When it comes to maintaining the efficiency and longevity of your home’s essential cleaning device, it’s crucial to have a clear grasp of its internal components. Knowing the structure of such equipment allows you to address any potential issues swiftly and ensures that every cleaning cycle operates smoothly.

The intricate network of mechanisms within these machines is carefully designed to deliver optimal performance. Recognizing how various elements interact can help in troubleshooting, should any malfunctions occur. This insight can be invaluable in ensuring that everything runs as intended.

Each element, from the water distribution system to the motor responsible for driving the whole operation, plays a critical role in achieving a seamless cleaning experience. Understanding these elements individually will give you a better appreciation of how the entire system functions as a cohesive unit.

Overview of Bosch Ascenta Dishwasher Components

Modern cleaning appliances are made up of several key elements, each contributing to the machine’s overall performance and efficiency. Understanding these components helps ensure proper maintenance and troubleshooting when necessary. Below is an outline of the essential parts that work together to deliver optimal washing results.

- Spray Arms: These rotating mechanisms distribute water evenly across the load, ensuring all items are thoroughly cleaned.

- Filters: Responsible for capturing debris and preventing it from recirculating, filters help maintain water clarity and protect the inner workings.

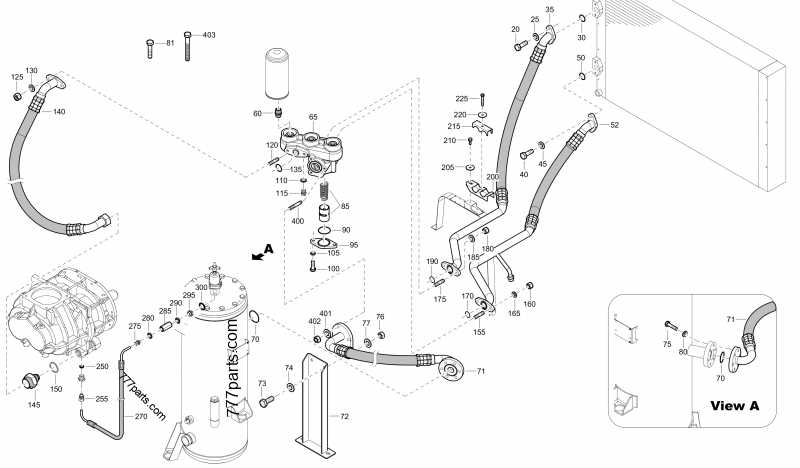

- Pump Assembly: This component directs the flow of water through the system, controlling both the spray and drainage cycles efficiently.

- Detergent Dispenser: The compartment releases cleaning agents at the right time to achieve the best possible cleaning results.

- Heating Element: Located at the bottom, this element heats water during the wash and drying cycles to enhance cleaning power and ensure proper drying.

Each of these features plays a crucial role in achieving effective operation, combining advanced technology with a user-friendly design to deliver reliable performance. Keeping these components in good condition is essential for extending the appliance’s lifespan and ensuring it functions smoothly.

Key Elements of the Spray Arm Assembly

The spray arm system is a crucial component that ensures effective water distribution during the cleaning process. Its design promotes optimal water flow, reaching all areas to remove debris and dirt efficiently. Understanding the various parts that make up this mechanism can help in maintaining its performance.

- Nozzles: These small openings allow water to be propelled at high pressure, ensuring even coverage across all surfaces.

- Rotation Hub: The central point that enables the arm to rotate, driven by water pressure, covering a wide area.

- Arm Body: A hollow structure through which water flows, providing the necessary force for rotation and spray distribution.

- Support Bearings: These ensure smooth movement, reducing friction and preventing wear over time.

- End Caps: These caps prevent water from escaping the ends of the arm, ensuring all pressure is directed through the nozzles.

Each of these components works in unison to deliver a thorough and consistent cleaning action, making it vital to keep the system in good condition for optimal results.

Understanding the Water Inlet System

The water inlet system plays a crucial role in ensuring the proper flow of water into the appliance, regulating the amount and pressure of water that enters during operation. This component manages the water supply, contributing to the overall efficiency and performance of the machine.

Several key elements work together to control the intake and distribution of water:

- Inlet Valve: This part opens and closes to allow water to enter based on the program settings, ensuring the right amount is supplied.

- Water Hose: A flexible tube that connects the system to the water source, channeling water from the main supply into the appliance.

- Flow Meter: A device that monitors the volume of water entering the system, ensuring it meets the programmed requirements for optimal washing cycles.

These components work in harmony to maintain the necessary balance of water flow and pressure, ensuring efficient cleaning without wasting water.

Inner Workings of the Drain Pump

The drain pump plays a crucial role in managing the flow of water, ensuring efficient removal of liquids during the cleaning process. By understanding how it operates, one can gain insight into the mechanics that keep the overall system functioning smoothly. Let’s explore the key components and how they contribute to this essential process.

Main Components of the Drain Pump

- Impeller: This rotating part creates the necessary suction force, drawing water into the pump and pushing it out through the drain hose.

- Motor: The motor powers the impeller, providing the energy needed for the pumping process. It operates at specific speeds to control the water flow rate.

- Seal: To prevent leaks, the pump is equipped with a durable seal that ensures water stays within the designated pathways.

How the Pump Operates

- When the system initiates the draining cycle, the motor engages, activating the impeller.

- The spinning impeller draws water from the machine’s base and directs it toward the drain hose.

- Once the liquid exits, the motor gradually slows down, ensuring a complete and efficient removal of water.

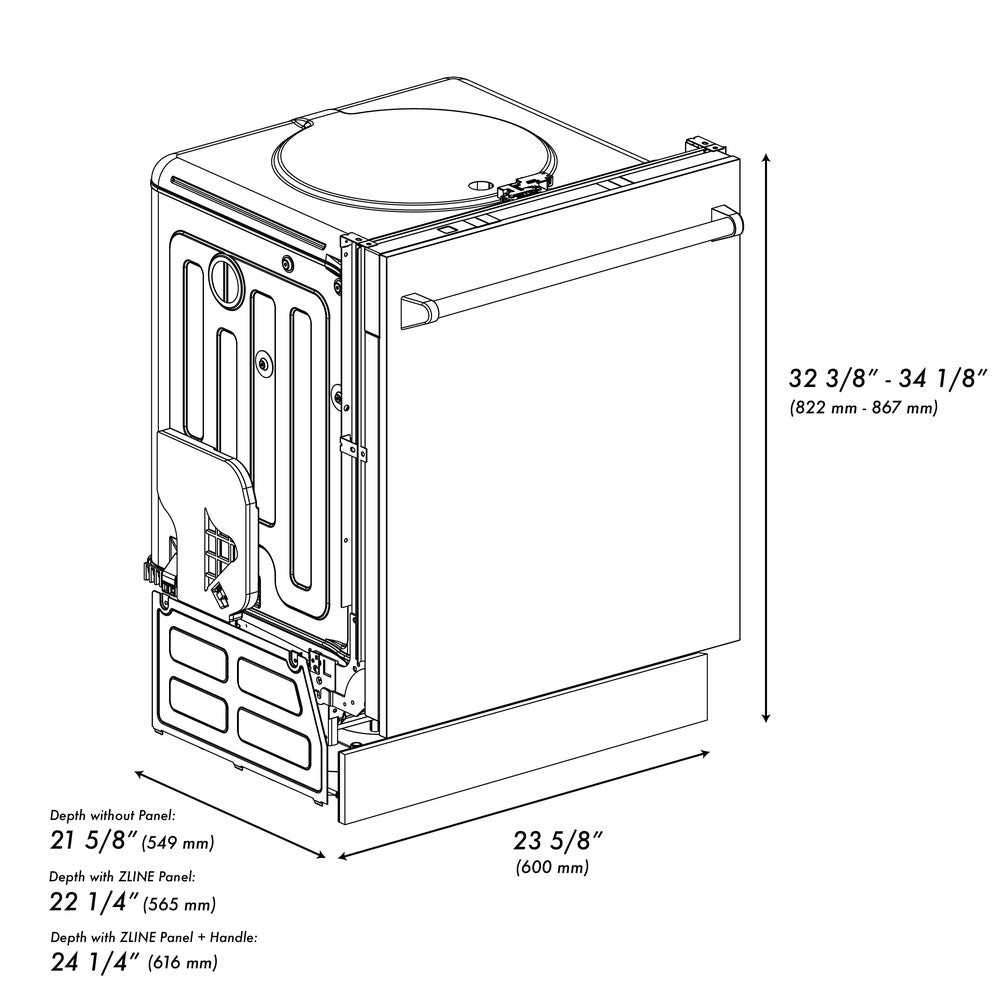

Guide to the Dishwasher Racks Layout

Efficient organization of the racks plays a vital role in ensuring optimal cleaning and drying performance. Understanding how to best utilize the available space allows for better placement of various items, leading to more thorough washing and faster drying times.

Upper Rack Configuration

The top section is designed to accommodate lighter items such as glasses, mugs, and small bowls. It often includes adjustable or foldable tines to fit taller objects, like stemware or larger cups. Positioning items with enough space between them helps prevent water spots and improves airflow during drying.

Lower Rack Arrangement

The lower area is generally intended for larger and heavier items like pots, pans, and plates. By arranging plates vertically and larger cookware flat, water and detergent can reach all surfaces evenly. Utilizing the cutlery basket or designated slots for utensils ensures a thorough cleaning and prevents them from nesting together.

Filter Maintenance and Replacement Tips

Regular upkeep of filtration components is essential for optimal performance and longevity of your appliance. Neglecting these parts can lead to inefficient operation and reduced cleaning effectiveness. This guide offers practical advice on how to maintain and replace these crucial elements.

Start by identifying the location of the filtration unit, as it may vary between models. Typically, this component can be found at the bottom of the unit. To ensure a thorough cleaning process, remove any debris or residue from the area surrounding the filter.

Maintenance Steps

| Step | Description |

|---|---|

| 1 | Detach the filter according to the manufacturer’s instructions. |

| 2 | Rinse the filter under warm water to remove trapped food particles and grease. |

| 3 | Use a soft brush to clean hard-to-reach areas if necessary. |

| 4 | Allow the filter to dry completely before reinstallation. |

Replacement should be considered when the filter is damaged or excessively worn. Check for signs of cracks or deformities, as these can impair the filtering process. Always refer to the user manual for guidance on selecting compatible replacements, ensuring you maintain the efficiency of your appliance.

Exploring the Control Panel Features

The control interface serves as the command center for your kitchen appliance, enabling users to navigate various settings with ease. Understanding its functionalities is crucial for optimizing performance and ensuring a seamless experience during operation.

At the heart of the interface are several intuitive buttons and indicators, each designed to streamline the user experience. These elements allow for the selection of different cycles, temperature adjustments, and additional options, catering to a wide range of cleaning needs. Each feature is thoughtfully placed to enhance accessibility, making it easy for users to choose their desired settings with minimal effort.

Moreover, many modern interfaces include digital displays that provide real-time feedback on the cycle status, remaining time, and selected options. This not only enhances user engagement but also allows for better planning and efficiency in the kitchen. Familiarity with these features can greatly improve the overall performance of your appliance, ensuring that every load is handled effectively.

Importance of the Heating Element

The heating component plays a crucial role in the overall functionality of a cleaning appliance, ensuring optimal performance and efficiency. This essential element is responsible for raising the temperature of the water, which is vital for effective soil removal and sanitization of dishes and utensils. Without this mechanism, the appliance would struggle to achieve the desired cleanliness, leaving behind residues and bacteria.

Enhanced Cleaning Performance

By elevating water temperatures, the heating component facilitates the breakdown of stubborn food particles and grease. Higher temperatures enable detergents to work more effectively, enhancing their ability to dissolve tough stains and residues. This results in a more thorough cleaning process, ensuring that items emerge spotless and sanitized.

Energy Efficiency

An efficient heating element not only improves cleaning results but also contributes to energy savings. Modern appliances are designed to optimize energy consumption while maintaining performance levels. By effectively managing temperature, these components help reduce overall energy use, making them a sustainable choice for consumers.

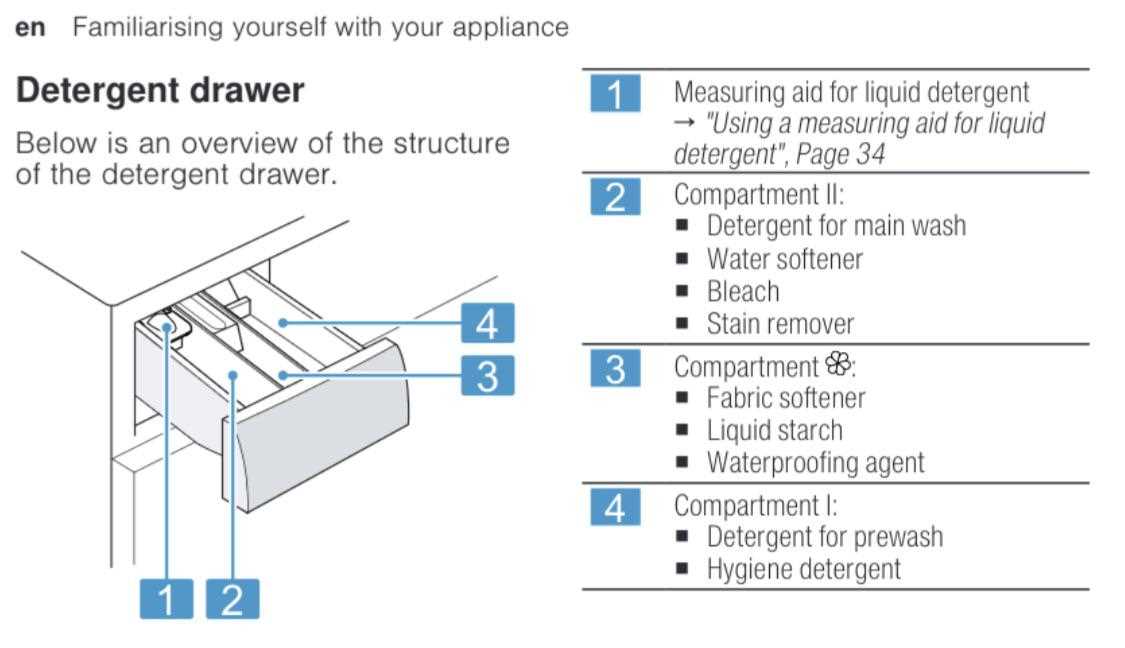

Role of the Detergent Dispenser in Cleaning

The component responsible for releasing cleaning agents plays a vital role in ensuring effective sanitation during the washing process. Its primary function is to dispense the right amount of detergent at the optimal time, enabling surfaces to be thoroughly cleansed of food residues and grease. This mechanism not only enhances the cleaning efficiency but also contributes to the longevity of the equipment.

Importance of Timely Dispensing

Accurate timing in releasing the cleansing solution is crucial for achieving desired results. When the agent is dispensed at the right moment, it interacts effectively with the water, maximizing its cleaning potential. This process ensures that all items receive an even distribution of the detergent, preventing any residues from remaining after the cycle.

Maintenance for Optimal Performance

To maintain the efficacy of the dispensing mechanism, regular cleaning and inspection are necessary. Over time, residue buildup can obstruct the flow of detergent, compromising cleaning effectiveness. Ensuring that this component remains in optimal condition not only aids in better sanitation but also enhances the overall performance of the machine.

Door Seal and Its Functionality

The door seal plays a crucial role in ensuring the efficient operation of household cleaning appliances. This component serves as a barrier, preventing water from leaking during cycles while also contributing to energy conservation by maintaining the desired temperature inside the unit.

Importance of a Properly Sealed Door

A well-functioning seal is essential for optimal performance. It helps to create a tight fit when the door is closed, effectively minimizing the risk of leaks that can lead to water damage and decreased energy efficiency. Over time, wear and tear can affect its integrity, making regular inspection and maintenance vital.

Signs of Wear and Maintenance Tips

Visible signs of deterioration include cracks, brittleness, or gaps. Regular cleaning of the seal can help prevent buildup of debris and maintain its elasticity. In case of significant wear, replacing the seal promptly is recommended to ensure continued efficiency and prevent potential damage to surrounding areas.

Flow Meter and Its Influence on Water Use

The flow meter plays a crucial role in monitoring and regulating the amount of liquid consumed during various processes. Its functionality directly affects efficiency and resource management, impacting both operational costs and environmental sustainability. Understanding its operation can lead to better practices and improved performance in applications requiring precise water usage.

Mechanism of Action

This device operates by measuring the rate at which liquid flows through a system. It often utilizes sensors to detect changes in pressure and velocity, translating these measurements into accurate flow readings. By maintaining an optimal flow rate, it ensures that the appropriate volume of water is utilized, minimizing waste.

Impact on Resource Management

Efficient water management is increasingly important in today’s context of resource scarcity. The implementation of a flow meter allows for real-time monitoring, enabling users to adjust consumption patterns accordingly. This capability can significantly reduce water usage and operational costs, leading to both economic and ecological benefits.

| Aspect | Description |

|---|---|

| Efficiency | Ensures optimal water usage, minimizing waste. |

| Monitoring | Provides real-time data for better decision-making. |

| Cost Savings | Reduces operational expenses through efficient resource management. |

| Environmental Impact | Supports sustainability efforts by conserving water. |

How the Float Switch Regulates Water Level

The float switch is a crucial component in maintaining the correct water level within a cleaning appliance. It operates on a simple principle: as water fills the tank, the float rises, activating the switch to either allow more water in or halt the flow. This mechanism ensures that the appliance functions optimally without overflowing or running dry.

Functionality of the Float Switch

The float switch plays a vital role in the appliance’s operation by monitoring the water level continuously. Here’s how it works:

- The float is attached to a rod that moves up and down with the changing water level.

- When the water level rises to a predetermined height, the float activates the switch.

- This action sends a signal to the control system, instructing it to stop the water intake.

Importance of Proper Regulation

Maintaining the appropriate water level is essential for efficient operation. If the water level is too high:

- Risk of overflow increases, potentially damaging surrounding areas.

- Can lead to inefficient cleaning, as water may not circulate properly.

Conversely, if the water level is too low:

- The cleaning cycles may be ineffective, resulting in poor cleaning outcomes.

- It can cause damage to the appliance, as it may run dry and overheat.

Troubleshooting the Circulation Motor Issues

Addressing problems related to the circulation motor is crucial for ensuring optimal performance in cleaning appliances. When these components malfunction, it can lead to inadequate water circulation, impacting the effectiveness of the cleaning cycle. This section outlines common symptoms and potential solutions to restore proper functionality.

Here are some typical signs that may indicate a circulation motor issue:

- Insufficient water spray during operation

- Strange noises coming from the appliance

- Water not heating properly

- Frequent error codes displayed on the control panel

To diagnose and resolve these problems, consider the following steps:

- Check the power supply to ensure the motor is receiving adequate voltage.

- Inspect for any blockages in the water inlet or drain paths.

- Examine the motor for signs of wear or damage, such as frayed wires or rust.

- Test the motor’s functionality using a multimeter to measure resistance.

- Replace any faulty components if necessary, following the manufacturer’s guidelines.

If the issues persist after these checks, consulting a qualified technician may be necessary to perform a thorough evaluation and repairs.