Maintaining and repairing garden machinery can often feel daunting, especially when it comes to understanding its components. Having a clear visual reference can simplify this process, allowing users to identify specific elements and their functions with ease. A comprehensive illustration serves as an invaluable tool for both novice and experienced gardeners alike.

In this guide, we delve into the intricate details of your outdoor equipment, breaking down its essential features. By exploring the layout and organization of various components, you can enhance your understanding of how to optimize performance and address any issues that may arise. Armed with this knowledge, you’ll be better equipped to ensure your machine operates smoothly throughout the gardening season.

Whether you’re troubleshooting a malfunction or performing routine maintenance, familiarizing yourself with the schematic of your machinery will prove beneficial. This visual reference not only aids in repairs but also empowers you to make informed decisions about replacements and upgrades, ensuring your gardening tasks are efficient and effective.

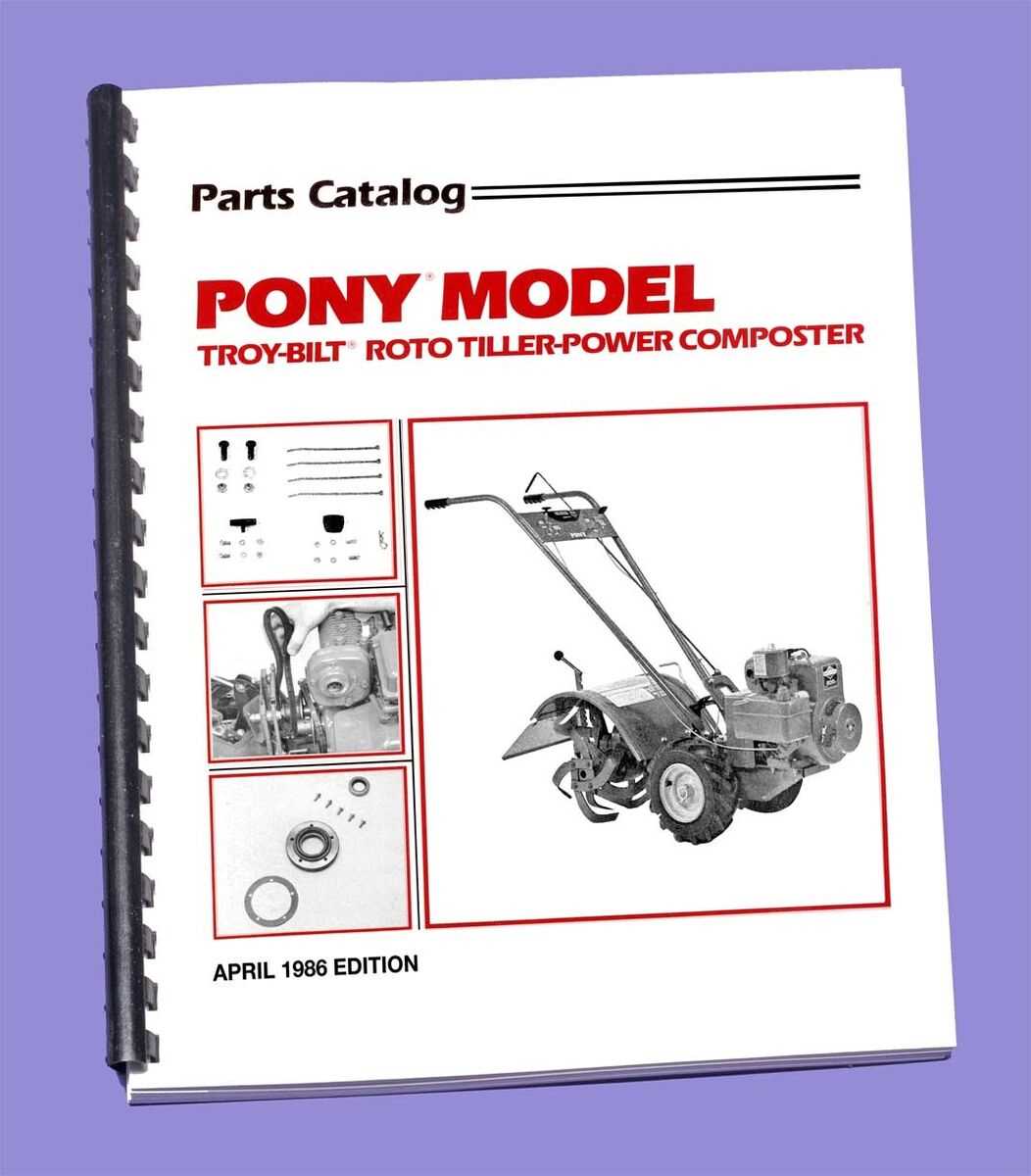

Troy Bilt Pony Tiller Overview

This section provides a comprehensive insight into a popular gardening machine known for its efficiency and reliability. Designed to assist with soil cultivation, it has become an essential tool for both amateur and professional gardeners. Below are key features and benefits that highlight its significance in gardening tasks.

- Powerful Engine: Equipped with a robust motor, it ensures optimal performance for various soil types.

- Durable Construction: Built with high-quality materials, it withstands the rigors of regular use.

- Easy Operation: User-friendly controls allow for straightforward handling and maneuverability.

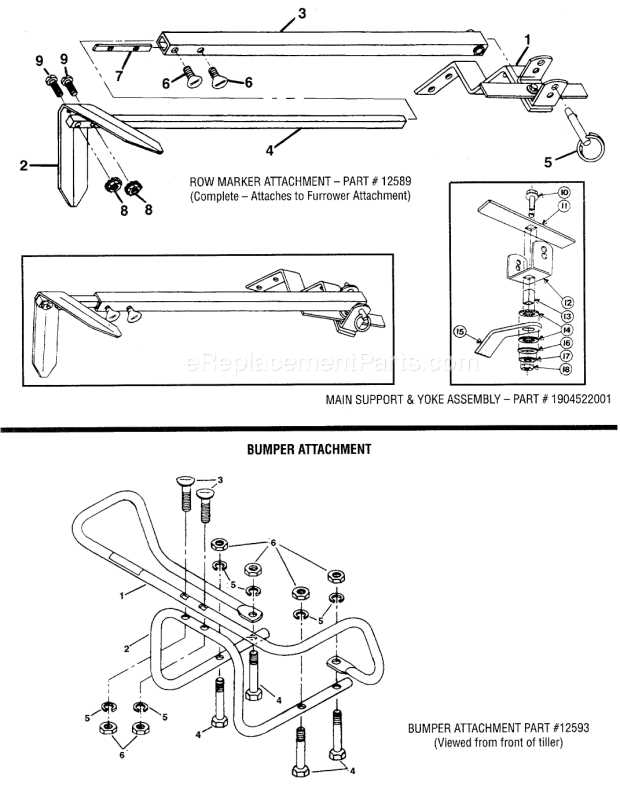

- Versatile Attachments: Compatible with various accessories, enhancing its functionality for different gardening needs.

- Compact Design: Its size makes it easy to store and transport, ideal for home gardens.

Understanding the features and capabilities of this gardening aid is crucial for making informed decisions and maximizing its potential in landscaping projects. Whether preparing a garden bed or maintaining an existing plot, this machine offers a reliable solution for efficient soil management.

Importance of Understanding Parts Diagram

Grasping the layout and function of components within machinery is crucial for effective maintenance and repair. A clear representation of each element allows users to identify issues quickly and efficiently, ensuring optimal performance and longevity of the equipment.

Enhances Repair Efficiency

When users comprehend the arrangement of parts, they can:

- Quickly locate faulty components.

- Streamline the repair process.

- Reduce downtime by addressing issues promptly.

Facilitates Proper Maintenance

Understanding the configuration supports regular upkeep in the following ways:

- Identifies areas requiring lubrication or adjustment.

- Helps in recognizing wear and tear on specific parts.

- Encourages proactive measures to prevent breakdowns.

Key Components of the Tiller

Understanding the essential elements of this gardening machine is crucial for effective operation and maintenance. Each part plays a significant role in the overall functionality, ensuring that soil preparation is efficient and manageable.

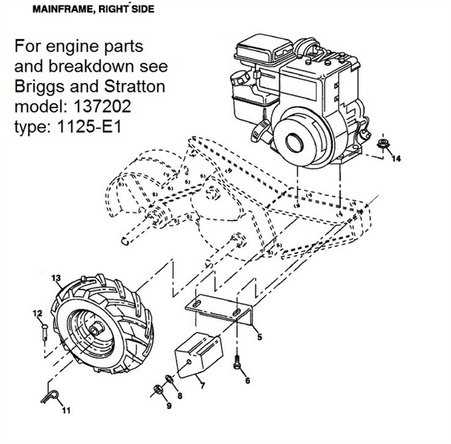

- Engine: The power source that drives the entire system, crucial for performance.

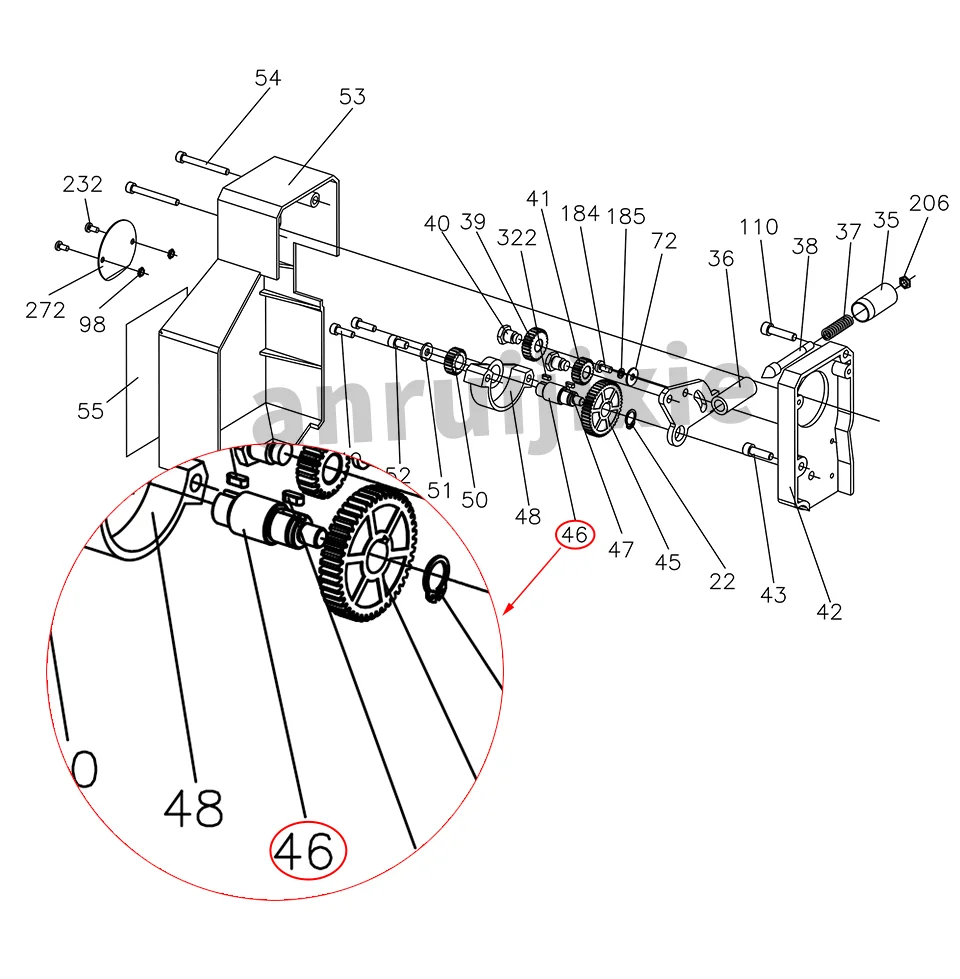

- Transmission: Responsible for transferring power from the engine to the tines, allowing for adjustable speed and torque.

- Tines: Sharp, rotating blades that break up and aerate the soil, essential for proper cultivation.

- Handlebars: Provide control and maneuverability, allowing the user to guide the machine easily.

- Frame: The structural foundation that supports all components, ensuring stability and durability.

Each of these components contributes to the overall efficiency and effectiveness of soil cultivation. Familiarity with their functions will aid in both operation and troubleshooting.

How to Read Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to identify components and their functions within machinery. These visual representations provide essential information, helping you troubleshoot issues and perform maintenance more effectively.

To effectively interpret these visuals, follow these key steps:

- Familiarize Yourself with Symbols: Different components are represented by various shapes and lines. Knowing what each symbol means is crucial.

- Identify Key Sections: Most illustrations are divided into sections. Focus on one area at a time to avoid feeling overwhelmed.

- Cross-Reference with Manuals: Use user guides or service manuals to correlate illustrations with written descriptions for better understanding.

- Note the Part Numbers: Each component is often labeled with a number or code. Keep a list of these for easy ordering and replacement.

By following these steps, you can enhance your comprehension of technical visuals and improve your repair and maintenance skills.

Common Replacement Parts Explained

Understanding the essential components of garden machinery is crucial for maintaining its efficiency and longevity. Various elements may require replacement due to wear and tear, ensuring that your equipment continues to function optimally. This section highlights some frequently needed components, their roles, and how they impact overall performance.

Engine Components

One of the most vital sections involves engine elements. Regularly replacing filters and sensors helps maintain proper airflow and fuel efficiency. Additionally, spark plugs are essential for ignition; replacing them can significantly enhance starting performance and reduce emissions.

Tilling Equipment

The tilling mechanism is crucial for soil preparation. Blades and tines experience substantial wear and may require frequent replacement to ensure effective soil penetration and mixing. Keeping these components sharp and intact allows for better aeration and nutrient distribution within the soil.

Maintenance Tips for Longevity

Ensuring the durability and performance of your gardening equipment requires regular attention and care. By following a few essential maintenance practices, you can significantly extend the lifespan of your machinery while enhancing its efficiency during use.

First, always refer to the manufacturer’s guidelines for maintenance schedules and recommended procedures. Regularly inspecting and cleaning your equipment prevents the accumulation of debris that can lead to malfunctions. Pay particular attention to the engine, air filters, and fuel systems, as these components are crucial for optimal operation.

Lubrication is another key factor in maintaining smooth functionality. Use appropriate oils and greases to keep moving parts well-oiled, which helps reduce friction and wear. Additionally, regularly checking and tightening bolts and screws ensures that everything remains securely in place during operation.

Furthermore, seasonal upkeep is essential. After heavy use, particularly at the end of the gardening season, perform a thorough checkup. Replace any worn-out components and address any issues immediately to avoid more significant repairs later on. Store your equipment in a dry, protected environment to safeguard it from harsh weather conditions.

By adhering to these maintenance tips, you will not only prolong the life of your gardening tools but also improve their performance, making your gardening tasks more enjoyable and efficient.

Where to Find Genuine Parts

Locating authentic components for your garden equipment is essential for ensuring optimal performance and longevity. Reliable sources can provide you with the high-quality replacements you need to keep your machine running smoothly.

Here are some effective places to consider:

- Manufacturer’s Website: The official site often offers a dedicated section for genuine replacements, along with detailed information on compatibility.

- Authorized Dealers: Local dealers typically stock original items and can assist with finding the right match for your equipment.

- Online Marketplaces: Reputable e-commerce platforms often feature sections for OEM components, but always verify the seller’s credibility.

- Repair Shops: Specialized repair services may have access to authentic pieces and can provide professional advice on what to purchase.

- Parts Catalogs: Printed or digital catalogs from manufacturers can guide you in identifying the correct items needed for your equipment.

Always prioritize authenticity when sourcing replacements to ensure compatibility and performance. This approach not only saves time but also enhances the longevity of your tools.

Popular Aftermarket Options Available

When it comes to enhancing the performance and functionality of gardening equipment, many enthusiasts turn to a variety of aftermarket alternatives. These options often provide improved durability, increased efficiency, and a wider range of features compared to original components. Exploring these alternatives can lead to better results in your gardening endeavors.

Types of Aftermarket Components

There are several categories of aftermarket items that can be beneficial for your gardening machinery. These include enhancements for ease of use, improved performance, and replacement parts that meet or exceed original specifications.

| Component Type | Benefits | Examples |

|---|---|---|

| Blades | Enhanced cutting efficiency | Heavy-duty steel blades |

| Engines | Increased power output | High-performance replacement engines |

| Handles | Improved ergonomics | Adjustable and padded handles |

Choosing the Right Options

Selecting the appropriate aftermarket alternatives requires careful consideration of your specific needs and the compatibility with your existing equipment. It’s important to research and compare different products to ensure they provide the desired benefits and meet quality standards.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to troubleshooting and restoring your gardening equipment. By following these systematic steps, you can identify issues and implement effective solutions to ensure optimal performance.

1. Safety First: Before beginning any repairs, make sure to disconnect the power source and wear appropriate protective gear. This will help prevent accidents and injuries.

2. Identify the Problem: Carefully examine the equipment to pinpoint the exact issue. Look for signs of wear, leaks, or other abnormalities that could be affecting functionality.

3. Gather Necessary Tools: Collect all required tools and replacement components. Having everything ready will streamline the repair process and save you time.

4. Disassemble the Unit: Follow the manufacturer’s guidelines to safely disassemble the equipment. Keep track of all screws and small parts, organizing them for easy reassembly.

5. Inspect Components: Check each part for damage or wear. Pay special attention to areas that are commonly problematic, such as belts, bearings, and gears.

6. Replace or Repair: Based on your inspection, decide whether to repair damaged components or replace them entirely. Ensure that any new parts are compatible with your specific model.

7. Reassemble Carefully: Once repairs are made, begin reassembling the unit. Follow the reverse order of disassembly, ensuring all parts are securely fastened.

8. Test the Equipment: After reassembly, reconnect the power source and conduct a test run. Observe for any unusual noises or behaviors, and make adjustments if necessary.

9. Regular Maintenance: To prolong the lifespan of your equipment, establish a routine maintenance schedule. Regular checks can help prevent future issues and ensure smooth operation.

Troubleshooting Common Issues

When operating garden machinery, users may encounter various challenges that hinder optimal performance. Identifying these problems quickly can save time and prevent further complications. This section provides insights into some prevalent issues and their potential solutions, helping you maintain efficiency in your gardening tasks.

One frequent problem is difficulty starting the engine. This can often be traced back to fuel-related issues, such as stale gasoline or clogged filters. Checking the fuel system and ensuring that fresh fuel is used can often resolve this matter.

Another common issue involves poor tilling performance. If the equipment struggles to penetrate the soil, inspect the blades for wear or damage. Sharpening or replacing them may restore functionality and improve the tilling process.

Lastly, vibrations during operation can indicate loose components or misalignment. Regularly inspecting bolts and connections for tightness can help mitigate these vibrations, ensuring a smoother experience while working in the garden.

Benefits of Using Original Components

Utilizing authentic elements for your equipment ensures optimal performance and longevity. These original components are designed to fit perfectly and work harmoniously with your machinery, providing numerous advantages over aftermarket alternatives.

Quality Assurance

One of the primary benefits of using original components is the guarantee of quality. These parts are manufactured to meet specific standards, ensuring:

- Durability under various conditions

- Consistent performance

- Enhanced safety during operation

Compatibility and Efficiency

Choosing genuine components also promotes compatibility with existing systems. This leads to:

- Seamless integration with your equipment

- Reduced risk of malfunctions

- Improved efficiency and productivity

In summary, opting for original components is a smart investment that supports the longevity and effectiveness of your machinery.