Maintaining a well-groomed outdoor space requires reliable machinery, particularly when it comes to grass care. Knowing the specific elements and their arrangement in your equipment is crucial for effective upkeep. This section aims to provide a clear overview of the various components involved in the operation of such machines, facilitating a better understanding for users.

Each piece of machinery comprises several integral parts that work together seamlessly. Familiarity with these components not only enhances operational efficiency but also aids in troubleshooting potential issues. With the right knowledge, users can easily identify and replace specific sections, ensuring their equipment remains in optimal condition.

Effective maintenance is key to prolonging the life of your machinery. By comprehending how different elements are structured and function, owners can make informed decisions about repairs and upgrades. This understanding ultimately contributes to a more efficient and enjoyable gardening experience.

As we delve deeper into the layout of these essential items, you’ll gain valuable insights that will empower you to handle any challenges with confidence. Whether you are a novice or a seasoned user, this guide will equip you with the necessary information to manage your gardening tasks effectively.

Grasping the various elements of a grass-cutting machine is essential for optimal performance and maintenance. Each component plays a vital role in ensuring that the device operates smoothly and efficiently. Familiarity with these elements can lead to improved care and troubleshooting capabilities.

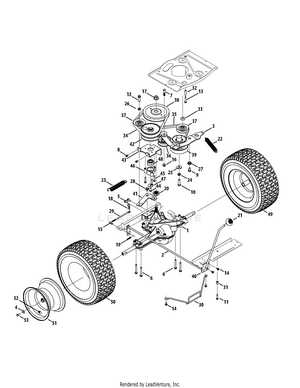

The primary components of a typical grass-cutting device include:

- Engine: The powerhouse that drives the entire machine.

- Blade: The cutting tool responsible for trimming the grass.

- Deck: The body that houses the blade and engine, providing structural support.

- Wheels: The elements that allow for movement and maneuverability across different terrains.

- Handle: The part that users grip to guide the machine during operation.

Understanding these key components can facilitate effective troubleshooting and enhance the overall user experience. Regular maintenance and inspection of each element will contribute to the longevity and reliability of the machine.

Identifying Key Parts and Functions

Understanding the essential components of lawn care equipment is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal performance and longevity of the machinery. Familiarity with these elements helps users troubleshoot issues and execute necessary repairs.

Engine: The heart of the equipment, responsible for powering the machine and enabling movement across the terrain. It converts fuel into mechanical energy, driving the blades that cut the grass.

Blades: Sharp implements designed to slice through grass, providing a clean and even cut. Regular inspection and sharpening are essential for maintaining their effectiveness and ensuring a healthy lawn.

Deck: The protective casing that houses the blades and engine. Its design influences the cutting width and overall maneuverability. A well-maintained deck prevents debris buildup and enhances airflow, improving cutting performance.

Wheels: Crucial for mobility, allowing the equipment to traverse various terrains. The size and tread pattern impact traction and stability during operation. Ensuring proper inflation and condition is vital for safe and efficient use.

By familiarizing oneself with these fundamental components, users can better manage their lawn care tasks and ensure their equipment remains in top working condition.

Common Issues and Solutions

When using a lawn maintenance device, users may encounter various challenges that can hinder performance. Understanding these common problems and their corresponding solutions is essential for effective upkeep and longevity.

Difficulty Starting: One prevalent issue is trouble initiating the device. This may arise from a drained battery or stale fuel. Ensuring fresh fuel and checking the battery charge can often resolve this problem.

Uneven Cutting: Another frequent concern is inconsistent trimming results. This can occur due to dull blades or improper height adjustments. Regularly sharpening the blades and correctly setting the cutting height can significantly improve cutting quality.

Excessive Vibration: Users might notice excessive shaking during operation. This issue could be linked to loose components or imbalanced blades. Tightening screws and ensuring proper blade alignment can help mitigate this concern.

Overheating: Overheating can also pose a problem, typically due to debris obstructing airflow. Keeping the device clean and free from clippings can prevent overheating and maintain optimal performance.

Addressing these common issues promptly can enhance the efficiency and lifespan of the equipment, ensuring a smoother lawn care experience.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of your equipment. By adhering to a few straightforward practices, you can significantly extend its lifespan while maintaining optimal functionality. These recommendations will help you create a robust maintenance routine that keeps your device in peak condition.

Routine Inspection

Conducting frequent checks can prevent minor issues from becoming significant problems. Here are some key areas to focus on:

- Examine the exterior for any signs of wear or damage.

- Inspect the blades for sharpness and integrity.

- Check for any loose bolts or components that may require tightening.

Proper Cleaning

Keeping your device clean is crucial for its longevity. Regular cleaning not only enhances performance but also helps in preventing rust and corrosion. Follow these steps:

- After each use, remove any grass clippings or debris from the surface.

- Use a soft brush to clean the blades and other components.

- Occasionally, wash the unit with mild soap and water, ensuring all parts dry thoroughly afterwards.

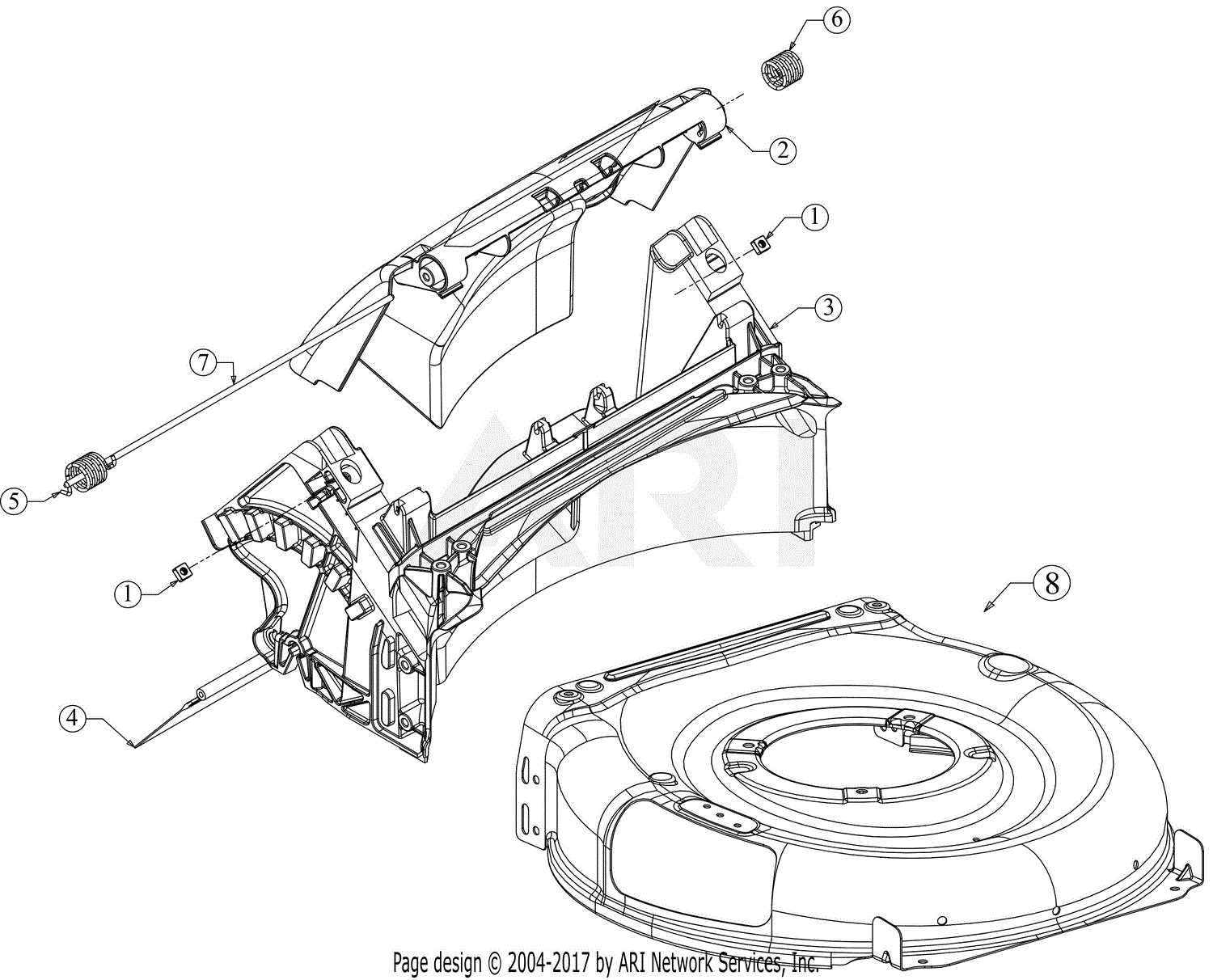

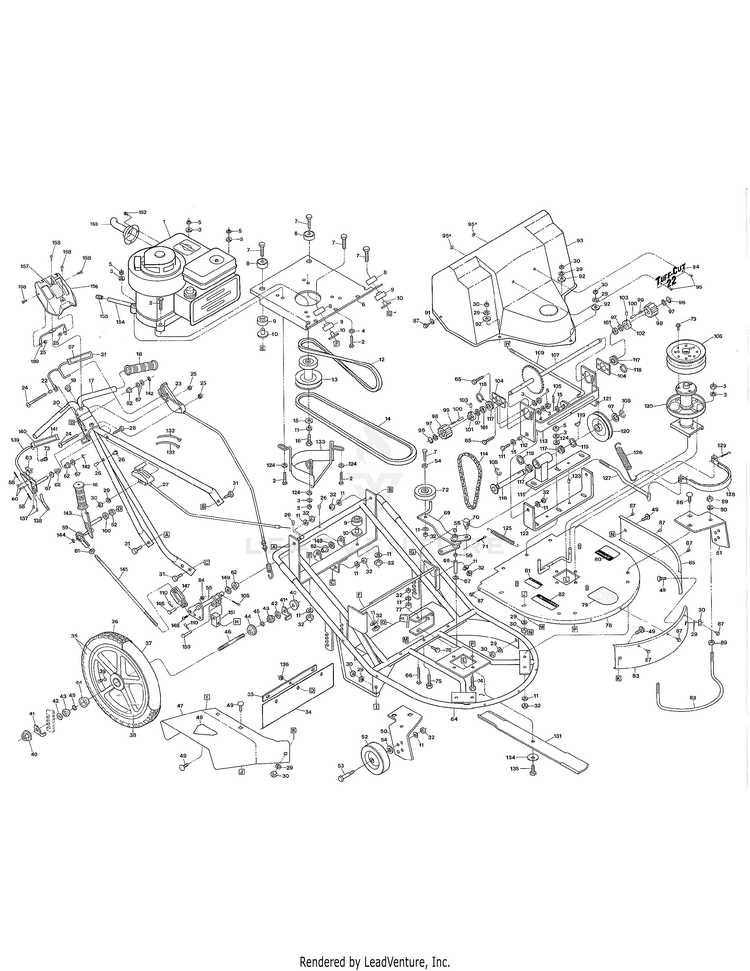

How to Replace Worn Parts

Over time, various components of lawn care equipment can become less effective due to wear and tear. Addressing these issues promptly ensures optimal performance and longevity of the device. This section outlines essential steps for replacing deteriorated components to maintain efficiency.

Begin by identifying which elements require replacement. Signs of wear can include unusual noises, reduced efficiency, or visible damage. Once you have determined the necessary parts, gather the appropriate tools, such as wrenches, screwdrivers, and replacement components, to facilitate the process.

Next, ensure the equipment is turned off and disconnected from any power source to prevent accidents. Carefully remove the old parts, following manufacturer guidelines where available. It’s crucial to take note of how components are assembled to ensure correct installation of the new ones.

After removing the worn items, install the new components by following the reverse procedure of disassembly. Make sure all parts are securely fastened and positioned correctly. Once everything is in place, reconnect the power source and conduct a test run to ensure the equipment operates smoothly.

Regular maintenance and timely replacements not only enhance performance but also extend the lifespan of your lawn care tools, making them a worthwhile investment in your yard care routine.

Tools Needed for Repair Work

When undertaking maintenance tasks, having the right tools at hand is essential for efficient and effective repairs. The appropriate equipment not only simplifies the process but also ensures that all components are handled correctly, minimizing the risk of damage.

Essential Tools

- Screwdrivers: Various sizes of flathead and Phillips screwdrivers are crucial for loosening and tightening screws.

- Wrenches: Both adjustable and fixed wrenches are necessary for dealing with nuts and bolts.

- Pliers: Needle-nose and standard pliers assist in gripping and manipulating small parts.

Additional Equipment

- Socket Set: A comprehensive socket set allows for quick removal and installation of fasteners.

- Measuring Tape: This tool helps in measuring dimensions accurately for replacement components.

- Work Gloves: Wearing gloves protects hands from sharp edges and provides a better grip on tools.

Safety Precautions During Maintenance

Ensuring safety during upkeep tasks is essential to prevent injuries and equipment damage. By adhering to specific guidelines, individuals can create a secure environment for themselves and others while conducting necessary checks and repairs.

General Guidelines

Before starting any maintenance activities, it is crucial to disconnect the power source to minimize the risk of accidental activation. Always use appropriate tools and wear personal protective equipment such as gloves, goggles, and sturdy footwear. Keeping the workspace clean and organized can further enhance safety, reducing the chances of slips or falls.

Handling Tools and Equipment

When utilizing various tools, ensure they are in good condition and suitable for the task at hand. Proper handling techniques should be employed to avoid mishaps. Always follow the manufacturer’s instructions for each tool and ensure that blades or sharp components are securely stored when not in use. Stay focused and avoid distractions to maintain concentration throughout the maintenance process.

Assembly Instructions for Components

Understanding how to assemble various elements of your equipment is crucial for ensuring optimal performance and longevity. This section will provide you with clear guidelines on how to properly connect and configure the individual components for effective operation.

Necessary Tools and Preparation

Before beginning the assembly process, gather the required tools to facilitate a smooth setup. Ensure that all components are available and in good condition. Proper preparation is essential for a successful assembly experience.

Step-by-Step Assembly Process

Follow the steps outlined in the table below to assemble the components effectively:

| Step | Description | Tools Required |

|---|---|---|

| 1 | Attach the main frame to the base. | Wrench |

| 2 | Secure the handle to the main assembly. | Screwdriver |

| 3 | Install the cutting mechanism and ensure it is locked in place. | Wrench |

| 4 | Connect the power source to the motor. | Multi-tool |

| 5 | Perform a safety check before operation. | N/A |

Comparing Parts Across Models

When examining various models of lawn care machines, it’s crucial to understand how components differ and align between different versions. Each design may incorporate unique elements, yet some features may remain consistent across several types. This analysis provides insights into similarities and differences that can influence performance and maintenance.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Type | Gas | Electric | Gas |

| Cutting Width | 21 inches | 20 inches | 22 inches |

| Height Adjustment | 6 positions | 5 positions | 7 positions |

| Weight | 65 lbs | 50 lbs | 70 lbs |

Where to Find Replacement Parts

Finding suitable components for your gardening equipment is essential for maintaining its functionality and performance. Fortunately, there are numerous avenues available for sourcing these necessary items, ensuring that your tools remain in optimal condition.

Online Retailers

One of the most convenient ways to acquire new elements is through various online platforms. Many websites specialize in selling accessories and components for outdoor machinery. Here are a few popular options:

- Specialized gardening equipment stores

- Major e-commerce websites

- Manufacturer’s official websites

Local Repair Shops

Another viable option is visiting local repair shops or service centers. These establishments often carry a selection of components and can provide assistance in finding the right fit for your device. Additionally, they may offer:

- Expert advice on compatibility

- Repair services to install new components

- Second-hand items at reduced prices

Exploring Upgrades and Accessories

Enhancing your lawn maintenance equipment can significantly improve performance and user experience. By incorporating various modifications and supplementary tools, you can achieve more efficient operation and achieve better results in your outdoor tasks.

Investing in high-quality attachments can provide added versatility. For example, mulching kits can optimize grass handling, while bagging systems help manage clippings effectively. Additionally, consider ergonomic enhancements such as cushioned handles or adjustable features for improved comfort during extended use.

Furthermore, exploring fuel efficiency options and environmentally friendly alternatives can not only save on operational costs but also reduce your carbon footprint. By selecting the right upgrades and accessories, you can transform your equipment into a tailored solution for your gardening needs.