This section aims to provide a comprehensive overview of the various elements that contribute to the structure of heavy-duty vehicles. A thorough understanding of these components is essential for effective maintenance and repair, ensuring optimal performance and longevity of the machinery.

Each component serves a specific function, working together to create a reliable and efficient machine. By exploring the configurations and relationships between these elements, one can gain insights into the overall design and engineering principles that govern their operation.

Equipped with this knowledge, individuals will be better prepared to identify issues, perform necessary repairs, and enhance the functionality of their vehicles. Understanding the layout and interaction of these components is a vital step for anyone involved in the care and operation of robust machinery.

In the construction of various vehicle elements, the selection of materials plays a crucial role in determining strength, durability, and performance. Different components are made from a variety of substances, each chosen for its unique properties and suitability for specific applications.

Common Materials

The most frequently utilized materials include metals, plastics, and composites. Each material offers distinct advantages that contribute to the overall efficiency and effectiveness of the vehicle structure.

| Material | Properties | Applications |

|---|---|---|

| Steel | High strength, durability | Structural components, chassis |

| Aluminum | Lightweight, corrosion-resistant | Body panels, engine components |

| Plastic | Lightweight, versatile | Interior parts, trim |

| Composite | Strong, lightweight | Specialty applications, performance parts |

Importance of Material Selection

Choosing the right material is essential not only for performance but also for safety and sustainability. Advances in technology continue to expand the range of materials available, allowing for more innovative and efficient designs.

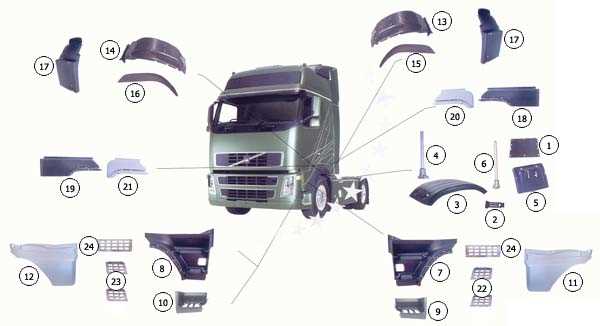

Common Body Components and Their Functions

This section focuses on essential elements that contribute to the structure and performance of heavy vehicles. Understanding these components is crucial for maintenance and operation, as each serves a specific purpose in ensuring the vehicle’s efficiency and safety.

- Chassis: The main framework that supports the vehicle, providing stability and strength.

- Cab: The driver’s compartment, designed for comfort and control, housing essential instruments and controls.

- Fenders: Components that cover the wheels, protecting them from debris and enhancing aerodynamics.

- Doors: Allow access to the cab and cargo area, designed for safety and ease of use.

- Grille: Located at the front, it facilitates airflow to the engine while offering protection against external elements.

- Roof: Provides shelter for the cab and contributes to the overall aerodynamics of the vehicle.

Each of these elements plays a vital role in the overall functionality and durability of the vehicle, making their proper maintenance critical for long-term performance.

How to Read Diagrams Effectively

Understanding visual representations is crucial for successful interpretation of complex information. These illustrations serve as guides, providing a structured way to convey details that may be difficult to express with words alone. Mastering the art of reading such representations can greatly enhance your ability to comprehend intricate systems.

Familiarize Yourself with Symbols

Each representation employs specific symbols and notations that carry particular meanings. Take the time to learn what these symbols signify. This foundational knowledge will aid in deciphering the information presented and improve your overall comprehension.

Follow the Flow of Information

Look for directional cues and pathways within the illustration. These elements indicate the relationship between different components. Tracking the flow allows for a better grasp of how each part interacts with others, leading to a more complete understanding of the entire system.

Maintenance Tips for Body Components

Regular care of external elements is crucial for ensuring longevity and optimal performance. These components not only enhance aesthetic appeal but also contribute to the vehicle’s overall functionality and safety. Adopting a proactive approach to upkeep can prevent costly repairs and extend the lifespan of your vehicle.

Regular Cleaning

Routine washing helps remove dirt, grime, and corrosive substances that can damage surfaces. Use mild detergents and soft cloths to avoid scratches. Pay special attention to areas where debris tends to accumulate, as this can lead to rust and deterioration over time.

Inspection and Repair

Frequent inspections are essential to identify signs of wear or damage. Look for cracks, dents, or loose fittings that may require immediate attention. Addressing minor issues promptly can prevent them from escalating into major repairs, ensuring that all external elements remain in optimal condition.

Identifying Replacement Parts

Determining the correct components for a vehicle’s restoration or repair is crucial for maintaining optimal performance and safety. Understanding the various elements involved can help streamline the selection process and ensure compatibility with the specific model in question.

Understanding Component Specifications

Each vehicle has unique specifications that dictate the necessary attributes of its individual elements. Familiarizing oneself with the dimensions, materials, and functional characteristics of these elements is essential. This knowledge allows for informed decisions when searching for suitable replacements.

Utilizing Reference Materials

Accessing reliable reference materials such as manuals, catalogs, or online resources can greatly aid in identifying the right components. These resources often provide detailed illustrations and descriptions, making it easier to compare existing elements with potential substitutes. Proper research ensures that the selected replacements will fit seamlessly and function effectively.

Customization Options for Volvo Trucks

When it comes to enhancing the performance and aesthetics of heavy-duty vehicles, numerous choices are available to owners. Tailoring these machines can significantly improve functionality and meet specific operational needs.

Several aspects can be adjusted to maximize efficiency and comfort. From interior fittings to exterior enhancements, each modification serves a distinct purpose.

| Modification Type | Description |

|---|---|

| Exterior Accessories | Includes bumpers, side skirts, and mud flaps that enhance appearance and aerodynamics. |

| Interior Upgrades | Custom seats, dashboard configurations, and storage solutions for improved driver experience. |

| Performance Enhancements | Upgraded exhaust systems and suspension components for better handling and power. |

| Technology Integration | Advanced navigation systems, telematics, and safety features for modern connectivity. |

Impact of Body Design on Performance

The configuration and structure of a vehicle significantly influence its functionality and efficiency. An optimized design can enhance aerodynamics, reduce weight, and improve stability, all of which contribute to overall performance.

Several factors play a crucial role in the relationship between design and performance:

- Aerodynamics: Streamlined shapes minimize air resistance, allowing for smoother movement and better fuel efficiency.

- Weight Distribution: Proper weight balance enhances handling and stability, particularly during high-speed maneuvers.

- Material Choice: Using lightweight yet durable materials can improve agility and reduce energy consumption.

- Structural Integrity: A well-designed framework ensures safety and durability while maintaining performance under various conditions.

Overall, the synergy between design elements and vehicle performance is vital for achieving optimal functionality in demanding environments.

Safety Features in Truck Bodies

Ensuring the protection of both the driver and cargo is paramount in commercial vehicles. Numerous advancements in design and technology contribute to enhancing safety, making these vehicles more reliable on the road. Various elements work together to mitigate risks and safeguard occupants during operation.

Structural Integrity

The framework of these vehicles plays a crucial role in maintaining safety standards. A robust structure is essential to withstand impacts and provide stability. High-strength materials are often utilized to enhance durability, ensuring the vehicle can endure various conditions.

Advanced Safety Systems

Modern vehicles are equipped with numerous safety mechanisms. These systems may include electronic stability control, anti-lock braking systems, and collision avoidance technologies. By integrating these features, manufacturers aim to reduce the likelihood of accidents and improve overall operational safety.

| Feature | Description |

|---|---|

| Rollover Protection | Structures designed to prevent overturning during sharp turns or uneven terrain. |

| Crumple Zones | Areas designed to deform and absorb impact energy during a collision. |

| Visibility Enhancements | Features such as rearview cameras and blind-spot detection to improve driver awareness. |

| Emergency Braking Systems | Automatic braking features that activate when an imminent collision is detected. |

Understanding the Repair Process

Repairing heavy vehicles requires a thorough understanding of the procedures involved to ensure safety and functionality. The process typically begins with a comprehensive assessment to identify issues, followed by systematic steps to restore the vehicle to its optimal condition.

Initial Assessment

The first stage involves examining the vehicle to pinpoint any damage or wear. This evaluation includes checking various components and systems to establish a clear understanding of the necessary repairs. Accurate diagnosis is crucial, as it sets the stage for effective solutions.

Repair Execution

Once the assessment is complete, the repair phase commences. Technicians may need to disassemble parts for detailed inspection or replacement. Utilizing quality materials and adhering to industry standards are essential to achieve lasting results. This stage emphasizes precision and attention to detail, ensuring that every aspect meets safety regulations and performance expectations.

Future Trends in Truck Body Design

The evolution of vehicle structures is increasingly influenced by advancements in technology, sustainability, and efficiency. Innovations in materials and manufacturing processes are paving the way for more robust and lightweight constructions.

Material advancements are at the forefront, with the rise of composite materials offering enhanced durability and reduced weight. This shift not only improves performance but also contributes to fuel efficiency and lowers operational costs.

Moreover, the integration of smart technologies is reshaping the approach to design. Features such as automated systems and real-time monitoring capabilities enhance safety and operational effectiveness. As connectivity becomes more prevalent, future designs will likely prioritize user experience and functionality.

Finally, an increasing focus on environmental impact is driving a demand for sustainable practices in the production and life cycle of vehicles. Emphasizing recyclability and eco-friendly materials will become essential components in the next generation of vehicle structures.