In the realm of aquatic transportation, the efficiency and reliability of a vessel hinge on the seamless interaction of its crucial elements. Among these, certain fixtures play a pivotal role in ensuring smooth navigation and optimal performance. A thorough comprehension of these components is vital for any enthusiast or professional involved in marine maintenance.

By exploring the intricacies of these mechanical assemblies, one can gain valuable insights into their functionality and maintenance. Proper knowledge not only enhances performance but also extends the lifespan of the entire system. This examination will serve as a guide to navigating the complex web of parts that contribute to maritime excellence.

Ultimately, a deep dive into the structure and arrangement of these essential elements can empower boaters to make informed decisions regarding upkeep and repairs. This understanding fosters a connection with the vessel, promoting both safety and enjoyment on the water.

Understanding Mercruiser Transom Components

This section explores the essential elements that contribute to the overall functionality of marine propulsion systems. By examining these critical components, we can appreciate their roles in ensuring a smooth and efficient operation on the water.

Key Elements of Marine Drive Systems

Various components work together to provide stability and control. Each element plays a specific role, from supporting the engine to facilitating movement through water.

Component Overview

| Component | Description |

|---|---|

| Engine Support | Stabilizes the engine and distributes weight evenly. |

| Steering Mechanism | Allows for precise navigation and maneuverability. |

| Drive Assembly | Transfers power from the engine to the propeller. |

| Mounting Hardware | Secures all components in place for optimal performance. |

Importance of Transom in Boats

The structural element at the rear of a vessel plays a crucial role in ensuring overall stability and performance on the water. It serves as a vital point of attachment for various components, contributing significantly to the boat’s integrity and functionality.

This section is essential for supporting the propulsion system, enabling efficient movement and maneuverability. A well-designed rear section not only enhances the aesthetic appeal but also impacts the vessel’s hydrodynamics, allowing for smoother navigation through different water conditions.

Moreover, the strength and durability of this area are critical for handling the stresses experienced during operation. Proper maintenance and timely repairs of this component can prevent more extensive damage, ensuring safety and longevity for the craft. In summary, this fundamental element is indispensable for both performance and safety in maritime activities.

Key Parts of Mercruiser Transom

Understanding the essential components that support and enhance the performance of marine engines is crucial for any boating enthusiast. These elements work in unison to ensure the stability, efficiency, and overall functionality of the vessel, playing a vital role in both operation and maintenance.

Essential Components

Among the most critical elements are the mounting brackets, which secure the engine to the hull, providing the necessary stability during navigation. Additionally, the trim tabs are pivotal in controlling the angle of the vessel, improving maneuverability and fuel efficiency. The alignment of these components is key to ensuring optimal performance on the water.

Maintenance Considerations

Regular inspection of these crucial elements can prevent potential issues and extend the lifespan of the engine system. Corrosion and wear are common concerns, making it essential to utilize appropriate protective measures and timely replacements. Familiarity with these components allows for informed maintenance practices, ensuring safe and enjoyable experiences on the water.

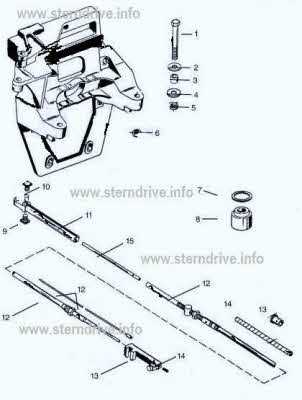

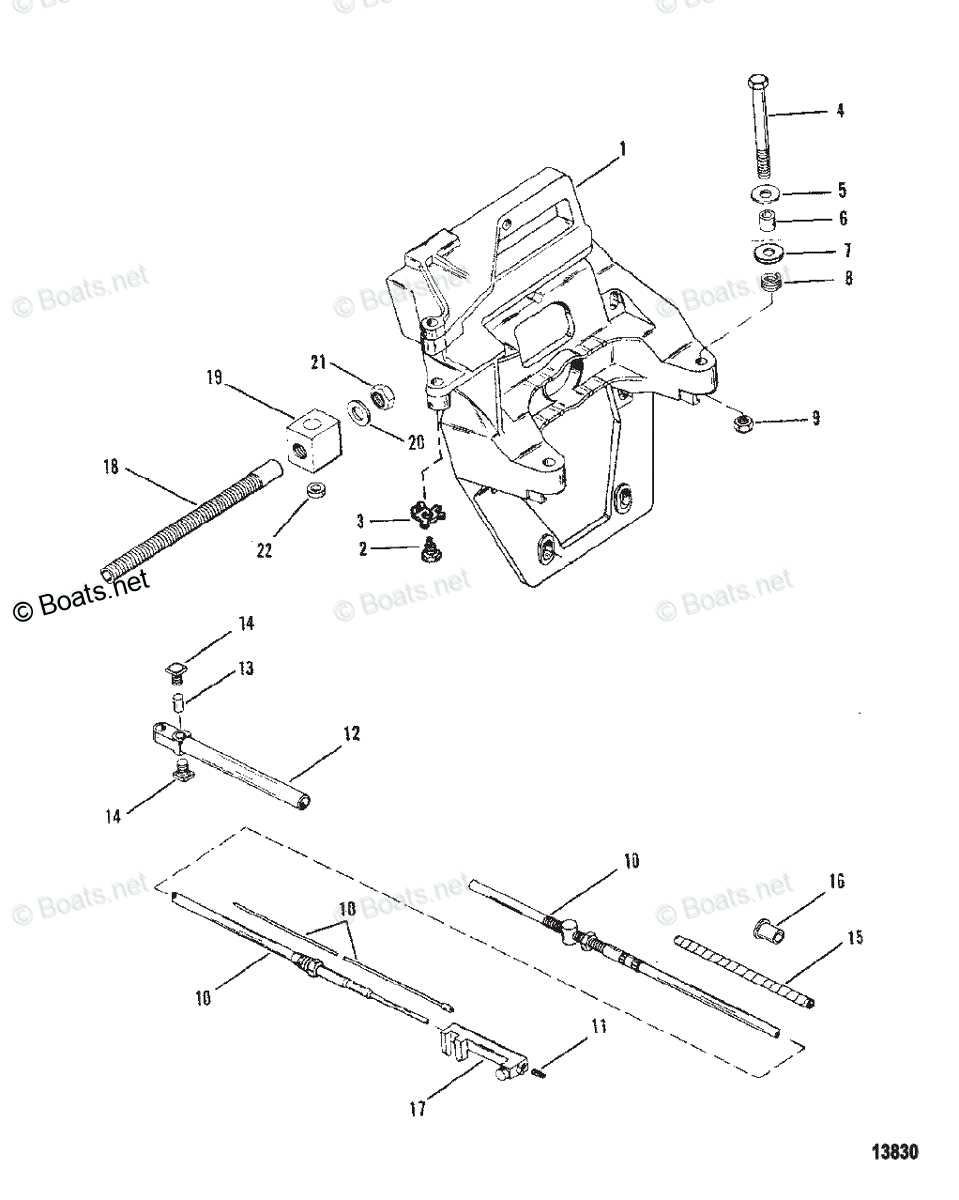

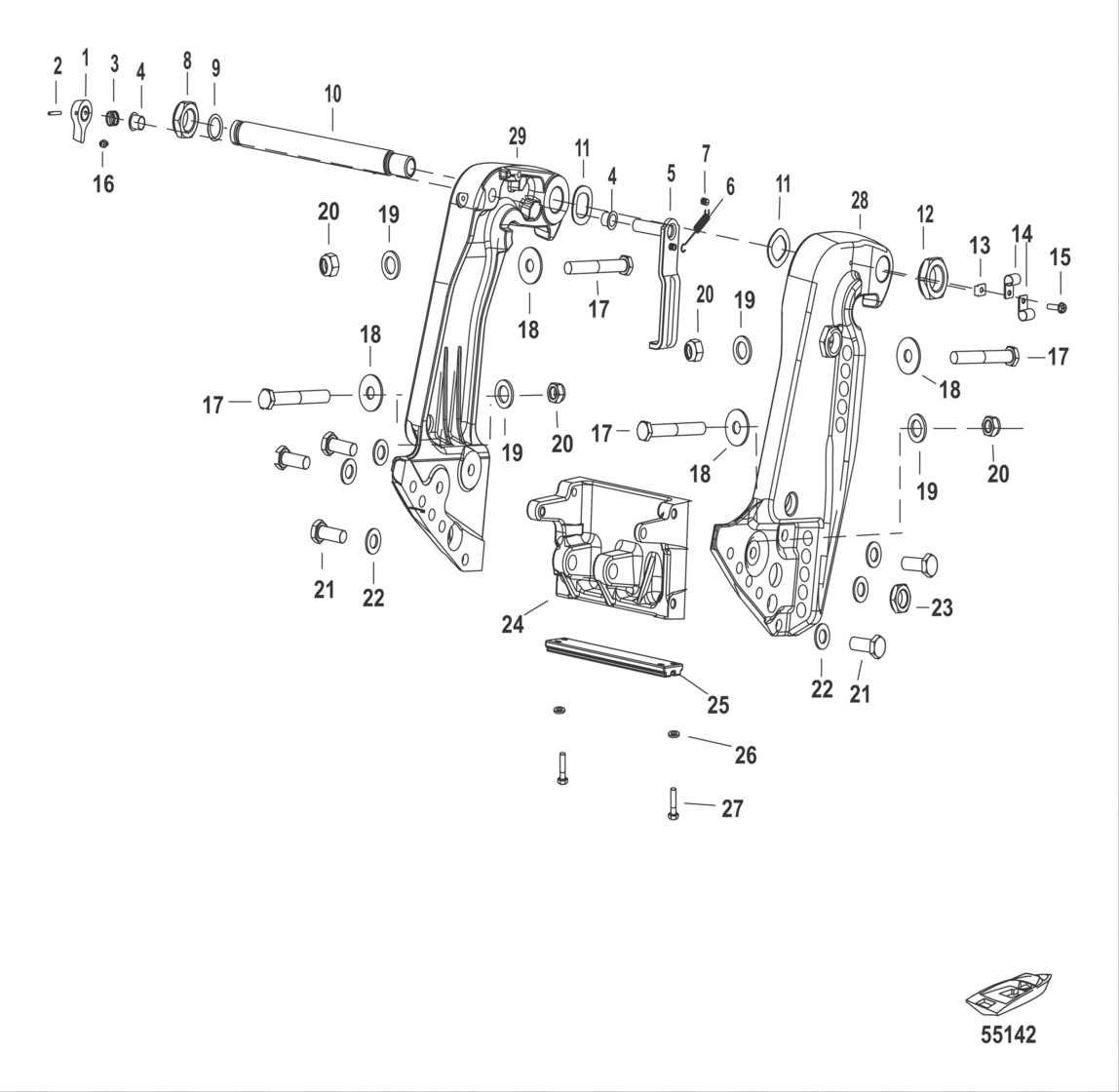

How to Read Transom Diagrams

Understanding technical illustrations related to marine systems is essential for effective maintenance and repair. These visual aids provide a comprehensive overview of components, their arrangement, and how they interact with each other. Familiarity with the symbols and notations used can significantly enhance your ability to troubleshoot and carry out repairs.

Begin by familiarizing yourself with the key elements depicted in the illustration. Each component will typically be labeled, allowing for easy identification. Pay attention to any reference numbers or codes, as these often correlate with a parts list or guide that provides further details about each item.

Next, take note of the layout. Often, these illustrations will show the relationship between different components, indicating how they fit together and function in the system. Understanding the flow of operation is crucial, as it helps to visualize how each part contributes to the overall mechanism.

Lastly, look for any additional notes or legends that may accompany the illustration. These can provide valuable insights into specific functions, maintenance tips, or troubleshooting advice. By mastering the ability to read these technical visuals, you empower yourself to tackle repairs more confidently and efficiently.

Common Issues with Transom Parts

When dealing with the rear support structure of marine vessels, several challenges can arise that impact performance and safety. Understanding these issues is crucial for effective maintenance and repair.

Corrosion is a frequent problem, especially in saltwater environments. Over time, metal components can deteriorate, leading to weakened structures. Regular inspections can help identify early signs.

Alignment problems may also occur, affecting the overall stability and handling of the vessel. Misalignment can stem from improper installation or wear over time, necessitating adjustments to restore functionality.

Seal failure is another common concern. Seals can wear out or become damaged, allowing water intrusion that can cause significant damage to internal components. Replacing seals promptly is essential to prevent further complications.

Finally, wear and tear from regular use can lead to various mechanical issues. Components should be routinely checked and replaced as needed to ensure optimal operation and extend the lifespan of the vessel.

Maintenance Tips for Transom Components

Proper upkeep of your vessel’s structural elements is essential for optimal performance and longevity. Regular attention to these components helps prevent wear and ensures a smooth operation on the water. Below are key practices to consider for effective maintenance.

- Regular Inspection: Routinely check for signs of corrosion, cracks, or any wear that may compromise integrity.

- Cleaning: Keep surfaces free of dirt, grime, and marine growth to prevent deterioration. Use gentle cleaners that won’t damage finishes.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and avoid seizing.

- Seal Maintenance: Examine and replace seals as necessary to prevent water ingress and protect internal mechanisms.

- Fastener Check: Ensure all bolts and screws are secure to maintain stability. Retighten as needed.

By following these guidelines, you can help ensure that your vessel remains in excellent condition, ready for your next adventure on the water.

Transom Installation Best Practices

Properly securing the rear structure of a vessel is essential for ensuring stability and performance on the water. This section provides crucial guidelines that will enhance the longevity and efficiency of your installation process.

Preparation and Inspection

Before beginning the installation, thoroughly inspect all components for wear and damage. Ensure that the surface is clean and free of debris, as this will facilitate a stronger bond and prevent future issues.

Secure Attachment Techniques

When fastening the assembly, use high-quality hardware that is resistant to corrosion. Employ appropriate sealants to protect against water ingress, which can lead to structural failure. Always follow the manufacturer’s specifications for torque settings to achieve the ultimate strength in your connections.

Tools Required for Transom Repairs

When undertaking repairs on the rear assembly of a boat, having the right equipment is crucial for ensuring a smooth and effective process. Proper tools not only facilitate the job but also help in achieving a high-quality finish, allowing for safe and reliable performance on the water.

Essential Equipment

Before starting your repair work, it is important to gather the following essential items:

| Tool | Description |

|---|---|

| Socket Set | Variety of sizes for loosening and tightening bolts and nuts. |

| Wrench Set | Adjustable and fixed wrenches for accessing tight spaces. |

| Drill | For creating holes or removing old fasteners. |

| Marine Sealant | To provide watertight seals during reassembly. |

| Screwdriver Set | Flat and Phillips head options for various screws. |

Safety Gear

In addition to the basic tools, it is essential to consider personal protection equipment. This includes gloves, safety goggles, and a dust mask to ensure your safety while working on your vessel. Proper gear can prevent injuries and improve comfort during repairs.

Identifying Parts in Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a structured way to recognize and analyze various elements, ensuring accurate identification and appropriate action.

| Component Name | Description | Function |

|---|---|---|

| Bracket | Supports other structures | Provides stability |

| Seal | Prevents leakage | Ensures integrity |

| Hinge | Allows rotation | Facilitates movement |

| Connector | Joins two elements | Enables functionality |

Upgrading Your Transom Parts

Enhancing the structural components of your vessel can significantly improve performance and longevity. This section explores key considerations and options for upgrading essential elements that support your marine experience.

Key Considerations for Enhancement

When contemplating an upgrade, it’s vital to assess the current condition of your structure. Factors such as material quality, compatibility with existing systems, and the intended use of your watercraft should guide your decisions. Prioritizing durability and efficiency will ultimately yield the best results.

Available Upgrades

| Upgrade Type | Description |

|---|---|

| Reinforced Structures | Improves stability and support under heavy loads. |

| Corrosion-Resistant Materials | Enhances durability against harsh marine environments. |

| Advanced Fasteners | Increases reliability and strength of connections. |

Frequently Asked Questions about Transoms

This section addresses common inquiries regarding the rear structure of watercraft. Understanding these components is essential for both maintenance and performance. Below are some frequently asked questions and their answers.

-

What is the primary function of this structure?

The rear structure plays a crucial role in supporting the engine and providing stability to the vessel.

-

How do I know if my structure needs repair?

Signs of wear, such as cracks, rot, or excessive movement, indicate that repairs may be necessary. Regular inspections can help identify these issues early.

-

Can I replace it myself?

While some experienced DIY enthusiasts may attempt a replacement, it is often best to consult a professional to ensure proper installation and safety.

-

What materials are typically used?

Common materials include marine-grade plywood, fiberglass, and aluminum, each offering different benefits regarding durability and weight.

-

How can I maintain this component?

Regular cleaning, sealing, and inspection can help prolong its lifespan. It’s important to address any signs of damage promptly.

These questions highlight key aspects of this essential component, aiding owners in making informed decisions about care and maintenance.

Resources for Further Learning

This section offers valuable materials to enhance your understanding of marine components and their functionalities. Engaging with these resources will help deepen your knowledge and support your projects effectively.

- Online Forums: Join discussions on platforms like BoatUS or The Hull Truth for insights and shared experiences.

- Video Tutorials: Explore YouTube channels dedicated to marine maintenance for visual guidance.

- Technical Manuals: Access official guides from manufacturers to get detailed specifications and installation tips.

- Books: Look for literature focusing on marine engineering and boat maintenance to broaden your expertise.

- Workshops: Participate in hands-on sessions offered by local marinas or marine schools for practical knowledge.