is selected. Wear and tear on these components can lead to difficulty in gear engagement, making it essential to understand their function and condition.

Internal Springs and Detent System

Internal springs and the detent system serve to hold the shifter in place and ensure that it stays in the selected gear. The springs provide the necessary tension, while the detent system prevents the shifter from moving into unintended positions. Any issues within this area can result in misalignment or sloppy shifting, highlighting the importance of maintaining these parts for a smooth and accurate gear selection.

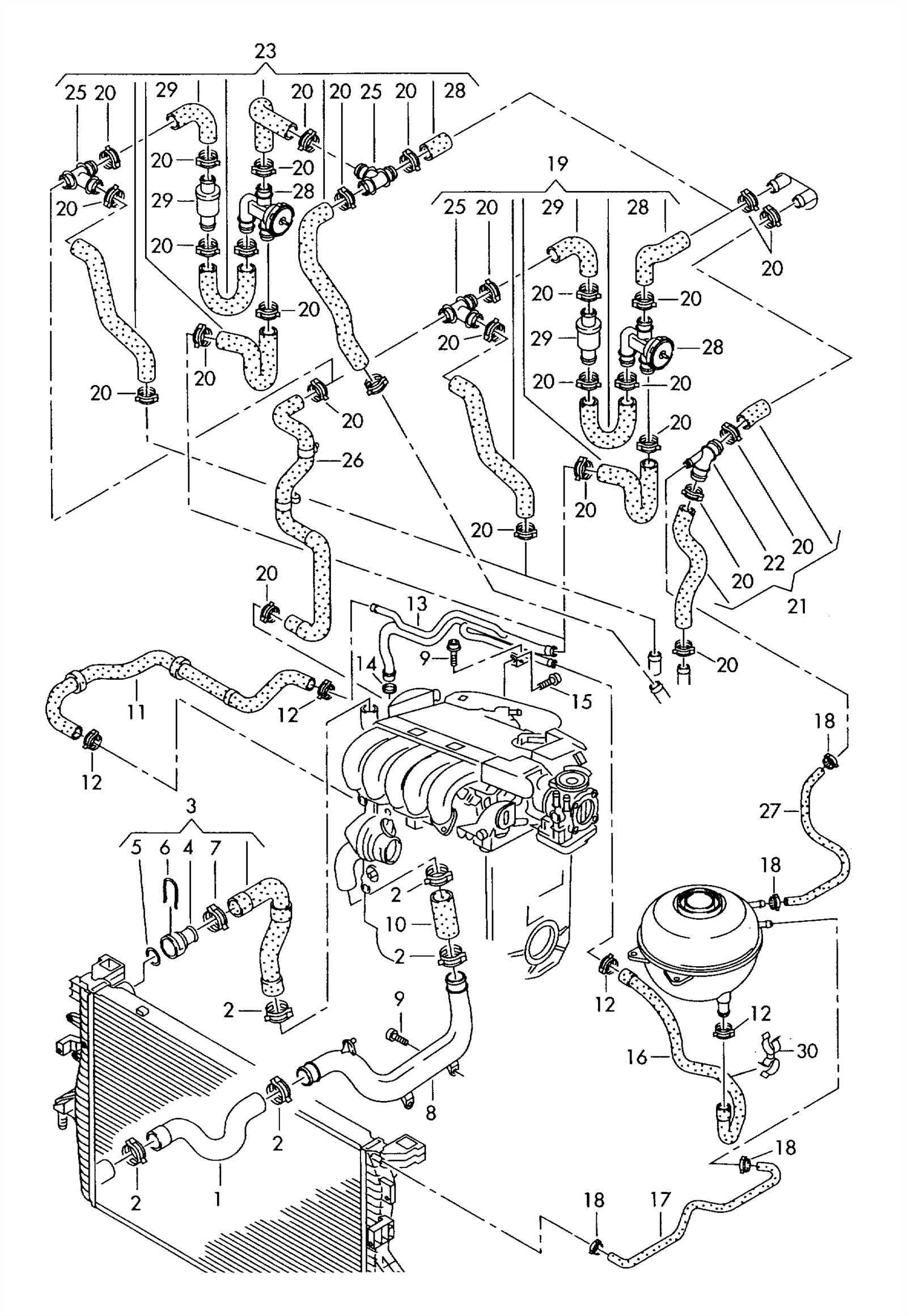

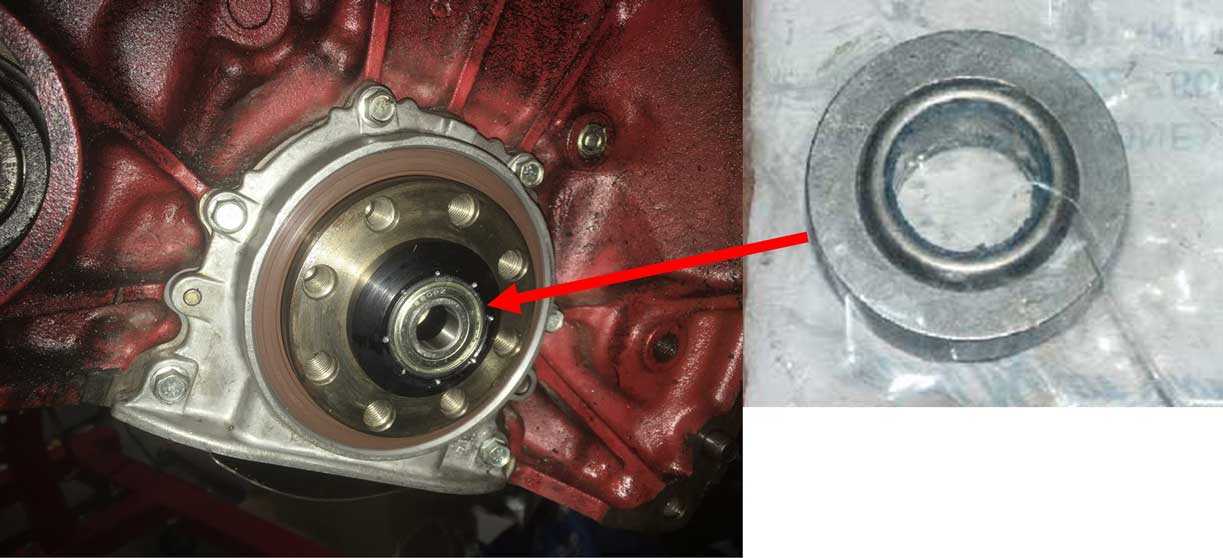

Critical Bearings and Seals in a T5 Transmission

In any gear system, the efficiency and longevity are largely determined by the integrity of key components that reduce friction and prevent fluid leaks. Among these, the rolling elements and sealing elements play crucial roles. Proper functioning of these components ensures smooth operation and protects other internal mechanisms from wear and contaminants.

Bearings: Essential for Smooth Rotation

Bearings are vital in supporting rotating shafts and allowing them to turn smoothly under load. They reduce the friction between moving surfaces, ensuring that the gears rotate efficiently. If a bearing becomes damaged or worn, it can lead to misalignment, excessive heat buildup, and ultimately, failure of the entire system.

Seals: Protecting Internal Components

Seals serve as barriers that prevent leakage of lubricants and keep foreign debris from entering the system. A compromised seal can result in lubricant loss, leading to increased friction and damage to the internal mechanisms. Regular inspection and maintenance of these sealing elements are necessary to avoid premature wear and system failure.

The Role of the T5 Mainshaft in Transmission Function

The mainshaft is a central component that plays a crucial role in the operation of the gearbox. It acts as the primary axis around which the various elements of the gear mechanism rotate, allowing for the transfer of power from the engine to the wheels. The efficiency and smoothness of gear shifts depend heavily on the mainshaft’s ability to maintain its alignment and handle torque effectively.

Key functions of the mainshaft include:

- Connecting multiple gears within the system to control the movement of the vehicle.

- Enabling the synchronized engagement of gears during shifts.

- Withstanding high levels of stress and torque transmitted from the engine.

- Maintaining rotational speed and torque distribution to various components.

The durability and performance of the mainshaft directly impact the overall functionality of the gearbox, making it an essential element for reliable operation.

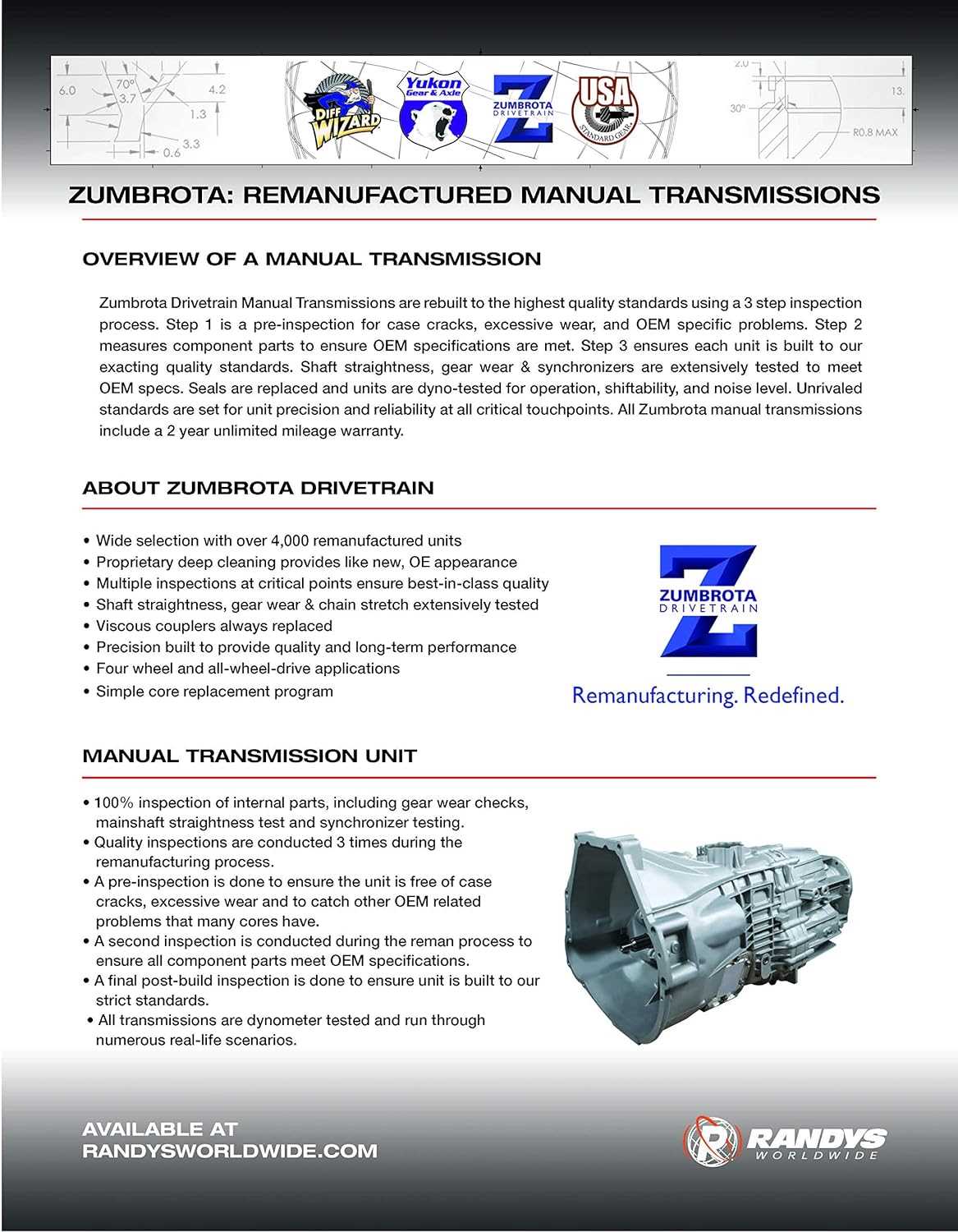

Maintenance Tips for T5 Transmission Parts

Proper upkeep of the components in a 5-speed gearbox system is essential for maintaining smooth performance and extending the lifespan of the vehicle. Regular attention to these elements ensures that the vehicle operates efficiently, minimizing the risk of costly repairs and enhancing the driving experience. This section provides key advice on how to care for these vital components.

Regular Fluid Checks and Replacement

Fluid levels and quality are crucial for keeping the mechanical components running smoothly. Regular inspections and timely changes of the lubricant prevent wear and ensure optimal function of the system.

Inspecting Wear and Tear

Routine inspection of the gearbox components, including seals, bearings, and shifters, can help identify signs of wear before they lead to serious issues. Early detection allows for more cost-effective repairs and avoids unexpected breakdowns.

| Component | Maintenance Frequency | Recommended Action |

|---|---|---|

| Fluid | Every 30,000-50,000 miles | Check levels, top up, or replace if necessary |

| Shifter Mechanism | Every 10,000 miles | Inspect for smooth operation and adjust if needed |

| Bearings and Seals | Every 50,000 miles | Examine for wear and replace if damaged |