The intricate world of marine propulsion systems is vital for ensuring optimal performance and longevity. A thorough understanding of the individual elements that comprise these systems can greatly enhance maintenance practices and troubleshooting efforts. Knowing how these components interact allows for better care and efficient operation of the vessel.

Comprehensive insights into the various parts can significantly aid in identifying issues and streamlining repairs. By analyzing the arrangement and function of each element, boat owners and technicians can improve their service routines. Awareness of these components not only contributes to effective management but also promotes safe and reliable navigation.

Additionally, possessing detailed knowledge about the structural organization facilitates informed decisions regarding upgrades and replacements. Familiarity with the different features can lead to enhanced functionality, ensuring the marine engine meets both performance and regulatory standards.

Understanding Volvo Penta SX Parts

When it comes to marine engines, having a clear understanding of the components involved is crucial for effective maintenance and operation. This section will delve into the essential elements that make up a typical inboard engine system, focusing on the various parts and their functions. Familiarity with these elements will empower owners and technicians to troubleshoot issues and ensure optimal performance.

Key Components of the System

- Engine Block: The foundation of the engine, housing the cylinders and other critical components.

- Fuel System: Responsible for delivering fuel to the engine, ensuring efficient combustion.

- Cooling System: Maintains the engine temperature to prevent overheating, which can lead to damage.

- Exhaust System: Expels gases produced during combustion, crucial for engine performance.

Maintenance Tips

- Regularly inspect all components for wear and tear.

- Ensure the cooling system is functioning properly to avoid overheating.

- Check fuel lines for leaks to maintain efficient operation.

- Perform routine oil changes to keep the engine lubricated.

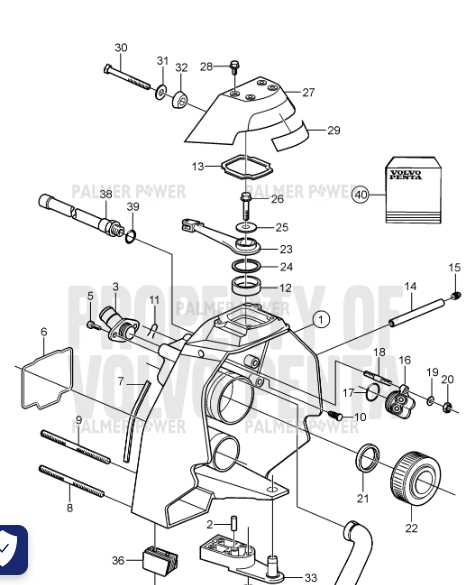

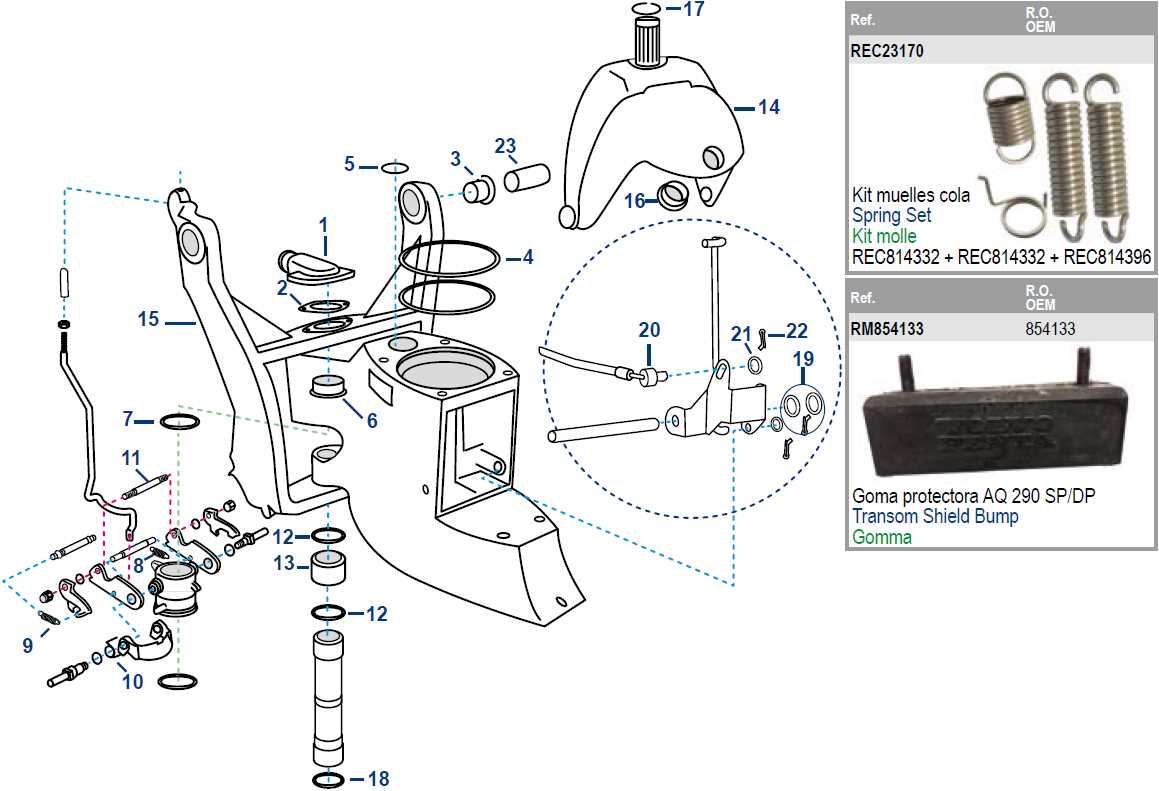

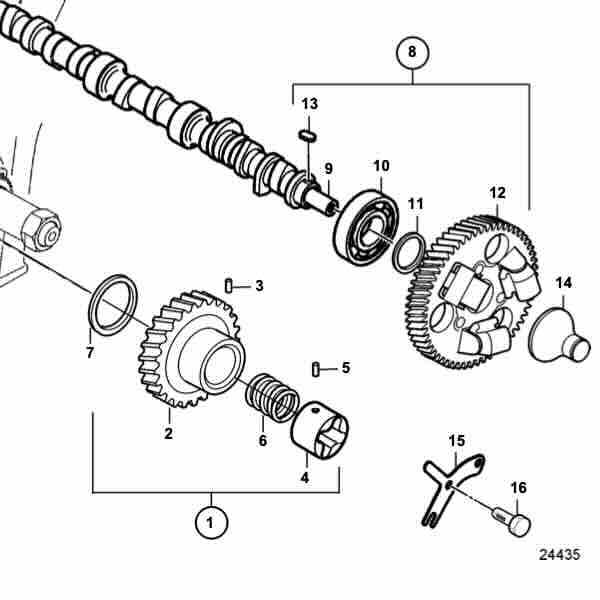

Key Components of the SX Drive

The SX drive system consists of several essential elements that work together to ensure efficient performance and reliability. Understanding these critical components is vital for maintaining and optimizing the overall functionality of the system.

1. Gearbox: The gearbox is responsible for transmitting power from the engine to the propeller. It allows for gear shifting, which optimizes the drive’s torque and speed.

2. Propeller: The propeller is the primary component that converts engine power into thrust. Its design and pitch are crucial for achieving the desired speed and maneuverability.

3. Stern Drive Unit: This unit integrates the gearbox and propeller shaft, playing a pivotal role in the drive’s operation. It also houses the hydraulic trim system, allowing for adjustments to the drive angle.

4. Anodes: Anodes are sacrificial components that protect metal parts from corrosion. Regular inspection and replacement are essential for maintaining the longevity of the drive.

5. Trim Tab: The trim tab helps stabilize the vessel and improve fuel efficiency by adjusting the angle of the drive relative to the water surface.

By familiarizing yourself with these core elements, you can ensure better maintenance and performance of the SX drive system, leading to a more enjoyable boating experience.

Importance of Proper Maintenance

Ensuring regular upkeep of marine equipment is essential for optimal performance and longevity. Routine checks and timely servicing can prevent unexpected breakdowns, enhance safety, and improve efficiency during operation. By investing in maintenance, owners can safeguard their assets and enjoy smoother journeys on the water.

Regular inspections and replacements of worn components help maintain the integrity of the system. This proactive approach reduces the risk of severe damage that could lead to costly repairs or replacements. Moreover, proper maintenance practices contribute to better fuel efficiency and lower emissions, aligning with environmental standards.

Ultimately, the commitment to diligent care reflects positively on the overall user experience, providing peace of mind and confidence while navigating aquatic environments. A well-maintained vessel is not only a testament to responsible ownership but also ensures that every trip is enjoyable and worry-free.

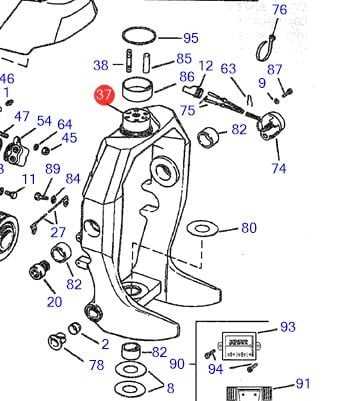

How to Identify Parts Quickly

Recognizing components swiftly is essential for effective maintenance and repair. Familiarizing yourself with the various elements can save time and enhance efficiency during tasks. A systematic approach to understanding the different pieces will streamline the process significantly.

Start by obtaining a comprehensive reference that illustrates the components. This can include manuals, online resources, or schematics. Reviewing these materials allows you to associate each element with its function and location, making it easier to pinpoint specific items when needed.

Additionally, labeling and organizing tools and materials can greatly enhance identification speed. Using clear, descriptive tags for containers or storage areas helps in locating items quickly. Developing a consistent storage method ensures that every piece has a designated spot, minimizing confusion during assembly or repairs.

Moreover, engaging with online communities and forums can provide valuable insights. Experienced individuals often share tips and tricks for identifying components efficiently. Participating in discussions or seeking advice can enhance your knowledge base and facilitate quicker recognition in practical scenarios.

Common Issues with SX Parts

The reliability of marine propulsion systems is crucial for seamless operation on the water. However, various components can experience wear and tear or malfunction over time, leading to performance issues. Identifying these common challenges is essential for effective maintenance and ensuring the longevity of the system.

One frequent concern involves the wear of seals and gaskets, which can lead to leaks and reduced efficiency. Additionally, corrosion is a prevalent issue, especially in saltwater environments, impacting the integrity of metal components. It’s also not uncommon for mechanical parts to suffer from misalignment, resulting in abnormal vibrations and increased stress on the system.

Another aspect to consider is the electronic systems associated with propulsion. Faulty wiring or connections can lead to intermittent functionality, causing unexpected failures during operation. Regular inspections and preventive measures are vital to address these issues before they escalate into more significant problems.

Where to Find Replacement Parts

Finding suitable components for your marine engine can significantly enhance performance and reliability. Numerous options exist for sourcing these essential items, ensuring your vessel remains in top condition.

Authorized Dealers: One of the most reliable ways to acquire the necessary components is through authorized dealers. These establishments often stock original items and can provide expert guidance tailored to your specific requirements.

Online Marketplaces: The internet offers various online platforms where you can explore a wide selection of aftermarket options. Websites specializing in marine supplies can provide competitive prices and user reviews, aiding in informed decision-making.

Local Marine Supply Stores: Visiting nearby marine supply retailers can yield valuable insights. Staff members typically possess extensive knowledge and can assist you in locating the exact items you need.

Forums and Community Groups: Engaging with online forums and community groups dedicated to boating enthusiasts can be beneficial. Members often share resources and recommendations for sourcing reliable components at reasonable prices.

Benefits of OEM Parts Over Aftermarket

Choosing original equipment manufacturer components offers several advantages that can significantly enhance the performance and longevity of your vessel’s systems. These components are specifically designed to fit seamlessly and work harmoniously with your equipment, ensuring optimal functionality and reliability.

Quality Assurance

OEM components are manufactured to strict specifications and quality standards. This ensures that each part meets the rigorous demands of marine environments, providing superior durability and performance compared to generic alternatives. The consistent quality found in OEM parts minimizes the risk of failure, which can lead to costly repairs and downtime.

Warranty and Support

Another significant benefit of selecting original components is the warranty that typically accompanies them. Manufacturers often provide extensive warranties on their products, offering peace of mind and protection against defects. Additionally, support from the manufacturer can be more reliable, as they have in-depth knowledge of their components and can offer expert assistance when needed.

DIY Repairs and Parts Replacement

Engaging in self-repair and component substitution can be a rewarding experience for enthusiasts looking to maintain their vessels. Understanding the layout and functionality of various elements allows for efficient troubleshooting and cost-effective solutions. By acquiring the necessary skills and knowledge, individuals can extend the lifespan of their marine equipment and enhance performance.

Common Issues and Solutions

Many common problems can arise in marine machinery, such as leaks, overheating, and mechanical failures. Identifying these issues early on is crucial. Simple tasks like tightening loose fittings, replacing worn seals, or adjusting alignment can prevent more significant repairs down the line. Thorough inspections and proactive maintenance are essential for optimal operation.

Essential Tools for Repairs

Having the right tools on hand is vital for any repair job. A comprehensive toolkit should include wrenches, screwdrivers, pliers, and specialized instruments tailored to the machinery being worked on. Additionally, having a reliable manual or resource for reference can greatly aid in understanding specific procedures and safety measures.

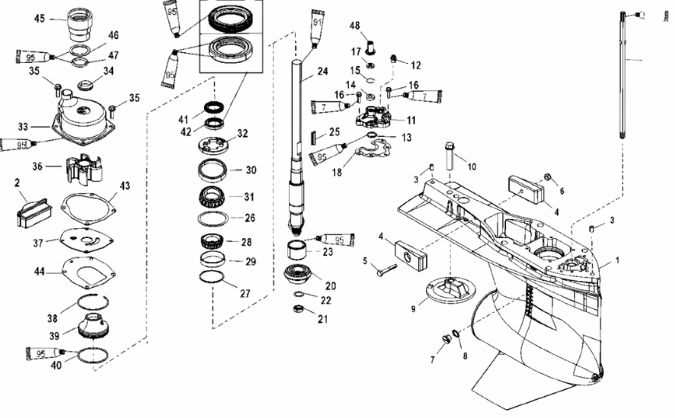

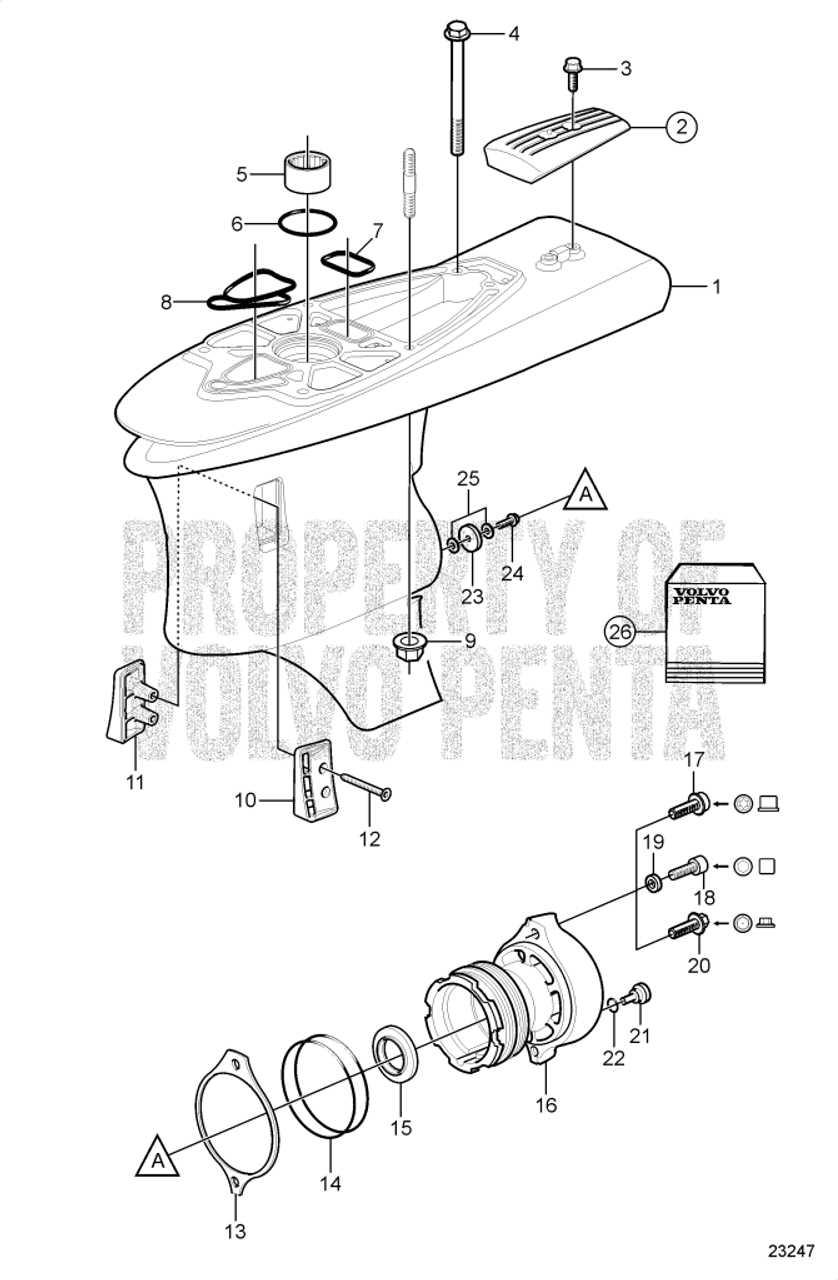

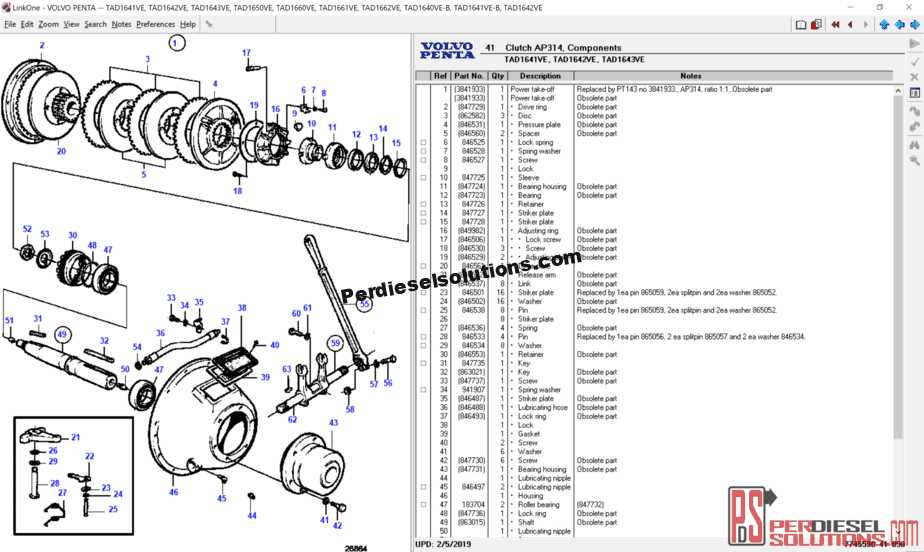

Exploring the Parts Diagram

This section delves into the intricacies of component layout for marine propulsion systems, providing insights into the various elements involved in the assembly and functionality. Understanding these elements is crucial for both maintenance and enhancement, ensuring optimal performance and longevity of the system.

Understanding the Layout

The visual representation of the assembly highlights how different components interact with each other. Each piece plays a vital role in the overall efficiency, and recognizing their positions aids in troubleshooting and repairs.

Key Elements in the Assembly

Familiarizing oneself with the essential components can significantly streamline maintenance efforts. Below is a table summarizing the key elements typically found in such a layout:

| Component Name | Function | Common Issues |

|---|---|---|

| Drive Shaft | Transmits power from the engine to the propeller | Worn bearings, vibration |

| Propeller | Generates thrust to propel the vessel | Damage, imbalance |

| Transmission | Controls the power output to the drive shaft | Slippage, noise |

| Coupling | Connects the engine to the drive shaft | Loose fittings, wear |

Ordering Parts: Tips and Tricks

Acquiring components for your marine engine can be a straightforward process with the right approach. Understanding the necessary steps can help ensure that you get the correct items efficiently and effectively.

Research Before You Buy

Before placing any orders, take the time to investigate the specifications you require. Consult manuals or online resources to gather detailed information about the components necessary for your engine’s maintenance or repair. This knowledge can save you from making costly mistakes.

Utilize Reputable Suppliers

Choosing reliable vendors is crucial. Look for suppliers who specialize in marine equipment and have a good reputation among users. Customer reviews and ratings can provide insights into their service quality and product availability.

In summary, diligent research and selecting trustworthy suppliers are essential steps for a smooth ordering process. Ensure that you are well-informed to make the best purchasing decisions.

Frequently Asked Questions About SX Parts

This section aims to address common inquiries related to components of the SX system. Understanding these elements can greatly enhance your experience and maintenance efforts.

What are the main components of the SX system?

The SX system includes various essential elements that contribute to its performance, such as the drive unit, steering mechanism, and control systems. Each component plays a critical role in ensuring smooth operation and reliability.

How do I identify if a component needs replacement?

Signs of wear or malfunction can manifest as unusual noises, decreased performance, or visible damage. Regular inspections are vital to determine the condition of each component and to ensure optimal functionality.

Where can I find quality replacements for these components?

Quality replacements can be sourced from authorized dealers or specialized retailers that offer a wide selection of high-grade alternatives, ensuring compatibility and durability.

Are there any maintenance tips for prolonging component life?

Regular maintenance, including cleaning, lubrication, and timely inspections, is crucial for prolonging the lifespan of these elements. Following manufacturer recommendations can prevent premature wear and costly repairs.

Can I install these components myself?

While some components may be installed by an experienced DIY enthusiast, others may require professional assistance. It’s essential to assess your skill level and the complexity of the installation before proceeding.

Understanding Warranty and Support Options

When investing in marine equipment, it’s crucial to comprehend the various warranty and support options available. These services ensure that users have access to assistance, repairs, and replacements, enhancing the overall experience and reliability of the product.

Types of Warranties

- Limited Warranty: This type covers specific parts and labor for a designated period, offering peace of mind regarding product performance.

- Extended Warranty: Available for purchase, this option provides additional coverage beyond the standard warranty period.

- Lifetime Warranty: Some products come with a lifetime guarantee, covering defects for the entire lifespan of the item.

Support Services

- Customer Service: Reach out to support teams via phone or email for any inquiries related to your equipment.

- Technical Assistance: Get help from experts for installation, troubleshooting, and maintenance issues.

- Replacement Parts: Access to genuine parts ensures that your equipment operates optimally and maintains its value.