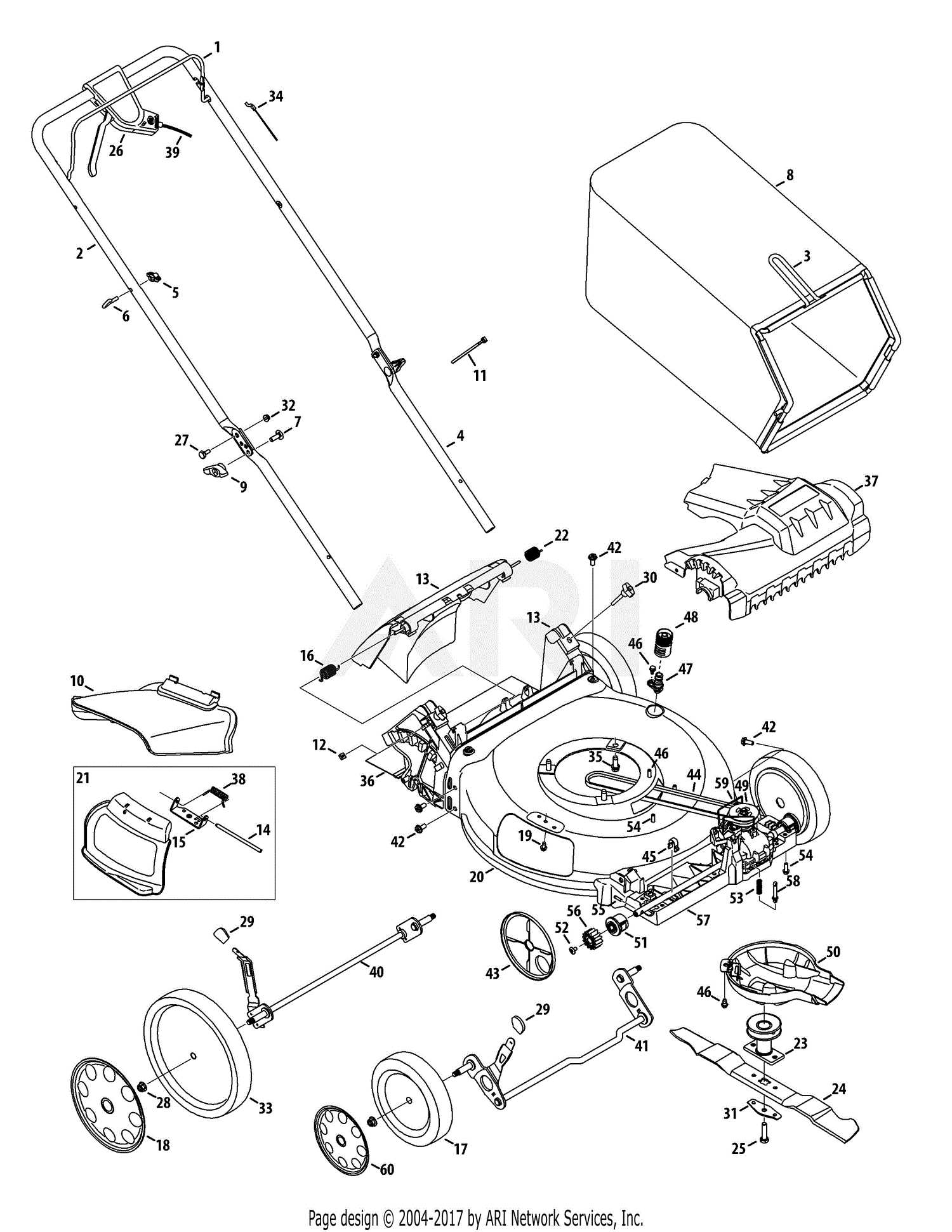

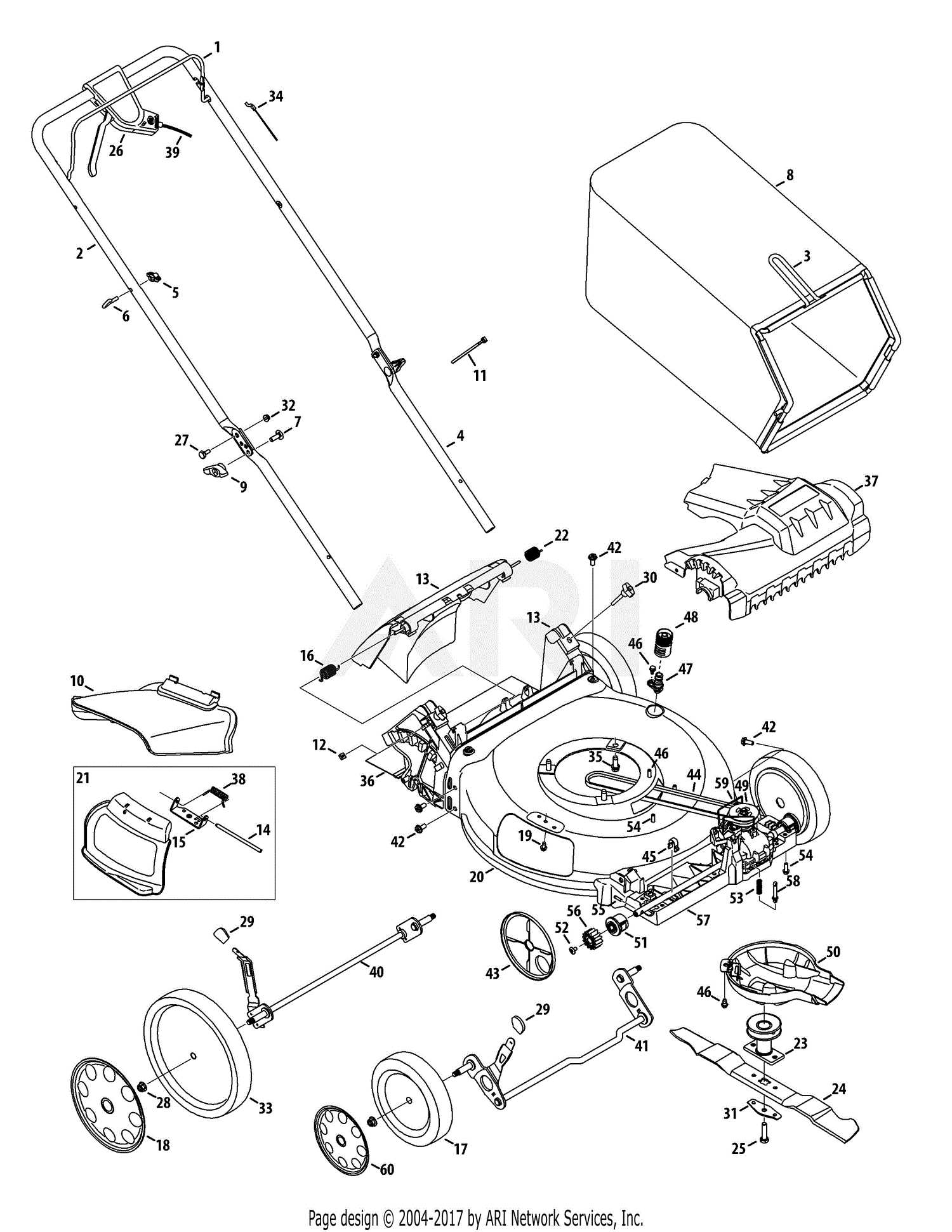

Handle – Provides control and balance, allowing for precise maneuvering

How to Maintain Your Trimmer Blades

Proper upkeep of your cutting tools is essential to ensure they remain efficient and safe for use. Regular care not only prolongs the life of the equipment but also enhances its performance, making yard work smoother and more precise.

Cleaning After Every Use

After each session, it’s important to clean the blades thoroughly. Dirt, grass, and debris tend to accumulate, which can dull the edges. Use a soft brush to remove particles and a damp cloth to wipe the surfaces. Ensuring the blades are dry before storage prevents rust formation.

Sharpening the Edges

Maintaining sharp edges is crucial for optimal cutting performance. Dull tools can damage plants and require more effort to operate. Use a sharpening tool specifically designed for cutting blades, following the manufacturer’s guidelines. Always wear protective gloves and handle the blades carefully during this process.

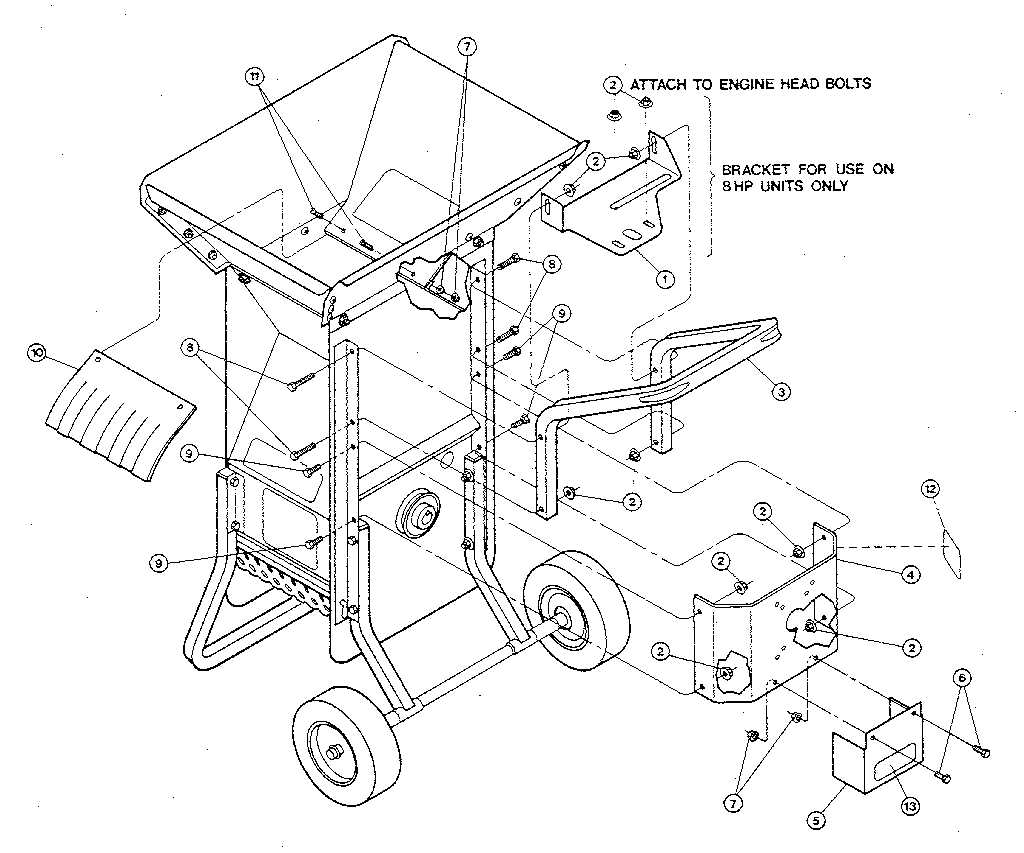

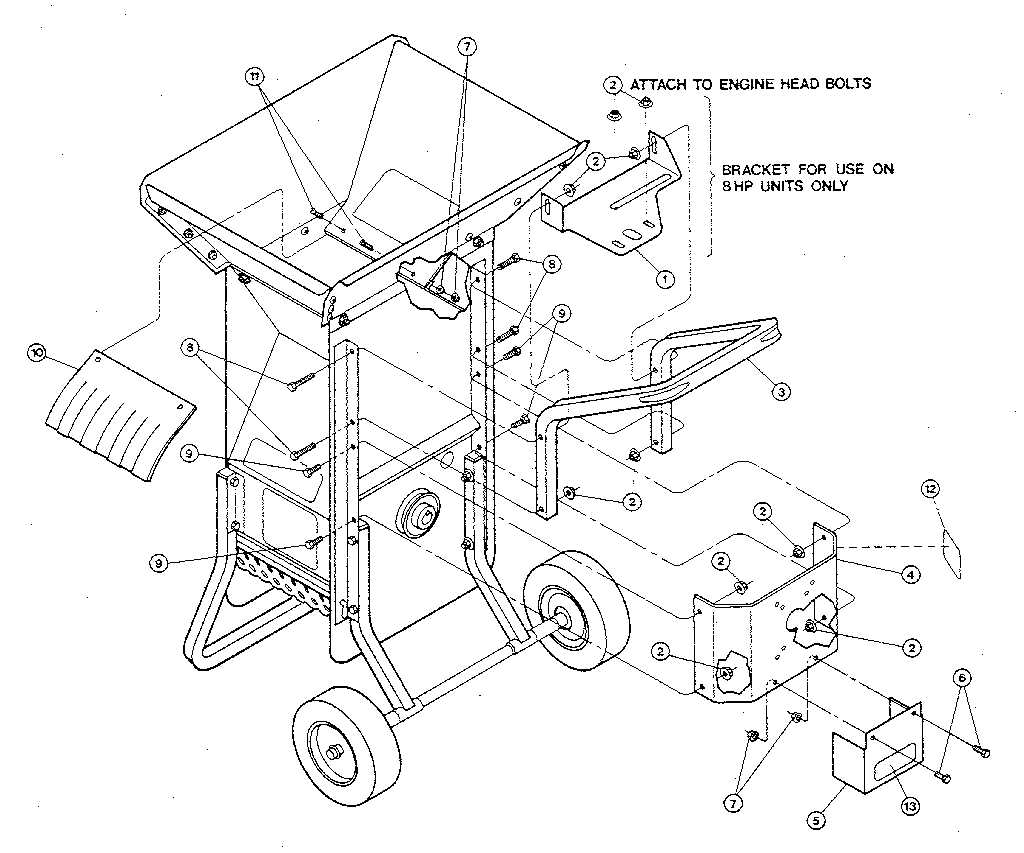

Replacing a Shaft on a Garden Tool

Over time, the shaft of your landscaping equipment may wear down, requiring replacement to ensure smooth and efficient operation. The process involves a few steps that will help restore the functionality of the tool without the need for purchasing a completely new machine.

Step-by-Step Instructions:

Begin by turning off the machine and ensuring it is completely cool before you proceed with any repairs. Locate the fasteners securing the existing shaft and use the appropriate tool to remove them carefully. Keep the screws and any small components in a safe place to avoid misplacement.

Next, gently slide the worn-out shaft out of its position, taking care not to damage surrounding parts. Before installing the new one, inspect the area for any signs of damage or debris that may need attention. Once everything is clear, align the replacement shaft with the existing mount and carefully reattach it, securing it with the

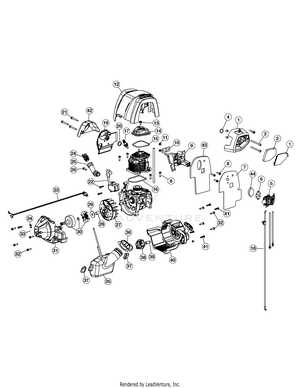

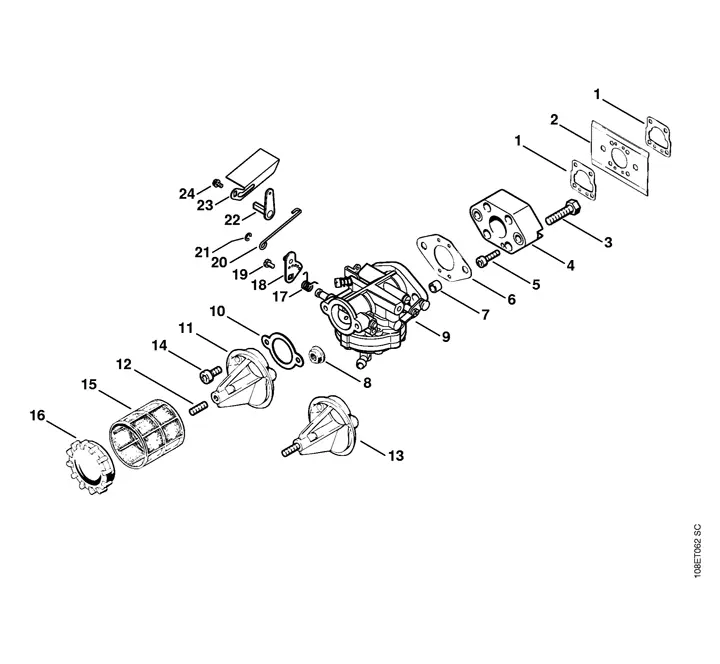

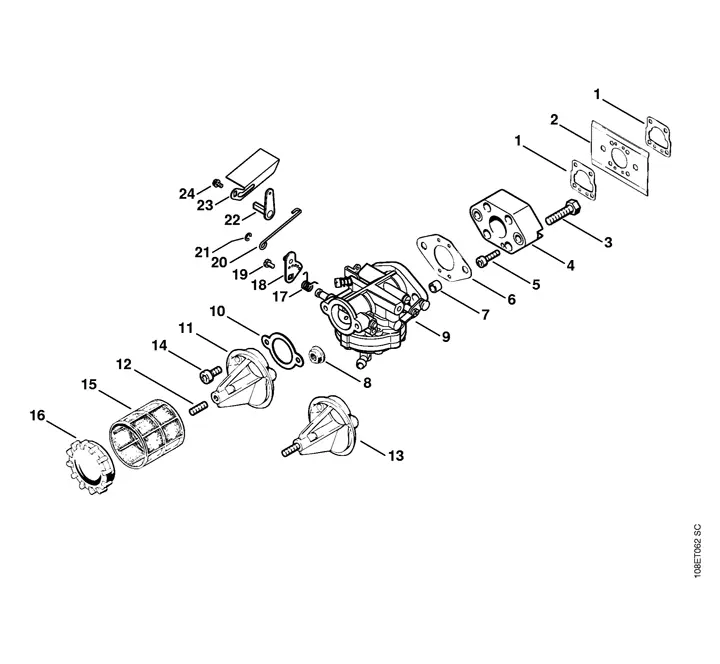

Understanding the Function of the Carburetor

The carburetor plays a crucial role in the operation of small engines by mixing air and fuel in the correct proportions. This process is essential for efficient combustion, ensuring that the engine runs smoothly and effectively. A well-functioning carburetor contributes to optimal performance and fuel efficiency.

Key Components of the Carburetor

Within the carburetor, several key components work together to regulate the flow of fuel and air. These include the float chamber, which maintains a steady supply of fuel, and the jet, which controls the fuel flow. The throttle plate also plays a significant role by adjusting the airflow, affecting engine speed and power.

Impact on Engine Performance

Proper adjustment and maintenance of the carburetor are vital for maintaining engine performance. If the mixture of air and fuel is too rich or too lean, it can lead to issues such as poor acceleration, increased emissions, and reduced efficiency. Regular checks and cleaning can help ensure that the carburetor functions optimally, contributing to the overall health of the engine.

Common Issues with Trimmer Parts

When using landscaping equipment, various challenges can arise due to worn or malfunctioning components. Identifying these issues promptly is essential to maintaining optimal performance and extending the lifespan of the equipment. Understanding the common problems that can occur with different elements of the machinery can help users troubleshoot effectively.

Wear and Tear of Components

Over time, frequent use can lead to deterioration of critical elements, resulting in decreased efficiency. Friction and exposure to the elements can cause components to degrade, leading to potential malfunctions. Regular inspections and timely replacements can mitigate these issues.

Improper Assembly and Alignment

Another frequent issue is related to the assembly and alignment of various parts. Misalignment can result in uneven operation and increased strain on the machinery. Ensuring that all components are correctly assembled and aligned can prevent these complications, promoting smoother functionality.

Choosing the Right Replacement Components

Selecting appropriate components for outdoor equipment maintenance is crucial for ensuring optimal performance and longevity. Understanding the different options available helps users make informed decisions that enhance functionality and reliability.

Identifying Compatibility

Before acquiring new components, it is essential to verify their compatibility with the existing equipment. Consider the following:

- Consult the user manual for specifications.

- Check manufacturer recommendations for suitable replacements.

- Ensure that dimensions match the original components.

Quality Over Price

While cost is a factor, prioritizing quality can lead to better performance and durability. Here are some tips:

- Choose reputable brands known for reliability.

- Look for materials that withstand wear and tear.

- Read customer reviews to gauge satisfaction levels.

Fuel System Components in Detail

The fuel system is essential for the efficient operation of small engines, ensuring that the correct mixture of fuel and air reaches the combustion chamber. Understanding the various elements involved in this system can enhance performance and maintenance. Each component plays a crucial role in delivering fuel effectively, contributing to the overall functionality and longevity of the engine.

Key Elements of the Fuel System

At the heart of the fuel system is the fuel tank, where the liquid is stored before being transported to the engine. Fuel lines connect the tank to the carburetor, allowing for a continuous flow of fuel. Additionally, the fuel filter plays a vital role in preventing impurities from entering the engine, safeguarding it from potential damage.

Importance of Proper Maintenance

Regular inspection and maintenance of the fuel system components are critical for optimal performance. Clogged filters or damaged fuel lines can lead to inefficient operation or engine failure. By ensuring that these parts are in good condition, users can prolong the lifespan of their equipment and maintain peak efficiency during use.

How to Change the Trimmer Head

Changing the cutting head of your gardening tool is a straightforward process that enhances its performance and efficiency. Over time, the cutting head can wear down, leading to subpar results. Regularly replacing it ensures optimal functionality and prolongs the life of the equipment.

To begin, gather the necessary tools, including a socket wrench or screwdriver, depending on the model. Ensure the tool is powered off and disconnected from any power source to guarantee safety. Locate the fastening mechanism that holds the cutting head in place. This may involve unscrewing a cap or loosening a bolt.

Once the old head is detached, inspect the mounting area for any debris or damage. Clean the surface thoroughly to ensure a secure fit for the new attachment. Follow the manufacturer’s instructions for installing the new head, aligning it properly before tightening the screws or bolts to secure it firmly in place.

After installation, perform a quick check to ensure everything is tightened correctly and in place. Reconnect the power source and conduct a brief test run to verify that the new head operates smoothly. Regular maintenance, including head replacement, contributes significantly to the longevity and efficiency of your gardening tool.

Importance of Air Filters in Trimmers

Air filtration systems play a crucial role in maintaining the efficiency and longevity of outdoor equipment. These components prevent contaminants from entering the engine, ensuring optimal performance and reducing the likelihood of damage. Understanding their significance can enhance the user experience and prolong the lifespan of the equipment.

Here are several reasons why air filtration is vital:

- Prevention of Contaminant Ingress: Filters act as barriers, trapping dust, dirt, and debris before they can reach sensitive engine parts.

- Enhanced Performance: Clean air supply ensures optimal combustion, leading to better power output and efficiency.

- Extended Equipment Lifespan: By preventing wear and tear on internal components, effective filtration can significantly prolong the life of the machinery.

- Cost-Effectiveness: Regular maintenance of air filters can reduce the need for costly repairs or replacements down the line.

Regular inspection and replacement of these essential components are necessary for keeping outdoor machinery in prime condition. Proper upkeep not only enhances performance but also contributes to a cleaner and healthier working environment.

Maintaining the Ignition System Properly

Ensuring the reliability of the ignition mechanism is crucial for optimal performance. Regular upkeep not only enhances functionality but also extends the lifespan of the equipment. Understanding how to care for this component can prevent issues that may hinder operation.

Regular Inspection and Cleaning

Routine examination of the ignition system is essential. Look for any signs of wear or damage, particularly around the connections. Cleaning any buildup from components helps maintain efficient operation. Use a soft brush or cloth to remove debris without causing harm to sensitive parts.

Replacing Worn Components

As with any mechanical system, certain elements may wear out over time. It is important to replace items such as spark plugs and ignition coils as needed. Using high-quality replacements ensures consistent performance and reduces the risk of breakdowns during use.

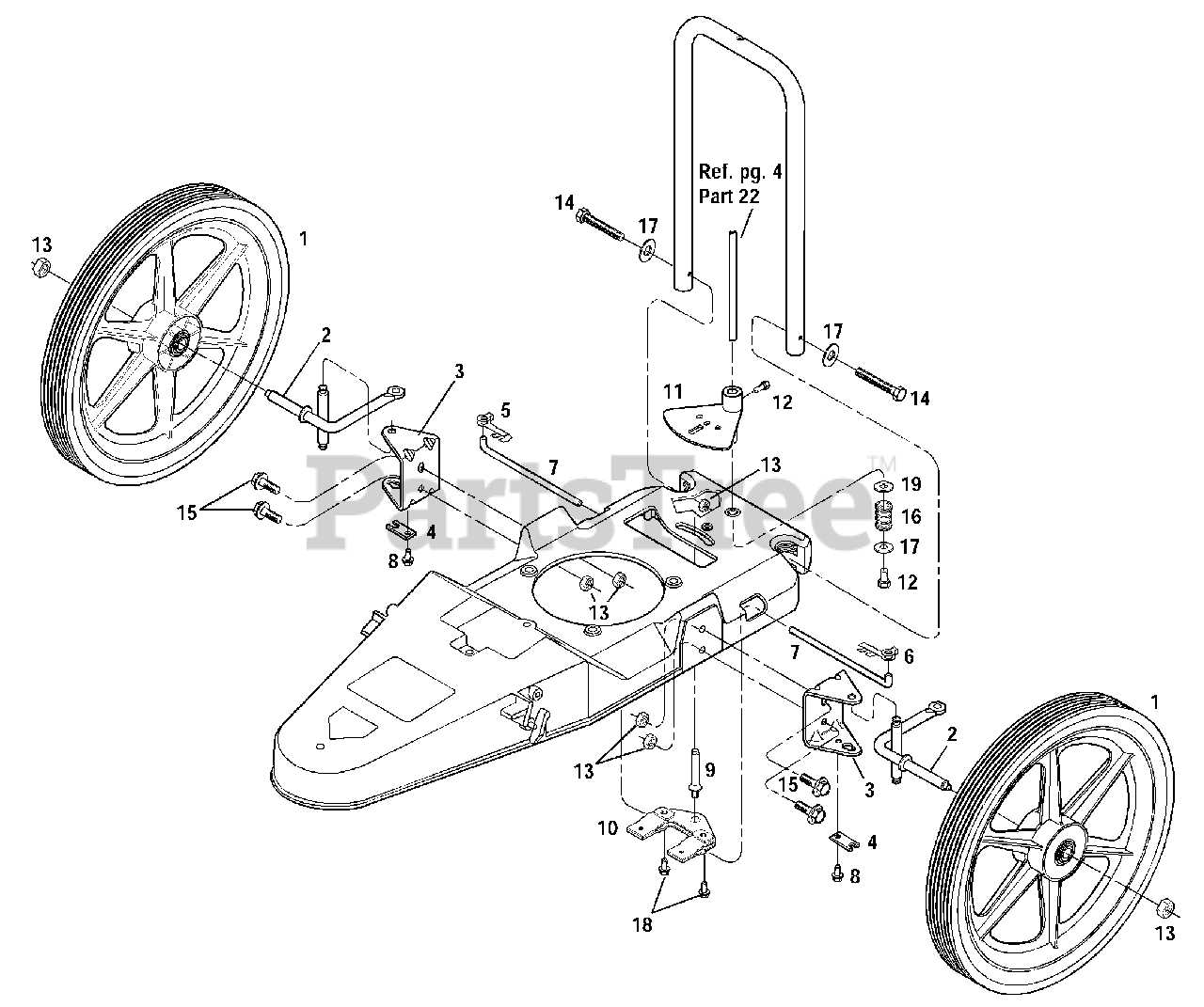

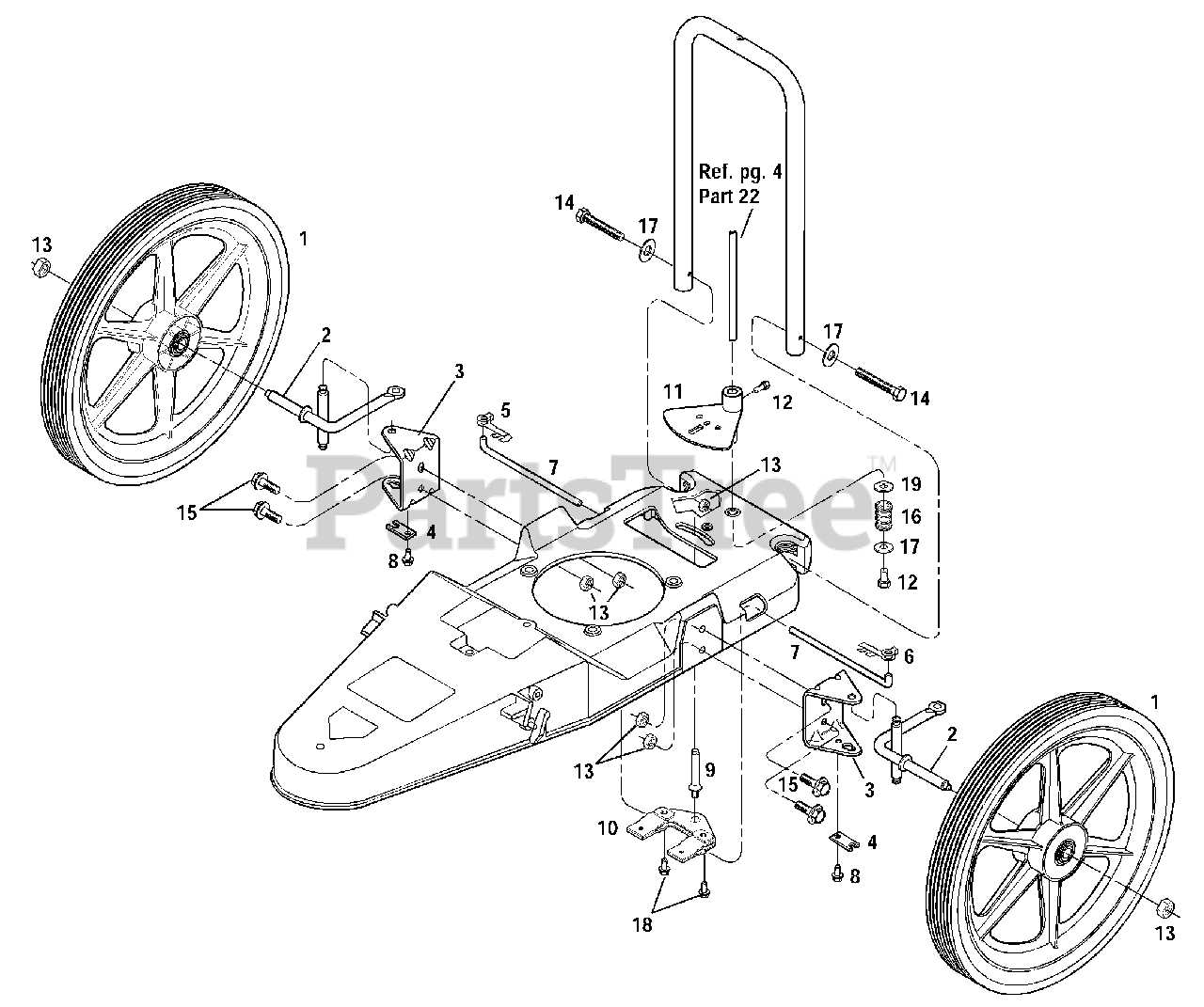

Guidelines for Belt and Pulley Replacement

Replacing the drive components is essential for maintaining optimal performance and efficiency in your equipment. Following proper procedures ensures that the replacement process is effective and minimizes potential issues during operation. Here are key guidelines to follow for a successful replacement.

- Safety First: Before beginning, ensure that the device is turned off and disconnected from any power source. Wear appropriate personal protective equipment, such as gloves and goggles, to prevent injuries.

- Gather Necessary Tools: Collect all required tools, including wrenches, screwdrivers, and a replacement belt and pulley set. Having everything ready will streamline the process.

- Remove the Cover: Detach the cover or housing to access the drive components. Be cautious when handling screws or fasteners to avoid losing them.

- Inspect Components: Before proceeding, check the existing belt and pulley for wear and tear. Identify any additional parts that may need replacement to prevent future issues.

- Detach the Old Components: Carefully remove the worn belt and pulley. Take note of their positioning, as this will guide you when installing the new parts.

- Install New Components: Position the new pulley and belt in the same configuration as the previous ones. Ensure they are fitted securely and correctly aligned to avoid operational problems.

- Reassemble the Housing: Once the new components are in place, reattach the cover or housing, ensuring all screws and fasteners are tightened properly.

- Test the Equipment: After completing the installation, reconnect the power source and run a test to confirm that everything operates smoothly. Listen for any unusual noises that may indicate improper installation.

By following these guidelines, you can effectively replace the drive components and ensure your equipment continues to function efficiently.