In the realm of outdoor maintenance, familiarity with the essential elements of your cleaning machinery can greatly enhance its efficiency and longevity. By grasping the intricate layout of these devices, users can identify key components that contribute to their overall performance. This knowledge empowers individuals to tackle common issues and streamline the upkeep process.

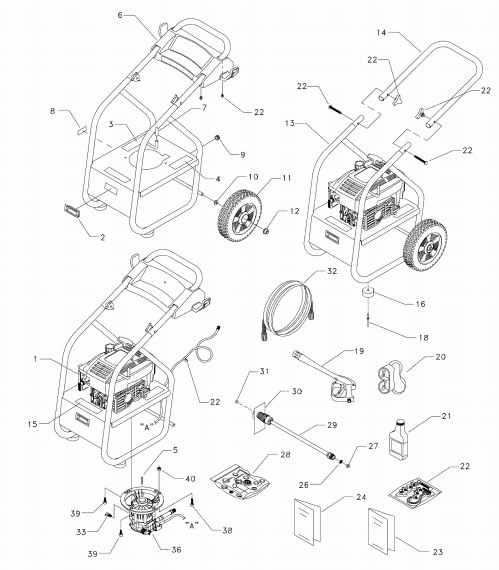

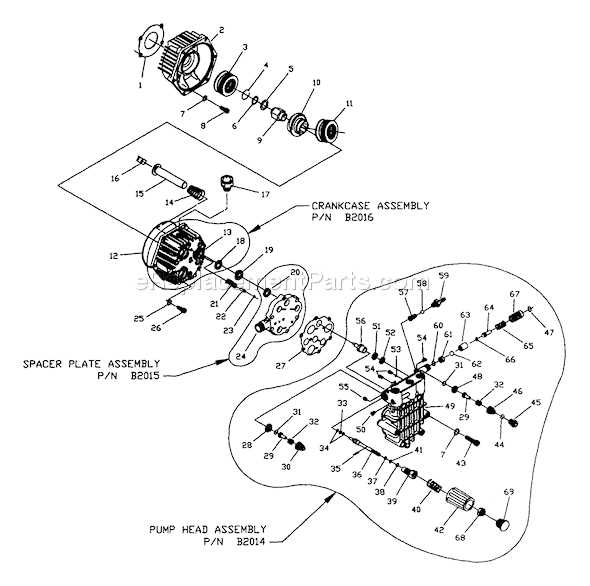

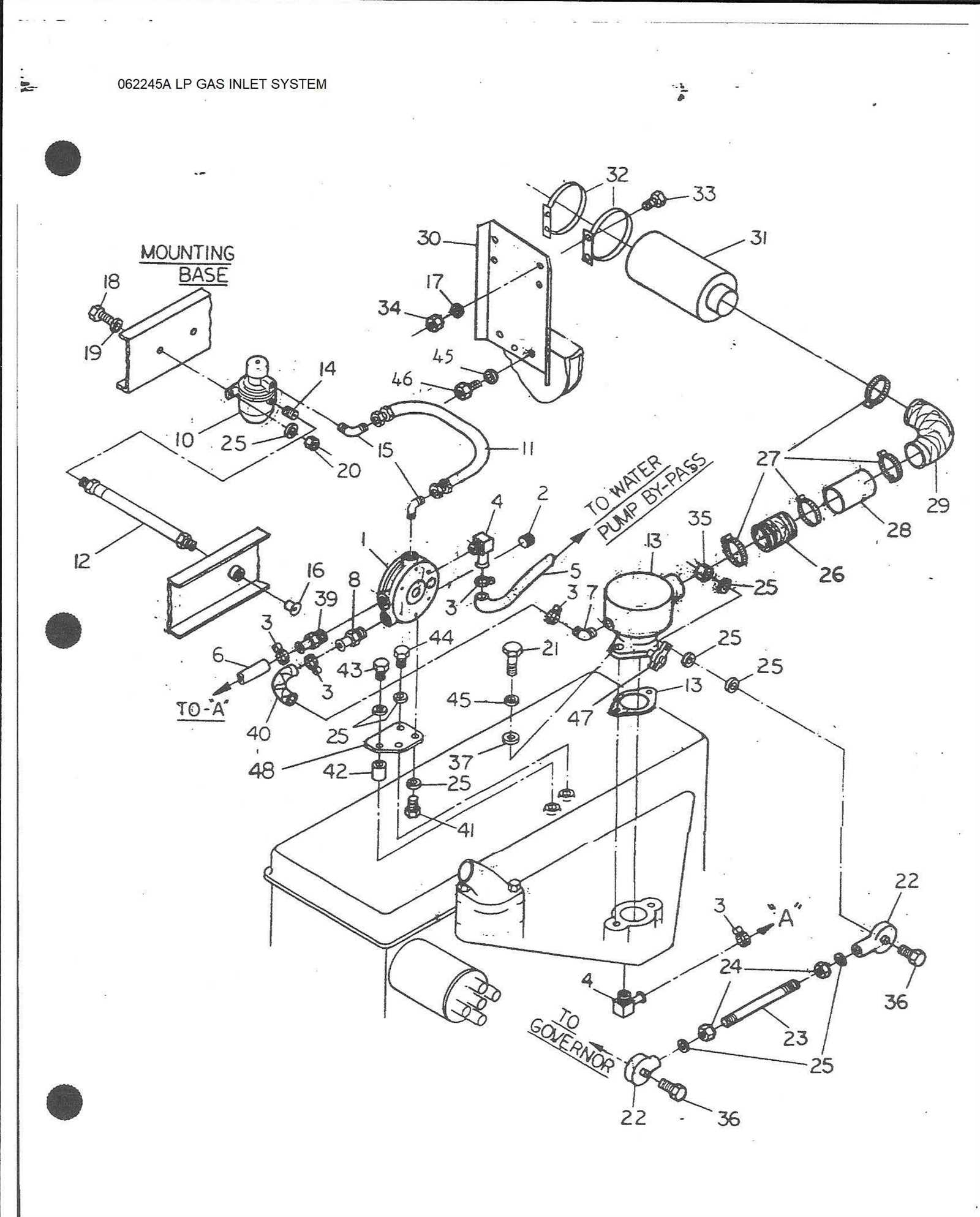

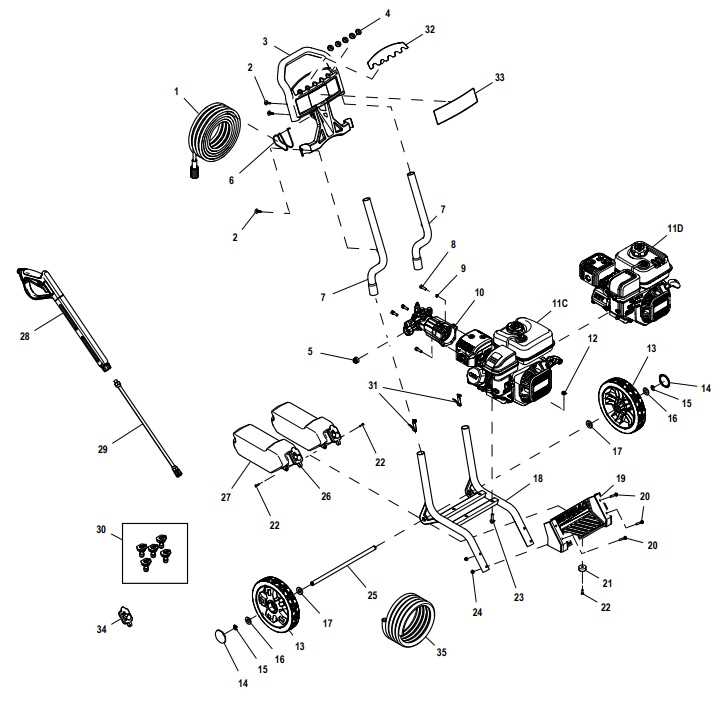

Visual aids that illustrate the arrangement and function of various elements serve as invaluable resources for both novice and experienced users alike. Such representations not only simplify the troubleshooting process but also enhance one’s understanding of how each segment works in harmony to achieve optimal results. Whether it’s a minor adjustment or a complete overhaul, knowing the specifics is crucial.

Moreover, being well-versed in the internal workings of your machinery fosters confidence when undertaking repairs or replacements. This article aims to provide a comprehensive overview of the essential components, ensuring you have the information necessary to maintain your equipment effectively and make informed decisions when repairs are needed.

Understanding Generac Power Washers

In the realm of outdoor cleaning equipment, certain devices stand out for their efficiency and reliability. These machines are designed to tackle a variety of tasks, making them essential for both residential and commercial use. By comprehending the components and functionalities of these devices, users can maximize their effectiveness and longevity.

Key Features

- High-pressure output for effective dirt removal.

- Versatile nozzles for different cleaning applications.

- User-friendly design for ease of operation.

- Durable construction for prolonged use in various environments.

Maintenance Tips

- Regularly check and clean the filter to ensure optimal performance.

- Inspect hoses for leaks or wear to prevent pressure loss.

- Store the unit in a dry place to avoid rust and corrosion.

- Follow the manufacturer’s guidelines for periodic servicing.

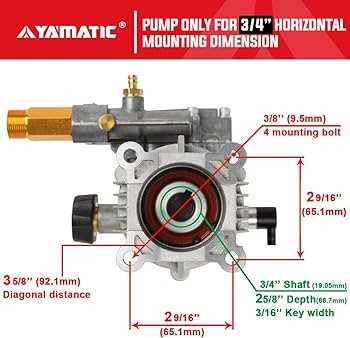

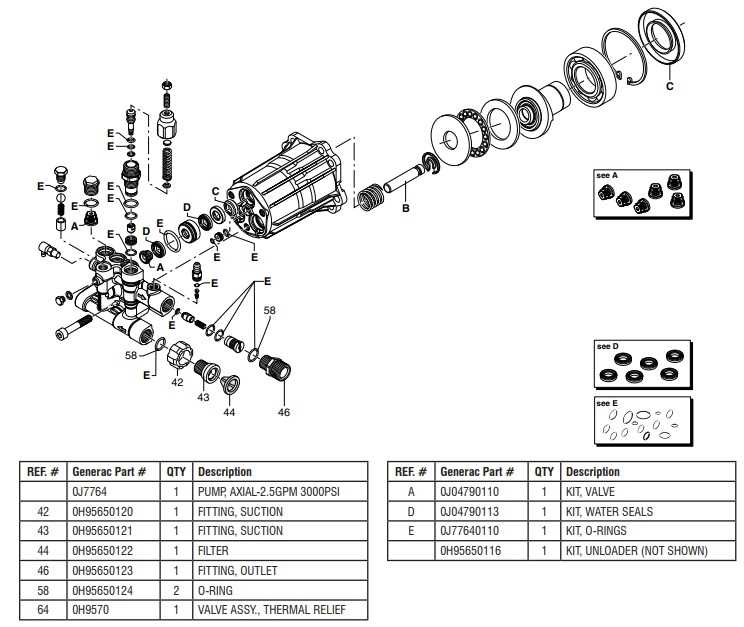

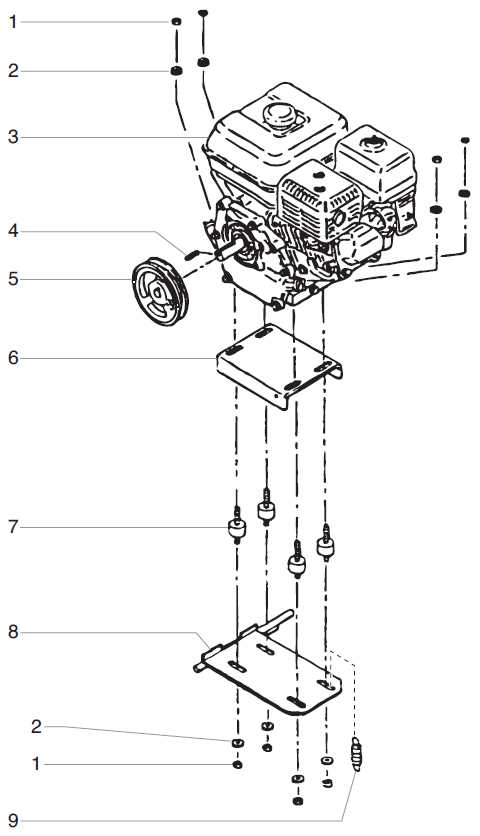

Key Components of Power Washers

Understanding the essential elements of these cleaning machines is crucial for effective maintenance and operation. Each component plays a significant role in achieving optimal performance and efficiency.

Core Elements

- Motor: Drives the system, providing the necessary energy.

- Pump: Responsible for generating pressure to expel water at high speeds.

- Trigger Gun: Controls the flow of water and allows the user to manage pressure.

- Nozzles: Adjust the spray pattern and intensity for various cleaning tasks.

- Hoses: Transport water from the source to the cleaning area.

Additional Features

- Detergent Tank: Holds cleaning agents to enhance the cleaning process.

- Wheels: Facilitate easy movement and maneuverability.

- Frame: Provides structural support and stability during operation.

Importance of a Parts Diagram

Understanding the components of a machine is essential for effective maintenance and repair. A visual representation of the individual elements facilitates identification, ensures proper assembly, and aids in troubleshooting. This clarity can significantly enhance the efficiency of repairs and prolong the lifespan of the equipment.

Enhanced Troubleshooting

A clear visual reference allows users to quickly locate issues and understand how each piece fits into the larger system. This can lead to faster diagnosis and resolution of problems, saving both time and resources.

Efficient Maintenance

Having a detailed outline of each component encourages regular checks and replacements, ultimately ensuring optimal performance. This proactive approach can prevent costly breakdowns and enhance the overall reliability of the machinery.

Identifying Essential Parts and Functions

Understanding the core components of a cleaning device is crucial for effective operation and maintenance. Each element plays a specific role that contributes to the overall efficiency and performance.

- Motor: Powers the system, providing the necessary force.

- Pump: Responsible for drawing in and pressurizing the fluid.

- Spray Gun: Controls the flow and direction of the liquid.

- Hoses: Transport the fluid from the pump to the spray gun.

- Nozzles: Alter the spray pattern and intensity for various tasks.

Familiarity with these key elements allows users to troubleshoot issues and optimize performance.

Common Issues and Troubleshooting Tips

Understanding potential challenges and their solutions is crucial for maintaining equipment efficiency. This section explores frequent problems that users may encounter and offers practical advice to address them.

Frequent Challenges

- Inconsistent performance

- Difficulty starting the machine

- Leaks in hoses or connectors

- Excessive vibrations during operation

Troubleshooting Steps

- Check fuel levels and ensure proper mixture.

- Inspect the air filter for clogs and clean if necessary.

- Examine hoses for cracks or wear; replace if needed.

- Ensure all connections are tight and secure.

Maintenance Practices for Longevity

Ensuring the extended lifespan of your equipment requires a combination of regular care and attention. Implementing effective maintenance routines can prevent wear and enhance performance over time.

- Regular Cleaning: Remove debris and dirt after each use to prevent buildup.

- Fluid Checks: Monitor oil and fuel levels, refilling or changing as necessary.

- Inspect Components: Regularly examine essential parts for signs of wear or damage.

- Follow Manufacturer Guidelines: Adhere to the recommended service schedule for optimal performance.

By dedicating time to these practices, you can significantly improve the reliability and efficiency of your equipment, ensuring it remains in top condition for years to come.

Where to Find Replacement Parts

Locating the necessary components for your equipment can be essential for maintaining its performance. Understanding where to search for these items can save you time and ensure you have reliable options at your disposal.

Authorized Retailers

Visiting authorized vendors guarantees that you receive genuine items that meet manufacturer specifications. Many retailers offer online platforms where you can easily browse and order what you need.

Online Marketplaces

Numerous e-commerce websites provide a vast selection of components, often at competitive prices. However, it’s important to verify the reputation of the seller to ensure quality.

| Source | Advantages |

|---|---|

| Authorized Retailers | Genuine products, warranty support |

| Online Marketplaces | Wide selection, competitive pricing |

Benefits of Using Genuine Parts

Utilizing authentic components for your equipment can significantly enhance performance and longevity. While generic alternatives may seem tempting due to lower prices, the advantages of original parts are often overlooked. Here are several compelling reasons to opt for genuine components:

- Quality Assurance: Authentic components are manufactured to meet strict quality standards, ensuring they function effectively and reliably.

- Optimal Performance: Using original items ensures compatibility with your equipment, leading to improved efficiency and smoother operation.

- Durability: Genuine components are designed for longevity, reducing the need for frequent replacements and saving costs in the long run.

- Warranty Protection: Many manufacturers offer warranties on their products when genuine parts are used, providing additional peace of mind.

- Safety: Authentic components are tested for safety standards, reducing the risk of accidents or malfunctions during use.

In conclusion, investing in genuine components is a wise choice that promotes optimal functionality and safety, ultimately enhancing the overall user experience.

DIY Repair Guide for Users

This section provides practical guidance for individuals looking to perform maintenance and repairs on their equipment. With a little know-how, users can tackle common issues and enhance the lifespan of their machines without relying on professional services.

Before starting any repair, ensure you have the right tools and safety equipment. Follow these steps to make the process smoother:

- Identify the Problem: Carefully observe the symptoms to determine what might be malfunctioning.

- Consult the Manual: Reference the user manual for specific instructions related to your model.

- Gather Necessary Tools: Assemble all tools needed for the repair, such as wrenches, screwdrivers, and safety gloves.

For a successful repair, consider these common areas to check:

- Hoses: Inspect for any signs of wear or damage that may affect performance.

- Connections: Ensure all fittings are secure and free from leaks.

- Filters: Clean or replace filters to maintain efficiency.

- Engine Components: Examine spark plugs and other parts for signs of wear.

Once you have completed the repairs, perform a test run to ensure everything is functioning correctly. Regular maintenance checks can prevent future issues and keep your equipment in optimal condition.

Safety Precautions When Repairing

When undertaking repairs on any equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure a safe working environment and reduce the risk of damage to both the device and the individual performing the task.

First and foremost, always disconnect the equipment from its power source before beginning any maintenance. This simple step significantly minimizes the risk of electrical shock and unexpected operation. Additionally, wearing appropriate personal protective equipment (PPE), such as gloves and safety goggles, can provide essential protection against potential hazards.

Furthermore, it is advisable to work in a well-ventilated area, especially when dealing with components that may emit fumes or contain harmful substances. Keeping your workspace organized helps prevent accidents caused by clutter and makes it easier to locate tools and components as needed.

Finally, consult the manufacturer’s instructions and guidelines for specific repair procedures. Understanding the equipment’s layout and components will enhance safety and efficiency during the repair process.

Upgrading Your Power Washer Components

Enhancing your cleaning equipment can significantly improve its efficiency and lifespan. By investing in quality enhancements, you can elevate performance, reduce maintenance issues, and achieve better results during use. Understanding which elements to upgrade will allow you to customize your machine for specific tasks, making it more versatile.

Identifying Key Areas for Improvement

Focus on critical components such as the motor, spray nozzle, and hose. Upgrading the motor can provide greater energy efficiency and power, while a high-quality nozzle can adjust spray patterns for varied cleaning needs. Additionally, a durable hose can withstand high pressures, enhancing overall durability.

Benefits of Component Upgrades

Investing in superior components not only boosts performance but also ensures longevity. Enhanced efficiency can lead to reduced water and energy consumption, making your cleaning tasks both effective and eco-friendly. Ultimately, these upgrades can save you time and money in the long run.

Cost Analysis of Repairs vs. Replacement

When faced with a malfunctioning machine, owners often grapple with the decision to repair or replace it. This dilemma is influenced by several factors, including the age of the equipment, the extent of the damage, and the financial implications of each option. Understanding these elements can lead to a more informed choice that balances cost-effectiveness with performance needs.

Repairs may appear to be a more economical option initially, especially for minor issues. However, the total cost can escalate if the problem recurs or if additional components fail shortly after the initial fix. Assessing the frequency and nature of past repairs can provide insight into whether ongoing maintenance is a sustainable solution.

On the other hand, replacement can seem daunting due to the upfront investment required. Nonetheless, new models often offer enhanced efficiency and warranties that may offset long-term operational costs. Additionally, technological advancements can significantly improve functionality, potentially leading to savings in time and energy.

Ultimately, the decision should consider not only immediate expenses but also the long-term benefits and drawbacks. A thorough analysis will help determine the most practical path forward, ensuring that resources are utilized wisely while meeting performance expectations.

Customer Support and Resources Available

Accessing reliable assistance and useful materials is essential for users seeking to maintain and troubleshoot their equipment effectively. A range of support options and informational resources are provided to ensure a smooth experience, whether you need guidance on operation or have specific inquiries regarding maintenance.

Support Channels

- Online Help Center: Comprehensive FAQs and troubleshooting guides.

- Customer Service Hotline: Speak directly with knowledgeable representatives for personalized assistance.

- Email Support: Reach out for inquiries that require detailed explanations or documentation.

Resource Materials

- Instruction Manuals: Step-by-step guidance on setup and usage.

- Tutorial Videos: Visual demonstrations covering a variety of topics.

- Community Forums: Engage with other users to share tips and solutions.

By utilizing these resources, customers can enhance their understanding and ensure optimal performance of their equipment.