Maintaining and repairing your gardening equipment can be a daunting task, especially when faced with a plethora of intricate components. Having a clear visual representation of the various elements that make up your machine is crucial for effective troubleshooting and restoration. A detailed overview not only simplifies the repair process but also enhances your understanding of how each piece functions within the whole system.

Whether you are a seasoned mechanic or a weekend warrior tackling minor repairs, familiarity with the essential components is key to ensuring the longevity and performance of your equipment. This guide aims to provide you with insights into the layout and functionality of the critical parts, facilitating easier maintenance and more informed decision-making during repairs.

In the following sections, we will delve into specific elements of the equipment, highlighting their roles and interactions. By breaking down these components, you will gain a better grasp of the overall mechanics, empowering you to tackle repairs with confidence and precision.

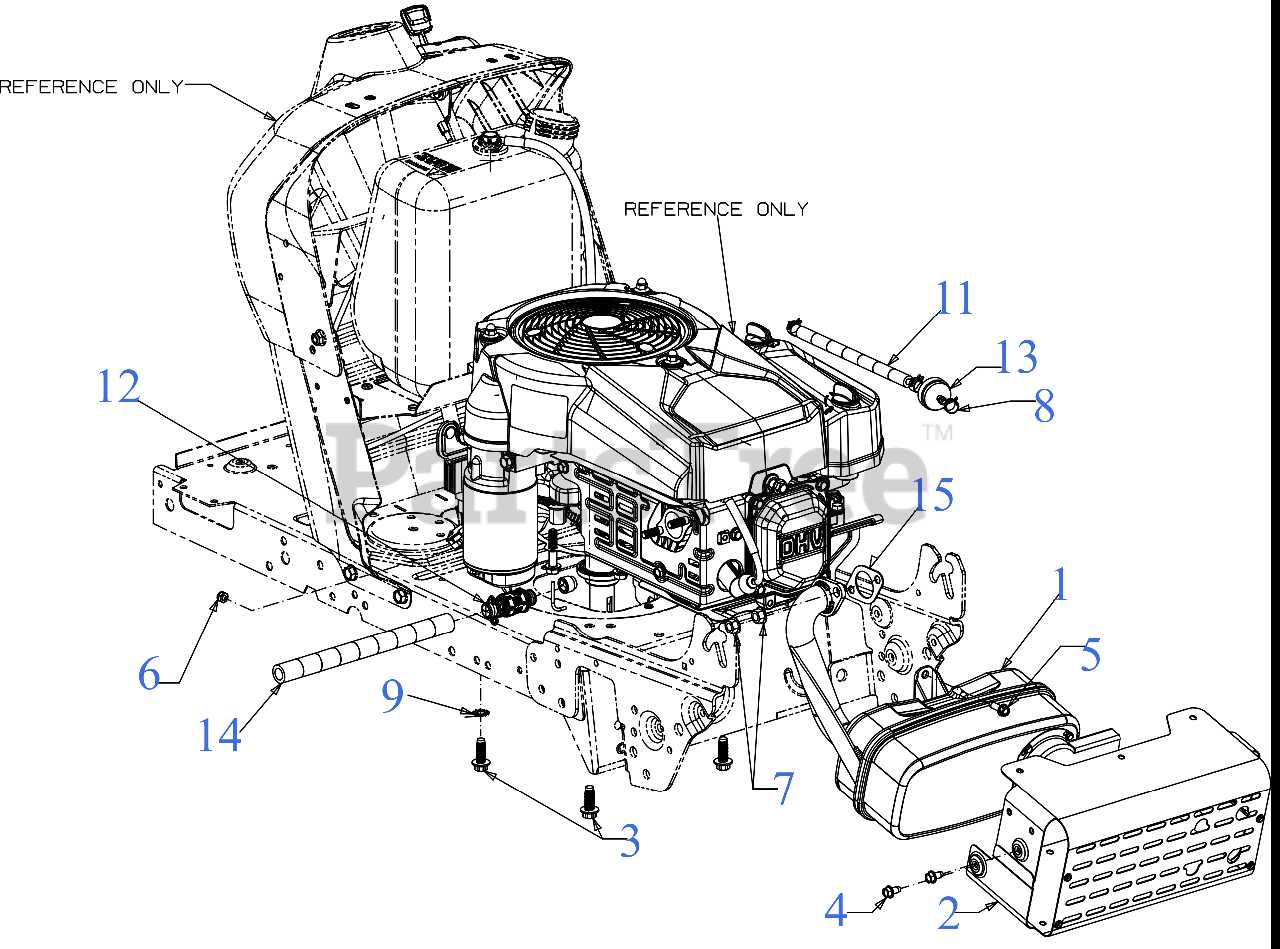

Troy Bilt Pony Overview

This section provides a comprehensive insight into a popular gardening and landscaping tool designed for efficiency and ease of use. With its robust construction and versatile capabilities, it caters to a variety of tasks, making it a valuable asset for both amateur gardeners and seasoned professionals.

The machine is engineered to tackle various outdoor jobs, from tilling soil to managing larger garden projects. Its user-friendly design ensures that even those with minimal experience can operate it effectively. Features such as adjustable settings and durable components contribute to its reliability and performance, allowing users to achieve desired results with minimal effort.

In addition to its functionality, this tool is also known for its maintenance accessibility. Understanding its components and how they work together is essential for optimal operation and longevity. Proper upkeep can significantly enhance its efficiency and lifespan, ensuring that it remains a trusted companion in any gardening endeavor.

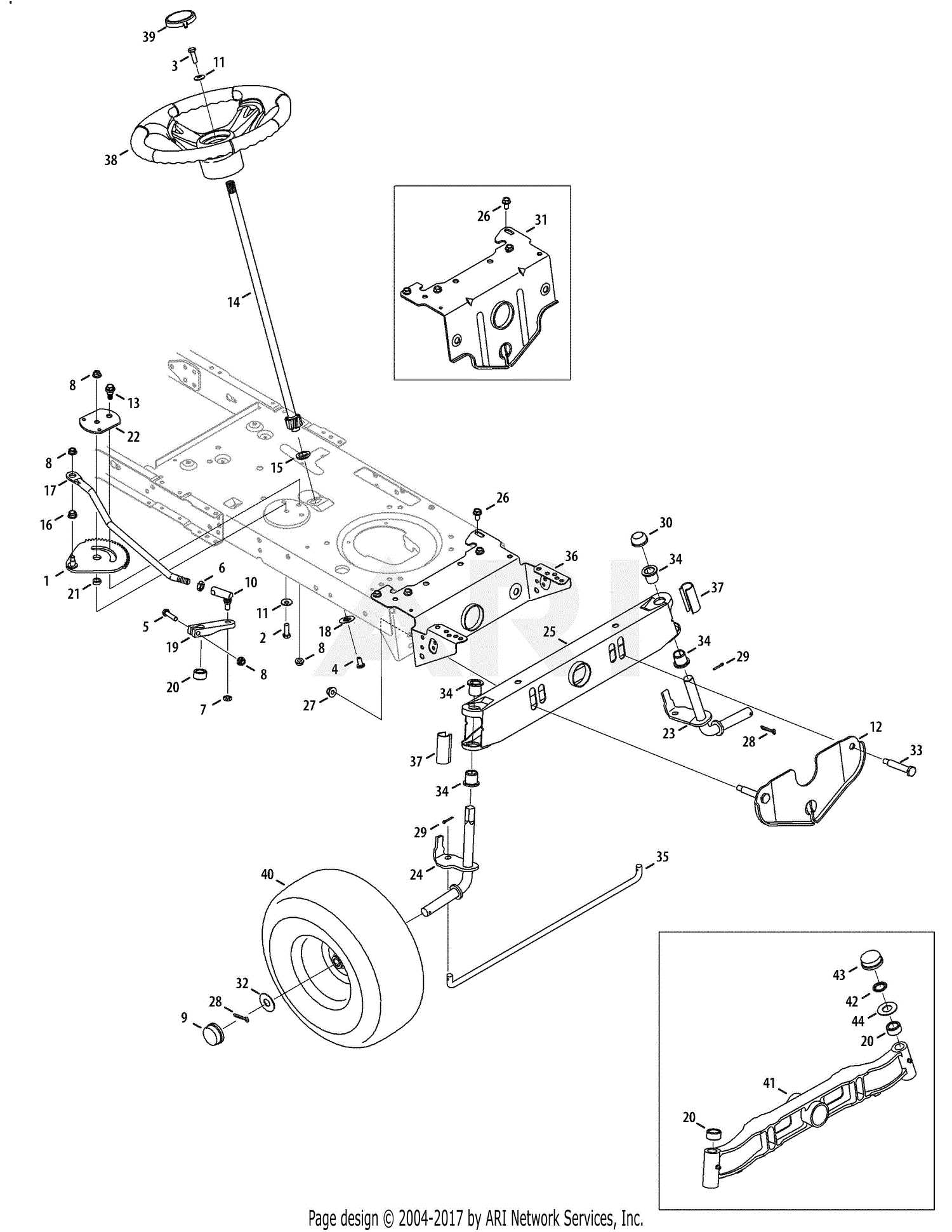

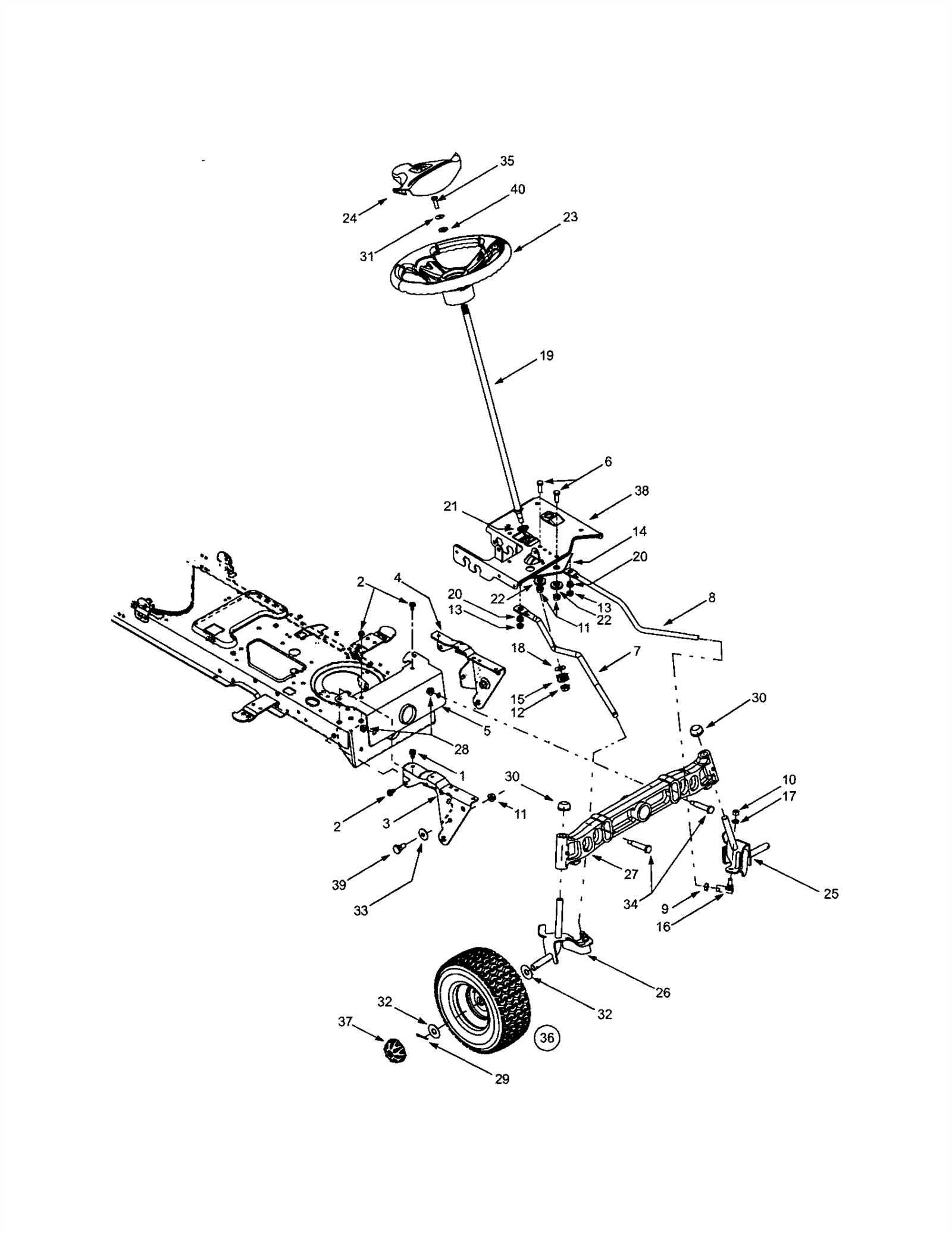

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations allow users to identify essential elements quickly, ensuring smoother operations and minimizing downtime. When issues arise, having a clear reference can significantly streamline the troubleshooting process.

Enhancing Repair Efficiency

Utilizing visual schematics facilitates rapid identification of faulty components, allowing for quicker replacements. This efficiency is vital in maintaining the longevity and performance of equipment, reducing the time spent on repairs.

Facilitating Proper Assembly

Clear illustrations guide users in the correct assembly of parts, ensuring that everything is fitted properly. This attention to detail helps avoid common errors, ultimately leading to better functionality and safety during operation.

Common Issues with Troy Bilt Pony

When operating a specific type of gardening equipment, users may encounter several frequent challenges that can affect performance and efficiency. Understanding these problems is essential for effective maintenance and troubleshooting.

Engine Troubles

One of the most prevalent issues involves the engine, which may exhibit starting difficulties or stalling during operation. Regular inspection of the spark plug, fuel lines, and air filter can help mitigate these problems.

Transmission Concerns

Transmission-related difficulties, such as slipping gears or difficulty shifting, are also common. Proper lubrication and timely adjustments can enhance functionality and prolong the lifespan of the equipment.

Essential Replacement Parts Explained

Understanding the critical components of outdoor equipment is vital for maintaining performance and longevity. Every machine has specific elements that may require replacement over time due to wear and tear. This section focuses on the essential components that ensure smooth operation and reliability, providing insights into their functions and the importance of timely replacements.

Commonly Replaced Components

Among the frequently changed items, belts and blades stand out. Belts facilitate movement and power transfer, while blades are crucial for cutting efficiency. Regular inspection of these components can prevent larger issues and enhance overall performance.

Signs of Wear and When to Replace

Recognizing the signs of wear is essential for effective maintenance. For instance, fraying belts or dull blades can significantly hinder performance. If you notice any unusual noises or a decrease in efficiency, it may be time to consider replacements. Prompt attention to these signs can save time and costs in the long run.

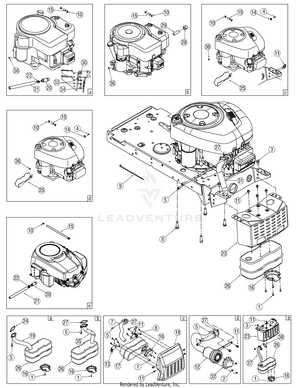

Understanding the Engine Components

Grasping the intricacies of engine elements is essential for effective maintenance and repair. Each part plays a vital role in the overall functionality, contributing to performance and reliability. Familiarity with these components can enhance your ability to troubleshoot and optimize engine operation.

Key Elements of an Engine

The primary components include the cylinder, piston, and crankshaft. The cylinder houses the piston, which moves up and down, converting fuel energy into mechanical motion. The crankshaft then transforms this linear movement into rotational energy, powering the machine.

Supporting Systems

Additionally, understanding the fuel delivery and ignition systems is crucial. The fuel system ensures proper fuel mixture for combustion, while the ignition system ignites this mixture at the optimal moment. Mastery of these interconnected systems is key to achieving the ultimate efficiency in engine performance.

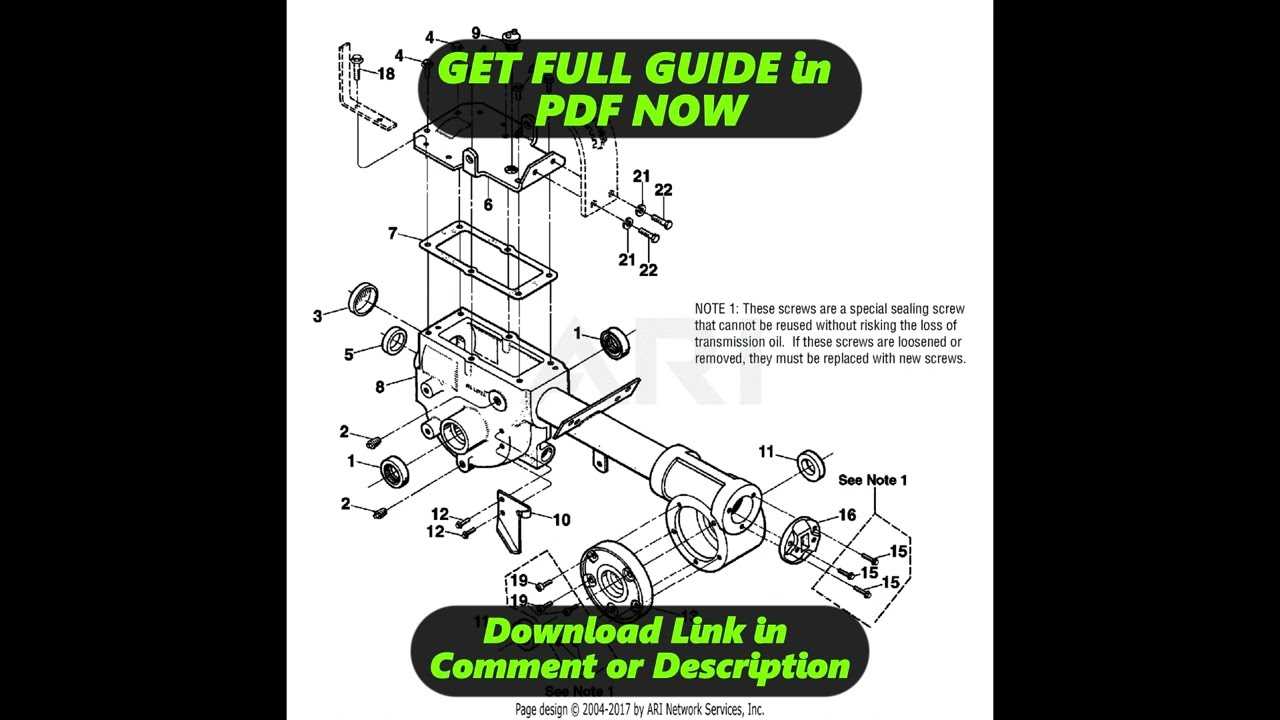

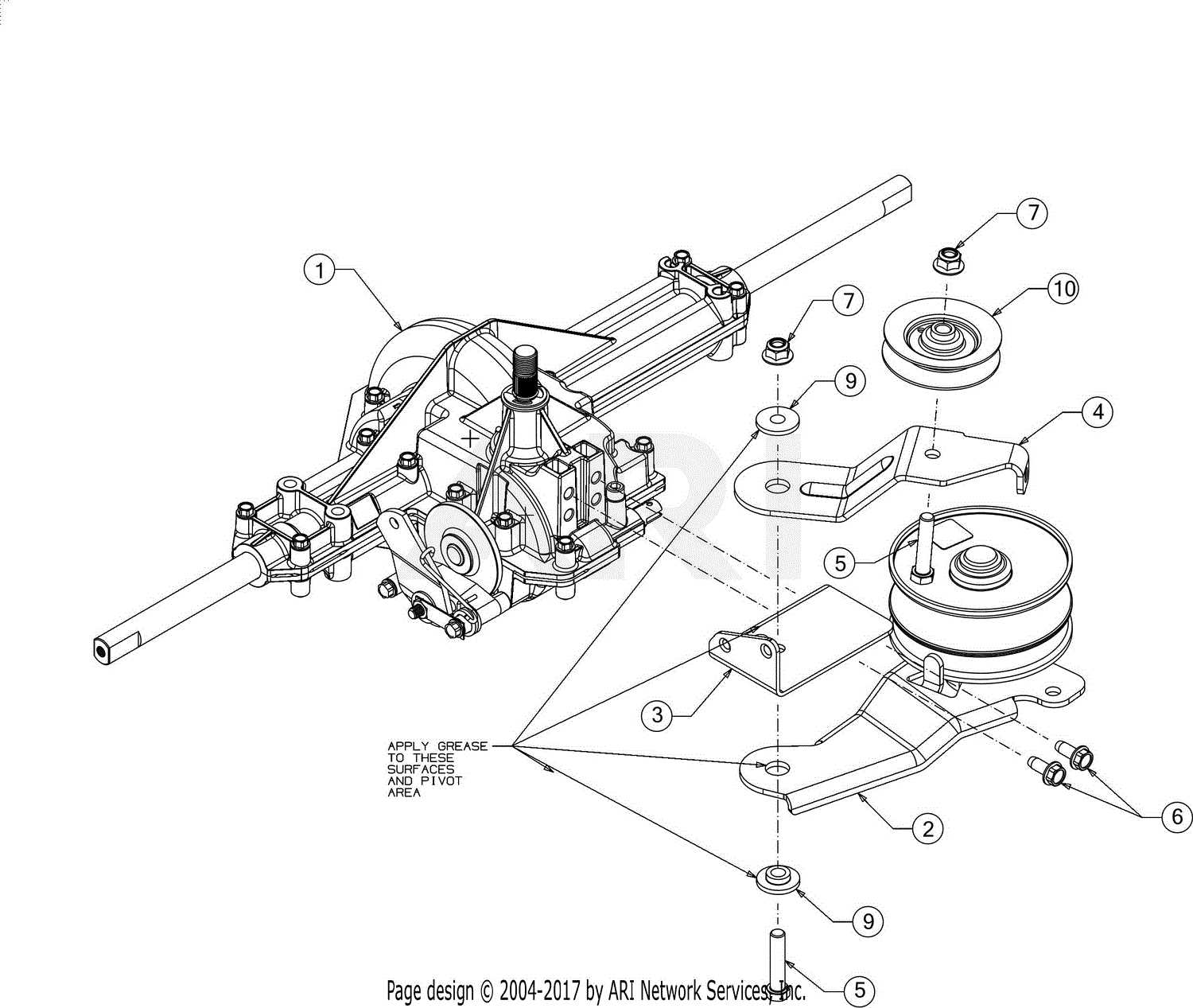

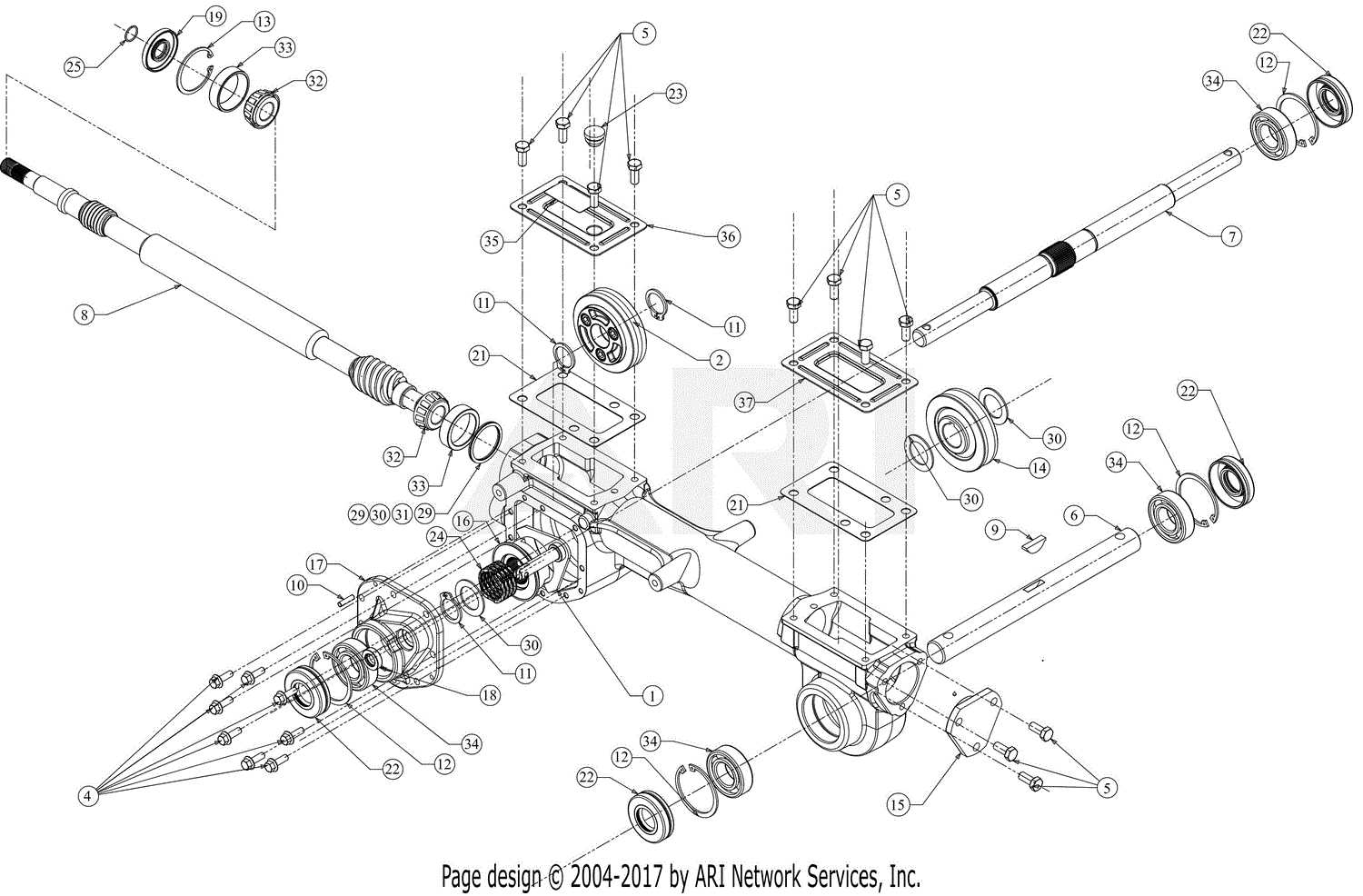

Transmission System Breakdown

The transmission system plays a crucial role in the overall functionality of machinery, enabling the transfer of power from the engine to the wheels. Understanding its components and operation is essential for effective maintenance and repair. This section delves into the various elements of the transmission system, their functions, and potential issues that may arise.

- Transmission Housing: The outer shell that protects the internal components and contains the fluid necessary for operation.

- Gear Assemblies: A series of gears that facilitate the changing of speeds and torque. Each gear is designed for specific operational conditions.

- Clutch Mechanism: Engages and disengages the engine from the transmission, allowing for smooth transitions between gears.

- Input Shaft: Connects to the engine, transferring power into the transmission system.

- Output Shaft: Sends the power from the transmission to the drive wheels.

Regular inspection of these components can prevent unexpected failures and extend the lifespan of the transmission system. Common issues may include fluid leaks, worn gears, and clutch malfunctions.

- Check for fluid leaks regularly to ensure optimal performance.

- Listen for unusual noises when shifting gears, as this may indicate wear.

- Inspect the clutch for signs of wear or damage.

- Ensure that the fluid levels are within the recommended range.

By maintaining a thorough understanding of the transmission system, operators can enhance the reliability and efficiency of their equipment.

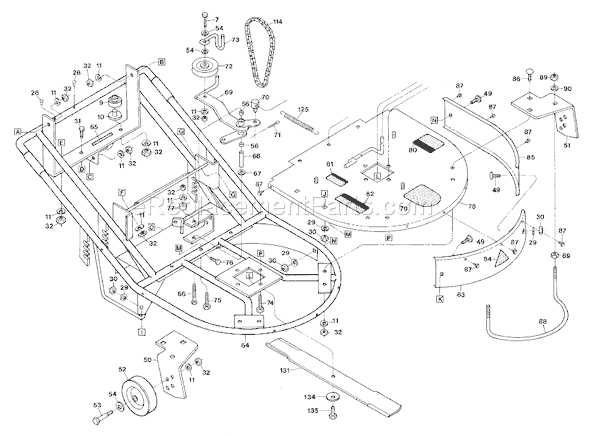

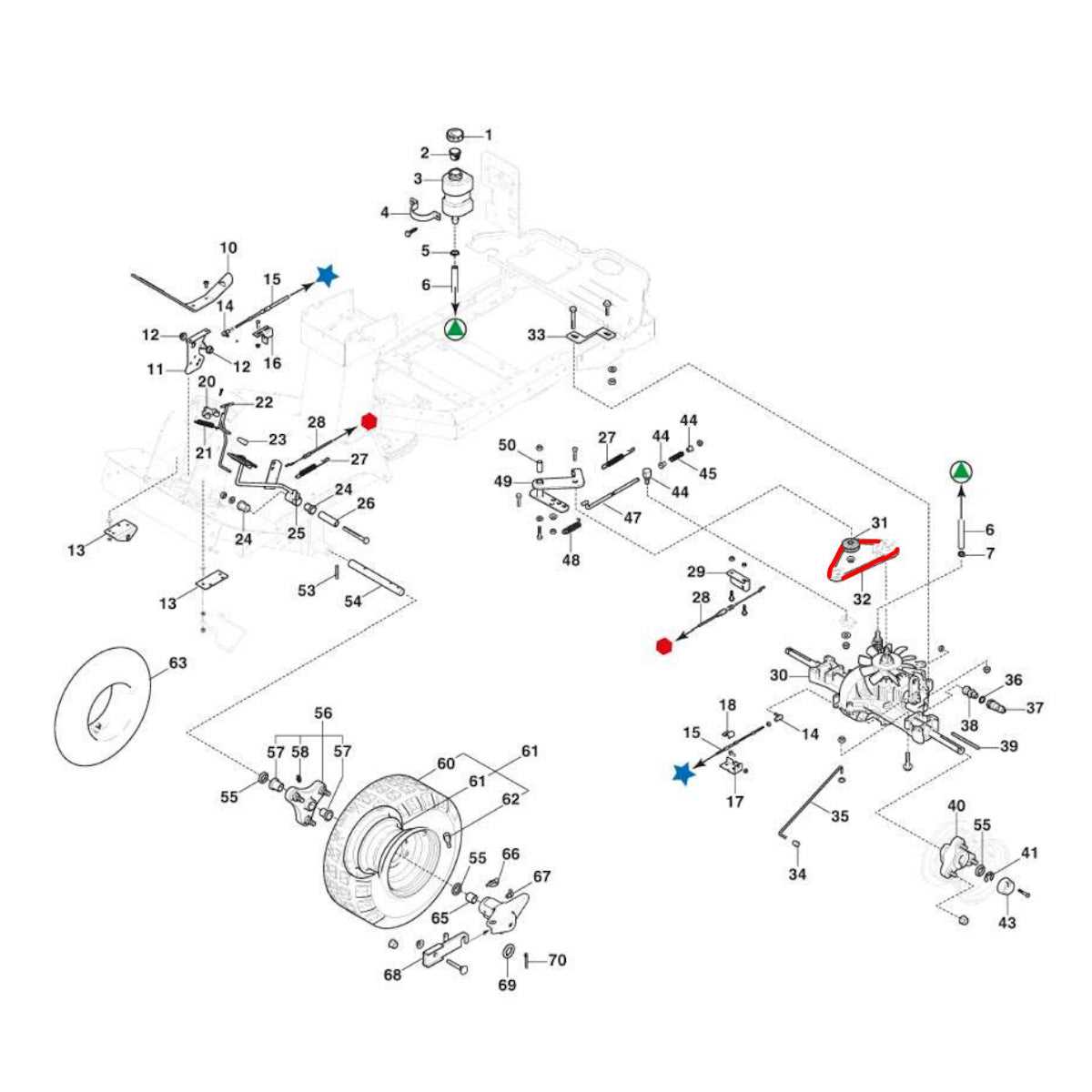

Deck Assembly and Maintenance

Proper assembly and upkeep of the cutting deck are essential for optimal performance and longevity of your mowing equipment. Understanding the components and their functions allows for effective maintenance, ensuring a smooth operation and a well-maintained lawn.

Assembly involves precise alignment of various elements, including the blades, spindles, and the deck housing. Each part must be securely fastened to prevent vibrations and ensure efficient cutting. It’s crucial to follow the manufacturer’s guidelines during this process to avoid common pitfalls that may arise from improper installation.

Maintenance is equally important and includes regular inspections for wear and tear. Blades should be sharpened periodically to maintain cutting efficiency, while belts and pulleys must be checked for signs of damage or slippage. Cleaning the deck after each use can prevent grass buildup, which can lead to rust and decreased performance over time.

Incorporating a routine maintenance schedule can extend the lifespan of the deck assembly and enhance the overall effectiveness of your mowing equipment. By dedicating time to these tasks, you ensure a consistently clean cut and a healthy lawn.

Wheels and Tires Selection Guide

Selecting the right wheels and tires is crucial for optimal performance and safety in any outdoor equipment. The right combination can enhance maneuverability, stability, and durability, ensuring that your machine operates effectively in various conditions. This guide will assist you in making informed choices tailored to your specific needs.

When choosing wheels and tires, consider factors such as terrain type, load capacity, and desired performance. Below is a table summarizing essential aspects to help guide your selection process:

| Factor | Considerations |

|---|---|

| Terrain Type | Choose tread patterns suited for grass, gravel, or mud. |

| Load Capacity | Ensure wheels and tires can support the weight of the equipment. |

| Size | Match sizes to maintain proper clearance and functionality. |

| Material | Consider rubber compounds for durability and performance. |

| Weather Conditions | Select options that perform well in wet, dry, or icy conditions. |

By understanding these factors, you can select the most suitable wheels and tires for your machinery, ensuring it performs at its best under varying conditions.

Electrical System Overview

The electrical framework of a machine plays a crucial role in its overall functionality and efficiency. This system encompasses various components that work together to ensure smooth operation, providing power to essential features and facilitating communication between different parts.

Key Components

At the heart of the electrical system are the battery, wiring harness, and ignition components. The battery supplies the necessary energy, while the wiring harness acts as the nervous system, distributing power throughout the unit. Ignition parts are responsible for starting the engine, making them vital for operation.

Maintenance Tips

Regular checks and maintenance are vital to keep the electrical system functioning optimally. Inspecting connections for corrosion, ensuring the battery is charged, and replacing faulty components can prevent larger issues down the line. Staying proactive will enhance the longevity and reliability of the system.

Identifying Belts and Cables

Understanding the various components that facilitate movement and control in machinery is essential for proper maintenance. This section focuses on recognizing the different types of belts and cables, which play a critical role in the functionality of equipment. Accurate identification ensures efficient repairs and replacements, enhancing overall performance.

Types of Belts

Belts come in various shapes and sizes, each serving a specific function. Common types include drive belts, deck belts, and transmission belts. Knowing their characteristics can aid in effective troubleshooting.

| Type | Description |

|---|---|

| Drive Belt | Transfers power from the engine to other components. |

| Deck Belt | Engages the blades for cutting action. |

| Transmission Belt | Helps in shifting gears and controlling speed. |

Identifying Cables

Cables are vital for controlling various functions, such as throttle and brakes. Recognizing their types and configurations is crucial for effective maintenance.

| Type | Description |

|---|---|

| Throttle Cable | Regulates engine speed. |

| Brake Cable | Controls braking action. |

| Clutch Cable | Manages the clutch mechanism. |

Where to Find Diagrams Online

Locating detailed schematics for machinery can greatly enhance your understanding of how various components interact. With the right resources, you can easily access visuals that break down complex systems into manageable parts, facilitating repairs and maintenance.

One reliable source is the official website of the manufacturer, where you can often find comprehensive resources tailored to their products. Additionally, online forums and community groups dedicated to machinery enthusiasts frequently share valuable information, including links to relevant schematics. Don’t overlook specialized websites that compile user manuals and technical drawings; these platforms are treasure troves for anyone seeking specific visual aids.

Another effective strategy is utilizing search engines. By entering targeted keywords related to your equipment, you can uncover a wealth of resources, including downloadable manuals and user-contributed content. Platforms like YouTube also feature video tutorials, which can offer step-by-step guidance alongside visual references.

Lastly, consider joining social media groups focused on equipment repair and maintenance. Members often share links to helpful materials, making it easier to find exactly what you need. With these strategies, accessing necessary visuals becomes a streamlined process, ensuring you have the information required to succeed in your projects.

Tips for Effective Repairs

Ensuring successful maintenance requires a blend of proper techniques and thoughtful planning. By focusing on a few key strategies, you can enhance your repair experience and achieve optimal results.

- Gather all necessary tools before starting to avoid interruptions.

- Consult a reliable guide or manual for reference.

- Clean the area thoroughly to identify any underlying issues.

When proceeding with repairs, consider the following:

- Take your time to examine each component carefully.

- Document the disassembly process to simplify reassembly.

- Use quality replacement materials for durability.

- Test the equipment after repairs to ensure everything functions correctly.

By implementing these tips, you can effectively tackle maintenance tasks and prolong the lifespan of your equipment.

Upgrading Your Troy Bilt Pony

Enhancing your garden machine can significantly improve its performance and longevity. By focusing on key components and features, you can achieve optimal efficiency and a more enjoyable gardening experience.

- Evaluate the current condition of your machine.

- Research available upgrades for engine performance.

- Consider improvements for cutting efficiency.

- Look into comfort-enhancing modifications for the operator.

Upgrading is not just about replacement; it’s an opportunity to delve into customization that aligns with your gardening needs.

- Start with a thorough inspection of essential components.

- Identify parts that require replacement or enhancement.

- Plan your upgrades according to your budget and priorities.

- Implement changes systematically for the best results.

Ultimately, a well-maintained and upgraded machine can transform your outdoor tasks into a more efficient and pleasurable endeavor.