High-pressure cleaning devices have become essential tools for both residential and commercial applications. Their efficiency in removing stubborn dirt, grime, and stains makes them invaluable for various tasks. To ensure optimal performance and longevity, it is crucial to comprehend the intricacies of these machines.

The functionality of these devices is rooted in a combination of several key elements. Each component plays a vital role in delivering the power and precision necessary for effective cleaning. A thorough grasp of these elements not only aids in troubleshooting but also empowers users to perform maintenance and repairs when needed.

In this section, we will delve into the specific components that make up these remarkable machines. By exploring the arrangement and interaction of these individual parts, users can gain insights into their operation, enhancing both understanding and performance.

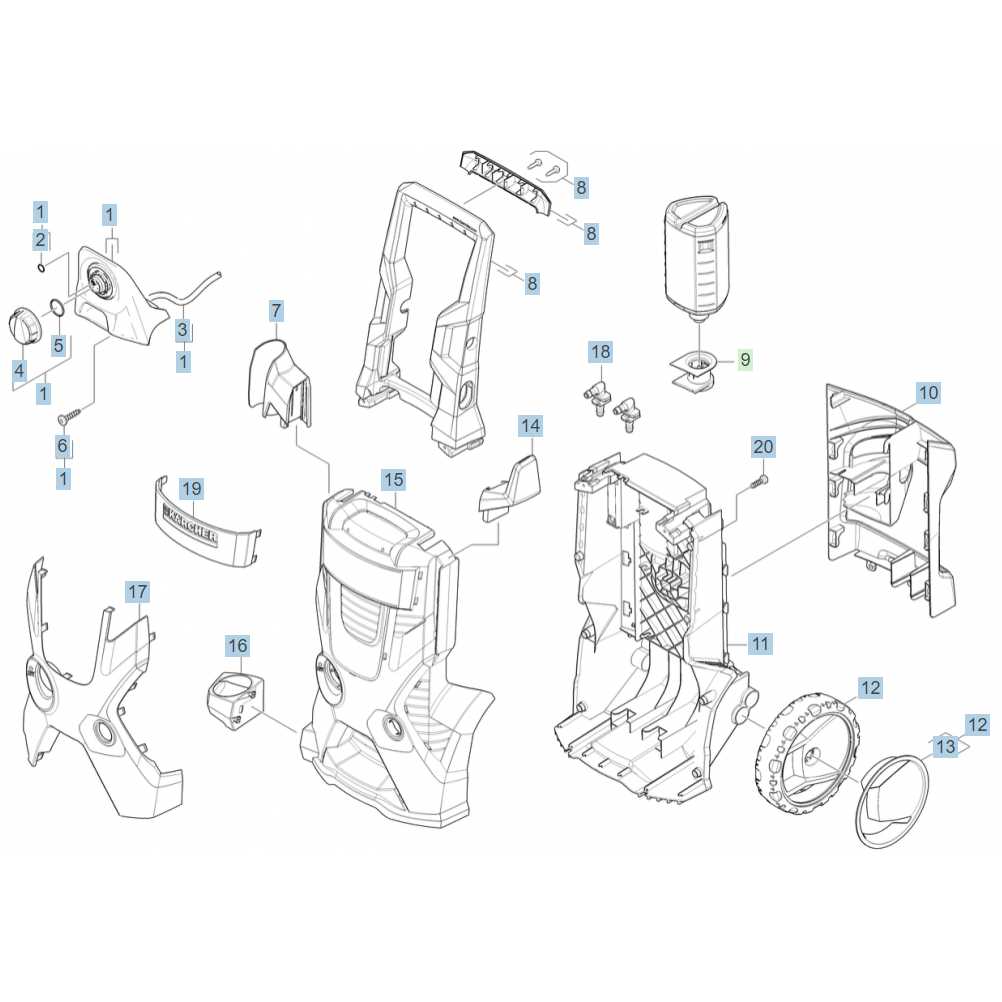

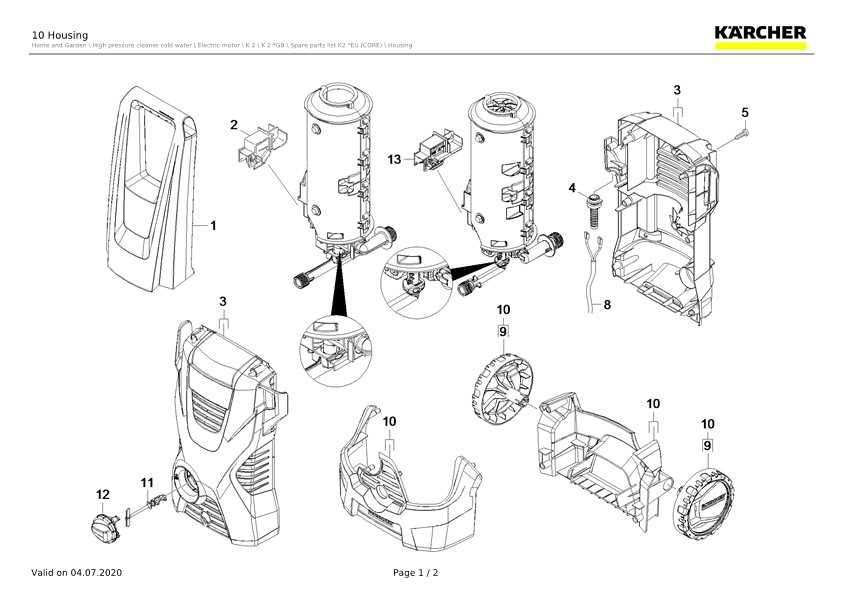

Karcher Electric Pressure Washer Overview

This section provides a comprehensive overview of a well-known cleaning tool designed for efficient outdoor maintenance. The device is favored by many for its ability to tackle tough grime and restore surfaces to their original luster. Its design combines functionality and user-friendliness, making it an essential appliance for homeowners and professionals alike.

These cleaning machines offer numerous benefits, including:

- Effective removal of dirt and stains from various surfaces

- Time-saving features that enhance productivity

- Environmentally friendly operation through efficient water usage

- Versatile applications for multiple cleaning tasks

Understanding the key components of this device can help users maximize its potential:

- Motor: Powers the unit, providing necessary force for effective cleaning.

- Pump: Facilitates water flow, essential for creating high pressure.

- Nozzle: Directs the stream, allowing for various spray patterns.

- Hose: Connects the unit to a water source, typically extending for convenience.

- Trigger Handle: Controls water flow, providing ease of use.

Users can explore various models and specifications to find the right fit for their cleaning needs, ensuring they choose an option that aligns with their requirements for both home and professional use.

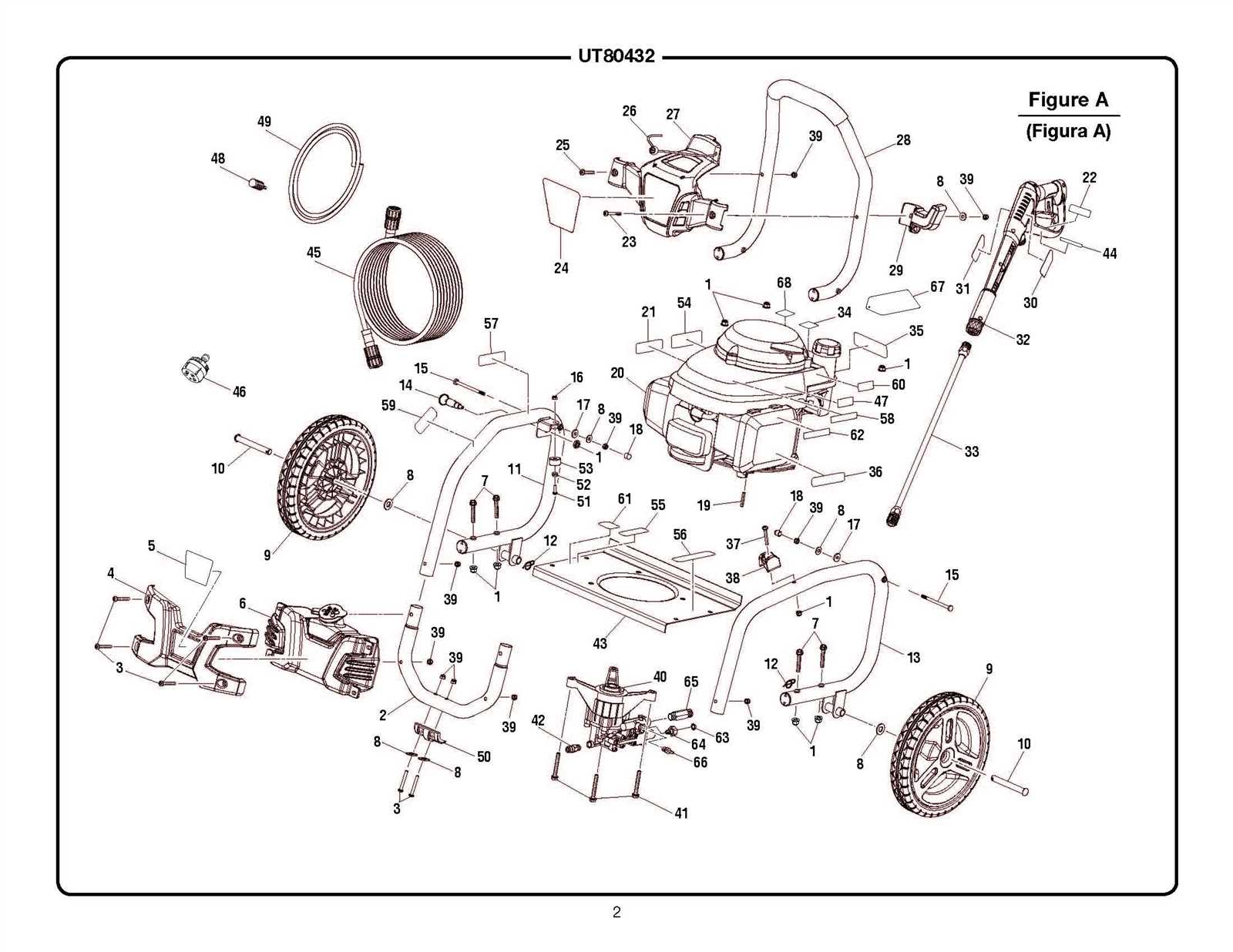

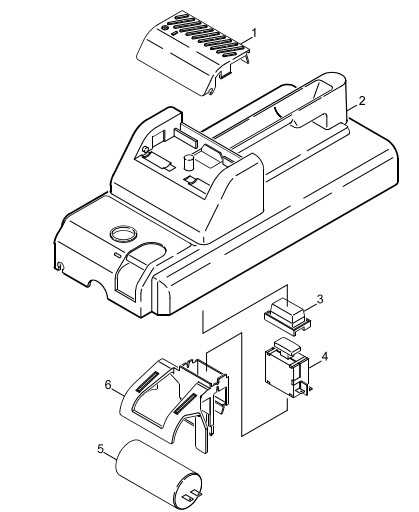

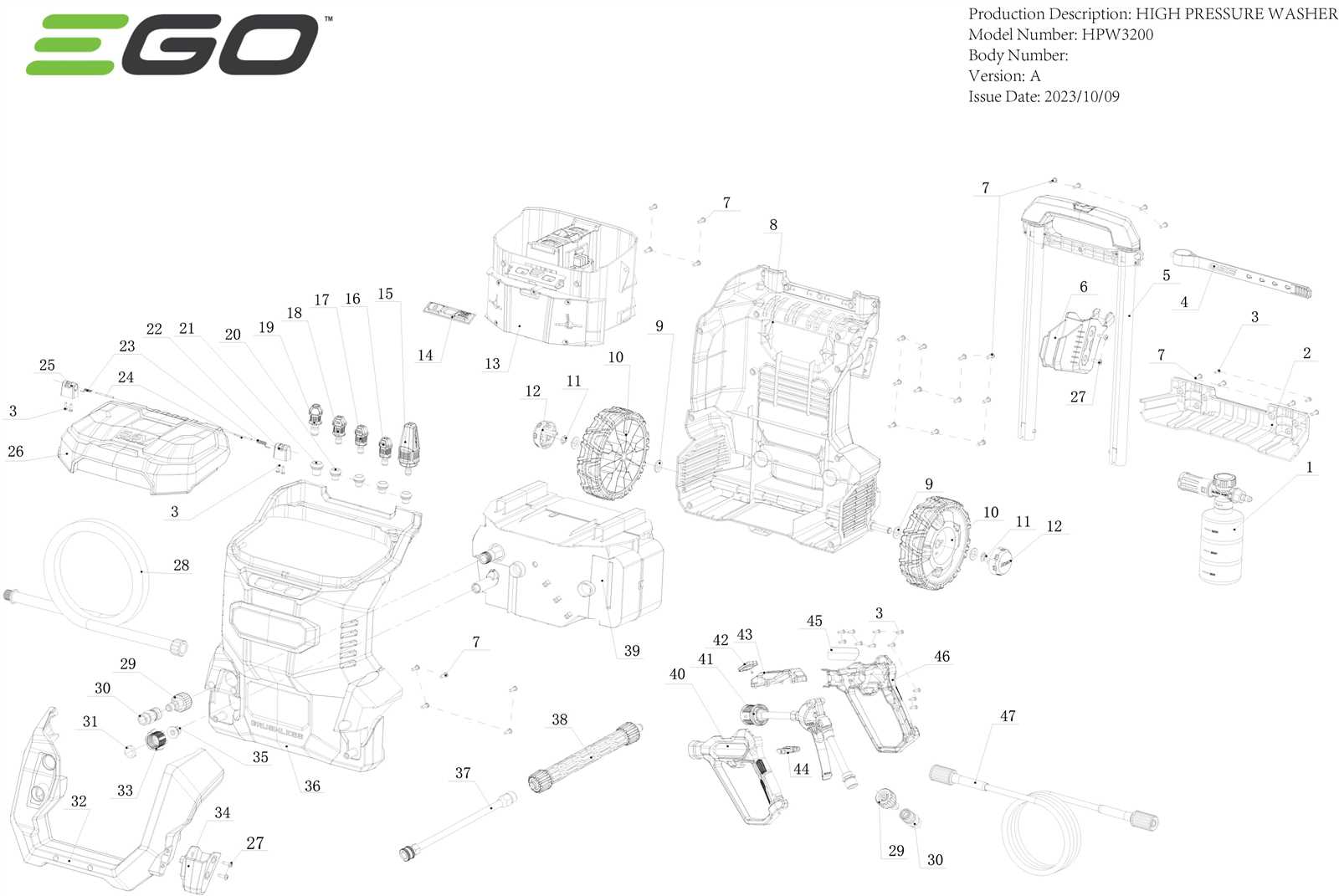

Understanding Pressure Washer Components

To effectively utilize a cleaning device, it is essential to grasp the various elements that contribute to its functionality. Each component plays a crucial role in ensuring optimal performance, efficiency, and durability. This knowledge aids users in troubleshooting issues and maintaining their equipment for long-term use.

Key elements of such devices include:

- Motor: The driving force behind the equipment, responsible for powering all operations.

- Pump: This component generates the necessary force to propel the fluid through the system, allowing for effective cleaning.

- Hose: A flexible tube that transports the liquid from the source to the cleaning nozzle.

- Nozzle: The attachment that determines the spray pattern and pressure of the liquid, allowing for versatile cleaning options.

- Trigger Gun: A handle that controls the flow of the liquid, providing the user with command over the cleaning process.

- Accessories: Various tools and attachments that enhance the capabilities of the equipment, making it suitable for different tasks.

Understanding these components is vital for users who wish to optimize their cleaning routines. By familiarizing oneself with the functionality of each part, it becomes easier to identify potential issues and ensure that the equipment operates efficiently.

- Regular inspection and maintenance can extend the life of the equipment.

- Replace worn or damaged components promptly to prevent further issues.

- Utilize the appropriate attachments for specific cleaning tasks to achieve the best results.

In conclusion, a thorough comprehension of the various elements that comprise the cleaning device is integral to effective operation and maintenance. By investing time in understanding these components, users can ensure they achieve the desired cleaning outcomes.

Common Issues with Pressure Washers

Many individuals encounter challenges when using high-pressure cleaning equipment. Understanding these typical problems can help users troubleshoot effectively and maintain their machines for optimal performance. Here are some frequent issues that might arise during operation.

Insufficient Water Flow

A prevalent concern is the lack of adequate water flow. This can stem from various sources, including blocked hoses or filters. To resolve this issue, it is essential to check all connections and ensure that there are no obstructions in the water supply. Regular maintenance of filters can prevent this problem from recurring.

Unusual Noise and Vibration

Another common problem involves unusual sounds and vibrations during operation. These symptoms may indicate an internal malfunction or wear of critical components. Users should inspect the equipment thoroughly, focusing on the motor and pump. Addressing any loose parts or damaged components promptly can help maintain the longevity of the equipment.

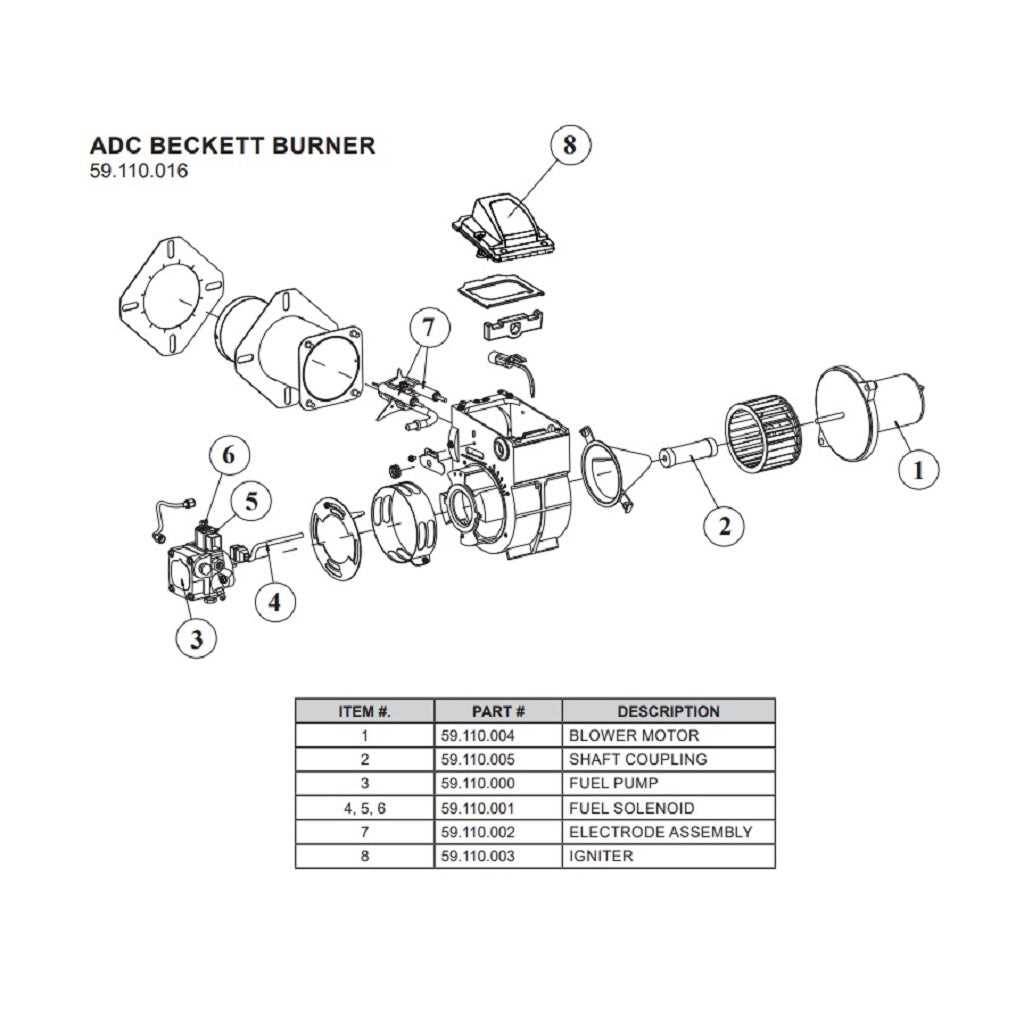

How to Read a Parts Diagram

Understanding a components illustration is crucial for effective maintenance and repair. These visual representations provide an organized way to identify various elements of a device, helping users comprehend their arrangement and function. Mastering this skill can streamline the troubleshooting process and enhance overall efficiency.

Key Elements to Identify

- Labels: Each component is usually accompanied by a label or part number. Familiarize yourself with these identifiers to ensure accurate reference.

- Connection Points: Observe how each piece connects to others. Understanding these points can help in disassembling and reassembling the device correctly.

- Orientation: Pay attention to the orientation of components. Some parts may have a specific direction for proper installation.

Steps to Interpret the Illustration

- Start by reviewing the legend, if available, which explains symbols and notations used in the visual.

- Identify the main assembly and break it down into its individual components.

- Cross-reference the numbers or labels with the manufacturer’s list to find detailed descriptions and specifications.

- Take note of any assembly instructions that may accompany the illustration for clarity on how to proceed with repairs or replacements.

Key Parts of Karcher Models

Understanding the essential components of various models can significantly enhance your maintenance experience. Familiarity with these elements enables users to troubleshoot issues, perform repairs, and ensure optimal performance over time.

- Motor: The driving force behind the device, providing the necessary power for operation.

- Pump: Responsible for generating pressure, this component plays a crucial role in the efficiency of the cleaning process.

- Trigger Gun: The handheld mechanism that controls the flow of liquid, allowing users to direct the spray as needed.

- Hoses: These flexible tubes transport the cleaning solution from the unit to the nozzle, ensuring a steady supply during use.

- Nozzles: Different attachments modify the spray pattern and intensity, catering to various cleaning tasks.

- Filter: Prevents debris from entering the system, safeguarding internal components and maintaining performance.

Each of these elements plays a vital role in the functionality and effectiveness of the equipment. Regular inspection and maintenance of these components can prolong the lifespan of your unit and improve its overall efficiency.

Knowing the specific function and maintenance needs of each part can empower users to tackle issues proactively, ensuring a seamless cleaning experience.

Replacement Parts and Accessories

Maintaining the functionality of your cleaning device is essential for optimal performance and longevity. Over time, certain components may wear out or become damaged, necessitating their replacement. Additionally, various accessories can enhance the efficiency and versatility of your unit, allowing you to tackle a broader range of cleaning tasks.

When seeking to replace any worn or broken elements, it is crucial to identify the specific components compatible with your model. This ensures seamless integration and reliable operation. Common replacements include hoses, nozzles, and filters, each playing a vital role in the overall effectiveness of your equipment.

Moreover, investing in compatible accessories can significantly expand your cleaning capabilities. From extension wands to specialized brushes, these tools are designed to optimize your device’s performance and adapt it to various surfaces and cleaning challenges. Always consult your user manual or manufacturer’s guidelines to ensure you select the right items for your needs.

Tools for Repairing Pressure Washers

Maintaining and fixing high-performance cleaning devices requires a specific set of instruments that ensure efficiency and precision. A well-equipped toolbox is essential for tackling various issues that may arise during operation or after prolonged use. Understanding the necessary tools will help you perform repairs effectively, extending the lifespan of your equipment and improving its functionality.

Essential Repair Tools

The foundation of any repair process starts with basic hand tools. Screwdrivers, wrenches, and pliers are fundamental for disassembling and reassembling components. Additionally, a set of socket wrenches allows for easy access to tight spaces, facilitating quicker repairs. Furthermore, utility knives can be useful for cutting through hoses or other materials when replacements are needed.

Specialized Instruments

In addition to standard tools, specialized equipment is beneficial for specific tasks. A multimeter is crucial for diagnosing electrical issues, while a pressure gauge helps to evaluate the system’s performance. Cleaning agents and lubricants are also necessary for maintaining optimal function and preventing wear. Having the right instruments on hand simplifies the repair process, making it more efficient and effective.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your cleaning equipment. Regular maintenance not only enhances performance but also prolongs the lifespan of the device. Following specific practices can significantly reduce the likelihood of malfunctions and improve overall functionality.

Here are some key maintenance strategies to consider:

| Tip | Description |

|---|---|

| Regular Inspection | Check the unit frequently for any signs of wear and tear, ensuring all components are functioning properly. |

| Clean Filters | Remove and clean the filters regularly to prevent clogs and maintain optimal flow. |

| Use Proper Detergents | Always use recommended cleaning solutions to avoid damaging internal components. |

| Store Correctly | Keep the device in a dry, protected area to shield it from environmental factors when not in use. |

| Check Hoses | Inspect hoses for any leaks or damages, replacing them promptly to ensure a steady supply of water. |

Implementing these maintenance tips will help maximize the efficiency and longevity of your cleaning apparatus, providing you with reliable performance for years to come.

Upgrading Your Pressure Washer

Enhancing your cleaning equipment can significantly improve its performance and efficiency. By investing in quality accessories and implementing modifications, you can transform an ordinary device into a powerful tool capable of tackling tougher jobs. This section explores various ways to elevate the capabilities of your cleaning apparatus.

Here are some key upgrades to consider:

- Higher Flow Rate Nozzles: Switching to nozzles that provide a greater flow rate can enhance water distribution, allowing for quicker and more effective cleaning.

- Durable Hoses: Upgrading to reinforced hoses can prevent leaks and withstand higher pressure, extending the lifespan of your equipment.

- Effective Detergents: Using specialized cleaning solutions designed for your machine type can help achieve better results, especially on tough stains.

- Powerful Motors: If feasible, consider replacing the motor with a more robust option to increase overall performance.

- Storage Solutions: Adding racks or holders for accessories and tools can keep your workspace organized and efficient.

When implementing upgrades, ensure compatibility with your existing system to avoid malfunctions. Regular maintenance and timely improvements can lead to a more effective cleaning experience and extend the longevity of your apparatus.

Finding Genuine Karcher Parts

When it comes to maintaining your cleaning equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Using original replacements not only guarantees compatibility but also enhances the overall functionality of your machine. In this section, we will explore effective strategies to help you identify and acquire the genuine items you need.

One of the most reliable ways to find authentic components is through authorized retailers or the manufacturer’s official website. These sources provide assurance that the items are legitimate and meet the necessary quality standards. Additionally, purchasing from recognized suppliers often includes warranties, further protecting your investment.

Furthermore, it is essential to familiarize yourself with the specific model and specifications of your equipment. This knowledge will aid in accurately identifying the right replacements and avoiding potential pitfalls associated with counterfeit alternatives. Look for unique identifiers such as serial numbers or model names, which can streamline your search for the correct components.

Lastly, consider joining online forums or communities dedicated to cleaning equipment enthusiasts. Engaging with other users can provide insights into where to find authentic items and share experiences regarding reliable suppliers. Networking with fellow users can be invaluable in navigating the marketplace and ensuring you procure only the best quality components for your machine.

DIY Repairs vs. Professional Help

When it comes to maintaining equipment, individuals often find themselves at a crossroads: should they tackle repairs themselves or seek assistance from a skilled technician? This decision can significantly impact both the outcome of the repair and the overall cost. Understanding the advantages and drawbacks of each approach is crucial for making an informed choice.

Benefits of DIY Repairs

Taking on repairs independently can be a rewarding experience. It not only saves money on labor costs but also provides a sense of accomplishment. Many individuals appreciate the opportunity to learn more about their equipment, enhancing their troubleshooting skills. Moreover, for those who enjoy hands-on projects, DIY repairs can be a fulfilling way to spend time. However, it’s essential to weigh these benefits against the potential risks involved, particularly when specialized tools or knowledge are required.

Advantages of Professional Assistance

Enlisting the help of a professional often ensures a higher quality of repair. Experts possess the necessary experience and tools to diagnose and resolve issues efficiently. Additionally, they may provide warranties for their work, offering peace of mind. While this route typically involves higher costs, it can ultimately save time and prevent further complications that may arise from improper repairs. For complex issues, relying on a professional may be the most prudent choice.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks on any machinery, it is essential to prioritize safety to prevent accidents and injuries. Adhering to certain guidelines can significantly reduce risks associated with handling tools and equipment.

Before starting any repair work, consider the following safety measures:

- Always disconnect the device from the power source to avoid accidental activation.

- Use personal protective equipment (PPE), including gloves, goggles, and masks, to shield yourself from debris and hazardous substances.

- Work in a well-ventilated area to ensure proper air circulation and reduce exposure to fumes.

- Keep your workspace organized and free from clutter to prevent tripping hazards and misplaced tools.

- Ensure that all tools are in good condition and appropriate for the tasks at hand.

Furthermore, familiarize yourself with the user manual and any specific safety instructions related to the equipment. It is crucial to understand the components involved and the potential risks associated with each part.

When performing repairs, follow these additional tips:

- Take your time and avoid rushing through tasks to maintain focus and accuracy.

- If you are unsure about any procedure, consult a professional or seek guidance from reliable resources.

- Be cautious when handling sharp or moving components, ensuring your hands are clear of any operational areas.

- After completing the repair, double-check all connections and test the equipment in a safe manner.

By implementing these safety practices, you can help ensure a safer working environment and reduce the likelihood of accidents during maintenance activities.

Frequently Asked Questions About Karcher

This section addresses common inquiries regarding the popular brand known for its innovative cleaning solutions. Whether you’re seeking advice on maintenance, operation, or troubleshooting, this guide aims to provide clear answers to enhance your experience.

What should I do if my device won’t turn on?

If your unit fails to power up, first ensure that it is properly connected to a functioning outlet. Check the power cord for any visible damage. If everything appears intact, consider inspecting the fuse or circuit breaker, as a blown fuse may be the cause of the issue.

How can I maintain my equipment for optimal performance?

To keep your equipment in top condition, regularly clean the filters and nozzles. It is also advisable to check for any wear and tear on hoses and connectors. Storing the device in a dry, protected area when not in use can significantly extend its lifespan.

Remember: Regular maintenance can prevent future issues and ensure your cleaning solutions remain effective.