In the realm of outdoor equipment, comprehending the intricacies of machinery is essential for effective maintenance and repair. A thorough grasp of the various elements that make up these devices empowers users to tackle issues efficiently, ensuring optimal performance and longevity.

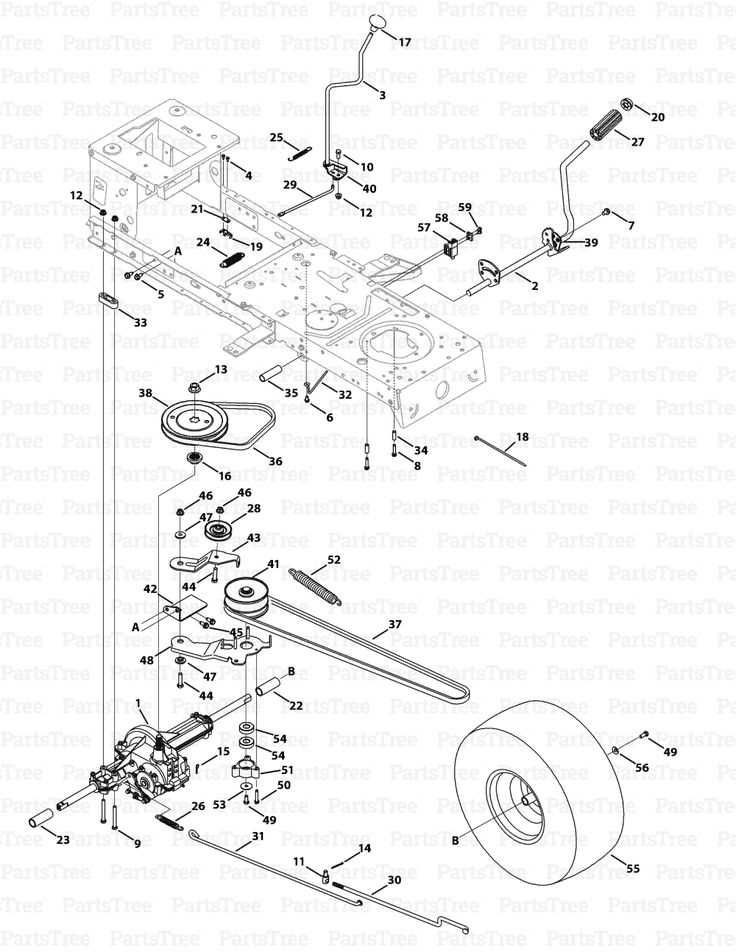

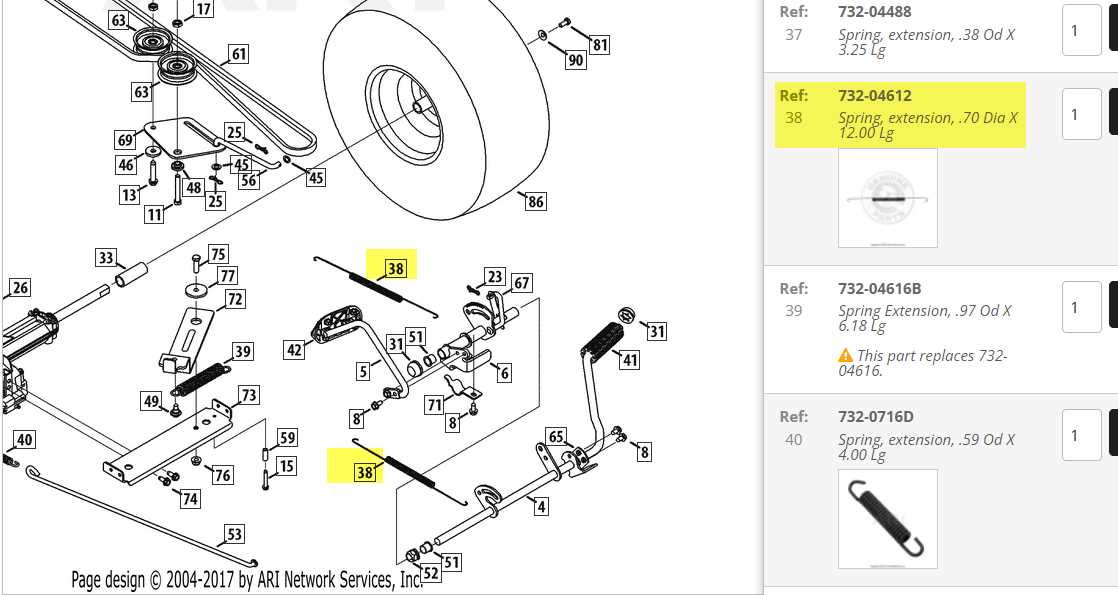

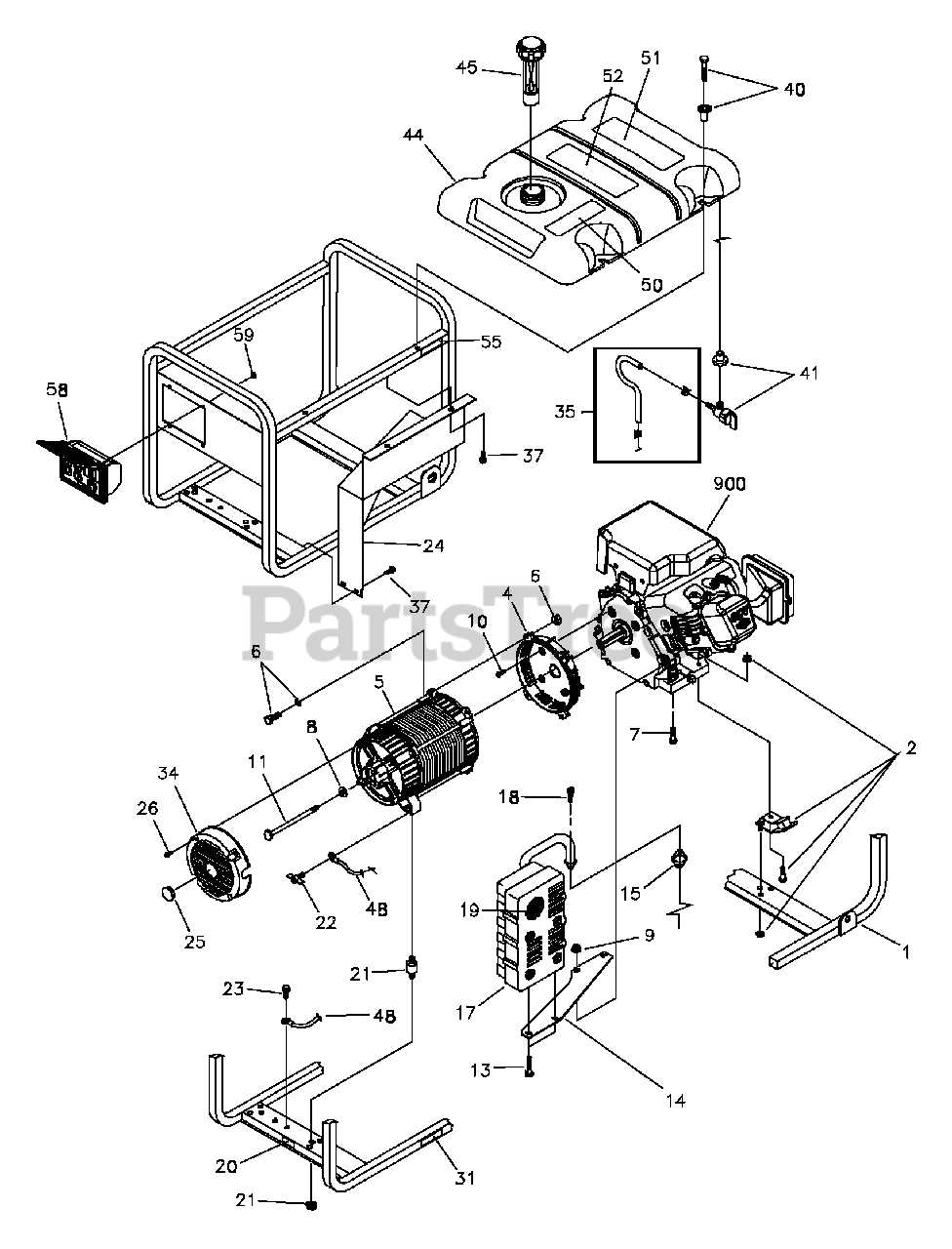

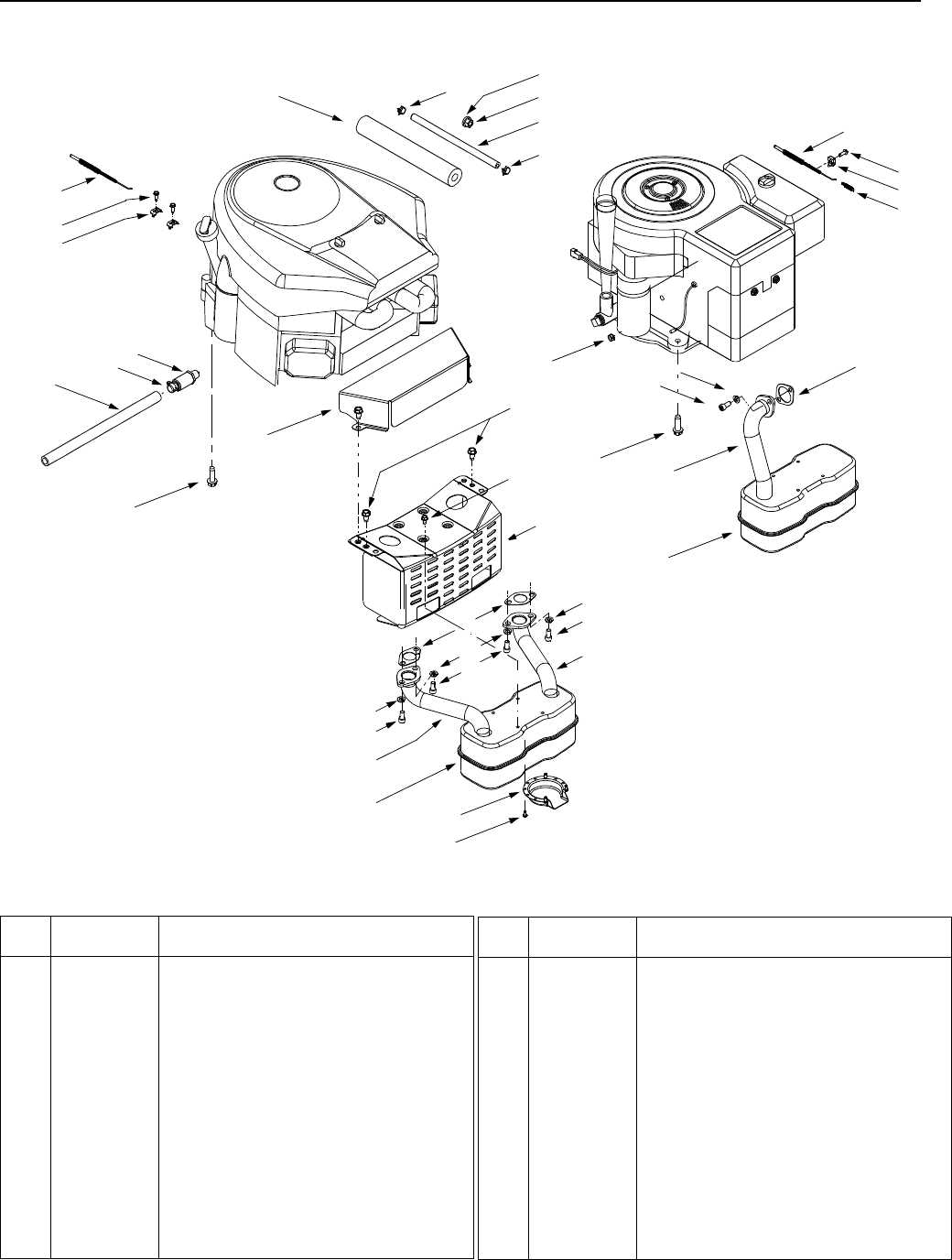

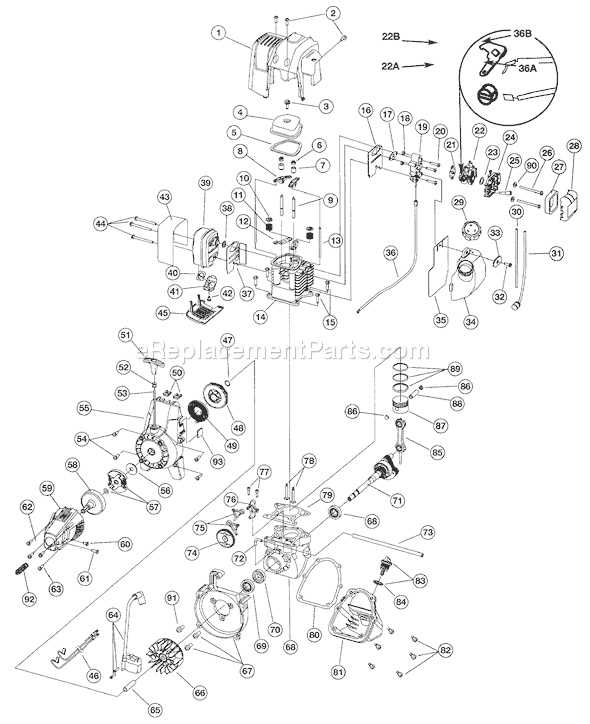

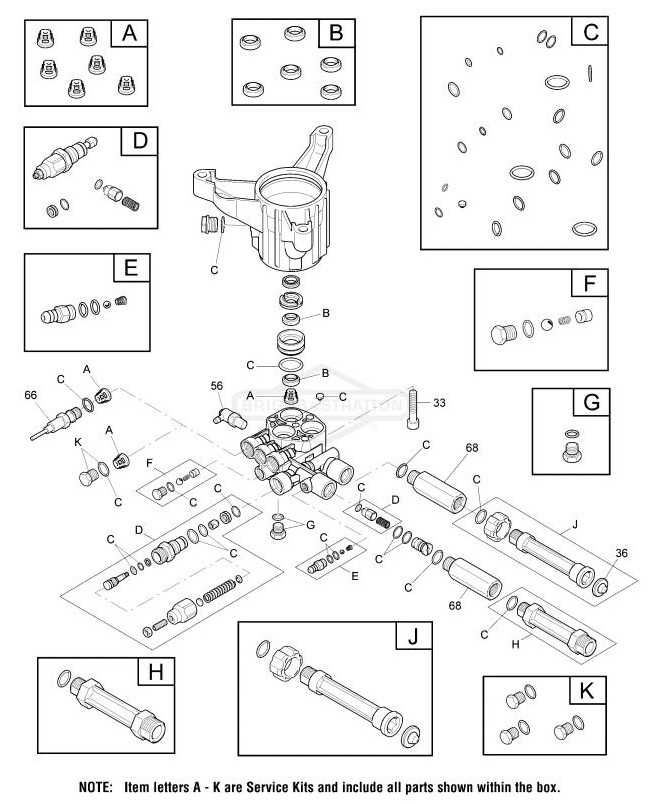

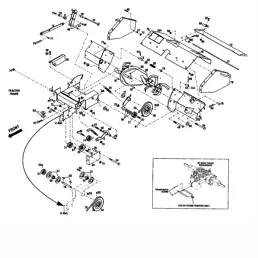

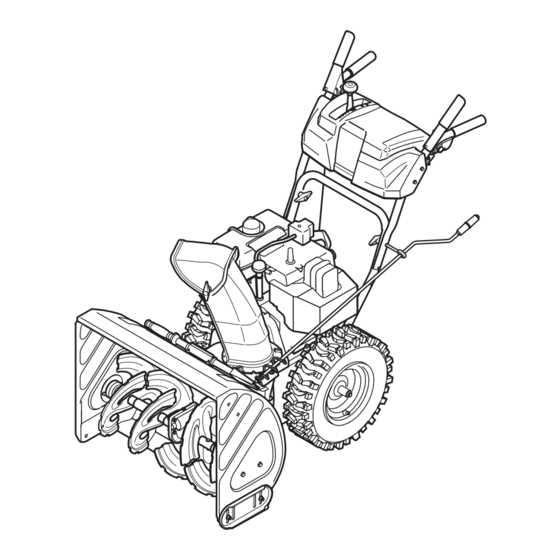

Visual representations of mechanical assemblies play a crucial role in this understanding. They provide insights into the arrangement and function of individual elements, facilitating easier identification of parts during service tasks. Such illustrations serve as invaluable references for both novice and experienced users alike.

By delving into these comprehensive guides, enthusiasts can enhance their knowledge, enabling them to perform repairs with confidence. Whether for personal use or professional application, having access to accurate and detailed references is ultimately key to successful upkeep and operation.

Troy Bilt Parts Overview

This section provides a comprehensive understanding of the various components that make up outdoor equipment, ensuring optimal performance and longevity. Recognizing the significance of each element allows users to maintain and repair their machinery effectively.

Key Components

- Engines

- Blades

- Frames

- Wheels

- Controls

Importance of Maintenance

- Enhances durability

- Improves efficiency

- Reduces downtime

- Ensures safety

Understanding these elements is crucial for anyone looking to delve deeper into the upkeep of their outdoor equipment, ultimately leading to better results in their gardening or landscaping tasks.

Understanding the Parts Diagram

Grasping the layout of components is crucial for effective maintenance and repair. Such representations serve as visual guides, simplifying the process of identifying individual elements and their relationships within a machine. Familiarity with these illustrations enhances troubleshooting and ensures efficient handling of repairs.

Key benefits of comprehending these visual aids include:

- Facilitating easier identification of specific components.

- Providing insight into the assembly and disassembly process.

- Enabling better understanding of how parts interact and function together.

To effectively utilize these resources, consider the following steps:

- Start by familiarizing yourself with the overall layout.

- Identify and note each component and its corresponding label.

- Refer to the accompanying manuals for detailed instructions related to each part.

By mastering these visual resources, users can significantly enhance their repair efficiency and reduce the likelihood of errors during maintenance tasks.

Importance of Accurate Diagrams

Precise visual representations are crucial for understanding complex systems and ensuring efficient maintenance and repair processes. They serve as essential guides, helping users identify components and comprehend their interrelationships. Without clarity in these illustrations, tasks can become time-consuming and error-prone.

Enhancing User Experience

Clear visuals significantly enhance the user experience by simplifying troubleshooting and assembly. When users can easily interpret the information presented, they are more likely to complete tasks accurately and swiftly, reducing frustration and increasing satisfaction.

Ensuring Safety and Efficiency

Accurate visuals not only streamline processes but also play a vital role in safety. Proper identification of components helps prevent mishaps and ensures that repairs are conducted correctly, ultimately leading to a more efficient operation.

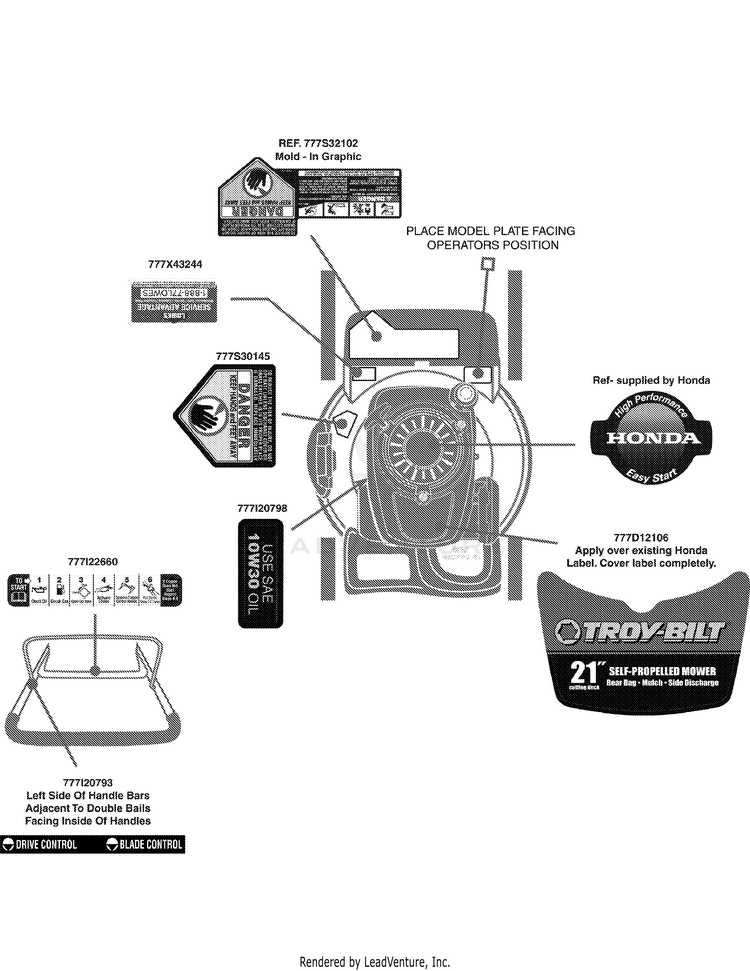

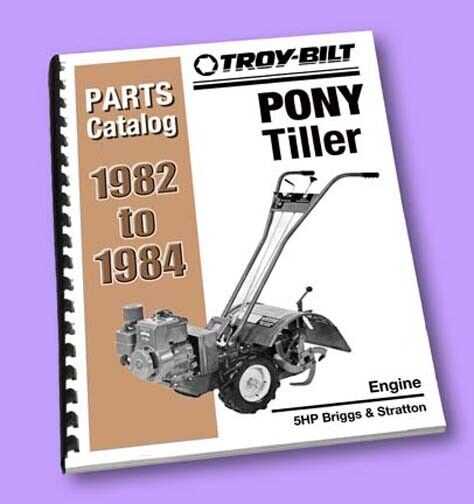

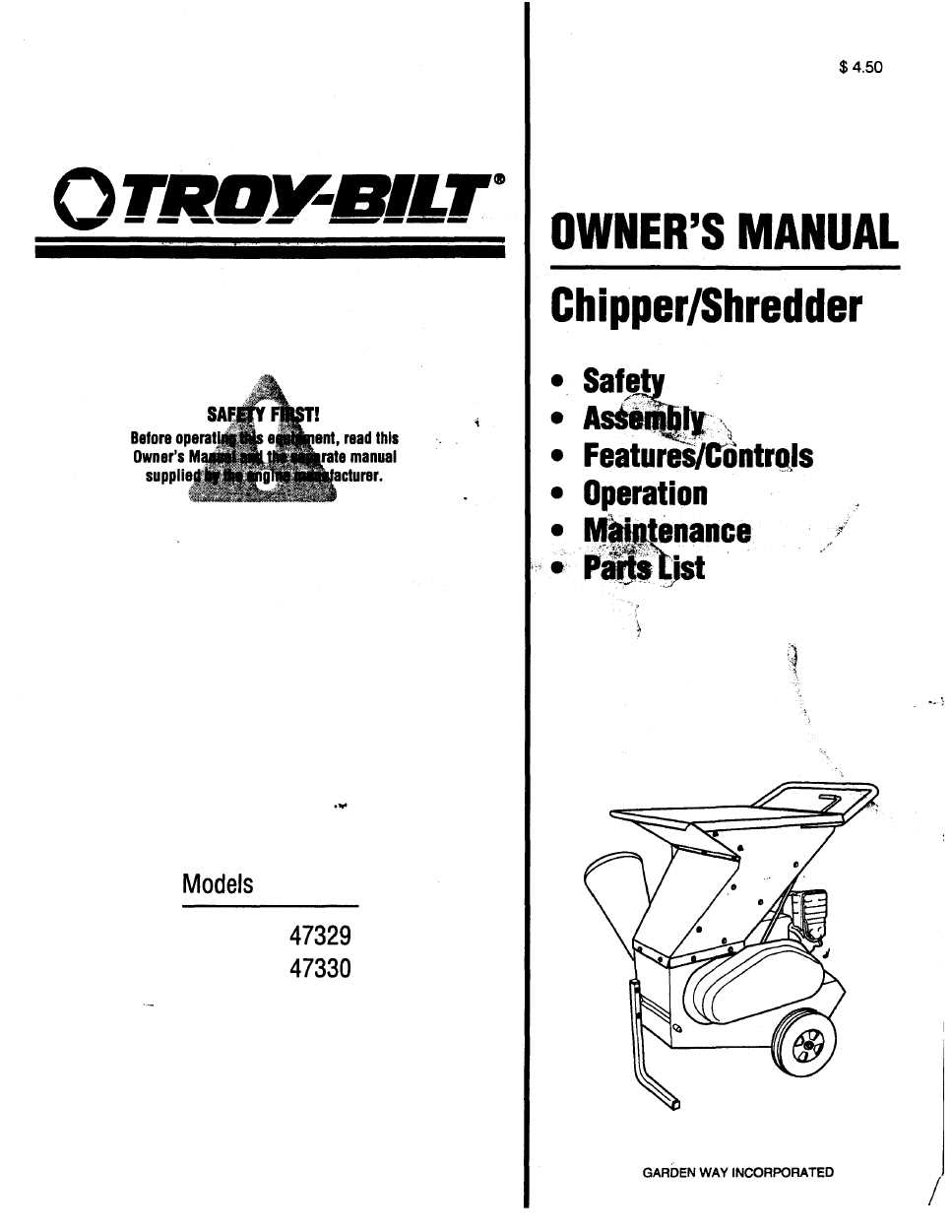

Common Troy Bilt Models Explained

This section delves into various popular lawn care and gardening equipment models known for their reliability and performance. Understanding these widely used machines can help users make informed decisions based on their specific needs, whether for residential or commercial applications.

Garden Tillers

Garden tillers are essential for preparing soil, allowing for efficient planting and cultivation. Models in this category often feature powerful engines and durable tines, designed to break up compacted earth with ease. Users can expect a range of sizes, from small, lightweight options for home gardens to larger, more robust machines for extensive landscaping tasks.

Walk-Behind Mowers

Walk-behind mowers are popular for maintaining lawns, offering a balance of maneuverability and cutting power. These machines typically come with adjustable cutting heights and various deck sizes, catering to different lawn sizes and types. Many models also feature mulching capabilities, allowing for eco-friendly grass disposal while enhancing soil health.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed overview of each element, allowing users to identify and locate necessary items easily. By becoming familiar with the symbols and layouts used in these visuals, one can streamline the repair process and ensure all required elements are accounted for.

Start with the Legend: Most visuals will include a legend or key that explains the symbols used throughout. Familiarizing yourself with this section is crucial, as it helps decipher what each symbol represents, whether it’s a specific part or a type of connection.

Identify Sections: Often, illustrations are divided into various sections, each corresponding to different assemblies. Paying attention to these divisions can assist in understanding how components fit together and their roles within the overall structure.

Follow the Numbering System: Components are frequently labeled with numbers or letters that correspond to a list. Cross-referencing these identifiers with the accompanying list ensures you have the right pieces for your project.

Look for Arrows and Lines: Arrows and lines often indicate relationships or connections between components. Observing these can provide insights into how parts interact, which is particularly useful when disassembling or reassembling equipment.

Take Notes: As you study the visual, jot down any notes about the components you may need or any observations regarding the assembly. This practice can save time and reduce confusion when working on the actual task.

Finding Your Model Number

Locating the identification number for your equipment is crucial for ensuring you access the correct information and resources. This unique identifier helps in pinpointing the specific version of your machine, facilitating easier navigation through manuals and support services.

Typically, the model number can be found in various locations on the device. Check areas such as the frame, beneath the seat, or near the engine. It may also be located on a sticker or a metal plate, often accompanied by other relevant information.

If you’re having difficulty locating this number, refer to the manufacturer’s website for guidance. Many companies provide detailed instructions and visual aids to assist you in the identification process.

Once you have the model number, you can delve deeper into finding manuals and other essential documentation that cater specifically to your device, ensuring you have the ultimate support for maintenance and repairs.

Where to Download PDFs

Finding reliable sources for downloadable documents can be crucial for maintenance and repair tasks. Various online platforms offer a wealth of information in digital format, allowing users to access necessary resources quickly and efficiently.

One of the best places to start is official manufacturer websites. These sites often provide a comprehensive library of materials that cater to specific models and products. Additionally, reputable online retailers may have downloadable resources available for their customers, ensuring access to the latest information.

Forums and community groups dedicated to particular equipment types can also be invaluable. Members frequently share links to documents, enhancing collective knowledge and support. Social media platforms and discussion boards can serve as additional channels for locating helpful files.

Lastly, specialized technical websites and libraries may house a variety of user manuals and guides. Searching through these resources can yield the necessary documentation to assist with any project effectively.

Benefits of Using OEM Parts

Choosing components from the original manufacturer brings a range of advantages that can significantly enhance the performance and longevity of your equipment. These items are specifically designed to meet the exact specifications and quality standards established by the original designer, ensuring a seamless fit and optimal functionality.

Reliability is one of the primary benefits of utilizing these authentic components. Since they are crafted to the same exacting standards as the original, you can trust that they will function as intended, reducing the likelihood of breakdowns and enhancing overall efficiency.

Additionally, warranty protection is often a crucial factor. Many manufacturers provide guarantees on their components, which can safeguard your investment and offer peace of mind. Using generic or off-brand items may void existing warranties, leaving you exposed to potential costs for repairs or replacements.

Moreover, performance consistency is another compelling reason to opt for original items. These components are engineered to work harmoniously with other parts of your machinery, delivering reliable results and maintaining the high performance for which the equipment was designed.

Lastly, investing in authentic components can lead to cost-effectiveness in the long run. While the initial price may be higher than alternatives, the durability and reliability of these components often result in fewer repairs and lower maintenance costs, ultimately saving you money over time.

Identifying Worn Components

Recognizing the signs of deterioration in machinery is crucial for maintaining optimal performance and longevity. Regular inspections can reveal components that may be struggling and require attention, ultimately preventing more significant issues down the line.

Common Indicators of Wear

Look for unusual sounds, vibrations, or performance issues as initial warning signs. A visual inspection can often uncover cracks, rust, or other physical damage that indicates a component is nearing the end of its life.

Evaluating Specific Parts

Pay special attention to areas like belts, blades, and bearings. Excessive wear on these elements can lead to inefficiency and may necessitate replacement. Understanding the typical lifespan of these components can help in planning maintenance and ensuring reliability.

Replacement Process for Key Parts

Replacing essential components of outdoor equipment is a crucial task for maintaining optimal performance and extending the lifespan of the machine. Understanding the process can significantly simplify repairs, ensuring that users can tackle maintenance confidently and effectively.

Preparation Steps

- Gather the necessary tools, including wrenches, screwdrivers, and pliers.

- Refer to the manual or guides to identify the specific components needing replacement.

- Ensure the machine is turned off and disconnected from any power source.

Replacement Procedure

- Carefully remove the old component, taking note of how it is installed.

- Inspect surrounding areas for wear or damage that may affect the new part’s performance.

- Install the new component, ensuring it is secured properly.

- Reconnect any power sources and test the machine to confirm functionality.

By following these steps, users can efficiently replace vital components and keep their equipment in top shape for years to come.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By implementing a consistent maintenance routine, you can significantly extend its lifespan and performance. Below are essential practices to consider for optimal upkeep.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil to maintain engine efficiency and prevent wear. |

| Air Filter Cleaning | Every 25 hours | Clear dirt and debris to ensure proper airflow and performance. |

| Spark Plug Inspection | Every season | Check for wear and replace if necessary to ensure smooth ignition. |

| Belts and Cables Check | Monthly | Inspect for fraying or damage and replace to avoid breakdowns. |

| Cleaning | After each use | Remove dirt and debris to prevent corrosion and maintain functionality. |

Resources for Additional Support

For those seeking further assistance, a variety of valuable resources are available to enhance your understanding and troubleshooting skills. Whether you’re looking for manuals, expert advice, or community forums, these tools can provide the ultimate guidance needed to ensure optimal functionality.

Online Forums: Engaging with fellow enthusiasts on dedicated platforms can yield practical insights and solutions. Members often share personal experiences that can help you navigate specific challenges.

Instructional Videos: Numerous channels offer step-by-step visual guides, making complex tasks more manageable. Watching these tutorials can help you delve deeper into repair techniques and maintenance practices.

Manufacturer Support: Many brands maintain official websites with extensive resources, including FAQs and troubleshooting tips. These sites are essential for obtaining accurate information directly from the source.

Local Repair Shops: Consulting with professionals in your area can provide hands-on assistance and expert advice. They can offer tailored solutions based on their experience with similar models.