When it comes to maintaining outdoor tools, understanding the layout and interaction of various elements is key to ensuring long-lasting performance. This guide provides an in-depth look into the essential components that make up a reliable lawn care tool, offering insights into their functionality and how they work together efficiently.

Each part plays a crucial role in the overall operation, contributing to precision and durability. By familiarizing yourself with the different sections and their purposes, you can easily identify potential issues and perform necessary maintenance or replacements with confidence.

In the following sections, we will explore the arrangement of key elements, detailing how they contribute to the overall performance of your equipment, making upkeep more straightforward and effective.

Troy-Bilt Trimmer Essential Components Overview

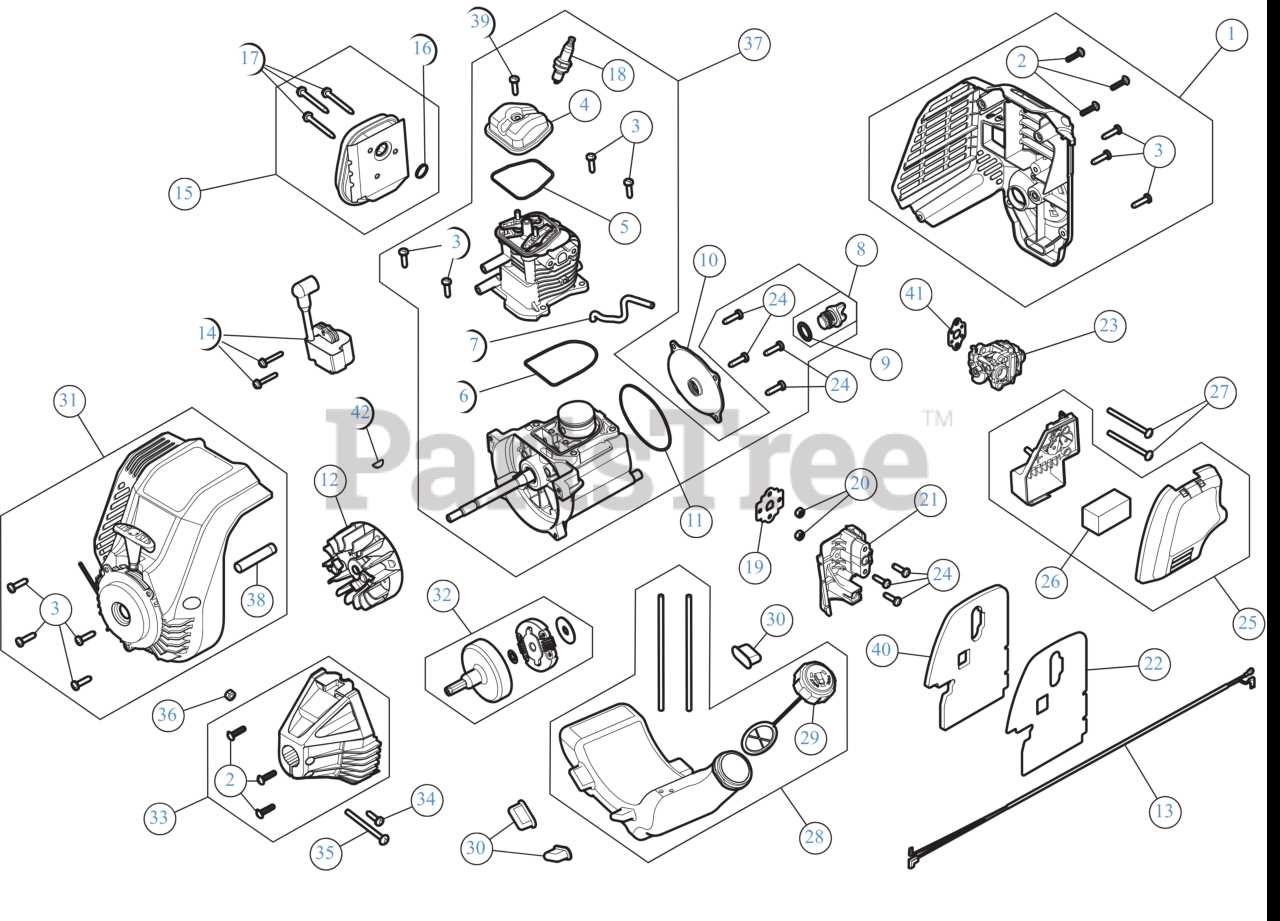

Understanding the key elements of a versatile outdoor tool is crucial for proper maintenance and efficient operation. Each component works together to ensure smooth functionality, enabling effective handling of various landscaping tasks. In this section, we will explore the main features that contribute to the performance and reliability of this device, highlighting the essential aspects of its structure.

Power Unit

The power unit forms the core of the device, responsible for delivering the necessary force to operate the tool. It typically houses the engine, which can vary in power and type. Ensuring that the power unit remains in good condition is essential for consistent operation and extended durability.

Cutting Mechanism

The cutting mechanism plays a pivotal role in how the tool performs its primary function. Whether using blades or other attachments, this component determines the precision and speed of cutting. Regular inspection and upkeep of the cutting mechanism are essential to maintain sharpness and efficiency over time.

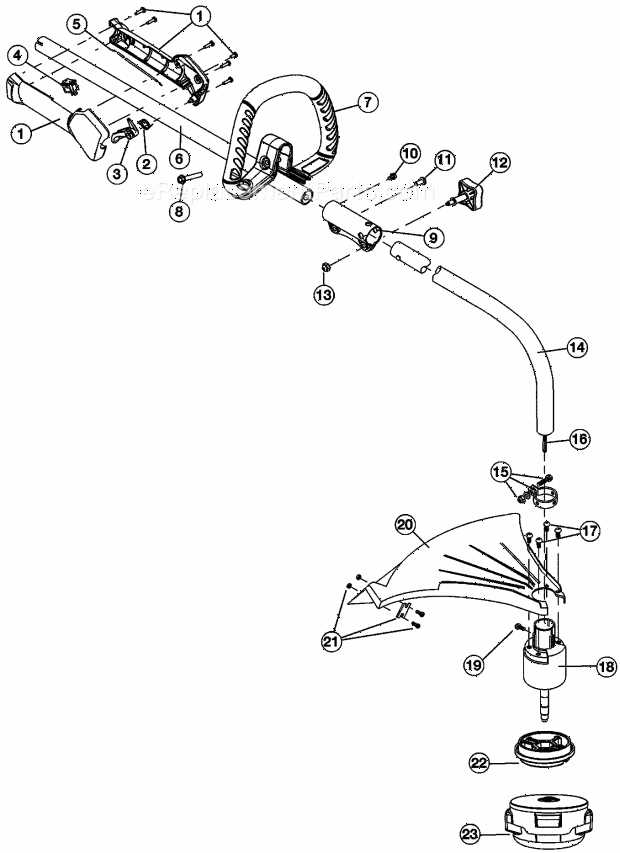

Exploring the Main Shaft Assembly

The main shaft assembly plays a crucial role in ensuring the efficient operation of outdoor power equipment. This component connects various moving parts, allowing the tool to function seamlessly during use. Understanding how the assembly works and its relationship to other components is key to maintaining optimal performance and longevity.

Key Components of the Main Shaft

The assembly consists of multiple elements that work together to deliver power from the engine to the cutting mechanism. Each part of this system needs to be properly aligned and secured to ensure smooth functionality. Any misalignment or wear can affect the overall performance, making regular inspection essential.

Maintenance and Care

Proper care of the main shaft assembly involves routine checks for wear and tear, lubrication of moving parts, and timely replacement of worn elements. Regular maintenance helps prevent operational issues, prolonging the lifespan of your equipment and ensuring its reliability during extended use.

How to Identify the Cutting Head Parts

Understanding the components of the cutting mechanism is essential for maintaining and repairing your tool. Each part plays a specific role in ensuring smooth operation and efficient performance. By familiarizing yourself with these elements, you can easily spot potential issues and address them promptly.

| Component | Description | ||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blade Housing | The outer casing that protects the internal components and provides a secure attachment for the cutting element. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Spool | This part holds the cutting line and feeds it out as needed, allowing the tool to cut effectively. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Cap | A cover that secures the spool in place, preventing it from becoming dislodged during use. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Spring | A small component that adds tension, enabling the cutting line to extend properly when the tool is in operation. | ||||||||||||||||||||||||||||||||||||||||||||||||

| Bolt |

| Component | Condition |

|---|---|

| Spool Holder | Ensure it is intact and free from cracks. |

| Spring | Check for signs of wear or deformation. |

| Retaining Clip | Confirm it holds the parts firmly in place. |

Once the new mechanism is in place, reassemble the parts, ensuring everything fits

Guide to Installing New Line Properly

Installing a new cutting line is essential for maintaining the efficiency and effectiveness of your outdoor equipment. A proper installation not only enhances performance but also prolongs the life of the machine. This guide will walk you through the steps to ensure that the line is fitted correctly, allowing for smooth operation.

Follow these instructions to achieve the best results:

| Step | Description |

|---|---|

| 1 | Power off your equipment and unplug it from any power source to ensure safety during the installation. |

| 2 | Remove the spool from the device by following the manufacturer’s guidelines to avoid damaging any components. |

| 3 | Cut a new length of cutting line according to the recommended specifications, ensuring it is the correct gauge and length. |

| 4 | Insert one end of the line into the spool’s designated slot and begin winding it around the spool in the direction indicated. |

| 5 | Once the spool is adequately filled, leave a few inches of line extending from the spool for easy installation. |

| 6 | Reattach the spool to the device, ensuring it is secured in place to prevent any operational issues. |

| 7 | Finally, check the line length and adjust as necessary before powering on the equipment to ensure optimal performance. |

By following these steps, you will ensure that the cutting line is installed correctly, leading to efficient cutting and extended equipment longevity.

Gearbox and Clutch Assembly Breakdown

The gearbox and clutch assembly is a crucial component in the operation of outdoor power equipment, ensuring the efficient transfer of power from the engine to the cutting mechanism. Understanding the function and layout of this assembly can significantly aid in maintenance and troubleshooting, enabling users to achieve optimal performance and longevity from their equipment.

Functionality of the Gearbox

The gearbox plays a vital role in adjusting the rotational speed and torque of the engine output. By modifying these parameters, it allows the cutting tool to operate effectively under varying conditions. A well-functioning gearbox ensures that the machinery runs smoothly, providing users with the desired cutting results.

Clutch Mechanism Overview

The clutch mechanism is designed to engage and disengage the power transfer between the engine and the cutting attachment. This functionality prevents unnecessary strain on the engine and allows for precise control during operation. Regular inspection and maintenance of the clutch assembly are essential for ensuring reliable performance and minimizing wear.

Maintaining Smooth Trimmer Operation

Ensuring efficient performance of your gardening tool requires regular attention and care. Proper maintenance not only enhances the device’s functionality but also prolongs its lifespan. By following a few essential practices, you can achieve optimal operation and prevent common issues.

Regular Cleaning

Keeping your equipment clean is crucial for smooth operation. After each use, remove debris, grass, and dirt from the exterior and any moving parts. This helps prevent clogs and ensures that components work together seamlessly. Utilize a brush or compressed air to access hard-to-reach areas.

Routine Inspections

Performing frequent checks on all elements of the tool is vital. Look for signs of wear, such as frayed wires or loose connections. Identifying and addressing these issues early can save you time and expense down the road. Additionally, ensure that all components are securely fastened to avoid malfunctions during operation.

Handle and Control Assembly Insights

The handle and control assembly plays a crucial role in the operation of gardening equipment. This component not only provides a comfortable grip for the user but also houses various controls that enable the operator to manage the functionality of the device effectively. Understanding the design and features of this assembly can enhance the overall user experience and ensure optimal performance.

Functionality and Design

The design of the handle and control assembly is tailored to facilitate ease of use while maintaining control during operation. Features such as adjustable grips and strategically placed controls allow for ergonomic handling. Additionally, the layout of switches and levers is crafted to minimize the need for excessive hand movement, enabling a smoother and more efficient workflow.

Maintenance Considerations

Improving Ergonomics for Better Control

Enhancing the ergonomic design of gardening tools is essential for improving user comfort and operational efficiency. By focusing on user-friendly features, manufacturers can significantly reduce fatigue and increase control during prolonged use. This section explores key factors that contribute to better handling and maneuverability of outdoor equipment.

| Feature | Description | Benefits |

|---|---|---|

| Adjustable Handles | Handles that can be modified to suit different user heights and preferences. | Promotes a natural grip, reducing strain on arms and back. |

| Lightweight Design | Construction using lightweight materials to minimize overall weight. | Allows for extended use without excessive fatigue. |

| Vibration Dampening | Technology that absorbs vibrations during operation. | Decreases hand and arm fatigue, enhancing comfort during use. |

| Comfort Grip | Ergonomically designed grips that provide better tactile feedback. | Improves control and reduces slippage during operation. |

Fuel System and Carburetor Layout

The fuel system plays a crucial role in the operation of outdoor power equipment, ensuring that the engine receives the right mixture of fuel and air for optimal performance. Understanding the arrangement of components within this system, particularly the carburetor, is essential for maintenance and troubleshooting.

Components of the Fuel System

The fuel system typically consists of several key components, including the fuel tank, fuel lines, fuel filter, and the carburetor itself. Each part works together to deliver fuel efficiently to the engine, contributing to its overall functionality.

Carburetor Functionality

The carburetor is responsible for mixing the fuel with air before it enters the engine. Proper adjustment and maintenance of the carburetor can enhance performance and fuel efficiency. Regular checks for clogs or leaks can prevent common issues that may arise during operation.

| Component | Function |

|---|---|

| Fuel Tank | Stores fuel for the engine |

| Fuel Lines | Transport fuel from the tank to the carburetor |

| Fuel Filter | Removes impurities from the fuel |

| Carburetor | Mixes fuel with air for combustion |

Steps for Ensuring Efficient Fuel Use

Maximizing fuel efficiency is essential for maintaining optimal performance and reducing costs. By implementing a few key practices, users can ensure that their equipment operates effectively while consuming less fuel.

First, always use the recommended fuel type, as specified by the manufacturer. This ensures that the engine runs smoothly and reduces the likelihood of damage. Additionally, regularly check the fuel mixture ratio to maintain proper combustion. An incorrect mixture can lead to inefficient fuel use and increased emissions.

Moreover, keep the air filter clean to promote adequate airflow. A clogged filter restricts air intake, leading to poor combustion and higher fuel consumption. Regular maintenance of the spark plug is also crucial, as a worn or dirty plug can hinder ignition efficiency.

Finally, avoid overloading the equipment, as excessive weight can strain the engine and lead to higher fuel consumption. By following these steps, users can optimize fuel use, enhance performance, and contribute to a more environmentally friendly operation.

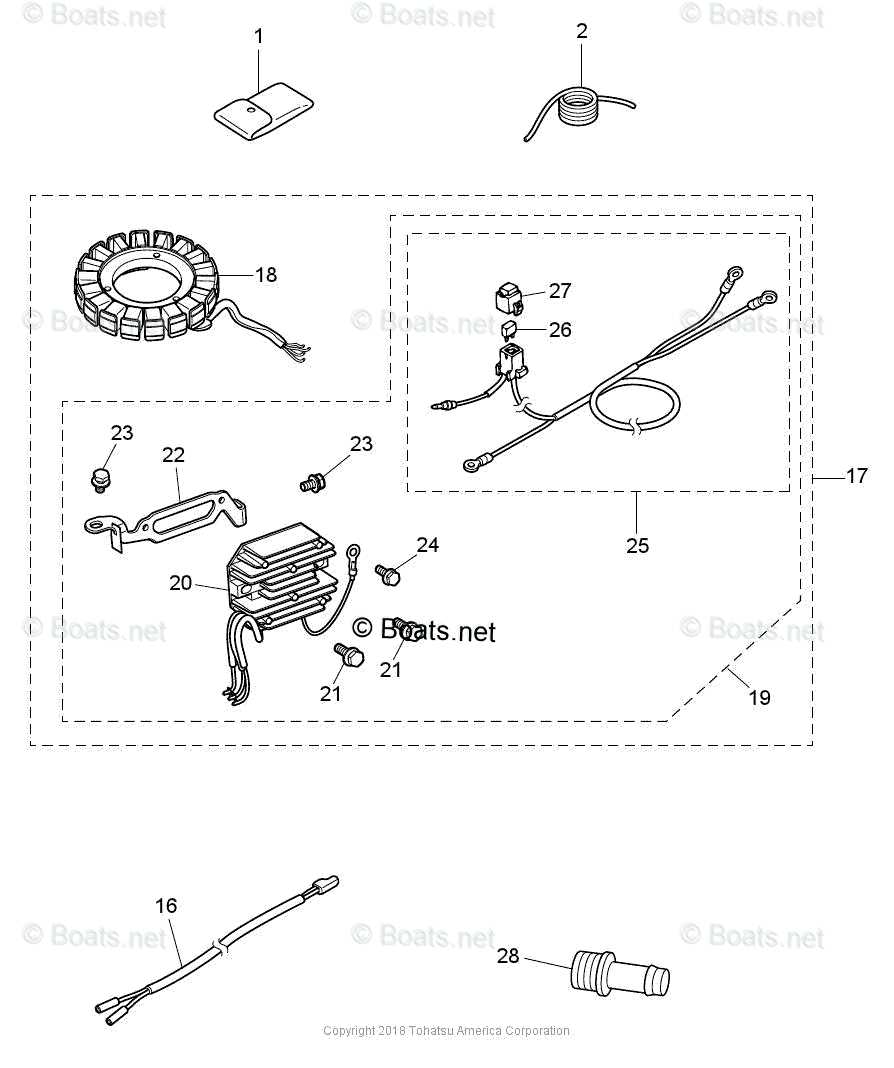

Ignition System Components Explained

The ignition system plays a crucial role in the operation of small engines, ensuring that the combustion process occurs efficiently. Understanding the various elements of this system is essential for maintenance and troubleshooting, as they work together to produce the necessary spark for ignition. Each component contributes to the overall functionality, affecting the engine’s performance and reliability.

Key Components of the Ignition System

At the heart of the ignition assembly is the spark plug, which ignites the air-fuel mixture within the combustion chamber. It produces a high-voltage spark that initiates the combustion process. Surrounding the spark plug are several critical components, including the coil, which generates the electrical energy needed for the spark, and the flywheel, which not only aids in creating the necessary magnetic field but also helps to maintain the engine’s momentum.

Functionality and Importance

Another vital part of the ignition mechanism is the ignition switch, which controls the flow of electricity to the coil and spark plug. A malfunction in this switch can prevent the engine from starting. Additionally, the starter system engages the engine’s flywheel, allowing it to reach the necessary speed for ignition. Understanding these components and their functions is essential for diagnosing issues and ensuring optimal performance of the engine.