When maintaining equipment for outdoor tasks, it’s crucial to have a clear understanding of its internal and external elements. Each component plays a vital role in ensuring the efficiency and performance of the device. Knowing how the different sections interact can help with both repairs and regular upkeep.

The various mechanical and electrical units within such tools serve specific purposes. From the engine to the cutting head, each part must function seamlessly to deliver optimal results. Familiarity with these components will enable smoother troubleshooting when issues arise, ensuring a longer lifespan for the equipment.

Exploring how these pieces fit together provides insight into their operation. This knowledge not only simplifies maintenance but also enhances safety, as proper handling depends on understanding how each section contributes to the whole.

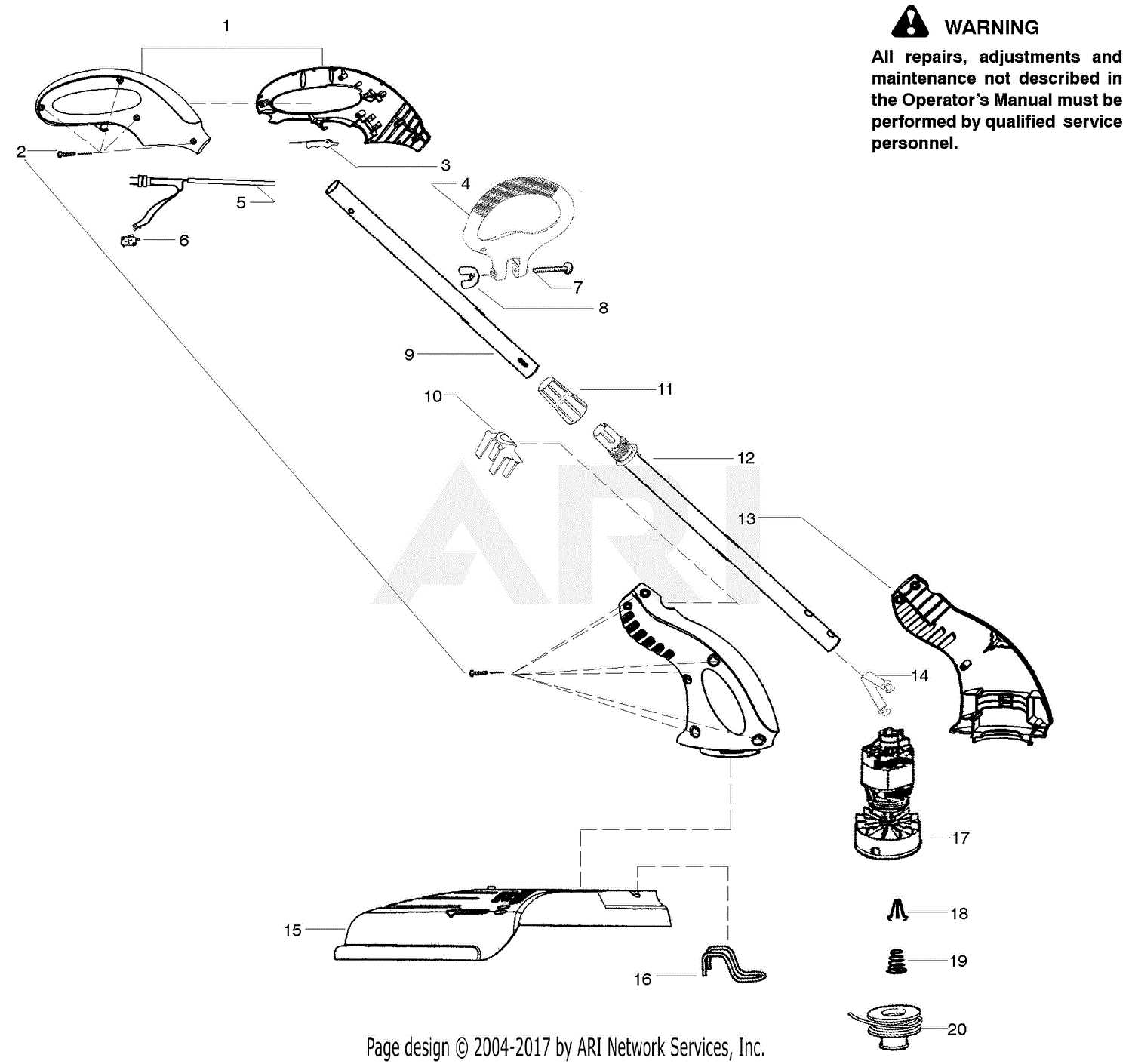

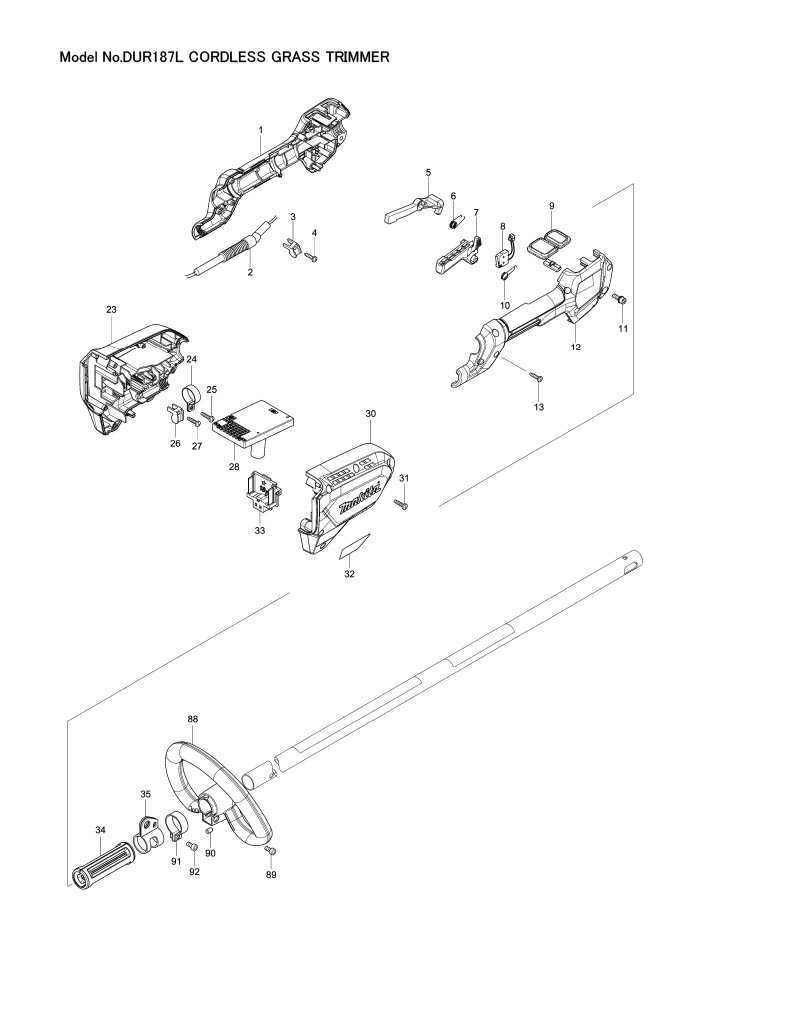

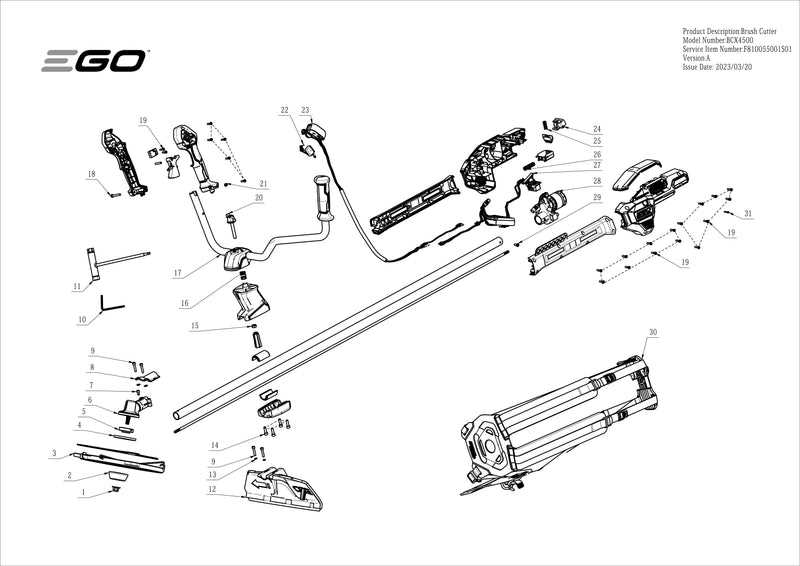

Overview of Grass Trimmer Components

These machines are made up of several key sections, each playing an essential role in their operation. Understanding these different elements can help you maintain and use the equipment more efficiently.

- Motor Unit: Powers the entire system, providing the necessary force for cutting.

- Cutting Head: Houses the line or blades that carry out the trimming work.

- Shaft: Connects the power source to the cutting mechanism, ensuring smooth energy transfer.

- Handle and Controls: Designed for user comfort, this section includes the throttle and grips.

- Guard: Shields the operator from debris while trimming.

By recognizing these components, users can ensure their equipment stays in top working condition.

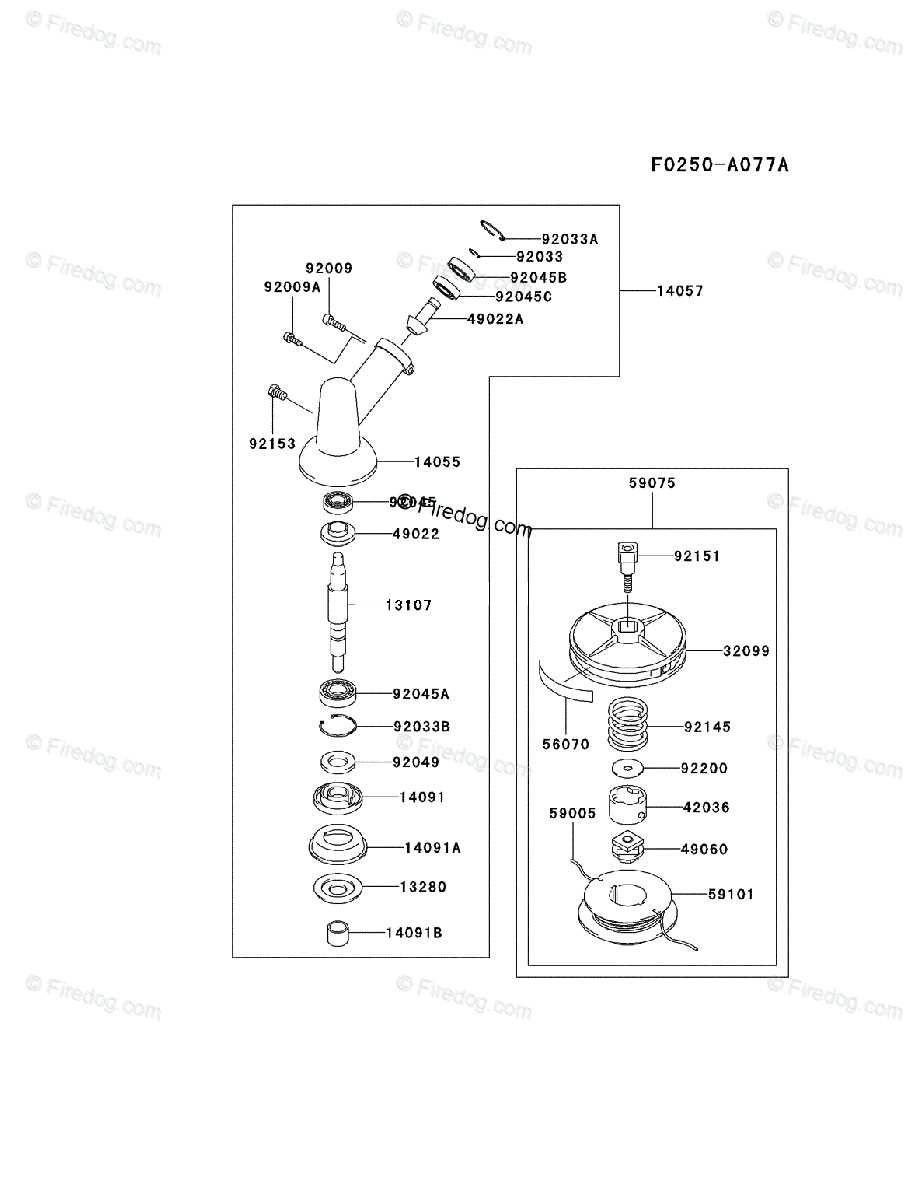

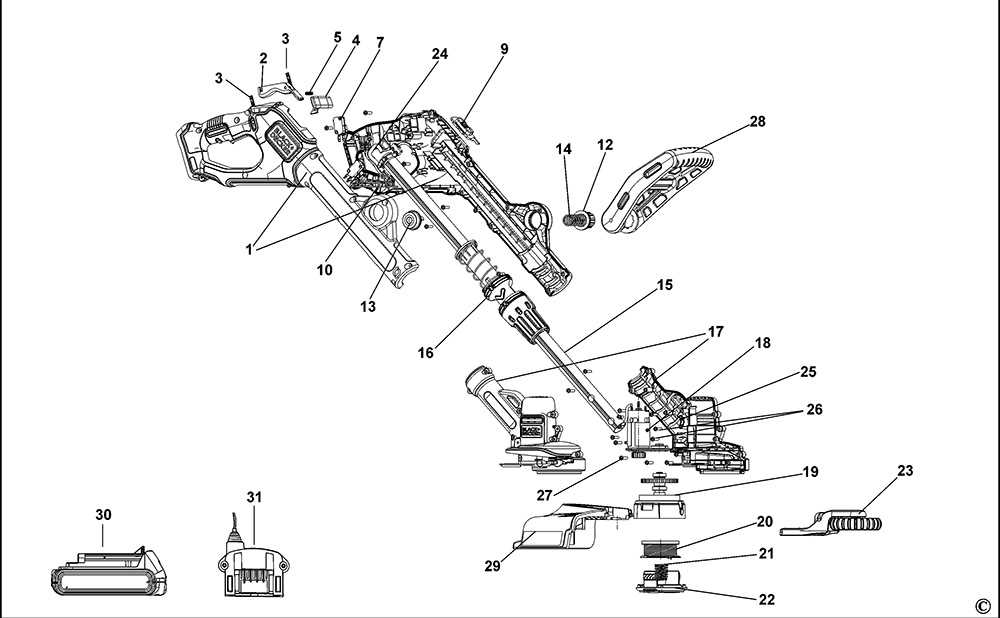

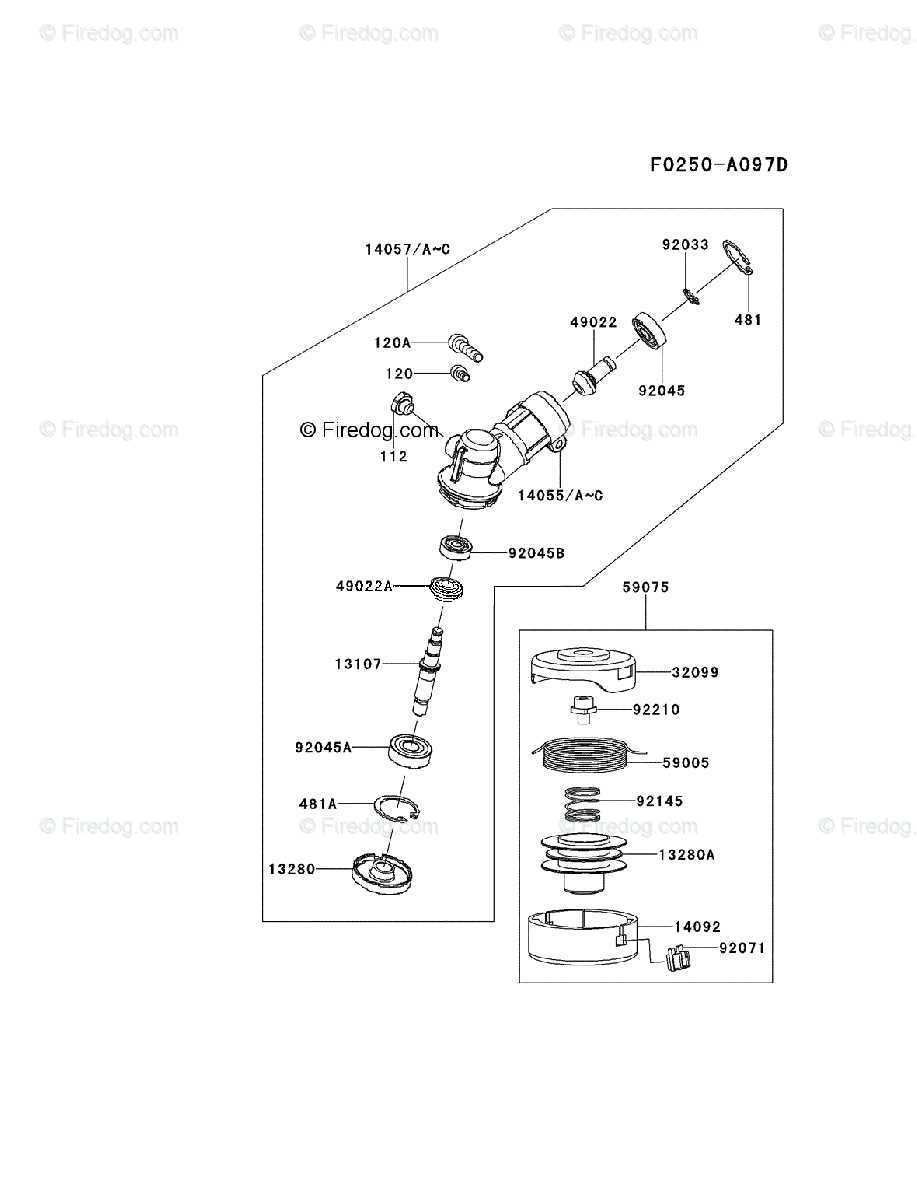

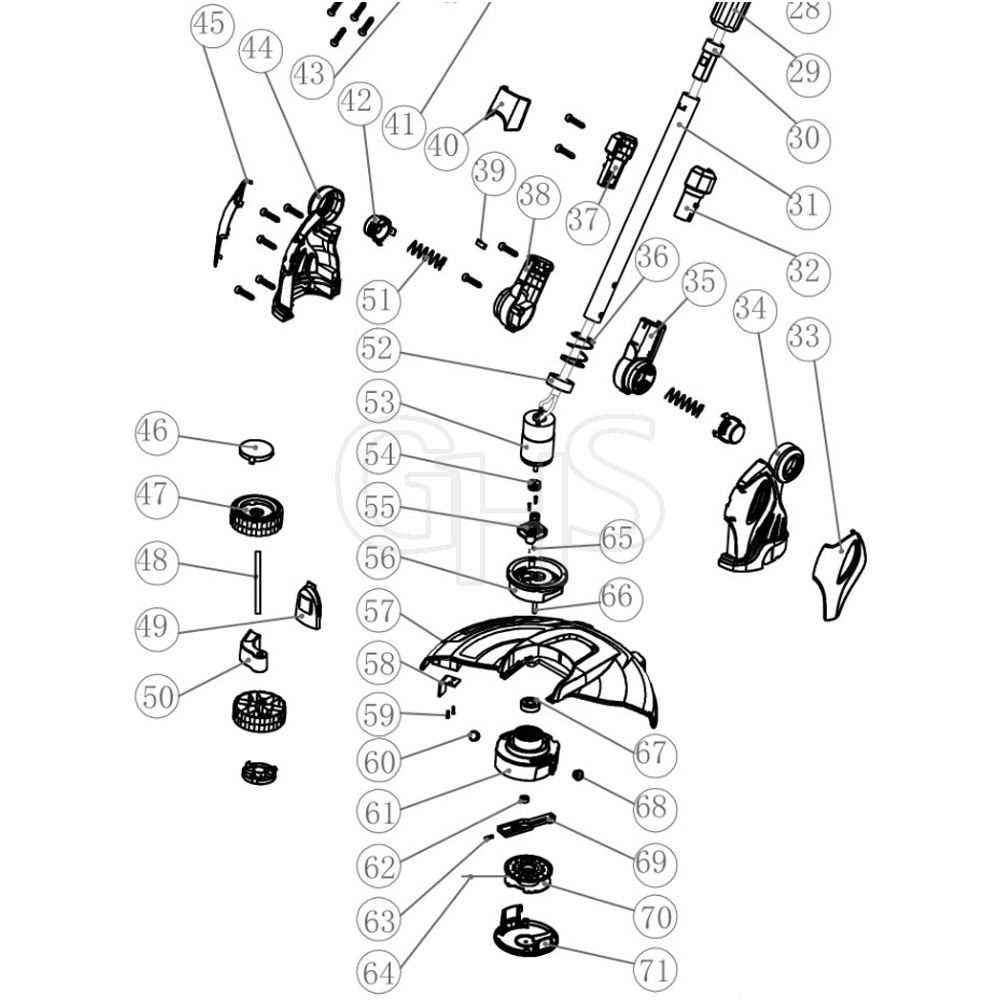

Understanding the Trimmer Head Assembly

The head assembly plays a critical role in ensuring the tool operates efficiently. It houses key components that contribute to the overall functionality, allowing for seamless rotation and proper cutting performance. A solid understanding of how these elements work together ensures easier maintenance and troubleshooting.

Main Components and Their Roles

Within the assembly, several essential elements come together to form a cohesive unit. The cutting line mechanism is one of the primary features, enabling the tool to slice through vegetation effectively. The spool, which holds the cutting line, works in conjunction with the feed system to ensure continuous performance during operation.

Key Considerations for Maintenance

To maintain smooth operation, it’s crucial to regularly inspect and replace worn elements of the assembly. The line’s wear, spool integrity, and housing should be checked periodically to avoid disruptions. Regular upkeep extends the lifespan of the

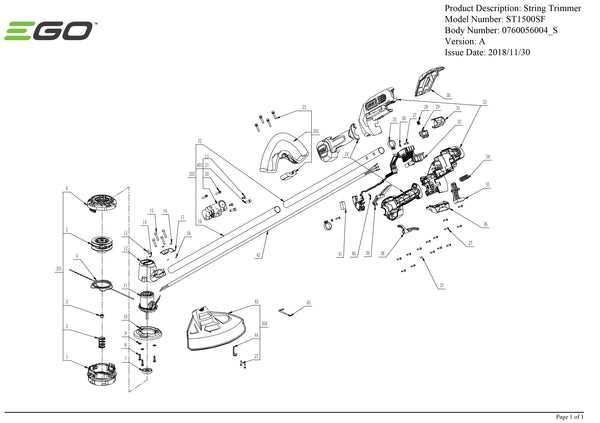

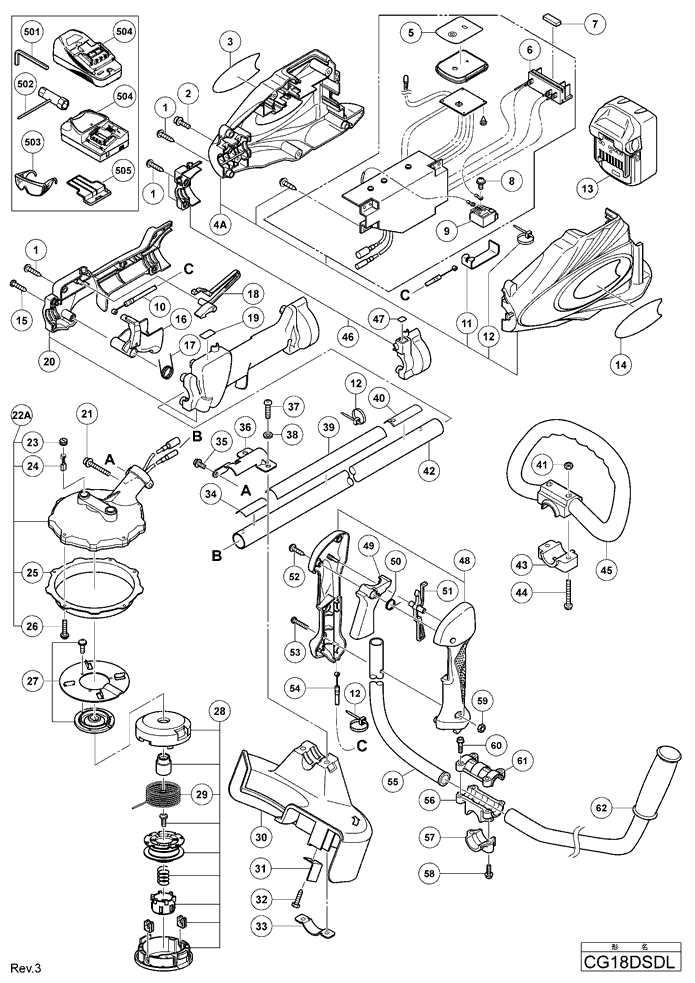

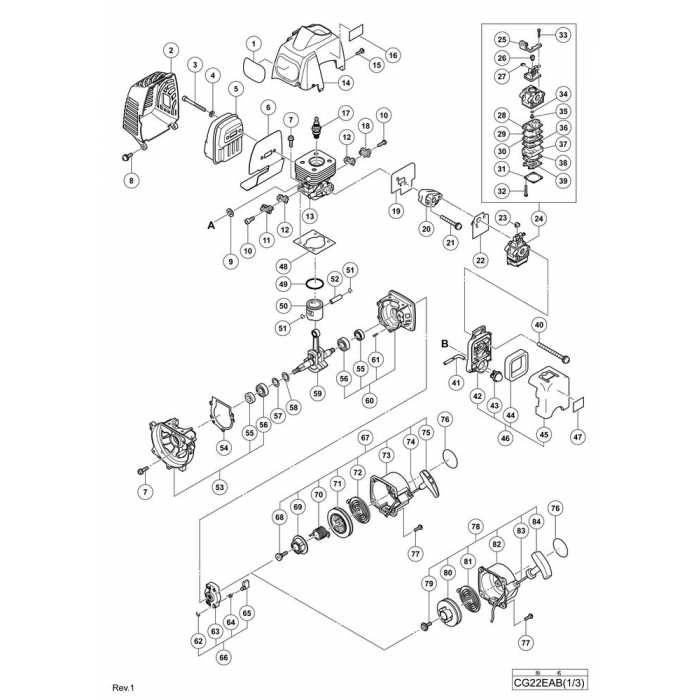

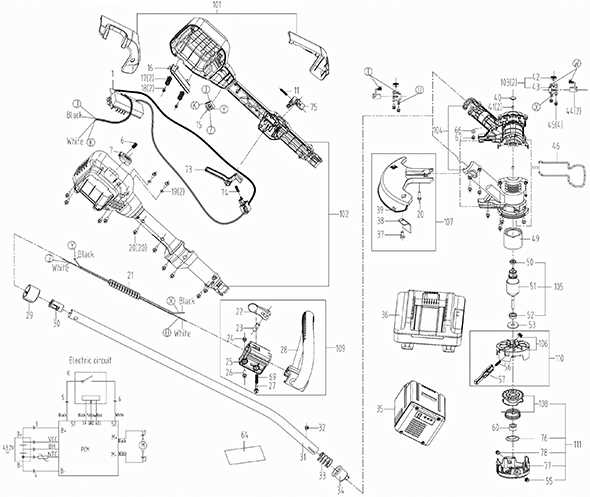

Exploring the Engine and Motor System

The engine and motor system plays a crucial role in ensuring the functionality of the cutting equipment. It provides the necessary power and movement for effective performance, whether powered by fuel or electricity. Understanding the components that make up this system allows for better maintenance and troubleshooting when issues arise.

Main Components of the Power Source

- Power unit: The central element that generates energy for movement.

- Ignition system: Responsible for starting the unit and maintaining consistent operation.

- Fuel system: In fuel-powered variants, this ensures efficient fuel delivery to the engine.

- Electric motor: In electric models, this part converts electrical energy into mechanical power.

Drive Mechanism and Performance Control

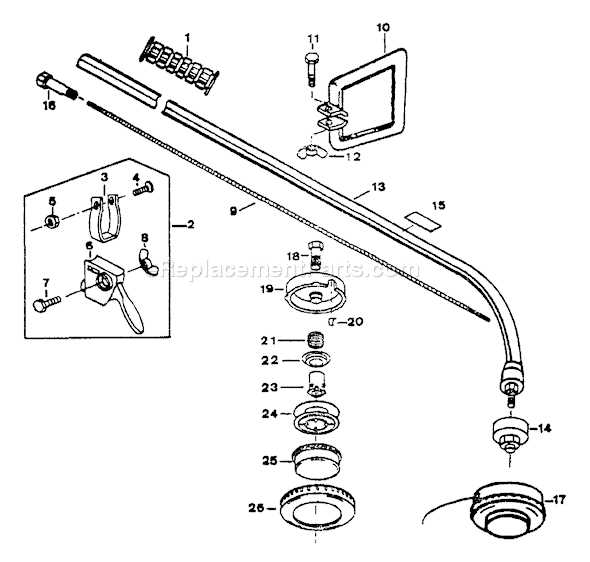

Role of the Driveshaft in Functionality

The driveshaft is essential in ensuring efficient operation of the tool by transmitting rotational energy from the motor to the cutting mechanism. It plays a critical role in maintaining the consistency of movement and overall performance.

The driveshaft’s design affects the tool’s durability and operational smoothness. A well-constructed shaft minimizes vibrations, contributing to user comfort and reducing wear on the mechanical components. The quality of materials used in its construction directly influences longevity and reliability.

In addition, the driveshaft must be properly aligned to avoid issues such as excessive noise or inefficiency. Misalignment or damage can significantly impact the tool’s capability, resulting in decreased cutting precision and power.

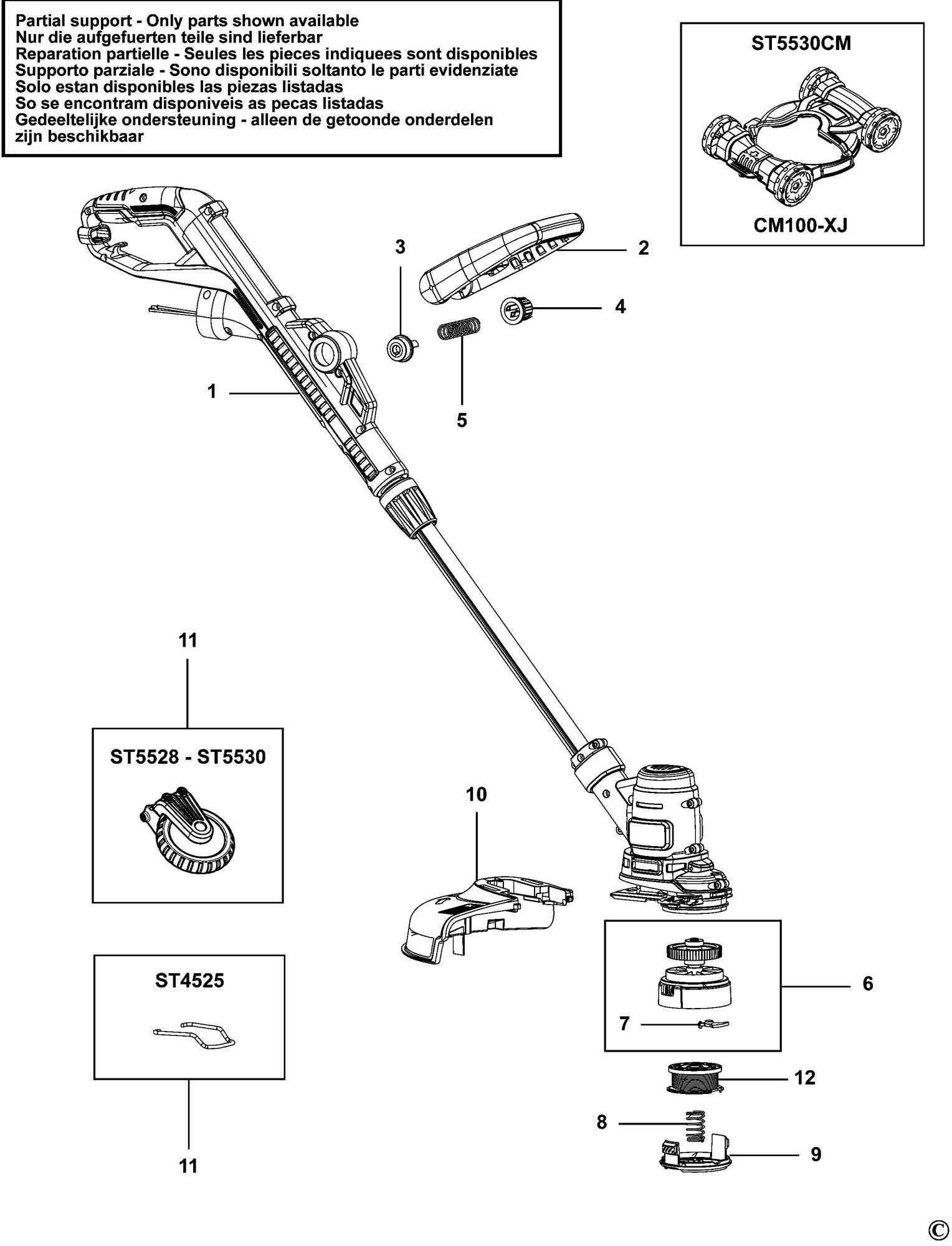

Significance of the Cutting Line Mechanism

The cutting line mechanism plays a vital role in ensuring the efficiency of the tool during vegetation management. This element defines how effectively the machine can slice through different types of foliage, contributing directly to the precision and quality of the work. Its importance cannot be overstated, as it influences both performance and durability.

The flexibility and strength of the cutting line determine how well the tool can handle various tasks, from light trimming to dealing with thicker, more resistant growth. The mechanism ensures consistent operation by maintaining the ideal tension and release of the cutting line, which directly impacts overall effectiveness.

Maintaining the proper functionality of this system is essential for achieving smooth and efficient operation. By regularly checking the mechanism for wear and adjusting the line, the user can extend the lifespan of the tool and ensure it operates at peak capacity. Ignoring the condition of this mechanism could lead to inefficiencies or even

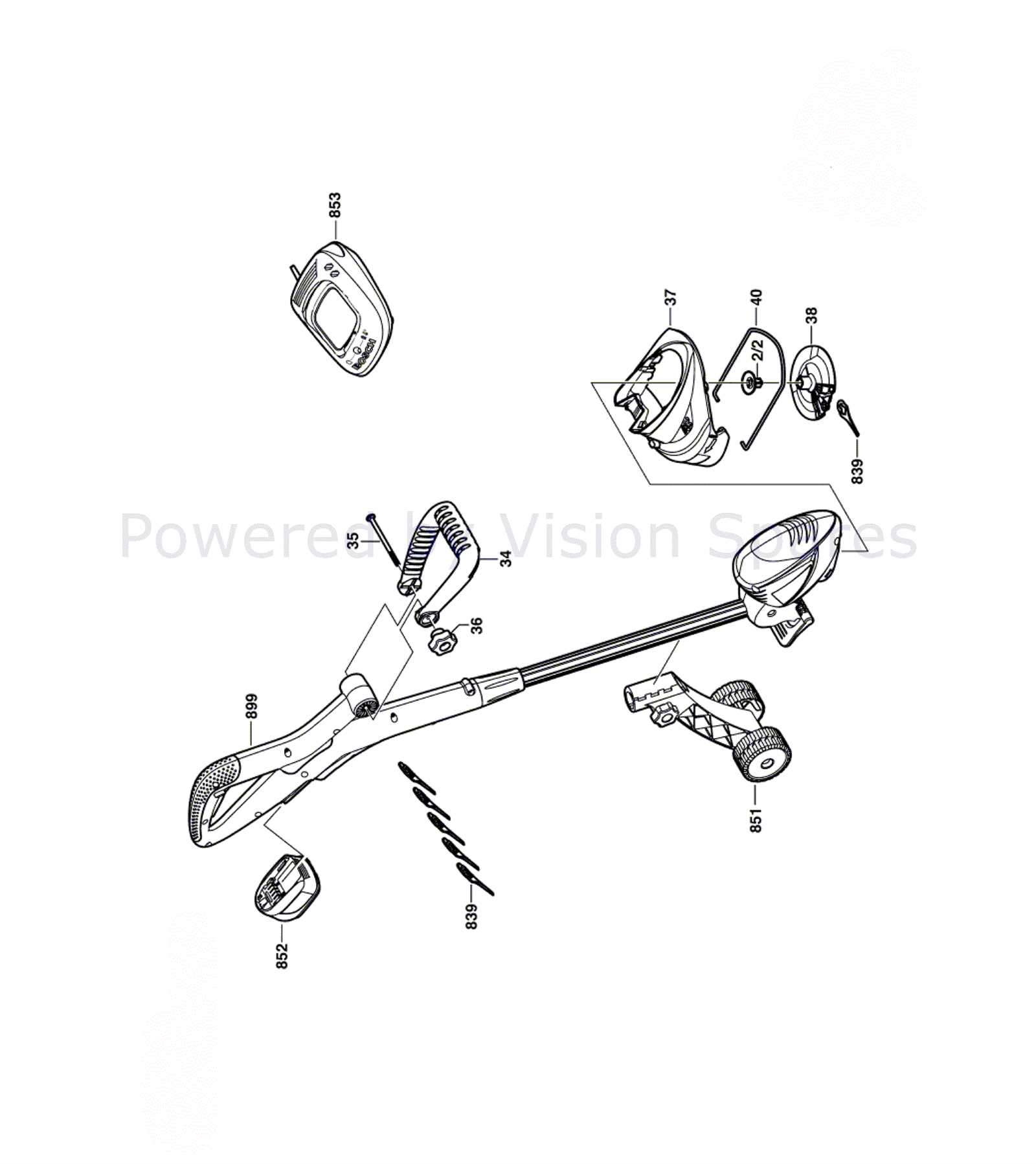

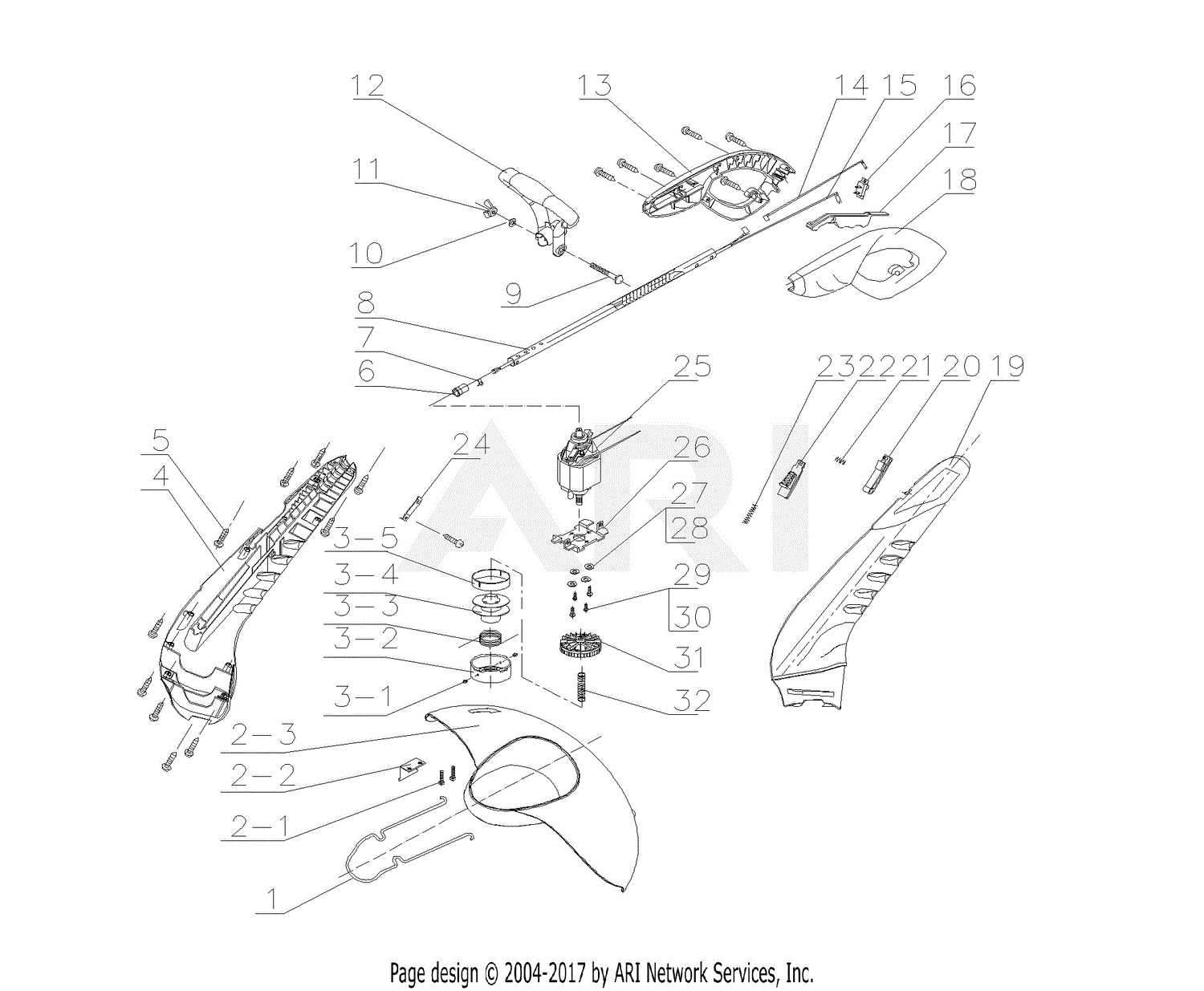

Handlebar and Control Layout Explained

The handlebar and control layout of a cutting tool is crucial for ensuring efficient and comfortable operation. This arrangement allows users to maintain optimal control while navigating various terrains. Understanding how these components interact can enhance the user experience and improve overall performance.

Functionality of Controls

Controls are strategically positioned to enable easy access and intuitive handling. Operators can quickly adjust settings or power levels without losing grip or balance. This ergonomic design minimizes fatigue, especially during prolonged use, allowing for more precise and effective handling.

Importance of Handlebar Design

The handlebar’s configuration significantly influences maneuverability. A well-designed handlebar provides stability and support, facilitating smoother movements across uneven surfaces. Additionally, features such as adjustable heights can accommodate different user preferences, enhancing comfort and efficiency during operation.

Fuel Tank and Power Source Connections

The functionality of outdoor equipment significantly relies on the integration of the fuel reservoir and the energy supply systems. Understanding how these components interact is essential for optimal performance and maintenance. Proper connections ensure a consistent flow of power and fuel, allowing the device to operate efficiently.

Connecting the Fuel Reservoir

The fuel reservoir serves as a vital component, holding the necessary liquid to power the equipment. It is crucial to securely attach the reservoir to prevent leaks. Ensuring a tight fit at all connection points will help maintain the integrity of the fuel system and enhance operational reliability.

Power Supply Links

Establishing the right connections for the power source is equally important. This includes ensuring that the electrical wiring is properly insulated and connected to the power unit. Regular inspection of these links can prevent electrical failures and ensure consistent performance throughout the equipment’s use.

Guide to Protective Shields and Covers

Protective shields and covers are essential components designed to enhance user safety while operating various outdoor tools. They serve as barriers that prevent debris from causing harm, ensuring a secure working environment. Understanding the different types and functions of these protective elements is crucial for maintaining equipment and ensuring safety during use.

Types of Protective Shields

There are several types of protective shields available, each designed for specific applications. Below is a table outlining common types along with their features:

| Type | Description |

|---|---|

| Guard Shield | Provides coverage around the cutting area to prevent debris from flying toward the operator. |

| Debris Cover | Designed to minimize the dispersion of cut material, protecting the operator and surrounding areas. |

| Safety Shield | A transparent barrier that allows visibility while providing protection from projectiles. |

Maintenance and Care

Regular maintenance of protective shields and covers is necessary to ensure their effectiveness. Inspect for any signs of wear or damage, and clean them regularly to prevent buildup of debris that can hinder performance. Replacing worn-out components promptly can help maintain safety standards and prolong the lifespan of the equipment.

Importance of the Air Filter in Performance

The air filter plays a crucial role in the overall efficiency of small engine equipment. It ensures that only clean air enters the combustion chamber, which is vital for optimal engine function and longevity. A well-maintained air filter not only enhances performance but also contributes to fuel efficiency.

When the air filter is clogged or dirty, it restricts airflow, leading to a reduction in engine power and an increase in fuel consumption. This situation can cause the engine to run hotter, potentially resulting in damage over time. Regular inspection and replacement of the air filter are essential for maintaining the reliability of the equipment.

| Effects of a Clean Air Filter | Consequences of a Dirty Air Filter |

|---|---|

| Improved engine performance | Reduced power output |

| Increased fuel efficiency | Higher fuel consumption |

| Longer engine lifespan | Potential engine damage |

Explaining the Starter Assembly Mechanism

The starter assembly is a crucial component in initiating the operation of various handheld tools. This mechanism is designed to provide the necessary force to start the engine, enabling the tool to function efficiently. Understanding its components and their interactions can enhance maintenance practices and troubleshooting efforts.

Key Components of the Starter Assembly

- Starter Rope: A durable cord that users pull to engage the engine.

- Recoil Spring: Provides the tension needed to retract the starter rope.

- Pulley: A rotating component that guides the rope during the starting process.

- Housing: The protective casing that encases the assembly.

Operation Process

- When the user pulls the starter rope, it unwinds from the pulley.

- The recoil spring becomes compressed, storing potential energy.

- Once the rope is fully extended, the spring releases, causing the pulley to rotate.

- This rotation engages the engine, leading to ignition and operation of the tool.

Maintenance Tips for Gearbox Assembly

Proper upkeep of the gearbox assembly is essential for ensuring optimal performance and longevity of your equipment. Regular maintenance helps prevent premature wear and enhances efficiency during operation.

Regular Inspection

- Check for any signs of wear or damage to the components.

- Inspect seals and gaskets for leaks or degradation.

- Ensure all screws and bolts are tight to prevent vibrations from causing further issues.

Lubrication Practices

- Apply high-quality lubricant to moving parts to reduce friction.

- Use the manufacturer’s recommended lubrication schedule.

- Clean any old grease or debris before applying new lubricant.

Throttle Control and Cable Functions

The throttle control mechanism plays a crucial role in regulating the engine’s speed and power output. It enables the operator to adjust the performance of the equipment, providing the necessary force for various tasks. Understanding its functionality is essential for achieving optimal operation and efficiency.

Typically, the control lever is connected to a cable that transmits the operator’s input to the engine. This cable is designed to respond quickly and accurately, ensuring smooth acceleration and deceleration. Regular maintenance of the throttle cable is vital to prevent issues such as sticking or fraying, which can hinder performance and pose safety risks.