Modern cleaning appliances have evolved into efficient tools, designed to tackle even the most demanding household tasks. These machines are composed of various essential elements that work together to ensure optimal performance. Familiarizing yourself with these components can help enhance their longevity and functionality.

In this guide, we’ll explore the internal and external features of these devices, providing a clear overview of how each element contributes to the overall operation. Whether it’s for regular maintenance or troubleshooting, understanding how everything fits together is key to keeping your cleaning appliance in top shape.

By taking a closer look at the structure and configuration, you can gain valuable insights into maintaining and repairing your device. Let’s break down the most important sections and how they influence efficiency and usability.

Exploring the Components of a Shark Navigator

Understanding the internal elements of a cleaning device helps to enhance its performance and prolong its lifespan. By breaking down the various mechanisms within, it becomes easier to maintain and troubleshoot any potential issues that may arise during regular use.

Main Functional Systems

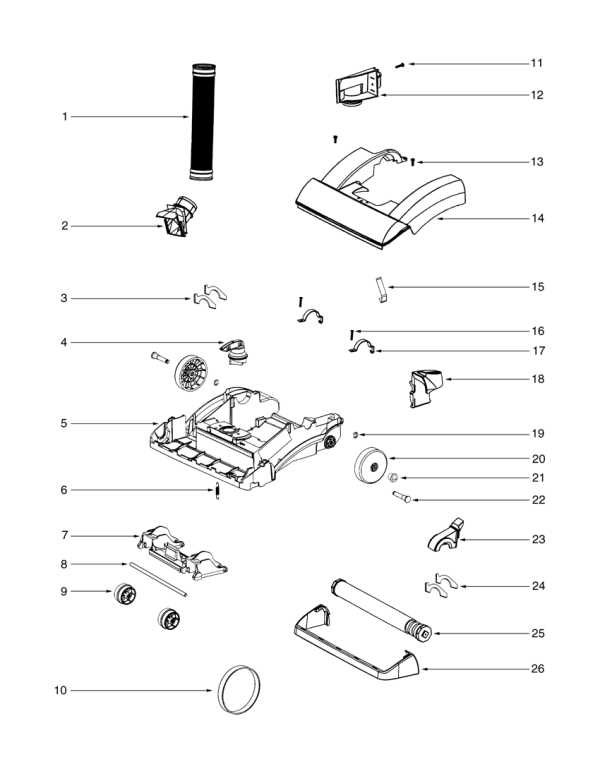

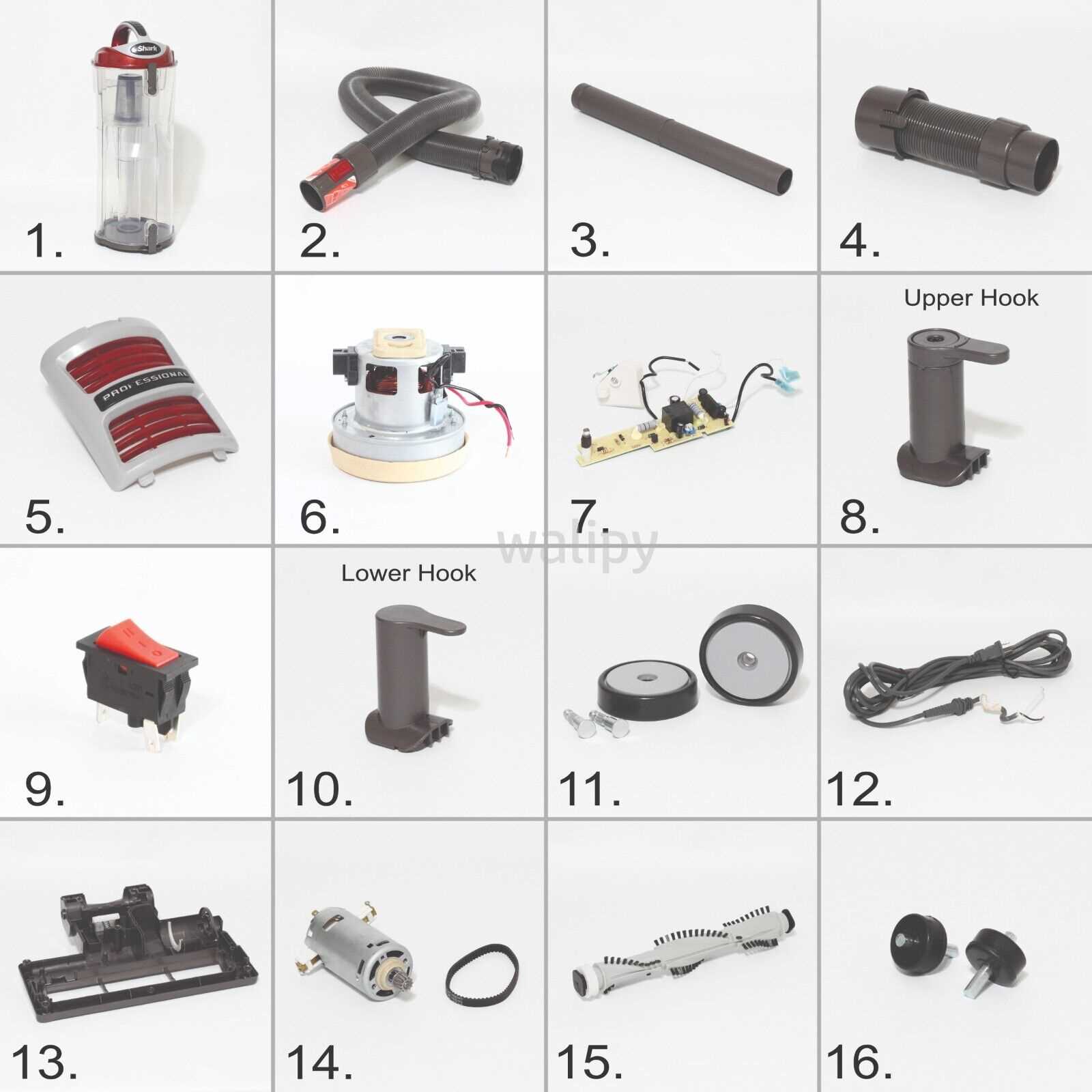

The device is built around several crucial systems that work together to ensure efficient operation. The first key element is the motor assembly, which drives the suction force. Another important system involves the brush roller, responsible for agitating surfaces to lift dirt and debris. These components are supported by airflow channels and filtration mechanisms, which trap unwanted particles.

Connections and Power Flow

To ensure everything operates seamlessly, the internal wiring and electrical connectors play a vital role. These connections transmit power from the source to the various sections of the machine, keeping it functional. Maintaining these connections and understanding how power is distributed within the device can help in troubleshooting any malfunctions.

Key Features of the Vacuum Assembly

The assembly of this cleaning device includes several important elements that work together to provide efficient operation. Each component is designed to enhance functionality and improve the overall experience of keeping spaces clean.

- Suction Mechanism: The heart of the system ensures consistent airflow to capture dust and debris from various surfaces.

- Filtration System: Equipped with multiple layers to trap particles, it helps maintain air quality by reducing allergens and fine particles.

- Brush Roll: A rotating feature designed to loosen dirt from carpets and other surfaces, ensuring a deep clean.

- Adjustable Height: This function allows the device to adapt to different floor types, improving cleaning efficiency across a variety of surfaces.

- Easy Maneuverability: With smooth wheels and a lightweight design, the device glides easily, making it convenient to use in tight spaces.

Each of these components plays a vital role in creating a powerful and effective cleaning solution, allowing users to maintain cleanliness with minimal effort.

Understanding the Motor Unit Structure

The motor system plays a pivotal role in ensuring optimal functionality, providing the necessary force to drive various internal components. To gain a comprehensive understanding of how the motor unit operates, it’s essential to explore its arrangement and how each part contributes to efficient performance.

Main Components

The core of the motor system consists of multiple interconnected elements that work together to produce power. These include the primary rotor, the housing structure, and a set of bearings that enable smooth movement. Each part has a specific function, ensuring that energy is transmitted efficiently to other internal systems.

Component Interactions

Understanding the way the elements interact within the motor unit is key to recognizing how energy is generated and distributed. Below is a breakdown of the essential components and their role within the unit.

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotor | Generates rotational force to drive other parts.

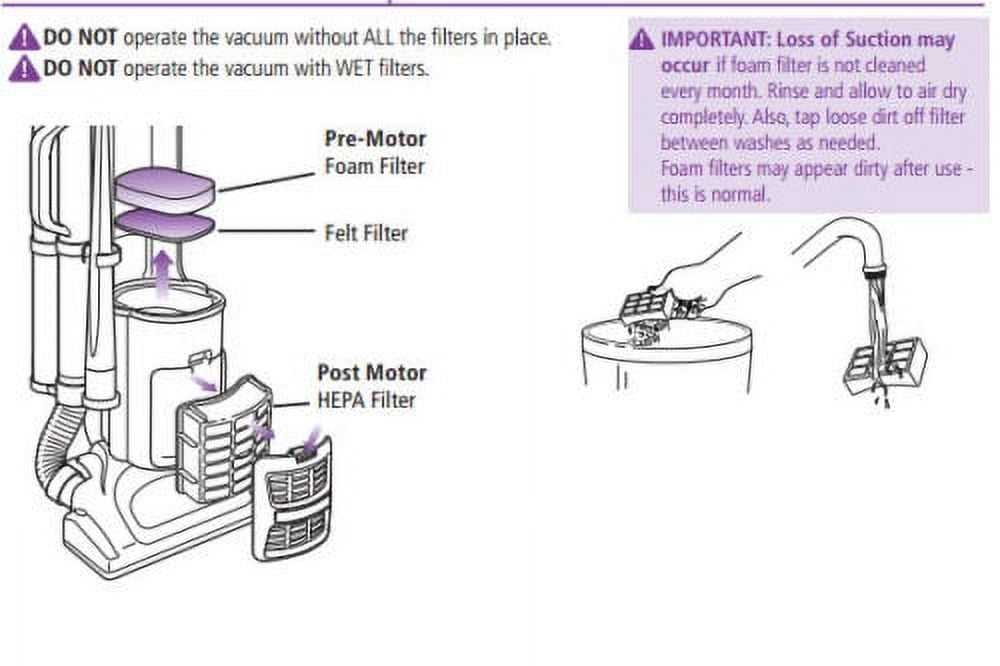

The Role of Filters in Cleaning Efficiency

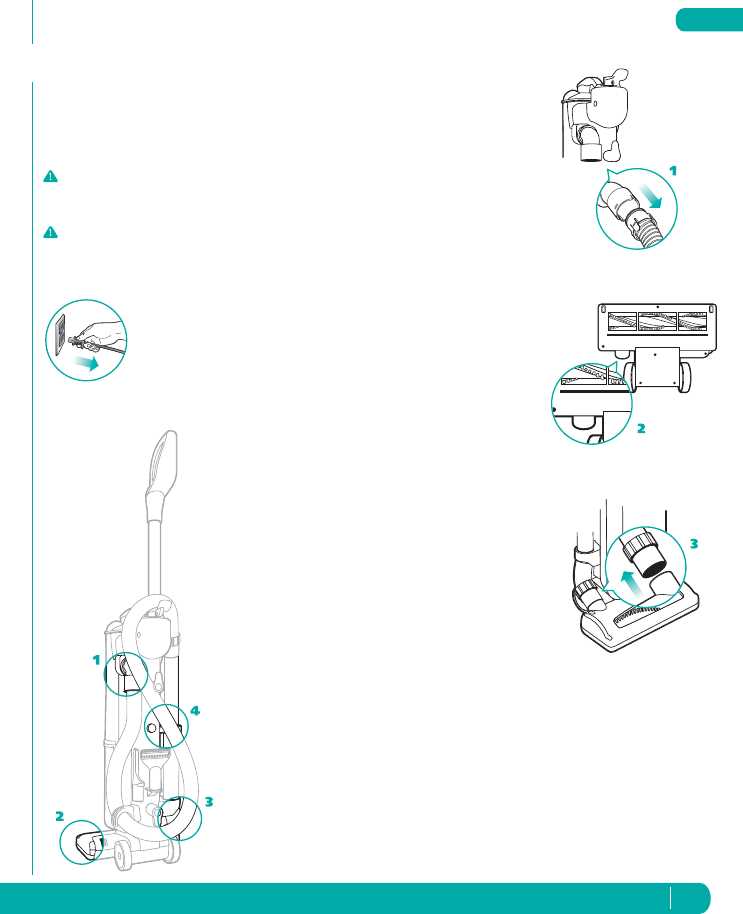

Filters play a vital role in maintaining the overall performance of any cleaning device by trapping small particles and preventing them from re-entering the air. They ensure that debris, dust, and other unwanted substances are efficiently captured during use. This process not only keeps surfaces clean but also enhances the air quality in the surrounding environment. Properly functioning filters help in maximizing the effectiveness of the cleaning process. Regular maintenance and timely replacement of these components are essential to maintain optimal results. Neglecting filter upkeep can reduce the efficiency, leading to a build-up of particles, which can negatively affect overall performance. In addition to ensuring a thorough clean, filters also protect the inner components of the device from potential damage caused by dust accumulation. This prolongs the lifespan of the equipment and helps avoid costly repairs or replacements. Analyzing the Brush Roll MechanismThe brush roll mechanism plays a crucial role in maintaining efficient cleaning performance. Its primary function is to sweep up debris by rotating at high speed, aiding in the removal of dirt and particles from various surfaces. Understanding how this component works and how it interacts with other internal systems is essential for ensuring optimal performance and longevity. Rotation and Motion: The rotation of the brush roll is driven by a motor, which powers the movement of the bristles. These bristles, in turn, agitate the surface, loosening embedded dirt. Proper alignment and consistent motion are key for thorough cleaning. Maintenance and Upkeep: Regular inspection and maintenance of the brush roll are necessary to prevent blockages and ensure smooth operation. Clearing out tangled hair or fibers from the bristles helps maintain their efficiency over time. Potential Issues: A malfunctioning brush roll can lead to reduced performance. Common issues may include the roll not spinning or uneven wear on the bristles. Addressing these problems Hose System and Its Connectivity

The hose assembly plays a crucial role in the overall functionality of cleaning devices, ensuring efficient airflow and maneuverability. This system comprises flexible tubing that connects various components, enabling seamless dirt pickup and surface cleaning. Understanding how this assembly interacts with the rest of the machine is essential for optimal performance. Connection Types are vital for maintaining the integrity of the hose assembly. Different types of connectors are used to attach the hose to the main unit and other accessories. Each connector serves a specific purpose, facilitating easy assembly and disassembly for maintenance or replacement. Compatibility with other components is also a key factor. The hose system must align perfectly with attachments such as brushes and nozzles to ensure effective operation. Any misalignment can lead to reduced suction power and hinder overall cleaning efficiency. Regular inspection of the hose system is necessary to identify any signs of wear or damage. Cracks, tears, or blockages can significantly impact performance. By routinely checking the condition of the hose and its connections, users can maintain optimal functionality and prolong the life of their cleaning device. Dust Bin: Design and FunctionalityThe container designed for collecting debris plays a crucial role in the overall efficiency of cleaning devices. Its structure and operational features significantly impact how effectively dirt and particles are captured during use. Understanding the design elements and the role this component plays can enhance users’ experience and maintenance practices. Key Features

Functionality Aspects

How the Power Cord Enhances UsabilityThe power cord serves as a crucial element that significantly improves the functionality of cleaning devices. Its design and length directly influence how easily one can maneuver the appliance throughout different areas of a space. A well-engineered cord offers the convenience of reaching distant outlets without the need for extensions or constant repositioning. This flexibility allows users to clean larger areas efficiently, minimizing interruptions and enhancing the overall cleaning experience. Additionally, the cord’s length can reduce the hassle of changing power sources frequently, making it easier to tackle extensive tasks. Moreover, a power cord that is designed with user comfort in mind often features tangle-free technology, which prevents knots and entanglements during storage. This practical aspect ensures that the device is always ready for use, further enhancing its accessibility and user satisfaction. Attachments and Their Specialized UsesVarious tools designed for cleaning equipment serve distinct functions, enhancing efficiency and effectiveness during use. Each accessory is tailored to address specific cleaning tasks, ensuring optimal performance on a variety of surfaces. Understanding these attachments can greatly improve the overall cleaning experience. Upholstery ToolThis versatile attachment is ideal for maintaining furniture and fabrics. It effectively removes dirt, pet hair, and allergens from soft surfaces, ensuring a thorough clean without damaging delicate materials. Its design allows for easy maneuverability, making it perfect for reaching tight spaces and corners. Crevice Tool

Designed for hard-to-reach areas, this narrow accessory excels at removing dust and debris from tight spots. Whether it’s between cushions, along baseboards, or in the corners of rooms, the crevice tool ensures that no dirt is left behind. Its slim profile allows for precision cleaning, making it an essential component for comprehensive upkeep. Handle and Steering Mechanisms ExplainedThe effectiveness of a cleaning device greatly relies on its handle and steering features, which facilitate maneuverability and user comfort. These components play a vital role in ensuring ease of use while navigating various surfaces and obstacles within a space. Understanding the mechanics behind these elements can enhance user experience and operational efficiency. Handles are designed to provide a secure grip, allowing the user to control the movement of the device smoothly. Typically crafted from ergonomic materials, they help reduce fatigue during prolonged usage. Steering mechanisms, on the other hand, enable directional changes, assisting in reaching tight spots and around furniture with minimal effort.

By comprehending these mechanisms, users can maximize the performance of their cleaning device, ensuring it meets their needs while simplifying the task of maintaining cleanliness in various environments. Maintenance Tips for Long-Lasting Performance

To ensure that your cleaning device continues to operate efficiently over time, regular upkeep is essential. Proper care not only enhances functionality but also extends the lifespan of the appliance. Implementing a few straightforward practices can help maintain optimal performance and prevent potential issues. Regular Filter CleaningKeeping filters clean is crucial for maintaining airflow and suction power. Check the filters frequently, and rinse them under running water to remove accumulated dust and debris. Make sure to allow them to dry completely before reinserting them into the unit. Inspecting and Replacing Belts

Monitoring the belts for signs of wear and tear can prevent more significant problems. Look for fraying or damage, and replace them promptly to ensure smooth operation. A well-maintained belt not only enhances performance but also reduces the risk of motor strain. |