| Blades |

Curved elements that push water, creating thrust to move the vessel forward or backward. |

Common Wear Points in SX Outdrives

Over time, marine propulsion systems can experience degradation in specific areas due to constant use, harsh water conditions, and mechanical stress. Identifying these high-stress regions is crucial for maintaining efficiency and preventing unexpected breakdowns. Regular inspections and preventive care can greatly extend the lifespan of these components.

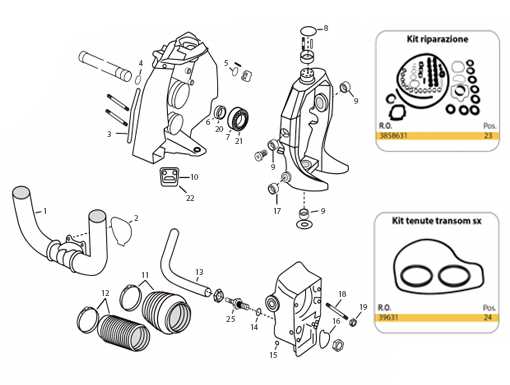

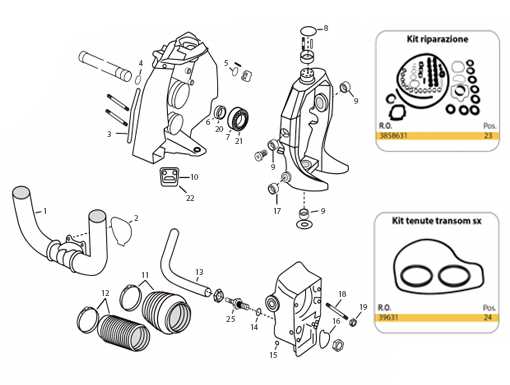

Seals and Gaskets: These elements are subjected to significant wear due to exposure to both water and high-pressure operations. Their deterioration can lead to leaks, affecting the overall performance and safety of the system.

Bearings: Bearings play a vital role in ensuring smooth rotation and reducing friction. However, they are prone to wear over time, especially if not adequately lubricated. This can result in grinding noises or a reduction in efficiency.

Propeller Shaft: The shaft that transfers power to the propeller is another area prone to wear. Continuous exposure to torque and water can cause erosion or bending,

Maintenance Tips for Volvo Penta SX Parts

Proper upkeep of marine propulsion systems is essential for long-lasting performance and smooth operation. Regular care can help prevent mechanical issues and ensure that your vessel remains reliable in a variety of conditions.

Regular Inspection

Frequent inspections should be part of your routine to detect any early signs of wear or corrosion. Pay special attention to moving components and exposed areas that may be vulnerable to damage. Early detection of issues can save time and avoid costly repairs.

- Check for unusual noises or vibrations during operation.

- Inspect seals and gaskets for leaks or signs of deterioration.

- Ensure that lubrication points are properly maintained to reduce friction.

Cleaning and Lubrication

Consistent cleaning and application of lubricants play a critical role in maintaining the system’s longevity. Saltwater and debris can accumulate, leading to corrosion and mechanical failure if left untreated.

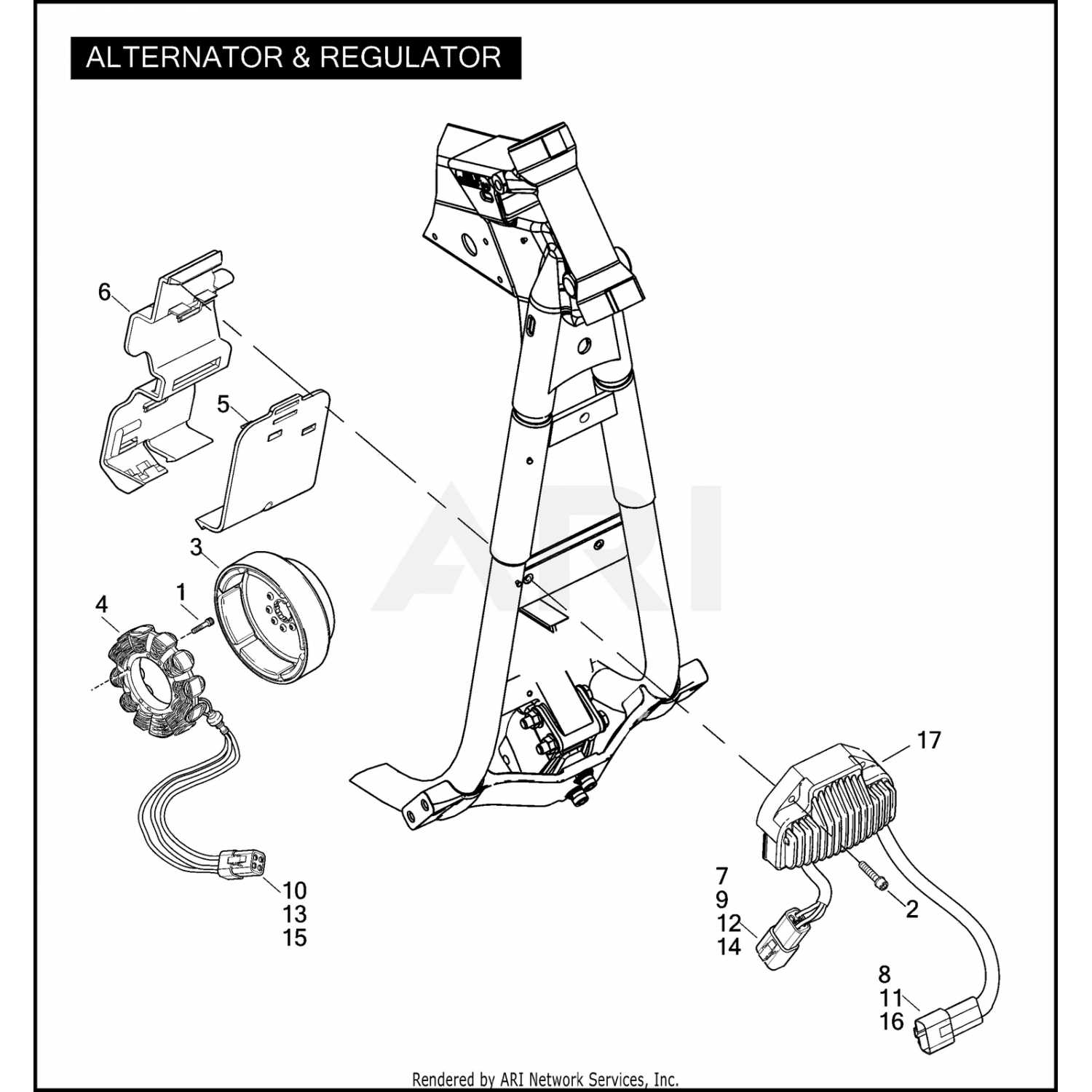

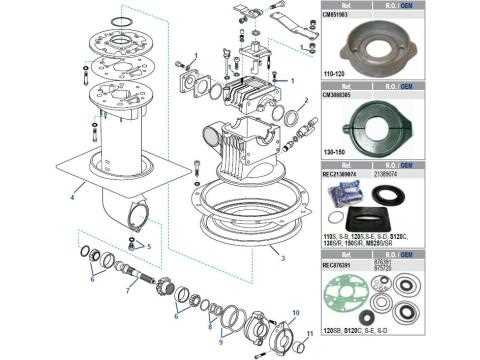

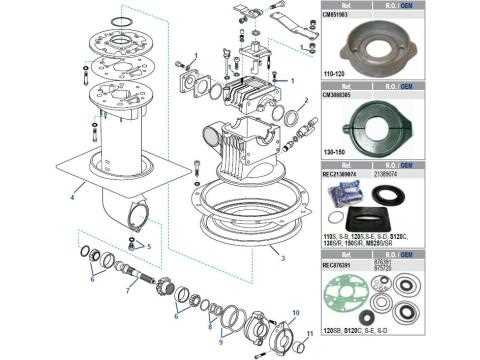

Understanding the Cooling System in SX Outdrives

The cooling mechanism in marine propulsion systems plays a vital role in maintaining optimal operating temperatures, ensuring efficiency and longevity. This system is responsible for dissipating excess heat generated during engine operation, protecting components from overheating and subsequent damage. Proper cooling is essential for maximizing performance and reliability, making it a crucial aspect of these marine setups.

Key Components of the Cooling Mechanism

At the heart of the cooling system are several critical elements. The water pump draws water from the surrounding environment and circulates it through the engine and related components. The heat exchanger is another essential component, facilitating the transfer of heat from the engine coolant to the incoming water, which helps regulate the temperature effectively. Additionally, thermostats play a key role in monitoring and controlling the flow of coolant, ensuring that the engine operates within the ideal temperature range.

Importance of Regular Maintenance

Regular inspection and maintenance of the cooling system are paramount to prevent potential issues. Clogged filters or damaged pumps can significantly impede performance, leading to overheating and costly repairs. Ensuring that all components are clean and functioning properly will enhance the overall efficiency and reliability of the marine propulsion system, allowing for safe and enjoyable operation on the water.

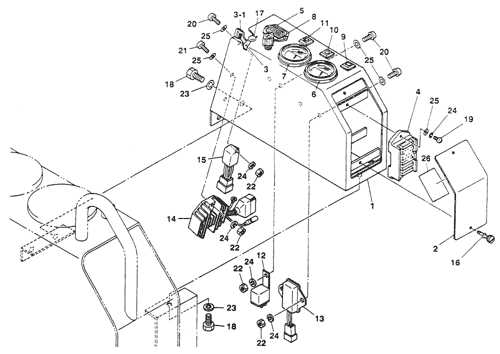

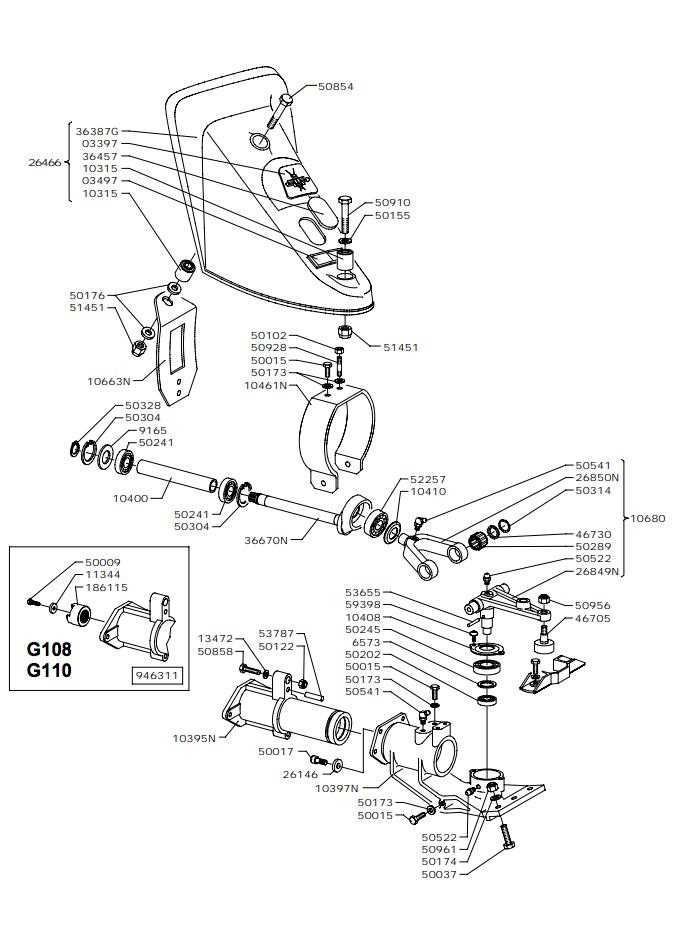

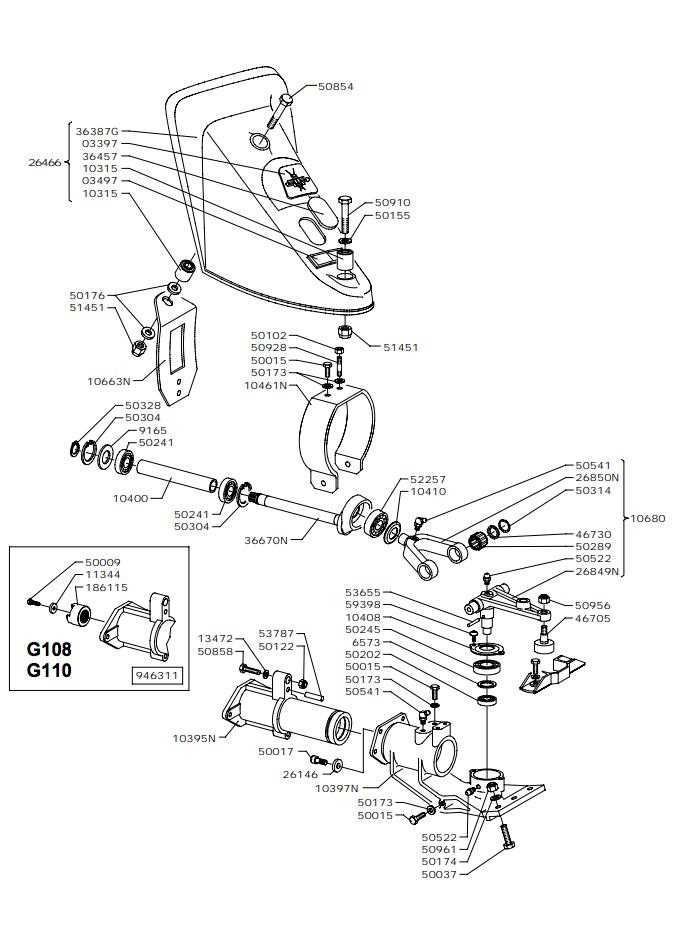

Steering Mechanism in Volvo Penta SX Drives

The steering system is a vital component of marine propulsion systems, ensuring precise control and maneuverability of the vessel. This mechanism allows for seamless navigation and handling, particularly in challenging water conditions. By integrating various components, the system enhances the overall performance and responsiveness of the drive unit, contributing to a more enjoyable boating experience.

Components of the Steering System

The steering assembly typically comprises several key elements, including the helm, steering cable, and the actuator. The helm serves as the control interface for the operator, enabling adjustments to the vessel’s direction. The steering cable transmits the input from the helm to the actuator, which ultimately alters the angle of the drive unit for directional changes. Together, these components work harmoniously to facilitate smooth and accurate steering.

Operational Mechanism

When the operator turns the helm, the steering cable transfers this motion to the actuator. This component then adjusts the angle of the drive, directing the propeller thrust to change the vessel’s trajectory. The effectiveness of this system is influenced by several factors, including the calibration of the steering gear and the overall condition of the mechanical components. Regular maintenance is essential to ensure optimal functionality and safety during operation.

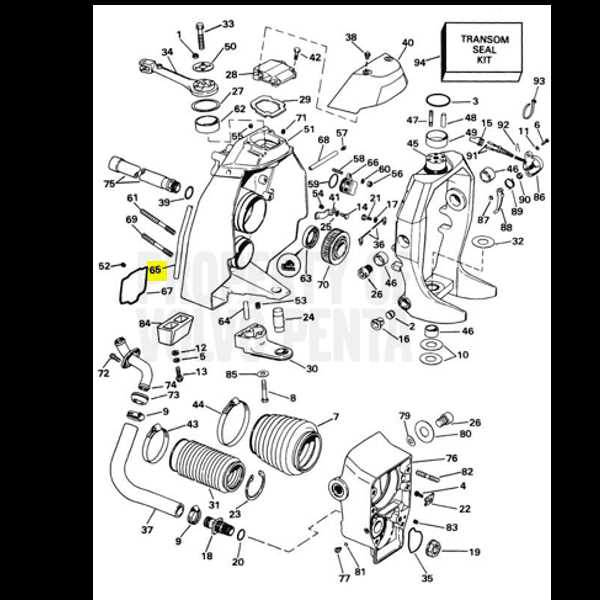

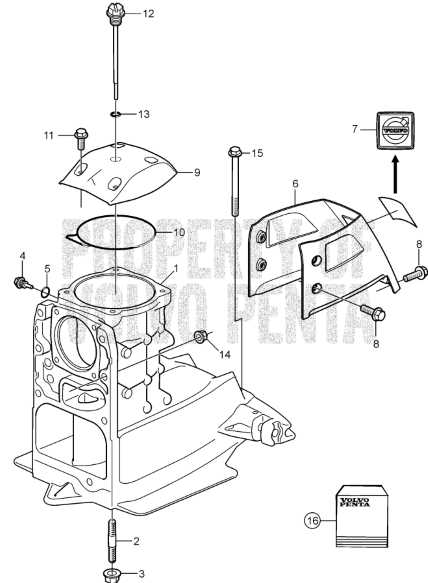

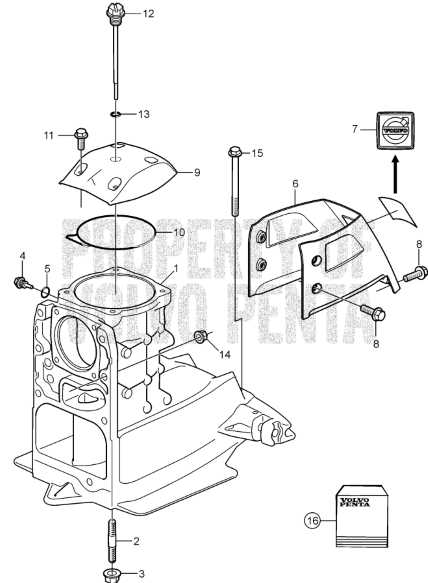

Replacing Seals and Bearings in SX Models

Maintaining the integrity of your propulsion system is crucial for optimal performance. One essential aspect of this maintenance involves the replacement of seals and bearings, which can wear out over time due to constant exposure to water and mechanical stress. Understanding the process of replacing these components can significantly enhance the longevity and reliability of your equipment.

Importance of Regular Maintenance

Regular maintenance not only ensures smooth operation but also prevents costly repairs in the future. Here are some key benefits:

- Improved efficiency and performance

- Extended lifespan of the propulsion system

- Reduced risk of leaks and mechanical failures

Steps for Replacing Seals and Bearings

- Gather necessary tools and replacement parts.

- Remove the drive unit from the boat for easier access.

- Carefully detach the old seals and bearings, taking note of their arrangement.

- Clean the housing thoroughly to remove any debris or old lubricant.

- Install the new seals and bearings, ensuring they are seated correctly.

- Reassemble the drive unit and reinstall it on the boat.

- Test the system to ensure everything is functioning properly.

Following these steps will help maintain the functionality of your system, ultimately leading to a safer and more enjoyable experience on the water.

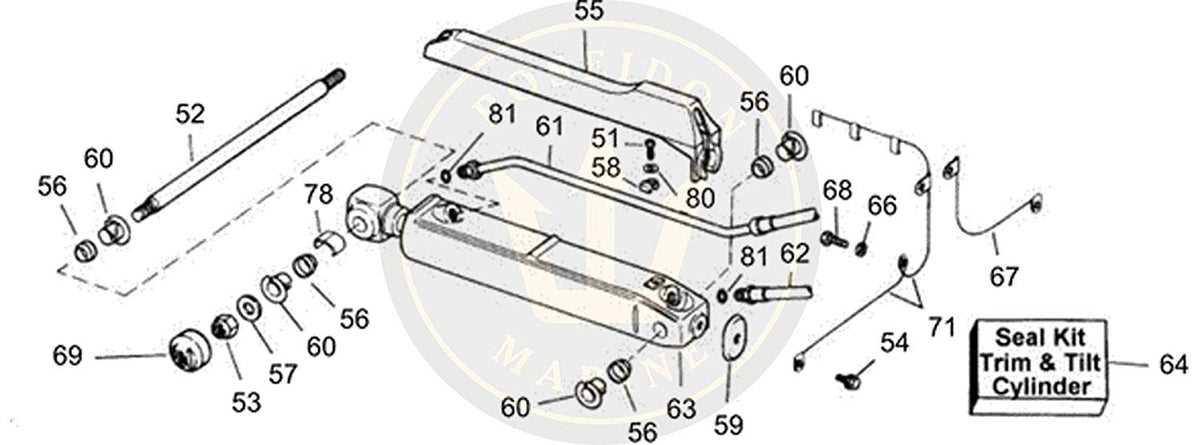

Volvo Penta SX Trim and Tilt System

The trim and tilt mechanism is a crucial component that enhances the performance and maneuverability of marine propulsion systems. This system enables adjustments to the angle of the drive unit relative to the transom, optimizing handling characteristics and fuel efficiency.

Key features of this system include:

- Trim Function: This allows for adjusting the drive angle to achieve better hydrodynamics, improving speed and reducing drag.

- Tilt Function: It enables the raising and lowering of the drive unit, making it easier to navigate shallow waters and protect the propeller from damage.

Components involved in this system are designed for reliability and ease of use. Regular maintenance is essential to ensure optimal performance. Here are some important aspects to consider:

- Hydraulic System: This system relies on hydraulic fluid to operate the trim and tilt functions smoothly.

- Trim Tab: An adjustable plate that helps stabilize the vessel during operation by counteracting bow rise.

- Actuator: This motorized device controls the movement of the drive unit, responding to the operator’s commands.

Understanding the operational principles and maintenance requirements of the trim and tilt system is vital for maximizing the efficiency and lifespan of the propulsion unit.

How to Troubleshoot Volvo Penta SX Issues

Troubleshooting mechanical systems can often seem daunting, but with a systematic approach, identifying problems becomes manageable. This section provides valuable insights into diagnosing common issues, allowing you to maintain optimal performance of your marine propulsion unit. By following these guidelines, you can ensure that your vessel operates smoothly and efficiently.

Identifying Common Symptoms

Start by observing any unusual behavior from the propulsion mechanism. Look for signs such as excessive vibrations, unusual noises, or difficulties in shifting gears. Additionally, check for fluid leaks or changes in performance while under load. Documenting these symptoms will assist in pinpointing the source of the issue.

Conducting Basic Inspections

Begin with a thorough inspection of the external components. Examine the connections, seals, and hoses for any wear or damage. Next, check the fluid levels and conditions, as low or contaminated fluids can significantly affect functionality. If necessary, perform a visual inspection of the internal components for signs of corrosion or wear. By addressing these basic checks, you can often identify the root cause of the problem before delving into more complex diagnostics.