A string trimmer is an essential tool for maintaining the look of your outdoor space. It allows for precise cutting and trimming, making it easier to keep hard-to-reach areas tidy. When maintaining this device, it’s crucial to be familiar with its individual components to ensure proper upkeep and functionality.

Each piece plays a significant role in the overall performance, from the engine to the trimming head. Knowing the purpose and location of each part can help when it comes time to replace worn-out elements or make repairs. This knowledge not only extends the lifespan of the equipment but also ensures it operates safely and efficiently.

Whether dealing with the engine housing, the spool, or other key segments, having a clear understanding of how these elements interact is beneficial. Identifying each component and understanding its function will make the maintenance process much smoother, allowing for quick troubleshooting and effective solutions.

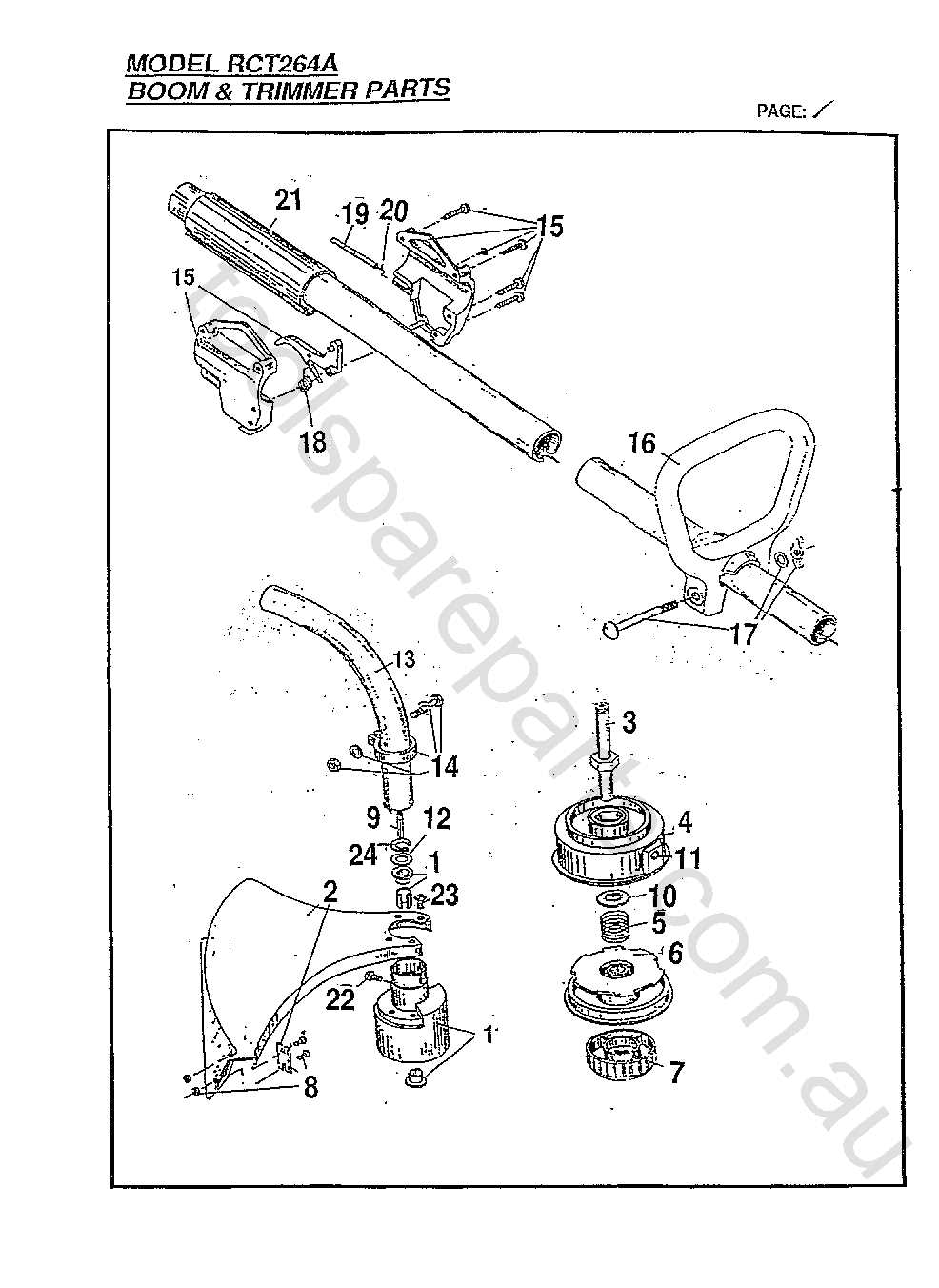

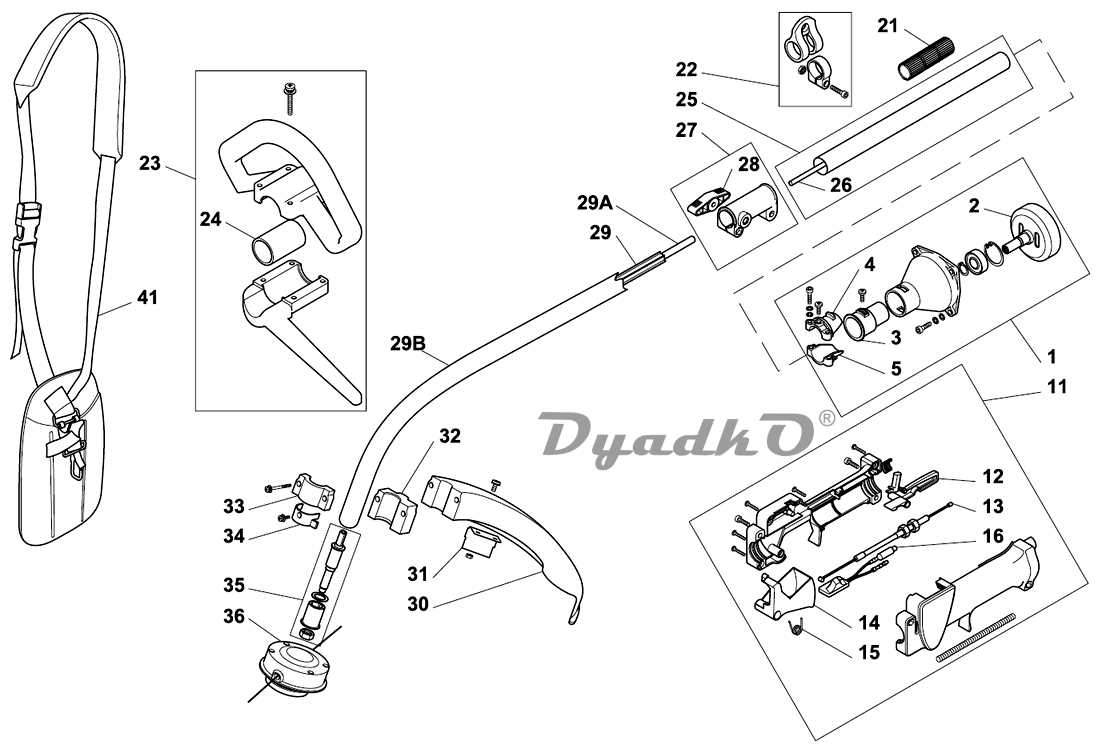

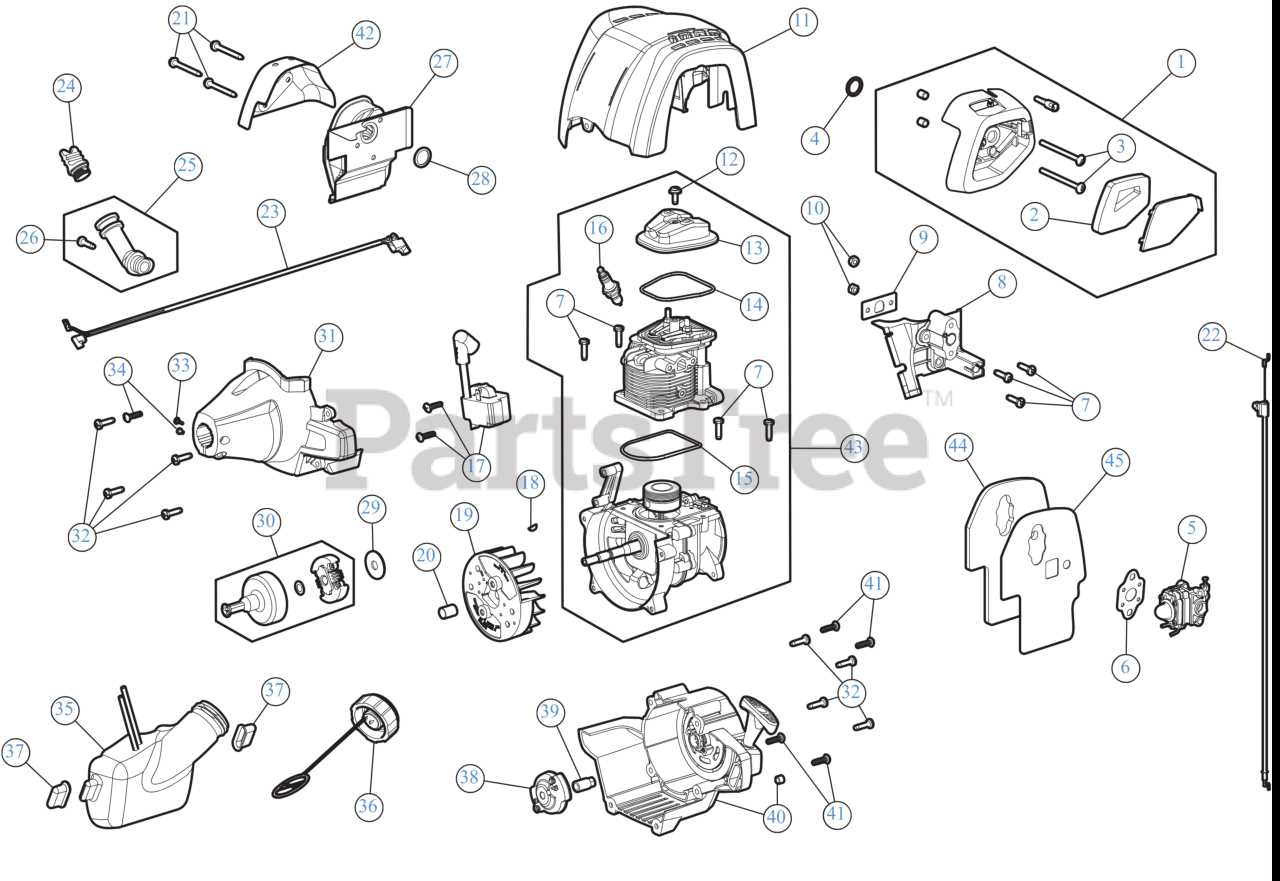

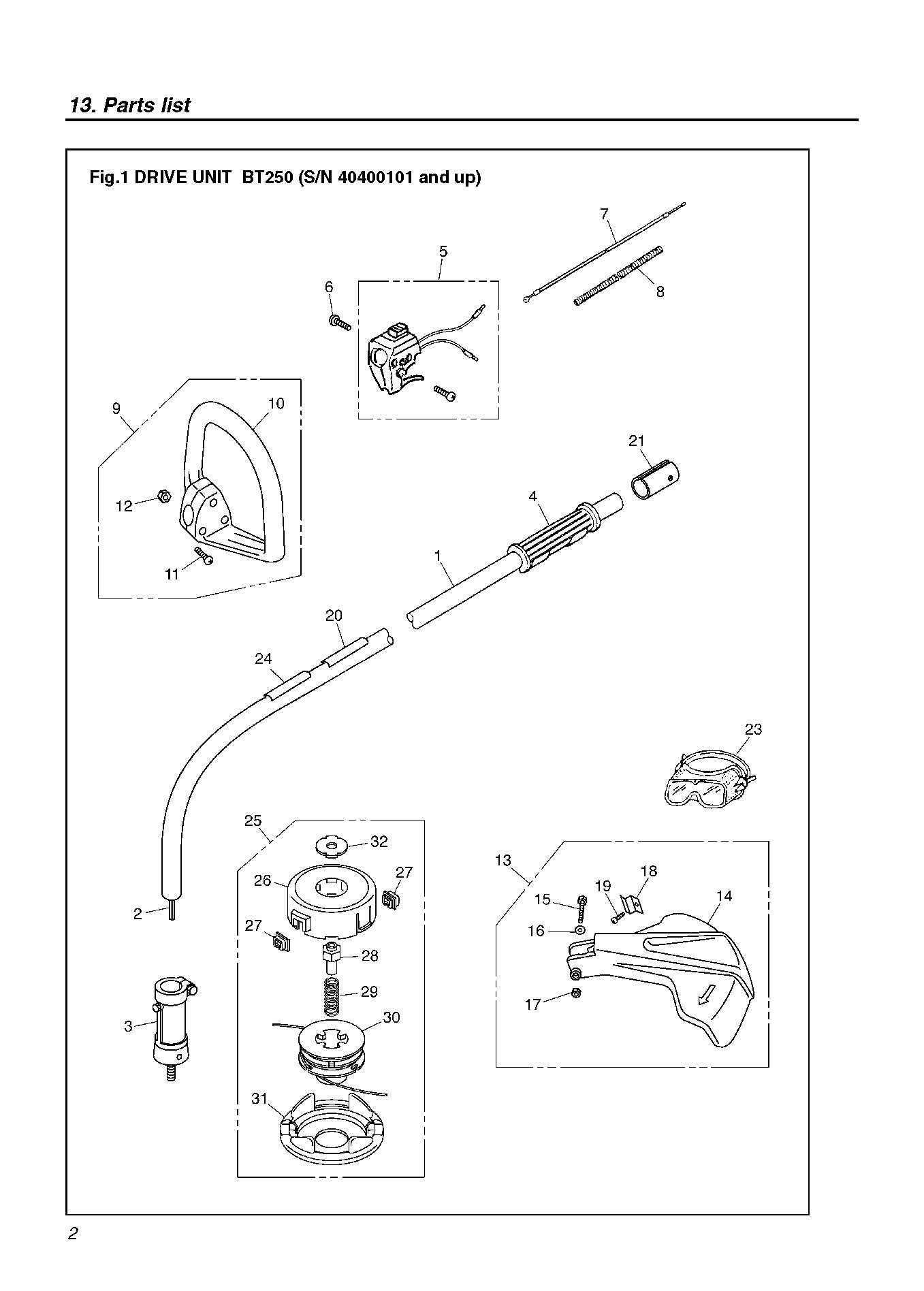

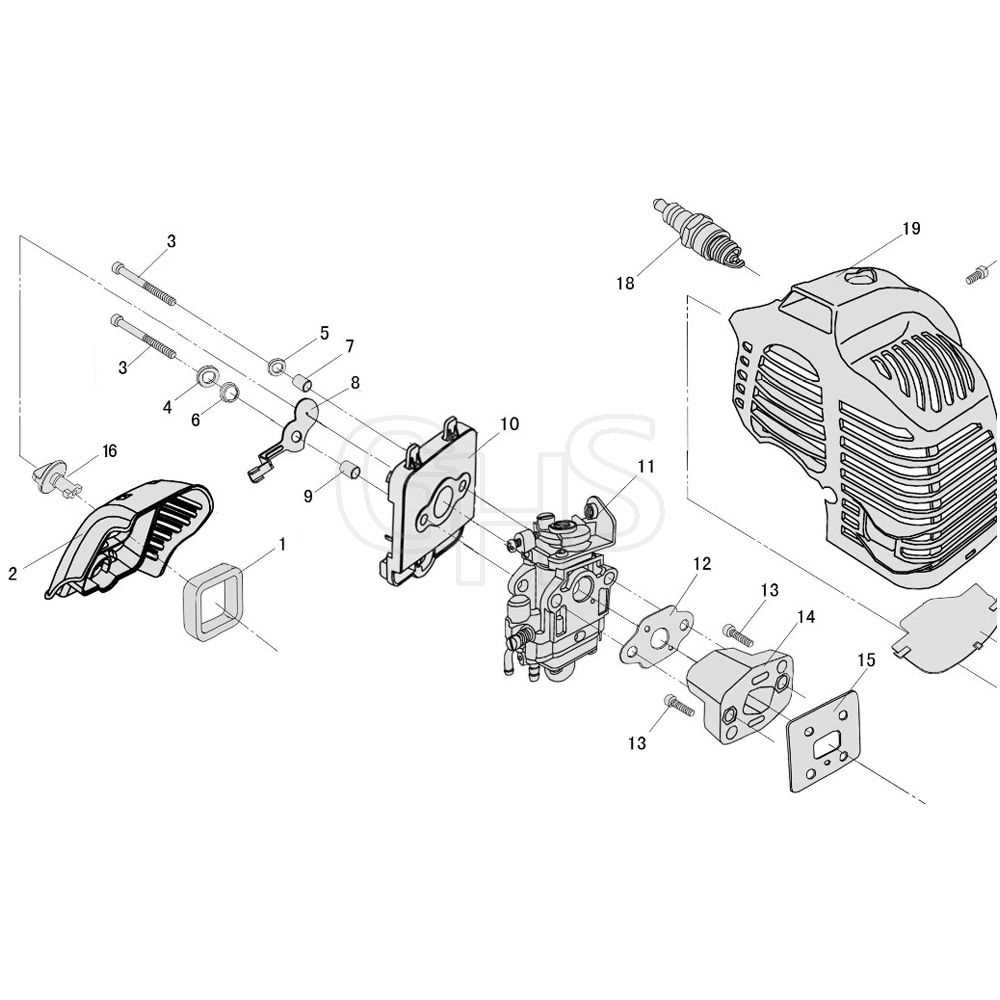

Troy-Bilt Weed Eater Parts Diagram

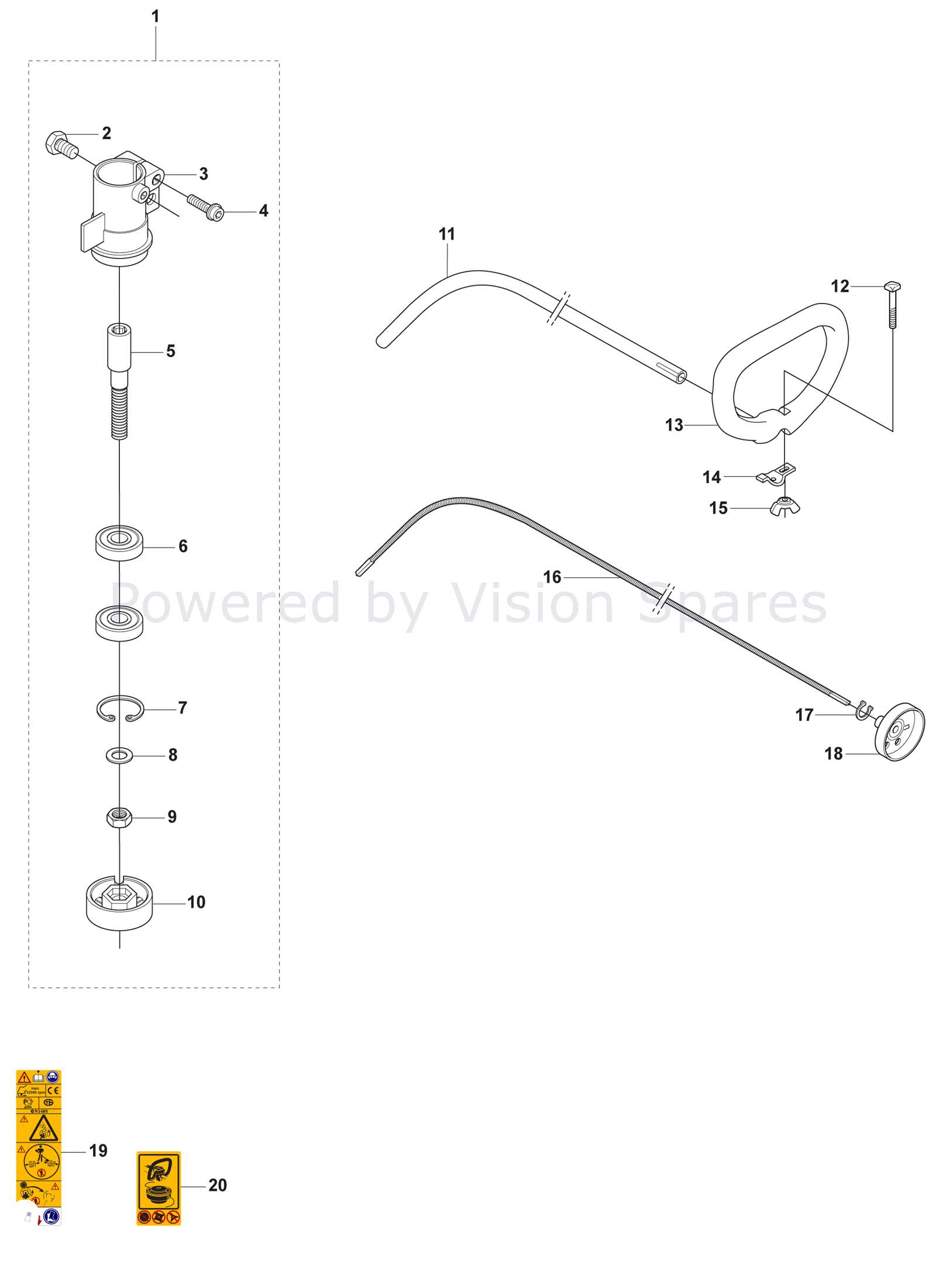

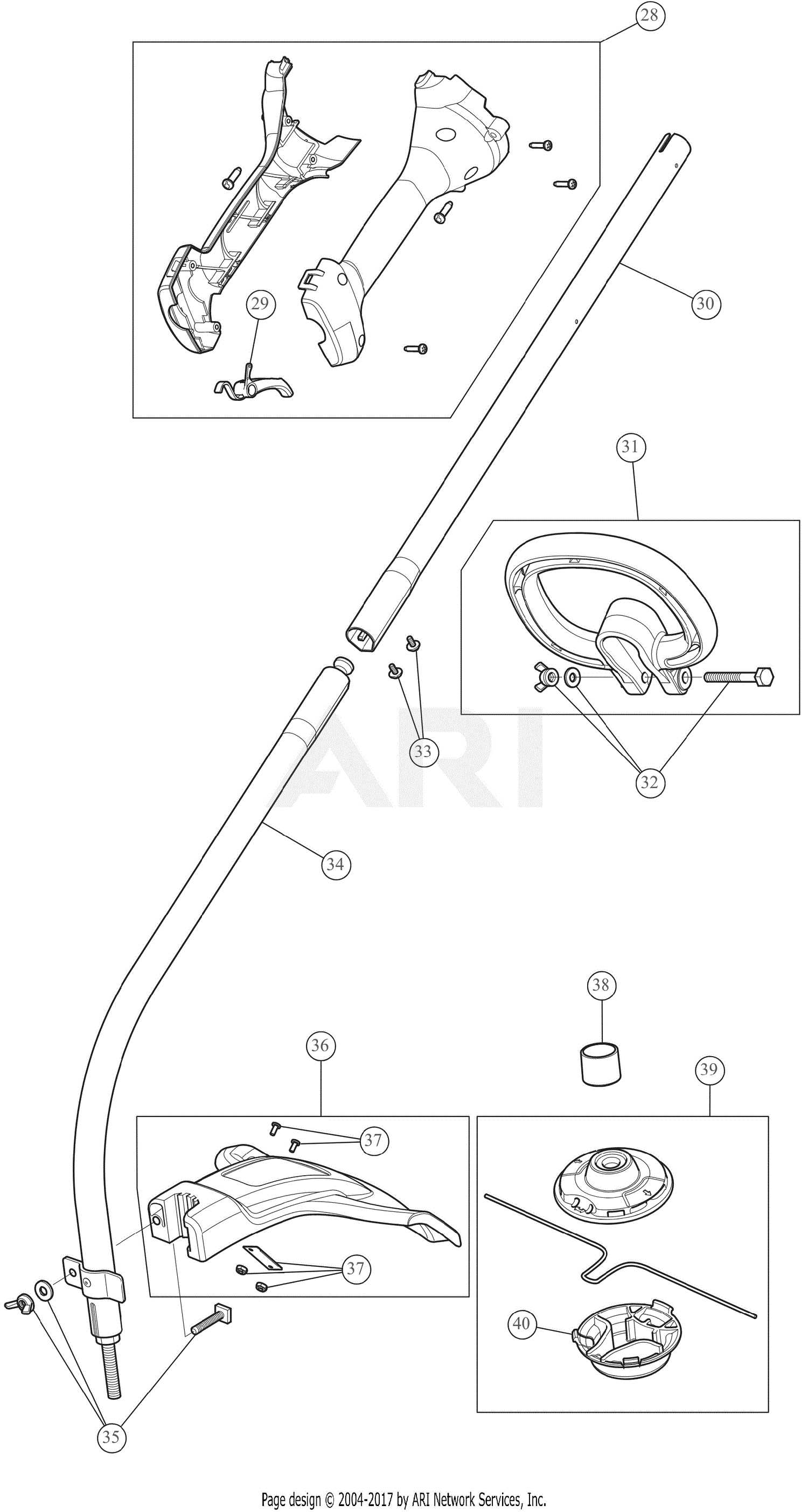

Understanding the layout and key components of your string trimmer can help with maintenance, repairs, and replacements. The visual breakdown of the machine’s structure allows users to identify different elements and how they interconnect. Familiarity with these components can aid in troubleshooting issues and keeping the device in optimal working condition.

Component Overview

The machine consists of various sections, each serving a specific function. These include the engine, which powers the device, the drive shaft that transfers motion, and the trimming head responsible for cutting. Proper identification of these sections ensures smooth operation and timely repairs.

Commonly Replaced Elements

Several parts may need periodic replacement to maintain performance. The trimmer line wears out frequently, while other elements, such as the spark plug or air filter, also require

Understanding the Weed Eater Components

Exploring the various elements of this garden tool can help you keep it in excellent condition and ensure it operates efficiently. Knowing how the individual components function and interact allows for easier maintenance and troubleshooting, reducing the likelihood of damage during use.

Main Mechanical Elements

The tool consists of several crucial mechanical elements that work together to achieve a balanced and effective trimming process. The engine or motor provides the power needed for the cutting head to rotate, while the shaft transfers this energy to the trimming mechanism. Each part contributes to the overall operation, allowing for controlled handling and precision.

Protective and Control Features

Beyond the core mechanical parts, there are several protective and control features designed to enhance safety and ease of use. For instance, the guard shields against debris during operation, while the handle allows for secure grip and maneuverability. These components are essential for maintaining both the operator’s safety and the tool’s longevity.

How to Identify Each Part

Understanding the various components of a trimmer helps maintain its functionality and ensures proper upkeep. Recognizing each element not only simplifies the replacement process but also aids in troubleshooting issues effectively. Below, we will explore how to distinguish each section of the machine, from the cutting head to the engine, including some smaller yet significant elements.

Exploring Key Sections

The trimmer is divided into multiple segments, each with a distinct function. By examining these sections, you can better understand which part may require attention during maintenance. Here’s a breakdown of the main components:

| Component | Description |

|---|---|

| Cutting Head | Located at the base, this section is responsible for trimming. It usually includes a line spool or blade. |

| Drive Shaft | The central rod that transfers power from the motor to the cutting head. It often has a protective cover for safety. |

| Throttle Control | A lever or button found on the handle that regulates speed. It enables precise control during operation. |

| Fuel Tank | The container for fuel, located near the motor. It typically has a secure cap to prevent leakage. |

| Air Filter | Situated near the engine, it protects the motor by filtering out dirt and debris. Regular cleaning or replacement is essential. |

Tips for Accurate Identification

To distinguish each part correctly, refer to the user manual or an online guide specific to your model. Look for unique features such as shapes, colors, or placement that can help in identifying individual components easily. Understanding these details makes repairs or adjustments more straightforward.

Replacement Guide for Weed Eater Parts

Maintaining outdoor equipment requires timely replacement of worn-out components to ensure optimal performance. Regular upkeep not only extends the lifespan of the machine but also improves its efficiency, making lawn care tasks more manageable. Understanding which elements need to be replaced and how to do it correctly can significantly enhance the equipment’s functionality.

Identifying Worn Components

Before starting the replacement process, inspect the equipment for signs of wear. Common indicators include reduced power, unusual noises, or visible damage to key areas. Regular checks can help you identify issues early and replace the necessary elements before they impact overall performance.

Steps for Replacing Key Elements

When replacing a specific component, ensure you have the correct replacement item. Carefully follow the disassembly instructions for the particular area, keeping all fasteners and small parts organized. Install the new piece securely, ensuring it fits well and operates smoothly. After reassembling, test the equipment to verify that everything functions as expected.

Maintaining Your Trimmer

Proper upkeep of your grass-cutting tool ensures that it runs smoothly and lasts longer. Routine care not only extends the machine’s lifespan but also improves its efficiency, making yard work less demanding. With consistent attention to detail, you can prevent common issues and keep your equipment in top shape.

Regular Cleaning

Debris and plant material can accumulate on the machine after each use, potentially causing damage or reducing performance. To maintain optimal operation, it’s important to clean the device thoroughly. Focus on removing any buildup from around the cutting head, air filter, and housing.

- Wipe down the exterior with a damp cloth to remove dirt and grime.

- Check the air filter regularly and replace it if it appears clogged.

- Clean around the cutting area to prevent entangled material from affecting the tool.

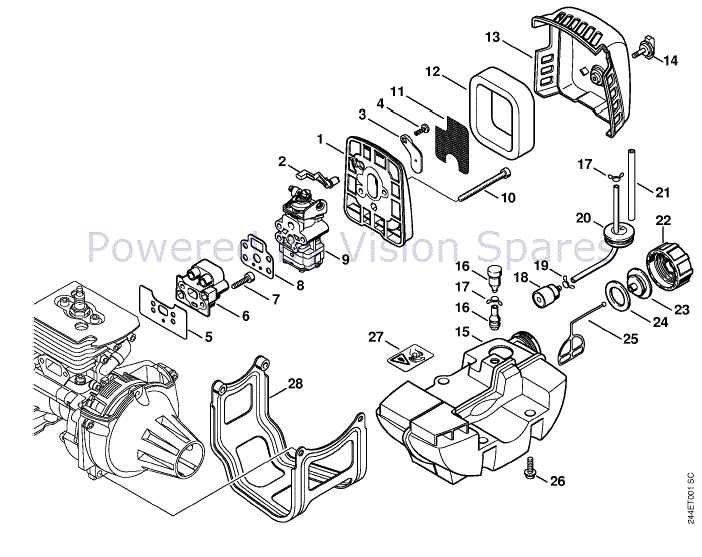

- Engine Assembly: The heart of the device, responsible for generating power.

- Fuel System: Includes the fuel tank, lines, and carburetor, crucial for proper operation.

- Cutting Head: Essential for performing the primary task, featuring various cutting attachments.

Exploded View of Key Components

An exploded view serves as a valuable resource for understanding the intricate relationships between various elements of a device. This visual representation allows users to easily identify and comprehend the functionality of each component, facilitating maintenance and repair processes. By examining these detailed illustrations, one can gain insight into the assembly and disassembly of the equipment.

Main Elements in the Assembly

Supportive Components

- Handle: Provides stability and control during use.

- Safety Guard: Protects the operator from debris and potential hazards.

- Starter Mechanism: Facilitates ignition and ensures ease of starting the engine.

Common Issues and Parts Solutions

In the world of gardening equipment, various challenges may arise that can hinder performance. Understanding these common difficulties and their respective solutions can enhance efficiency and prolong the lifespan of your tools. Below are some prevalent problems along with effective remedies, ensuring optimal functionality.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Engine Won’t Start | Clogged fuel filter or stale fuel | Replace the fuel and clean the filter. |

| Unusual Noise During Operation | Worn or damaged components | Inspect and replace any affected parts. |

| Inconsistent Cutting Performance | Dull cutting line | Sharpen or replace the cutting line. |

| Excessive Vibration | Loose screws or unbalanced components | Tighten screws and check for balance. |

| Fuel Leaks | Worn seals or cracked fuel lines | Replace seals and inspect fuel lines. |

Locating Part Numbers and Labels

Identifying the correct identifiers and labels for various components is crucial for efficient maintenance and repair. Understanding how to find these identifiers ensures that users can source the right replacements, enhancing the longevity and performance of their equipment. This process often involves checking specific areas where these markings are typically located, allowing for a smooth troubleshooting experience.

Common Locations for Identifiers

Component identifiers and labels are generally placed in several predictable locations. Users should examine the following areas:

| Location | Description |

|---|---|

| Engine Housing | Look for labels on the sides or top, often providing model and serial numbers. |

| Frame | Inspect the frame for tags or stickers that may indicate specific component numbers. |

| User Manual | The manual often includes a detailed list of components with their corresponding identifiers. |

Using Manufacturer Resources

Utilizing resources provided by the manufacturer can greatly assist in identifying specific numbers. Online databases and customer service can provide additional support in locating the necessary labels for a seamless repair process.

Comparing Different Troy-Bilt Models

When selecting the right equipment for outdoor maintenance, it is crucial to understand the variations among available models. Each variant offers unique features tailored to specific gardening needs. This section delves into the distinctions between popular models, highlighting their capabilities and performance.

Performance Features

Different models showcase a range of performance attributes that cater to various tasks. Here are some key aspects to consider:

- Engine power: Variations in horsepower affect the overall efficiency and cutting ability.

- Cutting width: A wider cutting path can reduce the time required to complete larger areas.

- Weight: Heavier models may provide more stability but can be more challenging to maneuver.

Design and Ergonomics

The design of each model impacts user experience significantly. Consider the following factors:

- Handle comfort: Ergonomically designed handles reduce fatigue during extended use.

- Adjustability: Models with adjustable shafts accommodate users of different heights.

- Storage options: Foldable or compact designs facilitate easier storage.

By understanding these differences, users can make informed choices to find the ideal tool that meets their landscaping demands effectively.

Installing New Parts Correctly

Ensuring the proper installation of components is crucial for optimal performance and longevity of your equipment. A well-executed assembly not only enhances functionality but also minimizes the risk of damage during operation. Understanding the steps involved can significantly improve your experience and satisfaction with your machine.

Preparation Before Installation

Before proceeding with the installation, gather all necessary tools and new components. Familiarize yourself with the specific requirements for your device, including any manufacturer guidelines. A clean workspace helps maintain organization and ensures that no small pieces are misplaced during the process.

Step-by-Step Installation Process

Begin by removing any existing elements that need replacement, taking care to follow any safety precautions. Install the new components systematically, ensuring each piece is positioned correctly and securely. Double-check connections and fittings to avoid future issues. Finally, run a brief test to confirm everything operates as intended, making adjustments if necessary.

Troubleshooting Problems with Diagrams

When dealing with mechanical issues, visual aids play a crucial role in identifying and resolving complications. Understanding the structure and functionality of equipment components allows users to diagnose problems more effectively. By referring to detailed illustrations, one can pinpoint areas of concern and facilitate efficient repairs or adjustments.

Common Issues and Their Solutions

Frequently encountered difficulties may include malfunctioning parts or inadequate performance. Identifying these issues through diagrams can streamline the troubleshooting process. For instance, if a particular section is not functioning as intended, examining its corresponding illustration may reveal misalignments or necessary replacements. Clear visuals serve as a guide for users to address issues methodically.

Benefits of Utilizing Visual References

Employing visual references not only simplifies the troubleshooting process but also enhances comprehension of the overall system. Users can grasp the relationships between components, allowing for a holistic approach to problem-solving. By following the visual cues, even those with minimal experience can navigate through repairs confidently, ensuring optimal functionality of their equipment.