Maintaining and troubleshooting outdoor cleaning machinery can be a daunting task, especially when dealing with intricate assemblies and numerous components. A clear understanding of each element’s function and layout is essential for effective repairs and upkeep. This knowledge not only enhances the performance of your device but also prolongs its lifespan.

In this section, we will explore the various components that contribute to the efficient operation of your cleaning device. By breaking down the construction into manageable parts, we aim to provide clarity and insight into the role each element plays. Whether you’re a seasoned user or new to this type of equipment, having a comprehensive grasp of its architecture will empower you to tackle maintenance tasks with confidence.

Furthermore, identifying and sourcing the correct components can be crucial when repairs are needed. With an organized overview, you’ll be better equipped to locate replacement items and ensure your equipment operates at peak performance. Join us as we delve into the essential features that make your cleaning equipment effective and reliable.

Understanding Generac Pressure Washer Basics

This section aims to provide an overview of essential components and functions related to high-powered cleaning devices. Knowing the different elements and their roles can significantly enhance user experience and maintenance practices.

Key Components of Cleaning Equipment

High-performance cleaning machines typically consist of several vital components, including the motor, pump, and nozzle. The motor serves as the power source, converting electrical energy into mechanical energy, while the pump generates the force needed to expel water. Nozzles are crucial for adjusting the spray pattern, allowing users to customize their cleaning based on the task at hand.

Importance of Regular Maintenance

To ensure optimal performance and longevity, routine upkeep is necessary. Regularly checking fluid levels, inspecting hoses, and cleaning filters can prevent common issues. Additionally, replacing worn-out components promptly can save time and enhance efficiency, making every cleaning session more effective.

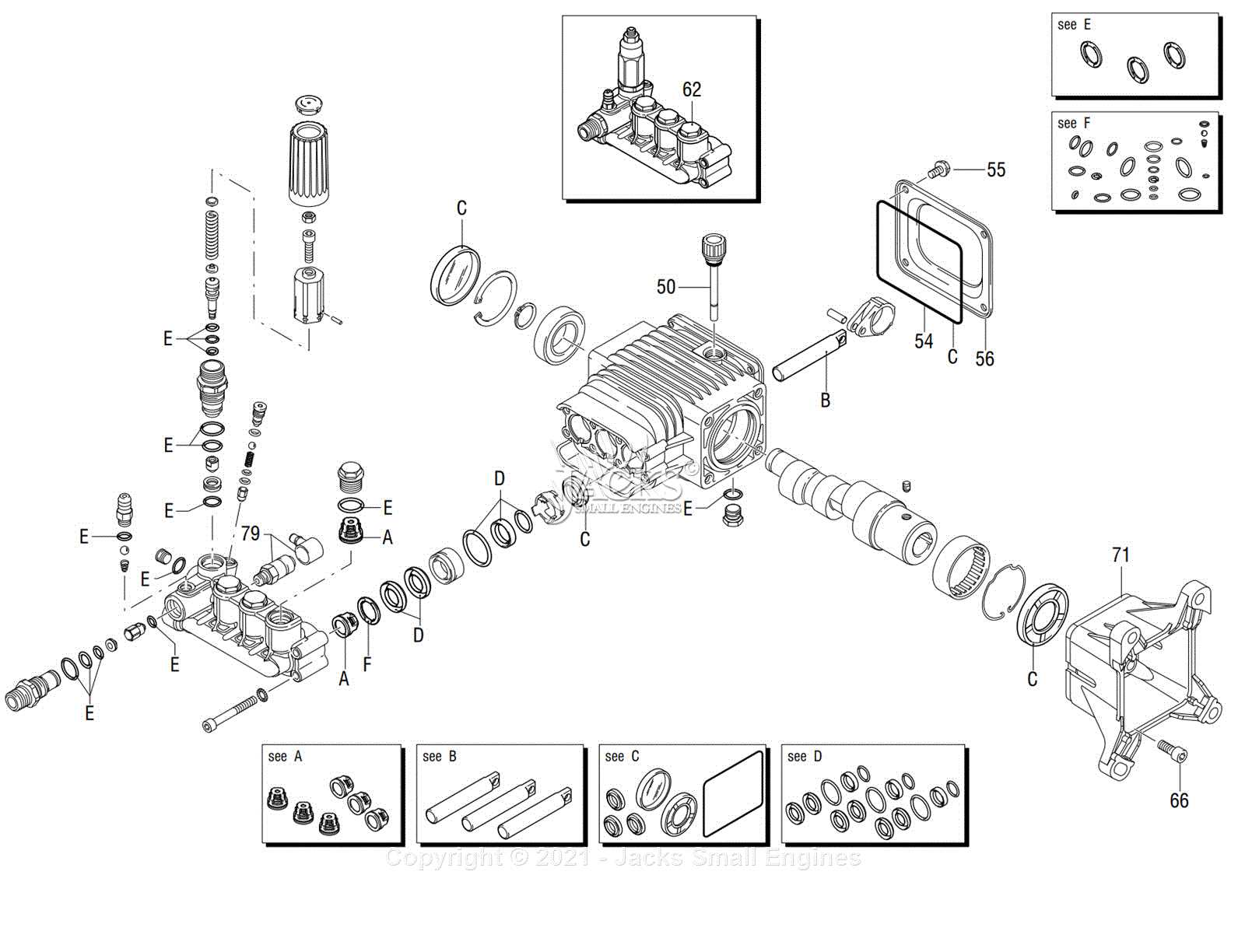

Key Components of the Pressure Washer

Understanding the essential elements of a high-pressure cleaning device is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficient operation and longevity.

Motor: The heart of the machine, providing the necessary power to operate effectively.

Pump: This component elevates the water pressure, enabling powerful cleaning capabilities.

Nozzle: Different nozzle types allow users to customize the spray pattern, adapting to various cleaning tasks.

Hose: A robust and flexible connection that delivers water from the pump to the nozzle, ensuring ease of movement.

Wheels: Facilitating mobility, allowing for easy transport across different surfaces.

Regular inspection of these components can enhance performance and extend the life of the equipment.

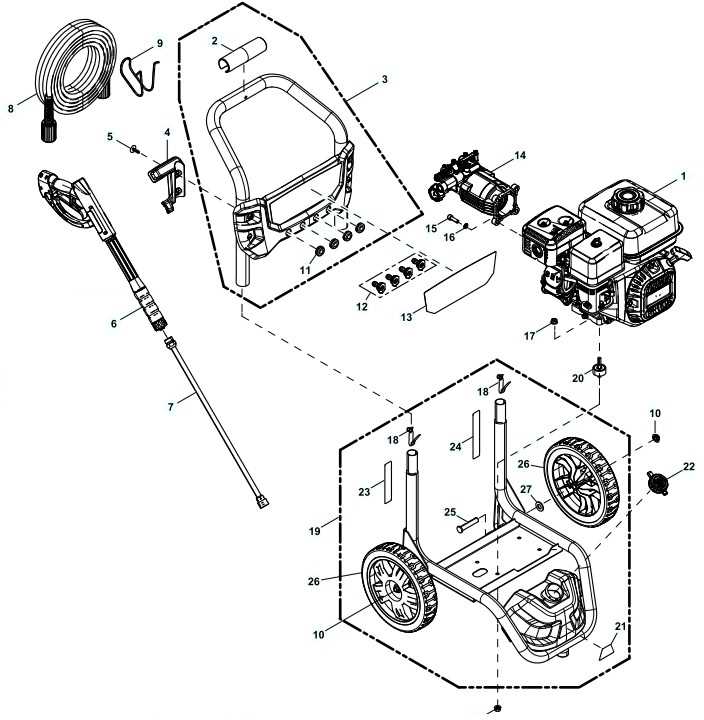

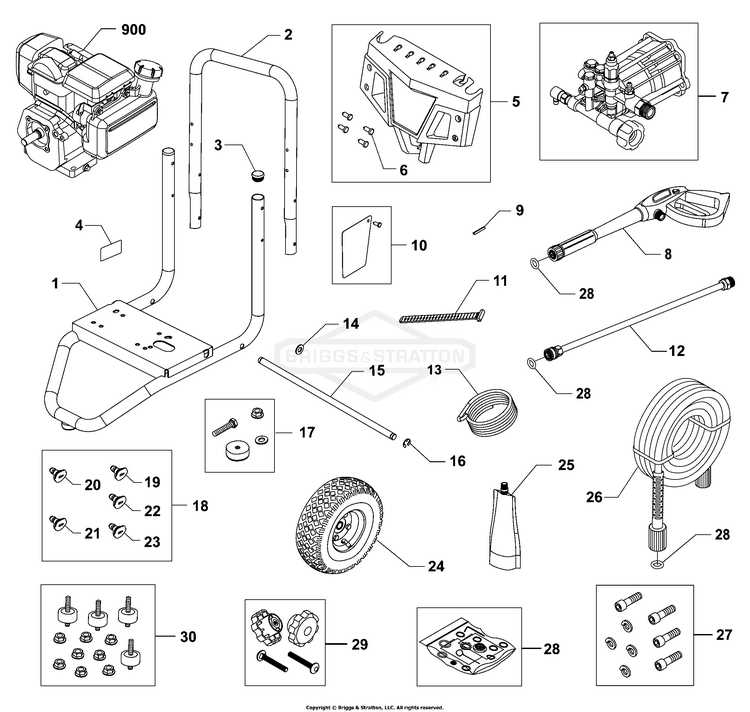

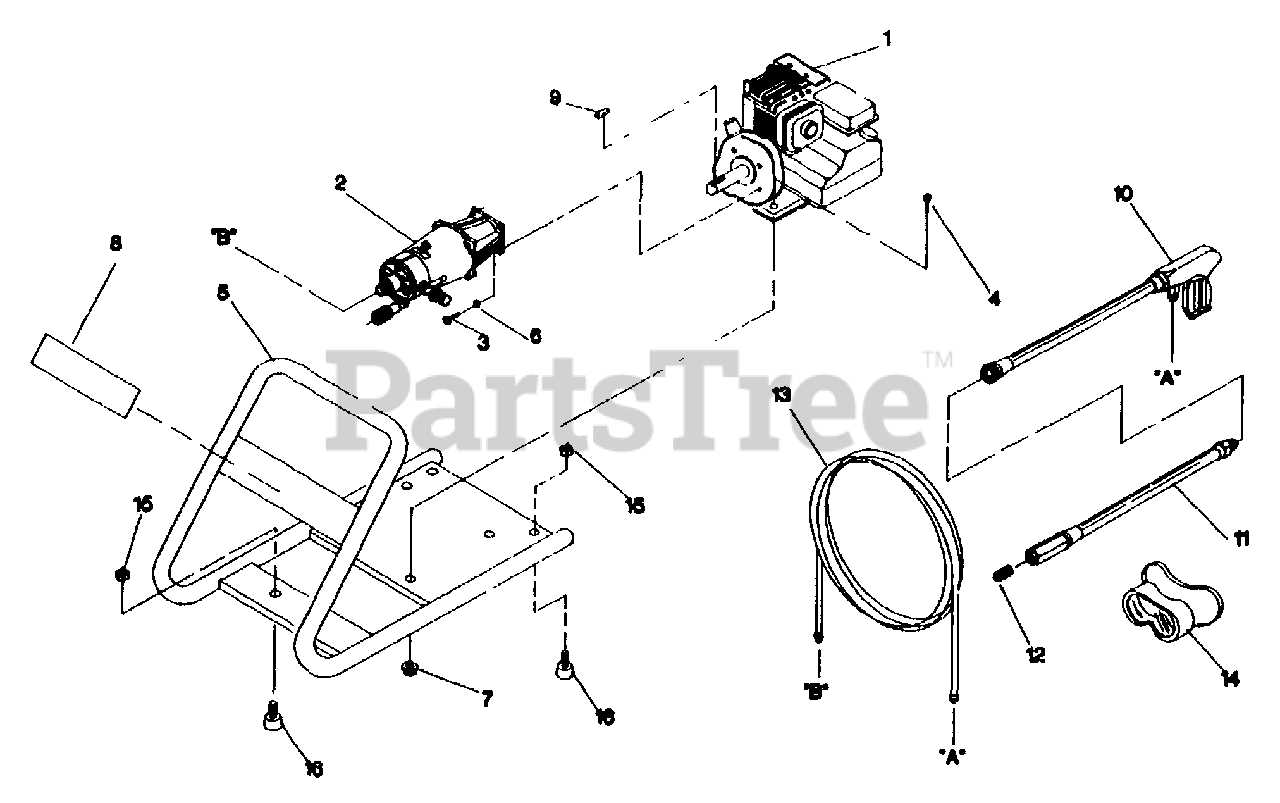

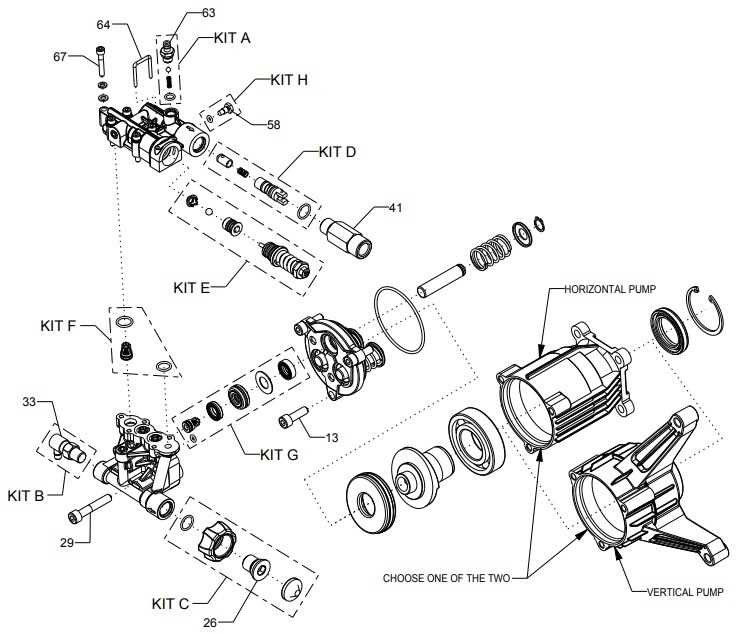

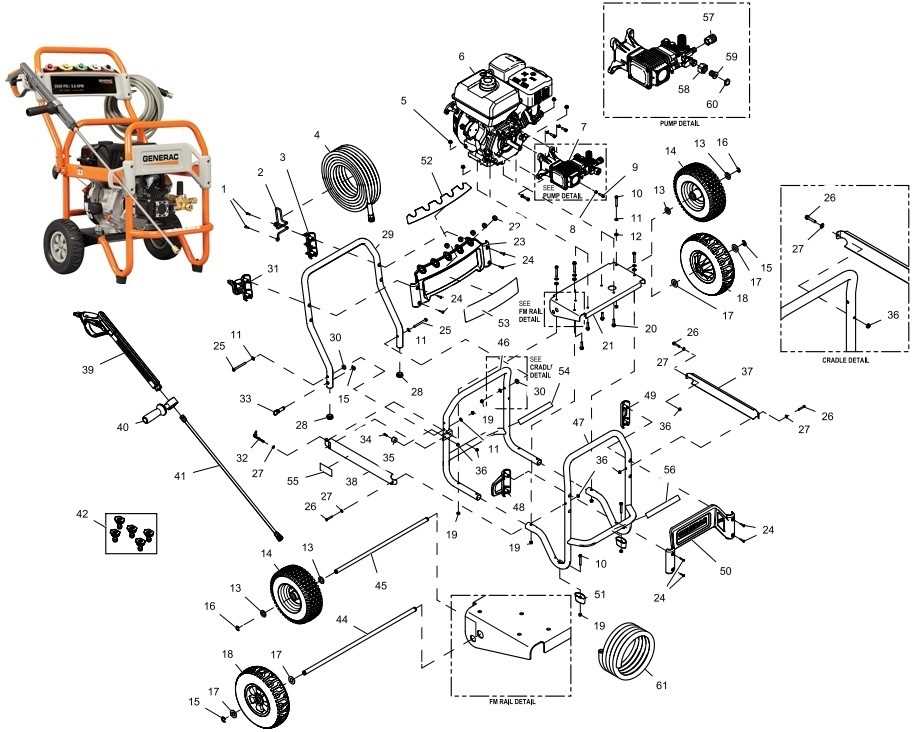

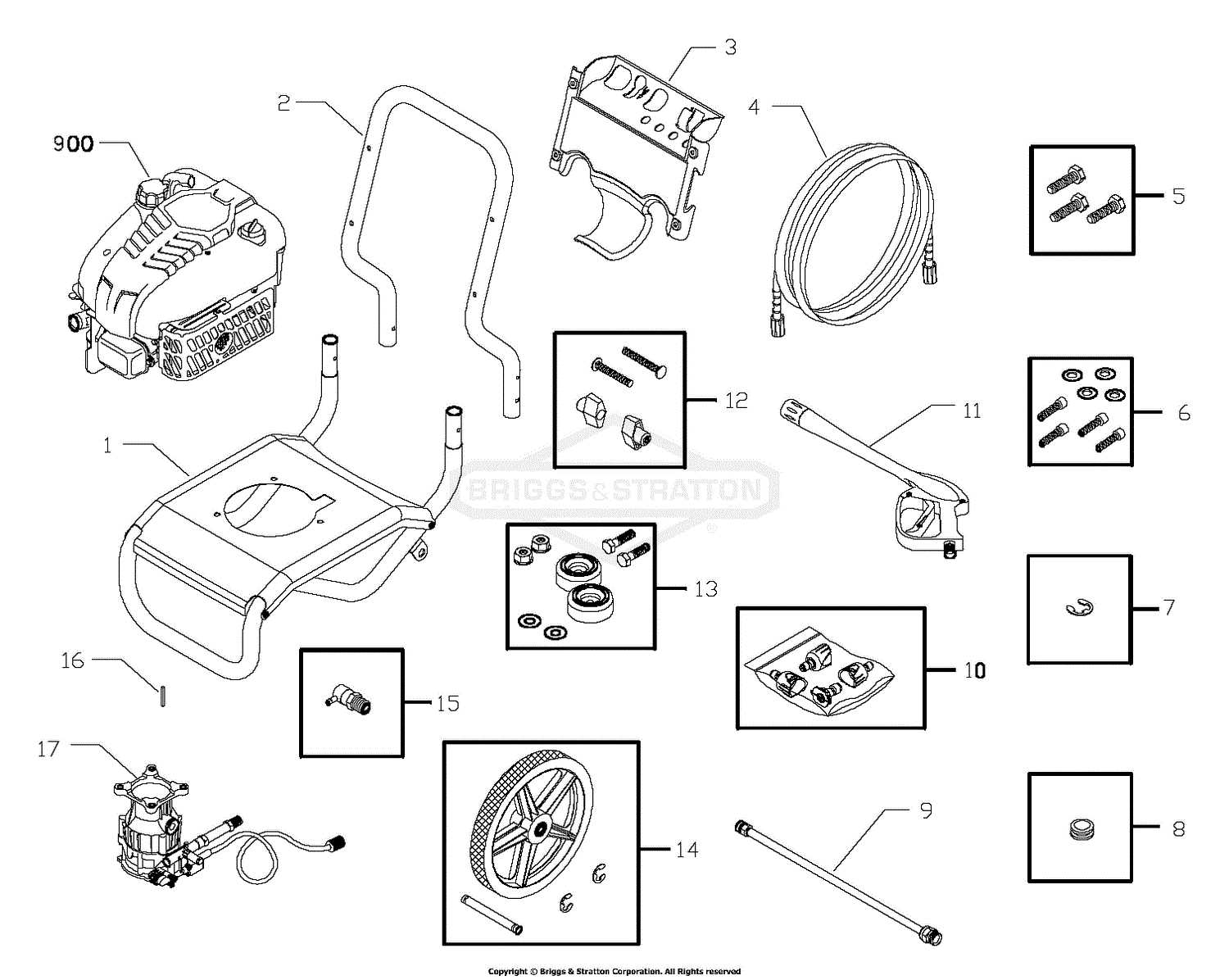

Importance of Pressure Washer Diagrams

Understanding the structure and components of cleaning equipment is crucial for efficient maintenance and repair. Visual representations serve as essential tools for users to navigate through their machines, ensuring optimal functionality and longevity.

- Facilitate troubleshooting: Clear visuals help identify issues quickly.

- Streamline repairs: Knowing the layout aids in disassembly and reassembly.

- Enhance safety: Understanding each component can prevent accidents during operation.

- Support upgrades: Diagrams provide insights into potential enhancements.

In summary, visual aids are indispensable for anyone looking to maximize the effectiveness and lifespan of their cleaning equipment.

Common Issues with Generac Washers

When utilizing high-performance cleaning devices, users often encounter various challenges that can impact functionality. Understanding these common problems is essential for effective maintenance and optimal performance.

Leakage: One frequent issue is water leakage, which can stem from damaged seals or connections. Ensuring all fittings are tight can help mitigate this problem.

Loss of Pressure: Users may experience a significant drop in cleaning force. This can be caused by clogged nozzles or worn-out pumps. Regular cleaning and replacement of parts can restore power.

Starting Difficulties: Difficulty in starting the machine often frustrates users. This may result from fuel issues, electrical faults, or a drained battery. Checking these components can aid in quick resolutions.

Excessive Noise: Unusual sounds during operation can indicate mechanical problems. Addressing any abnormal noise promptly can prevent further damage.

Overheating: Machines may overheat due to prolonged use or blockages. Taking breaks and ensuring adequate airflow can alleviate this issue.

By recognizing these common challenges, users can delve deeper into troubleshooting and maintenance, ultimately enhancing the longevity and efficiency of their cleaning devices.

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repair. These visuals offer a clear representation of individual elements and their arrangement, helping users identify and locate necessary components easily.

Key Features to Note

- Labels: Each component usually has a unique identifier, making it easier to reference.

- Connection Points: Look for how elements are linked to understand their interactions.

- Color Coding: Some diagrams use colors to distinguish between different categories or functions.

Steps to Follow

- Begin by familiarizing yourself with the overall layout.

- Identify key components using the labels provided.

- Trace connections to understand how each part fits within the system.

- Refer to accompanying documentation for additional details or explanations.

Replacing Damaged Parts Efficiently

Maintaining your equipment in optimal condition is crucial for performance and longevity. When components become worn or damaged, timely and effective replacement can prevent further issues and enhance overall functionality. Understanding the process can save both time and resources, ensuring your tools remain reliable.

Assessing the Damage is the first step in the replacement process. Carefully inspect each component to identify which ones require attention. Look for signs of wear, such as cracks, corrosion, or malfunctioning mechanisms. This will help you prioritize which elements need to be addressed immediately.

Gathering the Right Tools is essential. Before starting the replacement, ensure you have the necessary tools at hand. This may include wrenches, screwdrivers, or specific items suited for the components in question. Having everything ready will streamline the process and minimize downtime.

Following a Systematic Approach during replacement will enhance efficiency. Begin by carefully removing the damaged components, taking note of how they are assembled. Refer to any available guides or manuals for guidance, which can provide valuable insights into the correct installation methods.

Once the new components are in place, testing is crucial. After reassembly, conduct a thorough check to ensure everything operates smoothly. This step not only confirms that the new pieces are functioning correctly but also helps identify any remaining issues that may need attention.

In conclusion, a methodical approach to replacing damaged components can significantly improve the performance of your equipment. By being diligent in assessment, preparation, and execution, you can ensure your tools operate efficiently and last longer.

Maintenance Tips for Longevity

Proper care and attention can significantly extend the lifespan of your cleaning equipment. Regular maintenance not only enhances performance but also prevents costly repairs down the line. By following a few essential practices, you can ensure that your device remains in peak condition for years to come.

1. Clean After Use: Always rinse off dirt and debris after each session. This prevents buildup that can lead to malfunctions.

2. Check Hoses and Connections: Regularly inspect hoses for cracks or leaks, and ensure all connections are secure to avoid water loss.

3. Replace Filters: Clean or replace filters periodically to maintain optimal airflow and performance.

4. Store Properly: Keep your equipment in a dry, sheltered location to protect it from environmental factors that can cause wear.

5. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and guidelines provided by the manufacturer for best results.

By integrating these tips into your routine, you can delve into the ultimate care practices that will keep your equipment operating efficiently and reliably.

Finding Replacement Parts Easily

Locating suitable components for your equipment can often be a straightforward process if you know where to look. Understanding the layout and function of each element is essential in identifying what you need for repairs or upgrades. By following a few practical steps, you can ensure that your maintenance tasks are efficient and effective.

Start by consulting the user manual, which typically includes detailed information about each component, including its specifications and any part numbers. This can save you time and help you avoid purchasing incorrect items. Additionally, many manufacturers provide online resources that can further assist you in your search.

Another effective method is to explore various online retailers and local stores. Websites dedicated to home improvement often feature extensive catalogs where you can filter by brand and type. Don’t forget to check reviews to ensure the quality of the items you’re considering. In-store visits can also be beneficial, as you may receive direct assistance from knowledgeable staff.

Lastly, joining online forums or communities related to your equipment can offer valuable insights. Fellow enthusiasts can share their experiences and recommend trusted sources for acquiring necessary components. By leveraging these resources, you can simplify the process and find exactly what you need with confidence.

Upgrades for Enhanced Performance

Improving the efficiency and effectiveness of your cleaning equipment can significantly elevate its performance. By incorporating various enhancements, users can achieve superior results, reduce operational time, and extend the lifespan of their machinery. This section explores key upgrades that can transform your unit into a powerhouse of cleaning capabilities.

One of the most impactful modifications involves upgrading the nozzle. High-quality nozzles can provide better spray patterns and adjust the flow of water, allowing for tailored cleaning solutions suited to different surfaces. Additionally, replacing the existing pump with a more robust model can lead to increased pressure and flow rate, ensuring a thorough clean with less effort.

Another noteworthy enhancement is the inclusion of a more efficient motor. A powerful motor not only enhances the unit’s reliability but also minimizes energy consumption, contributing to overall efficiency. Consider also adding an advanced hose reel system, which simplifies maneuvering and storage, making the cleaning process smoother and more convenient.

Lastly, utilizing superior detergents specifically formulated for various tasks can boost cleaning performance. These solutions can break down tough grime and stains more effectively, making your equipment even more effective. With these upgrades, your cleaning experience can reach new heights, delivering outstanding results with every use.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Being aware of potential hazards and taking appropriate measures can ensure a secure environment for repairs.

- Always disconnect power sources before beginning any work.

- Wear appropriate personal protective equipment, such as gloves and goggles.

- Ensure the workspace is clean and free from clutter to avoid tripping hazards.

- Read the manufacturer’s manual to understand specific safety warnings and guidelines.

- Use tools that are in good condition and suited for the task at hand.

By following these essential precautions, you can create a safer repair environment and ultimately enhance your efficiency and effectiveness during maintenance activities.

Resources for Troubleshooting Generac Washers

When facing issues with your cleaning equipment, having reliable resources is crucial for effective resolution. Whether it’s minor hiccups or more complex failures, understanding where to find help can significantly enhance your repair efforts.

Online Resources

- Manufacturer’s Website: Access user manuals and FAQs for guidance.

- Forums and Communities: Engage with other users to share experiences and solutions.

- YouTube Tutorials: Visual aids can simplify complex repair processes.

Physical Resources

- Local Repair Shops: Professionals can provide hands-on assistance and advice.

- Hardware Stores: Find replacement components and tools necessary for repairs.

- Workshops: Attend sessions for practical learning on maintenance techniques.