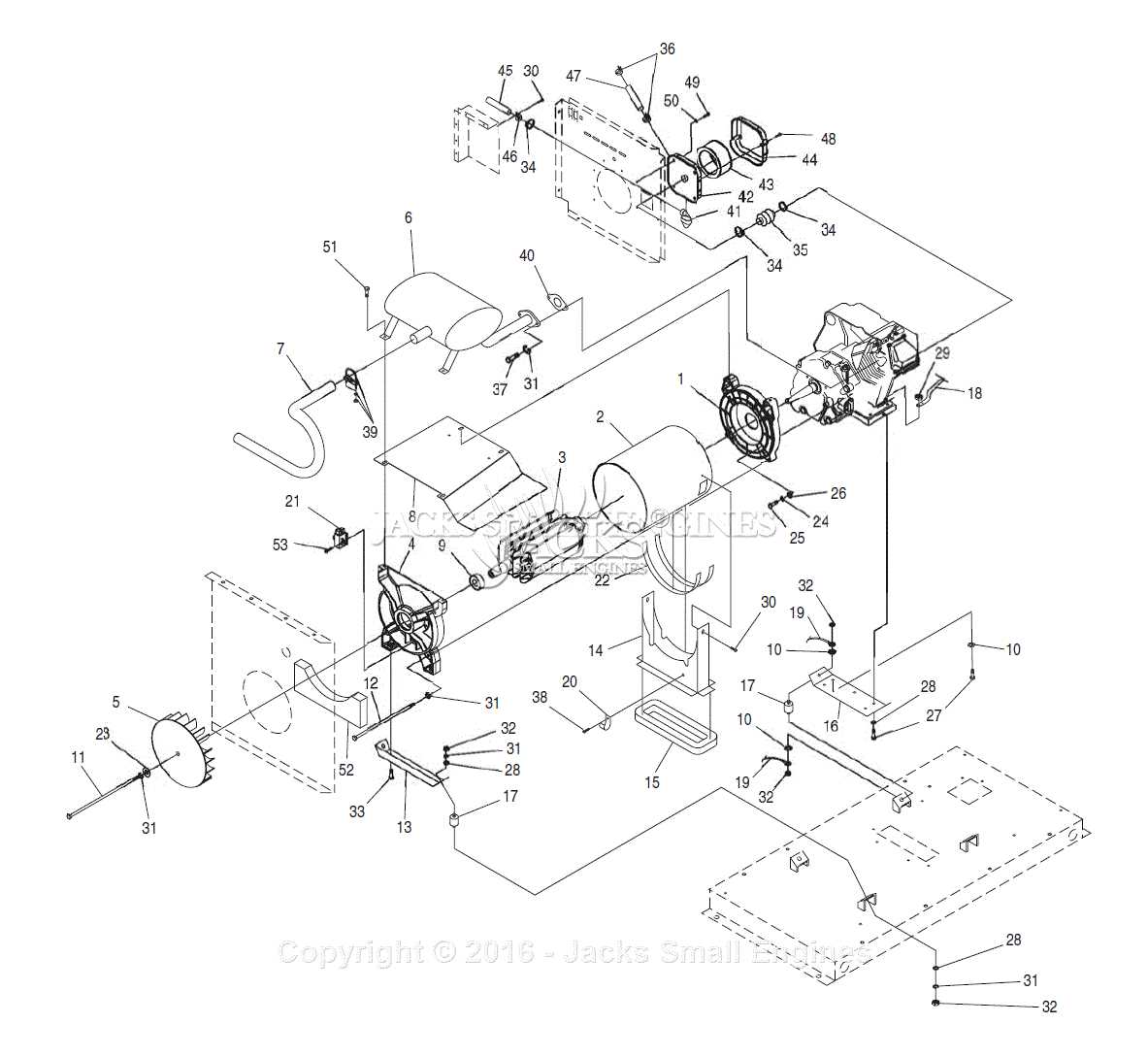

A pressure washer is a versatile tool designed to tackle a variety of cleaning tasks. With its high-powered jets, it efficiently removes dirt, grime, and debris from surfaces. However, like any mechanical device, understanding its internal workings and individual elements can help ensure better performance and longevity. In this section, we’ll take a closer look at the essential elements that make up this powerful equipment.

Each part of a pressure washer plays a crucial role in delivering optimal water pressure and efficiency. From the engine and pump to the nozzles and hoses, knowing how these components work together can provide valuable insight into maintaining and troubleshooting the machine. Understanding the connections and functions of each piece helps in identifying issues early on and ensuring smooth operation during use.

Whether you are looking to perform maintenance or upgrade certain features, having a clear view of the different elements involved can save you time and effort

Generac One Wash Parts Overview

The following section explores the key components essential for the proper functioning of a high-performance pressure cleaning machine. By understanding how these elements interact, users can maintain optimal operation and extend the lifespan of their device. This guide will provide an organized breakdown of various crucial elements.

Core Components

- Engine: The driving force behind the equipment, responsible for powering the entire system.

- Pump: An integral part that pressurizes the water, delivering the necessary output for cleaning tasks.

- Nozzles: Adjustable tips that control water flow and pressure, allowing different settings

Understanding the Engine Components

Grasping the various elements of an engine is essential for ensuring optimal performance and longevity. Each component plays a vital role in the overall functionality, working in harmony to facilitate smooth operation. Familiarity with these elements can enhance maintenance practices and troubleshooting skills.

The Engine Block serves as the foundation of the engine, housing critical components such as cylinders and crankshafts. This robust structure is designed to withstand high pressures and temperatures, providing stability and support for other parts.

Pistons are integral to the engine’s operation, moving up and down within the cylinders to compress the fuel-air mixture. Their reciprocating motion transforms chemical energy into mechanical energy, driving the engine’s power output.

The Crankshaft is another crucial element that converts the linear motion of the pistons into rotational motion. This transformation is essential for propelling the vehicle, as it ultimately connects to the transmission system.

Camshafts play a significant role in regulating the timing of the engine’s valves. By controlling when the intake and exhaust valves open and close, camshafts ensure efficient air and fuel flow, enhancing overall performance.

Understanding these engine components and their interactions is vital for anyone involved in maintenance or repair. By familiarizing oneself with the functionality of each part, one can better diagnose issues and optimize engine efficiency.

Pump Assembly Breakdown

The pump assembly is a crucial component in pressure washing systems, playing a vital role in converting mechanical energy into hydraulic energy. This assembly is responsible for delivering water at high pressure, ensuring efficient cleaning performance. Understanding the various elements within the pump assembly helps in troubleshooting, maintenance, and optimization of the system.

Key Components of the Pump Assembly

The primary elements of the pump assembly include the pump head, pistons, valves, and seals. The pump head houses the pistons that create pressure as they move. Valves control the flow of water into and out of the pump, while seals prevent leaks, maintaining the efficiency of the unit. Each of these components must work in harmony to achieve optimal functionality.

Maintenance Tips for the Pump Assembly

Regular maintenance of the pump assembly is essential for prolonging the lifespan of the system. Routine checks for leaks, wear on seals, and the condition of the pistons can help identify potential issues early. Additionally, ensuring that the pump is free from debris and properly lubricated contributes to its efficient operation, reducing the risk of breakdowns.

Identifying Key Frame Elements

Understanding the essential components of a framework is crucial for effective maintenance and repair. Each element plays a vital role in the overall functionality and performance of the assembly, ensuring that it operates smoothly and efficiently. Familiarizing oneself with these key elements can significantly enhance troubleshooting efforts and facilitate a more straightforward repair process.

Frame Structure: The primary framework provides the necessary support and stability for the entire unit. It is important to identify its configuration, as any damage or misalignment can impact the overall performance.

Mounting Points: These locations are critical for securing various components within the structure. Recognizing their positions helps in ensuring proper alignment during assembly or disassembly.

Connection Interfaces: Understanding how different parts connect and interact is essential. These interfaces facilitate the transfer of power and data, making their identification crucial for effective repairs.

Protective Covers: Often overlooked, these elements safeguard internal components from external factors. Identifying them can help in accessing the interior without causing damage.

Adjustment Mechanisms: These allow for fine-tuning the performance of the assembly. Recognizing their location and function is vital for achieving optimal operation.

By thoroughly familiarizing oneself with these fundamental components, individuals can enhance their repair capabilities and ensure the longevity of the equipment.

Fuel System Configuration

The fuel system in any equipment plays a crucial role in ensuring efficient operation and performance. A well-designed configuration optimizes fuel delivery and minimizes potential issues, contributing to the longevity of the machine. Understanding the components and their arrangement is essential for effective maintenance and troubleshooting.

Key components of the fuel system typically include:

- Fuel Tank: Stores the fuel required for operation.

- Fuel Pump: Delivers fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel to protect the engine.

- Fuel Lines: Transport fuel between components.

- Injector or Carburetor: Mixes fuel with air for combustion.

When configuring the fuel system, consider the following aspects:

- Fuel Type: Ensure compatibility with the equipment requirements to avoid performance issues.

- Flow Rate: Verify that the pump provides adequate pressure and flow for optimal engine performance.

- Filtration: Use appropriate filters to prevent contamination, extending the lifespan of the system.

- Leak Prevention: Check all connections and lines for signs of wear or damage to avoid leaks.

Regular maintenance and inspection of the fuel system components will enhance performance and reliability. Following a systematic approach ensures that the equipment operates efficiently and reduces the risk of failures.

Hose and Nozzle Specifications

The efficiency of any cleaning system heavily relies on the quality and configuration of its fluid delivery components. These essential elements play a crucial role in ensuring optimal performance, enhancing the user experience, and achieving effective results. Understanding the specifications of hoses and nozzles can significantly impact the overall functionality and effectiveness of the equipment.

Hoses are designed to transport fluids under various pressures and conditions. When selecting a hose, it is important to consider factors such as length, diameter, and material composition. A hose with a larger diameter can facilitate a higher flow rate, which is beneficial for quick cleaning tasks. Additionally, the choice of material affects durability and flexibility; options like rubber or reinforced vinyl provide resilience against wear and environmental factors.

Nozzles come in various types and designs, each suited for specific tasks. They influence the spray pattern and pressure of the water stream. For instance, adjustable nozzles allow users to switch between different spray patterns, from a fine mist to a concentrated jet. This adaptability is crucial for tackling diverse cleaning challenges effectively. It is also essential to ensure that the nozzle is compatible with the hose for optimal performance and to prevent leaks during operation.

In conclusion, the proper selection of hoses and nozzles is vital for maximizing the effectiveness and efficiency of any cleaning system. By understanding their specifications, users can make informed decisions that enhance their overall cleaning experience.

Exploring Electrical Connections

Understanding the intricacies of electrical connections is essential for maintaining optimal performance and safety in various equipment. This section delves into the fundamental aspects of wiring systems, highlighting the significance of proper configurations and secure linkages. By exploring the different types of electrical connections, users can gain insight into how these elements work together to ensure efficient operation.

Connections Overview

At the core of any electrical system are the connections that facilitate the flow of electricity. These connections can range from simple wire-to-wire linkages to more complex arrangements involving multiple components. It is crucial to recognize that each type of connection serves a distinct purpose and has its own requirements for installation and maintenance.

Types of Electrical Connections

Common varieties of electrical connections include soldered joints, crimped terminals, and screw connections. Each type possesses unique advantages and limitations, making them suitable for different applications. For instance, soldered joints offer excellent conductivity and mechanical strength but may require specialized tools and skills to create. Conversely, crimped terminals provide a quick and reliable method for connecting wires without the need for additional heating or adhesives.

Importance of Proper Installation

Correctly establishing electrical connections is paramount for the overall performance of any device. Improperly connected wires can lead to short circuits, overheating, and potential damage to components. Therefore, it is essential to follow manufacturer guidelines and adhere to safety standards when making these connections. Regular inspections and maintenance can also help identify wear and tear, ensuring continued functionality and safety.

In conclusion, a thorough understanding of electrical connections is vital for anyone working with electronic systems. By familiarizing oneself with the different types of connections and their installation requirements, users can enhance the reliability and efficiency of their devices.

Maintenance Guide for Water Filter

Proper upkeep of water filtration systems is essential for ensuring clean and safe water. Regular maintenance not only extends the lifespan of the unit but also enhances its performance, allowing it to effectively remove impurities. This guide outlines key practices to help maintain your filtration system in optimal condition.

Regular Inspection

It is crucial to routinely inspect the filtration unit for any signs of wear or damage. Look for cracks, leaks, or unusual noises during operation. Performing these checks can prevent larger issues from developing and ensure the system continues to function effectively. If any abnormalities are detected, address them immediately to avoid compromising the quality of filtered water.

Filter Replacement

Changing the filter at recommended intervals is vital. Over time, filters can become clogged with contaminants, reducing their efficiency. Consult the manufacturer’s guidelines for specific replacement schedules. When replacing the filter, ensure to use compatible replacements to maintain the system’s integrity. Additionally, following proper installation procedures will help achieve optimal filtration results.

By adhering to these maintenance practices, you can ensure that your water filtration system remains reliable and effective, providing you with the clean water you need.

Pressure Control Adjustments

Adjusting the pressure settings of your cleaning device is essential for achieving optimal performance. Proper calibration can enhance efficiency, prolong the lifespan of the equipment, and ensure safe operation. Understanding the fundamentals of pressure management is crucial for any user aiming to optimize their cleaning experience.

Below are some key considerations when making adjustments:

- Understand the Equipment: Familiarize yourself with the specifications and capabilities of your device. Knowing the recommended pressure range is vital for effective adjustments.

- Locate the Pressure Adjustment Valve: This component typically regulates the pressure output. It may be found near the pump or within the control panel.

- Make Incremental Adjustments: Begin with small modifications to the pressure settings. Gradually increase or decrease the pressure to observe its effects on cleaning performance.

- Test After Adjustments: After making changes, conduct a test run. Assess the cleaning efficiency and ensure there are no leaks or malfunctions.

- Consult the Manual: Refer to the user manual for detailed guidance specific to your model. This resource can provide valuable insights into the optimal settings and procedures.

Regularly checking and adjusting pressure settings will not only improve cleaning results but also prevent potential damage to both the equipment and the surfaces being cleaned. Adhering to these guidelines ensures that your device operates at its best, delivering effective cleaning with every use.

Safety Mechanisms and Features

In modern pressure cleaning equipment, a variety of safety mechanisms are integrated to ensure user protection and operational reliability. These features are designed to prevent accidents and enhance the overall user experience, making the equipment safer and more efficient in handling various tasks.

Automatic Shutdown Systems

One of the primary safety features is the automatic shutdown system, which activates in response to abnormal operating conditions. This mechanism helps to prevent overheating and potential damage by halting the operation when specific thresholds are exceeded. Such proactive measures not only protect the machine but also ensure the user’s safety during operation.

Pressure Relief Valves

Pressure relief valves are another critical component that safeguards against excessive pressure buildup within the system. These valves release pressure when it exceeds safe limits, minimizing the risk of hose bursts or equipment failure. This feature is essential for maintaining optimal performance while ensuring that the cleaning device operates within safe parameters.

Replacement Guide for Wheels and Tires

Ensuring the optimal performance of your equipment often relies on the condition of its wheels and tires. These components play a crucial role in mobility and stability, affecting overall functionality. Regular inspection and timely replacement are vital to maintaining efficiency and safety during operation.

When it comes to replacing wheels and tires, start by assessing the current condition of your existing components. Look for signs of wear such as cracks, bulges, or uneven tread. If any of these issues are present, it may be time to consider new replacements.

Next, determine the correct size and type of wheels and tires compatible with your equipment. Refer to the manufacturer’s specifications to ensure you choose the right products that will fit and perform effectively. Keep in mind that using the incorrect size can lead to further damage or reduced performance.

Once you’ve selected the appropriate replacements, follow the installation instructions carefully. Make sure to securely attach the new wheels and tires, ensuring they are properly aligned. This will help prevent any complications during use and prolong the lifespan of the components.

Finally, after replacing the wheels and tires, regularly check their condition to catch any issues early. Proper maintenance will enhance the durability of these parts and contribute to the overall effectiveness of your equipment.

Exhaust System Parts Analysis

The exhaust system of any engine is crucial for efficient operation and emission control. It comprises various components that work in harmony to channel exhaust gases away from the engine, reducing harmful emissions and enhancing performance. Understanding the intricacies of these elements is essential for maintaining optimal functionality and ensuring compliance with environmental regulations.

Key components of this system include the muffler, catalytic converter, exhaust manifold, and tailpipe. Each piece plays a specific role, from reducing noise to converting harmful gases into less harmful substances before they are released into the atmosphere. Regular inspection and maintenance of these components are vital to prevent performance issues and extend the lifespan of the engine.

In-depth analysis of the exhaust system components reveals the importance of their materials and design. For instance, high-temperature resistant materials are often utilized to withstand the extreme conditions present within the system. Additionally, the layout and connections between these parts can significantly impact exhaust flow and overall engine efficiency.

Furthermore, advancements in technology have led to the development of more efficient exhaust systems, which not only meet stringent emission standards but also improve engine performance. Awareness of these innovations is beneficial for anyone involved in engine maintenance or modification.

Troubleshooting Common Wear and Tear

Over time, equipment may experience various forms of deterioration that can affect its performance and efficiency. Recognizing these issues early on is crucial for maintaining optimal functionality and prolonging the lifespan of the unit. This section outlines common signs of wear and tear and provides guidance on how to address them effectively.

Signs of Deterioration

- Inconsistent performance during operation

- Unusual noises, such as grinding or rattling

- Leaking fluids or moisture around connections

- Increased vibrations during use

- Visible wear on components, including fraying or cracking

Basic Troubleshooting Steps

- Inspect for Loose Connections: Ensure that all connections are secure, as loose fittings can lead to inefficiencies.

- Examine Seals and Gaskets: Check for signs of wear and replace any damaged seals to prevent leaks.

- Clean Filters and Screens: Regularly clean or replace filters to maintain airflow and efficiency.

- Monitor Operational Sounds: Listen for any abnormal sounds that could indicate mechanical issues.

- Consult the User Manual: Refer to the equipment’s manual for specific troubleshooting procedures and part replacement recommendations.

By staying vigilant for these common issues and following the outlined steps, users can ensure that their equipment remains in peak condition and operates effectively for years to come.