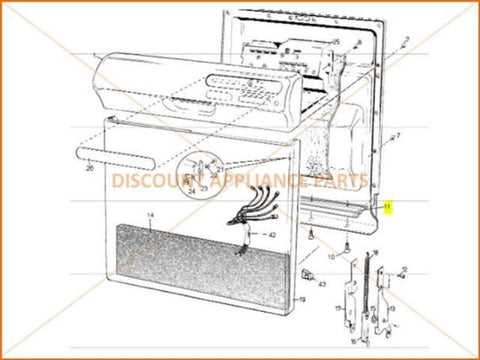

Understanding the inner workings of modern kitchen equipment can greatly enhance its maintenance and longevity. By exploring the various elements that make up these devices, users gain valuable insights into troubleshooting and potential repairs. This section provides a detailed look at the critical elements that ensure the smooth operation of these essential tools.

Key mechanical and electrical connections are vital to ensure the functionality of any kitchen machinery. Each component, from the internal pumps to the control modules, plays a specific role in maintaining the system’s efficiency. Recognizing these elements allows users to quickly diagnose issues and perform basic maintenance.

In addition to the operational elements, understanding the layout of such devices aids in correctly ide

Component Overview

Understanding the internal structure of a household appliance is essential for effective maintenance and repair. This section provides an overview of the key mechanisms and assemblies that ensure smooth operation and functionality. Each element plays a specific role in achieving efficient performance.

- Pump System: Responsible for circulating and draining water, this crucial mechanism ensures the proper flow during different phases of the cycle.

- Control Module: The brain of the machine, responsible for managing various functions such as wash cycles, water temperature, and timing.

- Heating Element: Used to warm the water to the desired temperature, playing a key role in both the cleaning and drying processes.

- Racks

Main Control Board Functions and Location

The central control unit plays a crucial role in managing and coordinating all the operational processes. It serves as the brain of the system, ensuring that each function is executed precisely and efficiently. This component regulates various cycles, power distribution, and overall system performance, making it essential for smooth functionality.

Located in a protected area, the control board is strategically positioned to monitor and direct the flow of electrical signals. Its placement ensures easy access for maintenance while being safeguarded from external factors that could interfere with its operation. Understanding its location is vital for troubleshooting and repairs.

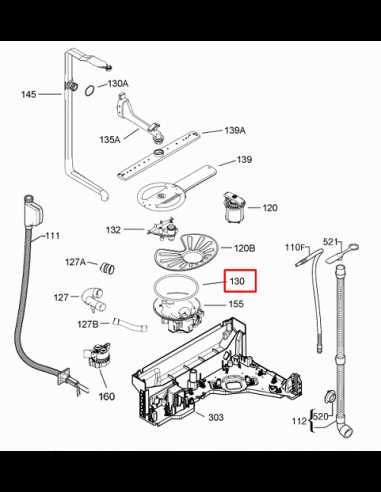

Circulation Pump and Motor Assembly

The circulation system is crucial for ensuring efficient water movement during the cleaning cycle. Its primary function is to drive water through the system, enabling effective rinsing and washing of various items. Without this mechanism, optimal water flow would not be achieved, leading to less satisfactory cleaning results.

Main Components

The assembly consists of a motor that powers the pump, ensuring consistent pressure. The motor’s power output directly influences the performance of the overall system, maintaining proper water circulation.

Function and Operation

This unit operates continuously during the cleaning process, recirculating water to ensure it reaches all areas.

Drain Hose and Its Maintenance

The drain hose plays a crucial role in ensuring the proper removal of wastewater during the cleaning process. Over time, this component may encounter various issues such as blockages, wear, or leaks. Regular inspection and care can prevent these problems and maintain the efficiency of the system.

Signs of a Clogged or Damaged Hose

A malfunctioning drain hose can lead to water not draining properly. Common signs include slow drainage, unusual noises, or water pooling inside the appliance. It is important to identify these symptoms early to avoid further complications.

Steps for Regular Maintenance

To maintain the hose, check for kinks or obstructions regularly. Ensure the hose is positioned correctly and is free of any visible damage. Cleaning the

Heating Element and Temperature Control

The heating element is a crucial part responsible for ensuring water reaches the proper temperature during washing and drying cycles. Maintaining an optimal temperature is essential for effective cleaning and sanitation, as well as for drying dishes efficiently after the cycle completes.

Temperature control works in coordination with the heating component, adjusting the power to the element as needed to maintain consistency. This system prevents overheating and ensures the water temperature remains within the desired range for the cleaning process.

Component Function Heating Element Heats the water to Water Inlet Valve Functionality

The water inlet valve plays a crucial role in controlling the flow of water into the appliance. Its main function is to regulate the amount of water that enters the machine, ensuring the proper level is maintained for optimal performance. Without this valve, the system would not be able to function efficiently, as it would lack control over water supply.

How the Valve Operates

When the system needs water, the valve opens, allowing water to flow through from the connected supply line. Once the desired water level is reached, the valve closes automatically. This process is managed by electrical signals that control the valve’s open and close functions. The valve prevents water from

Rinse Aid Dispenser Mechanism

The rinse aid mechanism plays a critical role in improving the efficiency of the washing process by ensuring that dishes dry without water spots. It controls the release of a liquid agent during the rinse cycle to minimize surface tension on glassware and other items, allowing water to sheet off smoothly.

Key components and operation of the rinse aid dispenser include:

- Reservoir: A chamber designed to store liquid rinse aid, typically located within the door of the appliance.

- Release Valve: A small valve responsible for dispensing a measured amount of rinse aid during the appropriate cycle phase.

- Adjustable Settings: Many systems allow users to adjust

Spray Arm Operation and Cleaning

The spray arm is a crucial component in ensuring effective cleaning performance. It plays a vital role in distributing water throughout the cleaning chamber, helping to remove food particles and grime from surfaces. Understanding how this mechanism operates and how to maintain it can significantly enhance its efficiency and longevity.

Proper functioning of the spray arm involves the following aspects:

- Water Distribution: The spray arm rotates and sprays water in multiple directions to cover all items within the chamber.

- Pressure Regulation: Adequate water pressure is essential for optimal performance, allowing the spray arm to effectively reach all surfaces.

- Rotation Mechanism: The arm’s rotation is facilitated by water pressure, ensuring consistent movement and coverage.

To maintain optimal performance, regular cleaning of the spray arm is recommended. Here are some steps for effective maintenance:

- Remove the spray arm from its housing according to the manufacturer’s instructions.

- Inspect the arm for any obstructions or buildup of debris.

- Soak the spray arm in warm, soapy water to loosen any residue.

- Use a soft brush or cloth to gently scrub the arm, paying special attention to the spray nozzles.

- Rinse thoroughly under warm running water to remove soap and debris.

- Reattach the spray arm securely in its original position.

By understanding the operation of the spray arm and following these cleaning guidelines, users can ensure their cleaning appliance continues to perform at its best, resulting in spotless dishes and optimal functionality.

Door Latch Assembly and Safety Features

The latch assembly is a crucial component that ensures the safe operation of your appliance. Its primary function is to secure the door during operation, preventing any accidental openings that could lead to hazards. In addition to maintaining a tight seal, this assembly is equipped with several safety features designed to protect users from potential risks.

Components of the Latch Assembly: The latch assembly typically consists of a locking mechanism, strike plate, and release button. These elements work together to ensure that the door remains closed during cycles, effectively containing all internal processes.

Safety Features: Integrated safety features include a door lock that engages when the machine is in operation, preventing users from opening the door until it is safe to do so. Additionally, many models are equipped with sensors that detect the door’s position, immediately halting operations if the door is ajar. This dual-layer of protection not only enhances user safety but also contributes to the overall efficiency of the appliance.

Understanding the functionality and safety mechanisms of the latch assembly is vital for ensuring safe and effective usage. Regular inspections and maintenance of this component can significantly prolong the lifespan of your device and enhance its operational safety.

Detergent Dispenser Functionality

The dispenser plays a crucial role in the cleaning process of kitchen appliances, ensuring that the appropriate amount of cleaning agent is released at the right time during operation. This component is designed to optimize performance by effectively managing the distribution of the cleaning solution, which is vital for achieving spotless results.

Operational Mechanism

Upon initiation of the cycle, the dispenser activates to release the detergent into the wash compartment. The timing and quantity of the release are engineered to coincide with specific stages of the cleaning process. This ensures that the cleaning agent is most effective when it comes into contact with soiled surfaces.

Maintenance and Troubleshooting

To maintain optimal functionality, regular inspection of the dispenser is recommended. Ensure that it is free from blockages and residues, as these can impede performance. If issues arise, such as incomplete dispensing or leaks, these may indicate a need for repair or replacement of the component.

Filter Assembly and Cleaning Procedures

The filter system plays a crucial role in maintaining optimal performance and efficiency in your appliance. Regular maintenance and proper cleaning of this assembly are essential for preventing clogs and ensuring effective operation. Understanding how to disassemble and clean the filter will prolong the life of the unit and enhance its cleaning capabilities.

Disassembly and Inspection

To access the filter assembly, first remove the lower rack to gain clear access. Locate the filter cover and carefully unscrew or unclip it. Once removed, lift out the filter components, including the mesh and any additional parts. Inspect each piece for debris, buildup, or damage. This step is vital as any obstruction can impede performance and lead to water drainage issues.

Cleaning Process

After disassembling the filter assembly, rinse each component under warm running water. Use a soft brush or cloth to gently scrub away any stubborn deposits. For heavy buildup, a mixture of mild detergent and warm water can be used to soak the parts for a more thorough clean. Ensure all components are completely dry before reassembling them back into their original positions to prevent mold or odor development.