In the realm of household appliances, a thorough grasp of their internal mechanisms is essential for effective maintenance and repair. Knowing how different elements interact within these machines can greatly enhance their longevity and performance. Each component plays a crucial role, contributing to the overall functionality of the equipment, and understanding this interconnectedness is vital for anyone looking to optimize their appliance’s efficiency.

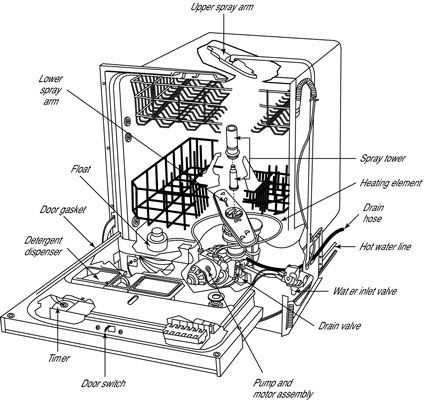

One of the most valuable resources for users and technicians alike is a clear representation of the internal architecture of these devices. Such a layout not only illustrates where each element is situated but also aids in diagnosing issues when they arise. By examining a well-structured visual guide, one can quickly identify which components may require attention, streamlining the troubleshooting process.

Whether you are a DIY enthusiast or a professional repair technician, having access to detailed schematics can empower you to tackle repairs with confidence. This understanding allows for more informed decisions regarding maintenance and part replacements, ensuring that the appliance operates smoothly and reliably. Ultimately, a comprehensive overview of these intricate systems equips individuals with the knowledge necessary to keep their devices running efficiently for years to come.

Understanding Hobart Dishwashers

In the realm of commercial kitchen equipment, the intricate systems that facilitate efficient cleaning operations are crucial. These appliances, designed with precision and functionality in mind, play a pivotal role in maintaining hygiene standards and workflow efficiency.

Exploring the inner workings of these advanced cleaning systems unveils a network of components and mechanisms meticulously integrated to handle various stages of the cleaning process. Key elements include mechanisms for water distribution, temperature control systems, and intricate pathways that manage detergent and rinse aid flow.

Each component within these cleaning units serves a specific function, contributing collectively to ensure dishes emerge spotless and sanitized. Understanding the synergy between these parts illuminates the engineering behind seamless operation and reliability in demanding kitchen environments.

Common Components of Dishwasher Models

In examining the inner workings of various dishwasher models, it becomes apparent that certain fundamental components are shared across different units. These essential elements play crucial roles in ensuring efficient operation and reliable performance.

Water Inlet System: Responsible for supplying water into the dishwasher, this system often includes a valve to control water flow and ensure proper filling during each cycle.

Spray Arm Assembly: Utilizing high-pressure water jets, the spray arm assembly is designed to distribute water evenly throughout the dishwasher, facilitating thorough cleaning of dishes and utensils.

Heating Element: Found either in the bottom or sides of the dishwasher, the heating element is pivotal for raising the temperature of the wash water to optimal levels, aiding in effective sanitization.

Control Panel: Serving as the interface for users, the control panel houses buttons and indicators that allow for the selection of wash cycles, temperature settings, and operational modes.

Drain Pump: Integral to the draining process, the drain pump expels used water from the dishwasher at the conclusion of each cycle, ensuring the interior remains clean and ready for the next load.

Racks and Baskets: Designed to hold dishes securely during washing, racks and baskets are typically adjustable to accommodate different sizes and types of kitchenware, optimizing space utilization.

Filtration System: Essential for maintaining water cleanliness, the filtration system traps food particles and debris, preventing them from recirculating and potentially affecting the cleaning performance.

By understanding these common components and their functions within dishwasher models, one gains insight into the intricate mechanisms that contribute to efficient cleaning and longevity of these kitchen appliances.

How to Identify Parts Quickly

In any complex system, recognizing different components efficiently is essential for maintenance and troubleshooting tasks. This section outlines effective strategies to swiftly identify various elements without relying on specific technical diagrams.

| Strategy | Description |

|---|---|

| Visual Inspection | Use visual cues such as size, shape, and color to distinguish different parts. |

| Labeling and Marking | Ensure parts are labeled clearly or marked with identifiers that denote their function. |

| Reference Documentation | Consult manuals or documentation that provide detailed descriptions of each component. |

| Functional Testing | Perform functional tests to understand the role of each part within the system. |

| Online Resources | Utilize online databases or resources that offer searchable information about machine components. |

By combining these methods, technicians can streamline the process of identifying and understanding parts, contributing to efficient maintenance practices and minimizing downtime.

Maintenance Tips for Longevity

Ensuring the extended life of kitchen appliances involves regular upkeep and careful handling. By following a few straightforward guidelines, users can significantly enhance the efficiency and durability of their equipment. Regular attention not only maintains performance but also prevents costly repairs.

Regular Cleaning

Cleaning is essential for optimal functionality. Residue buildup can impair performance and lead to malfunctions. Routine maintenance should include:

| Task | Frequency |

|---|---|

| Wipe down exterior surfaces | Weekly |

| Clean filters and screens | Monthly |

| Inspect and clean spray arms | Every 3 months |

| Check for leaks and water connections | Every 6 months |

Proper Usage Guidelines

Understanding and adhering to recommended operating practices can prevent premature wear. Key considerations include:

- Using suitable cleaning agents specifically designed for your appliance.

- Avoiding overloading to ensure even cleaning and reduce strain on components.

- Running the unit only when fully loaded to optimize water and energy use.

Troubleshooting Common Issues

Addressing frequent complications in cleaning appliances can significantly enhance their performance and longevity. By understanding typical malfunctions and their possible causes, users can effectively diagnose and resolve problems without professional assistance. This section outlines common issues encountered during operation and offers practical solutions to restore functionality.

Insufficient Cleaning Results

If your appliance is not delivering the desired cleanliness, it may be due to various factors such as clogged filters, improper loading, or suboptimal detergent use. Regular maintenance, including cleaning filters and ensuring the correct placement of items, can improve washing efficiency. Additionally, verifying that the detergent is appropriate for your model is essential for achieving optimal results.

Unusual Noises During Operation

Uncommon sounds emanating from the appliance can indicate underlying issues. Noises such as grinding, rattling, or excessive vibrations may suggest that components are loose or damaged. Inspecting the interior for any foreign objects and ensuring that all parts are securely fastened can help mitigate these disturbances. If noises persist, further examination of mechanical elements may be required.

Replacement Parts Availability

Ensuring the longevity and optimal performance of your equipment often requires timely access to components for repair or enhancement. Availability of these essential elements can significantly influence the efficiency of operations, minimizing downtime and maintaining productivity. Understanding where and how to source these items is crucial for smooth maintenance.

Local Suppliers: Many establishments provide a selection of these necessary components. By connecting with nearby distributors, you can often find quick access to replacements, ensuring that you can address any issues that arise without excessive delay.

Online Retailers: The internet has expanded the options for acquiring these items. Numerous e-commerce platforms specialize in offering a vast array of components, often with detailed descriptions and specifications to aid in the selection process. This convenience allows users to compare prices and availability efficiently.

Manufacturer Resources: The original producers of the equipment typically offer support services that include a catalog of available replacements. This option can ensure you receive authentic components that meet quality standards, which is vital for maintaining the integrity of your machinery.

Second-hand Market: For those looking to save costs, exploring the second-hand market can be beneficial. Many suppliers and online platforms provide pre-owned items at reduced prices, allowing for budget-friendly repairs. However, caution is advised to ensure the quality and compatibility of these components.

By exploring various avenues for sourcing these vital elements, you can effectively maintain and enhance your equipment’s functionality, ensuring it operates at peak performance for years to come.

Benefits of Genuine Components

Utilizing authentic components in your appliances ensures optimal performance and longevity. Genuine items are designed specifically for compatibility with your equipment, providing peace of mind and reliable operation. This choice not only enhances efficiency but also contributes to the overall value of the unit.

Quality Assurance

One of the primary advantages of using genuine components is the assurance of quality. These items undergo rigorous testing to meet industry standards, resulting in:

- Enhanced durability

- Improved functionality

- Lower risk of malfunctions

Cost-Effectiveness

While authentic components may come at a higher initial cost, they often lead to savings in the long run. Consider the following:

- Reduced maintenance expenses

- Minimized downtime

- Extended lifespan of the equipment

In summary, opting for genuine components not only guarantees superior quality but also offers significant financial benefits over time.

Installation Guide for Parts

This section provides essential instructions for the correct assembly and fitting of components within your appliance. Understanding the structure and functionality of each element is crucial for ensuring optimal performance and longevity. Following these guidelines will facilitate a seamless installation process and help avoid common pitfalls.

Preparation Steps

Before you begin the installation process, gather all necessary tools and components. Ensure you have a clean workspace and that the appliance is disconnected from any power source. Review the user manual for specific details on the required components, and familiarize yourself with the layout and connections to simplify the assembly.

Installation Process

Start by securing the main structure, ensuring that all mounting points are accessible. Align the components carefully, following the provided reference outlines. It is important to use the appropriate fasteners and avoid overtightening, which could damage the assembly. After securing each part, perform a thorough check to confirm that everything is in its designated position.

Final Inspection: Once the installation is complete, conduct a final review to ensure all connections are tight and there are no loose elements. Test the appliance briefly to verify that it operates smoothly. If any issues arise, refer back to the manual or seek professional assistance.

Comparing Different Hobart Models

When evaluating various models from this renowned brand, it’s essential to consider their unique features, efficiency levels, and suitability for different settings. Each variant comes with specific functionalities designed to meet diverse requirements, whether for commercial kitchens or smaller establishments. Understanding these distinctions can help you make an informed choice based on your operational needs.

| Model | Capacity | Energy Efficiency | Special Features |

|---|---|---|---|

| Model A | 30 racks/hour | High | Quiet operation, quick rinse cycle |

| Model B | 50 racks/hour | Medium | Built-in water softener, adjustable cycle settings |

| Model C | 40 racks/hour | Very High | Energy Star certified, dual wash system |

| Model D | 25 racks/hour | Low | Compact design, easy maintenance |

Assessing these models’ capacities and functionalities can guide potential buyers in selecting the most appropriate unit for their specific requirements, ensuring optimal performance and efficiency in their daily operations.

Importance of Regular Cleaning

Maintaining a clean and efficient appliance is crucial for its longevity and optimal performance. Regular maintenance helps to prevent the accumulation of residues and grime, which can lead to malfunctions and decreased efficiency. By ensuring that each component is kept in top condition, users can enjoy consistent results and extend the lifespan of their equipment.

Benefits of Routine Maintenance

Consistent upkeep not only enhances functionality but also promotes hygiene. A clean appliance reduces the risk of bacterial growth and unpleasant odors, ensuring that everything processed remains safe and fresh. Furthermore, regular attention to detail can help identify potential issues before they escalate into costly repairs.

Enhancing Efficiency

Cleaning contributes significantly to the overall effectiveness of the equipment. A well-maintained machine operates more smoothly and consumes less energy, resulting in lower utility costs. Ultimately, investing time in routine care leads to improved performance, reliability, and satisfaction.

Upgrading Your Dishwashing System

Enhancing your cleaning apparatus is essential for improving efficiency and performance in any kitchen environment. A well-designed system can not only streamline the cleaning process but also reduce energy and water consumption. By focusing on key components and functionalities, you can create a setup that meets your specific needs.

When considering an upgrade, it’s important to evaluate the existing features of your equipment. Assessing aspects such as cycle times, temperature controls, and drying capabilities can provide insights into areas that require improvement. Investing in advanced technology can result in a noticeable boost in productivity and a reduction in operational costs.

Furthermore, integrating modern features like automated settings and energy-efficient designs can significantly enhance the user experience. Look for innovations that allow for better water filtration, chemical dispensing, and maintenance alerts, ensuring that your equipment operates at peak performance.

Ultimately, upgrading your system not only improves the overall functionality but also extends the lifespan of your equipment. With a thoughtful approach to enhancements, you can ensure that your kitchen runs smoothly, providing exceptional service and maintaining high hygiene standards.