When it comes to maintaining or repairing a household laundry unit, knowing the key elements that make up the system is essential. Each component plays a crucial role in ensuring efficient operation, from the control panel to the internal mechanisms. Identifying and understanding these elements can simplify troubleshooting and enhance the lifespan of the appliance.

Internal mechanisms within a typical laundry machine are designed to work together harmoniously, allowing users to easily handle their daily cleaning tasks. From sensors that monitor water levels to motors that drive the spin cycle, these systems are built with precision. Recognizing how these pieces interact provides a clearer view of the machine’s overall functionality.

For those seeking to fix or upgrade their laundry equipment, having a clear understanding of the various elements involved will make the process significantly easier. A well-organized diagram can be an invaluable resource for both professionals and DIY enthusiasts, helping them to pinpoint issues or make improvements efficiently.

Understanding the Maytag Front Load Washer

When it comes to efficient cleaning solutions, this type of home appliance is designed to provide optimal results through a combination of advanced features and technology. Understanding its mechanisms and how various components work together is essential for proper maintenance and troubleshooting. The structure and design are specifically crafted to offer a balance of energy efficiency, convenience, and durability.

The overall design emphasizes user-friendly operation while incorporating cutting-edge technology to tackle even the most stubborn stains. By examining the key elements of this machine, users can gain insights into how each part contributes to the overall cleaning performance and longevity of the appliance.

Proper care and knowledge of how each component functions will ensure that your device runs smoothly and effectively for years to come. Familiarizing yourself with the operational aspects will not only help in extending the lifespan of the unit but also allow you to address potential issues more effectively.

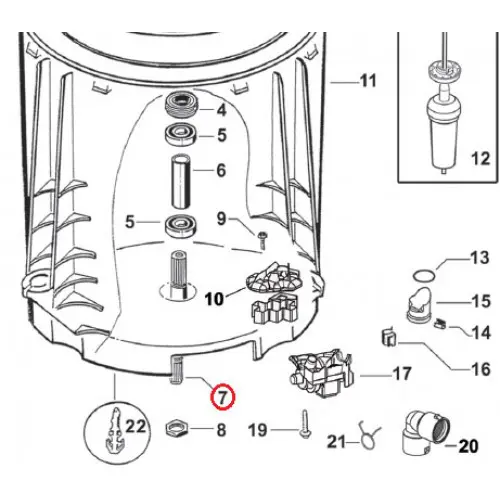

Key Internal Components of a Washer

Understanding the essential elements inside a laundry machine can help users identify potential issues and enhance overall performance. These components work together to deliver efficient cleaning and maintenance of clothes. Below is a breakdown of the core elements found in most modern machines.

Drum and Agitator System

The drum, where clothes are placed, is responsible for holding water and allowing for effective washing and rinsing cycles. Paired with the drum, the agitator or impeller creates the movement needed to scrub clothes clean, ensuring stains and dirt are removed.

- Outer Tub: Holds the water during the washing and rinsing processes.

- Inner Tub: Rotates and holds the laundry during the spin cycle.

- Agitator/Impeller: Moves clothes within the drum to clean them thoroughly.

P

How the Control Board Operates

The control board serves as the brain of the appliance, coordinating various functions to ensure proper operation. By managing inputs from sensors and user commands, it communicates with different components to regulate the entire cycle from start to finish.

At the heart of the system, the control board processes data received from sensors, such as water levels and temperatures, to optimize efficiency and performance. It then sends signals to actuators, controlling key functions like water flow, drum rotation, and temperature adjustments. Each stage of the washing cycle is managed with precision to ensure the best possible results.

Additionally, the control board monitors safety mechanisms, shutting down operations if any irregularities are detected. This intelligent system ensures that every part works harmoniously while maintaining safety and efficiency throughout the entire cycle.

Functions of the Washer Drum Assembly

The drum assembly is a critical component that plays a key role in the overall washing process. It ensures that clothes are properly cleaned by providing an effective environment for water and detergent to interact with fabrics. Understanding its functions can help users appreciate its importance in the machine’s performance.

- Rotation for Thorough Cleaning: The drum spins during the wash cycle, helping to agitate clothes and ensure that water and detergent are evenly distributed. This rotation is crucial for loosening dirt and stains.

- Water Drainage: During the spin cycle, the drum’s perforations allow water to drain away from clothes, reducing moisture levels and preparing fabrics for drying.

- Gentle Care for Fabrics: The smooth, rounded interior design of the drum is optimized to protect clothes from damage, ensuring that even delicate materials are handled with care.

- Balanced Movement: A well-designed drum provides balanced movement, minimizing vibrations and noise during the washing and spinning processes.

- Efficient Water and Energy Usage: The drum’s design contributes to efficient water usage,

Significance of the Door Lock Mechanism

The door lock system plays a crucial role in ensuring the safety and efficiency of modern laundry machines. This mechanism not only prevents accidental openings during operation but also serves as an essential safety feature, protecting both users and the machine itself. Its proper functioning is vital for the overall reliability and smooth performance of the washing process.

How the Door Lock Works

The door lock engages as soon as the wash cycle begins, preventing the door from being opened until the cycle is complete. This automatic locking ensures that water and clothes remain securely inside, reducing the risk of spills or interruptions. The mechanism typically includes sensors that communicate with the machine’s control system, allowing it to proceed with the wash once the door is safely locked.

Common Issues with Door Locks

Over time, door locks may face wear and tear, leading to issues such as failure to lock or unlock, or error messages appearing on the control panel. When this happens, it can disrupt the entire washing process. Regular maintenance and timely replacement of faulty components can help extend the lifespan of this critical part.

Role of the Drain Pump in Cleaning The drain pump is a crucial component in maintaining the efficiency and effectiveness of any cleaning appliance. Its primary function is to remove excess water from the drum after the washing cycle, ensuring that the items being cleaned are free of moisture and detergent residues. By facilitating proper drainage, this component plays a vital role in achieving optimal cleanliness and hygiene.

Efficient Water Removal is essential for a thorough cleaning process. When the appliance completes a wash cycle, the drain pump activates to expel any remaining water, preventing stagnation and the growth of mold or mildew. This timely removal of liquid ensures that the fabrics do not remain soaked, which could lead to unpleasant odors or even damage to the materials.

Moreover, the drain pump contributes to water conservation by allowing for a controlled and efficient drainage process. This not only saves water but also enhances the overall cleaning experience by ensuring that each cycle is as effective as possible. In addition, a well-functioning pump helps to minimize the risk of clogs or blockages, which can disrupt the cleaning process and lead to costly repairs.

In summary, the drain pump is integral to the cleaning process, promoting efficient water removal and enhancing the appliance’s performance. Regular maintenance of this component is essential for ensuring that the entire cleaning system operates smoothly and effectively.

Water Inlet Valve Purpose and Operation

The water inlet valve plays a crucial role in the functionality of any washing machine. This component is responsible for controlling the flow of water into the machine during the various stages of the cleaning cycle. By regulating the amount of water entering the drum, it ensures that the appliance operates efficiently and effectively.

Functionality of the water inlet valve is governed by electrical signals from the control board, which activates the valve when water is needed. Typically, this part consists of multiple solenoids, each corresponding to different water temperatures–hot, cold, or both. When the machine requires water, the control system sends a signal to the appropriate solenoid, allowing water to flow from the household supply into the drum.

In terms of operation, the valve must maintain a precise opening and closing mechanism. It must open fully when water is needed and close tightly once the desired level is reached. A malfunctioning valve can lead to issues such as overfilling or insufficient water supply, ultimately impacting the performance of the entire appliance. Regular maintenance and timely replacement of this component are essential to ensure optimal washing conditions.

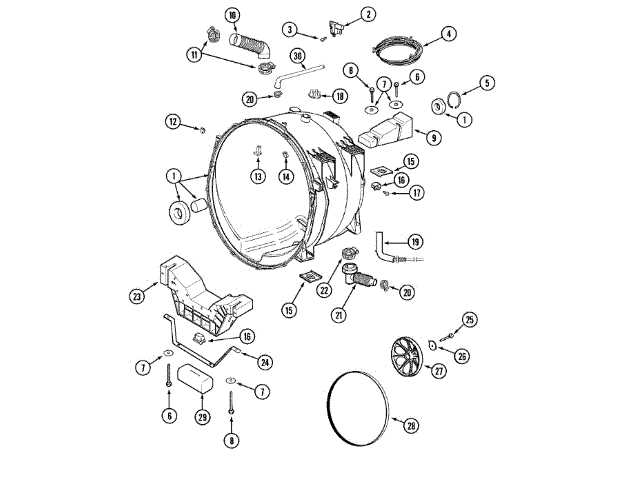

Motor Assembly: Power Behind the Washer

The motor assembly serves as the heartbeat of any cleaning appliance, driving the various mechanical components to ensure effective operation. This integral unit transforms electrical energy into mechanical motion, facilitating the essential cycles that contribute to optimal cleaning performance. Understanding the motor’s functionality and its role within the overall system is crucial for both maintenance and troubleshooting.

Components of the Motor Assembly

This assembly typically consists of several key elements, including the stator, rotor, and drive belt. The stator generates a magnetic field that interacts with the rotor, causing it to spin. This rotation is then transmitted to the drum via the drive belt, which plays a vital role in achieving the desired speed and efficiency during the cleaning process. Each component must work harmoniously to ensure the appliance functions smoothly and effectively.

Common Issues and Maintenance Tips

Importance of the Washer Suspension System

The suspension system in laundry appliances plays a crucial role in ensuring optimal performance and longevity. This component is essential for stabilizing the machine during operation, especially when it is spinning. A well-functioning suspension system contributes to reduced vibrations and noise, enhancing the user experience while protecting the internal mechanisms from excessive wear.

Here are some key reasons why the suspension system is vital:

- Stability: It keeps the appliance level and stable, preventing unnecessary movement during cycles.

- Vibration Reduction: By absorbing shocks, it minimizes vibrations that can lead to noise and disruption.

- Component Protection: A reliable suspension system safeguards sensitive internal parts from damage caused by excessive movement.

- Efficiency Improvement: Enhanced stability allows for more efficient washing and spinning processes, resulting in better cleaning performance.

- Longevity: Proper functioning of this system can extend the overall lifespan of the appliance by reducing stress on its components.

Regular maintenance and timely replacement of suspension elements are essential for optimal functioning. Users should be aware of the signs of a failing suspension system, such as increased noise, excessive vibrations, or visible movement of the appliance during operation. Addressing these issues promptly can prevent further damage and ensure the appliance operates smoothly.

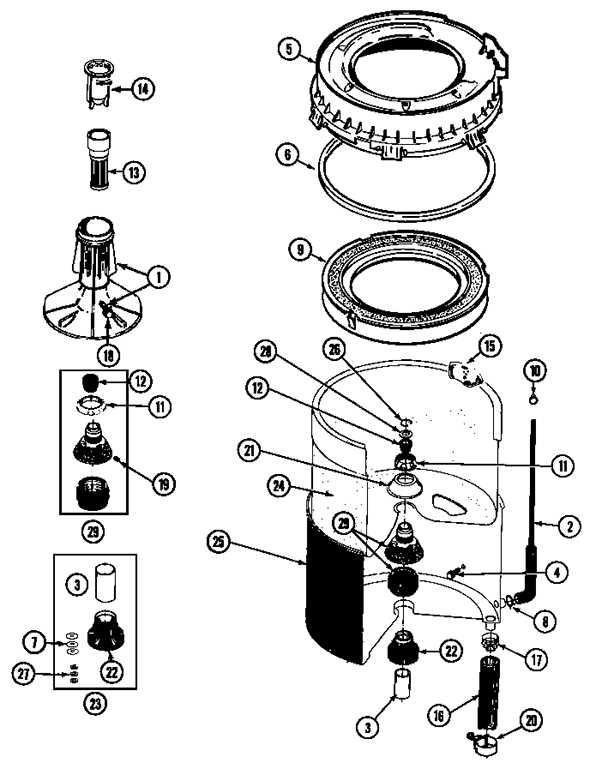

Exploring the Washer Tub and Its Functions

The tub of a laundry appliance plays a crucial role in the washing process, serving as the central component where garments are cleaned. This essential part is designed to facilitate the movement of water and detergent, ensuring that clothes are thoroughly saturated and agitated for effective cleaning. Understanding the design and functionality of this component can enhance your appreciation of its engineering and efficiency.

Typically, the tub is crafted from durable materials to withstand the rigors of frequent use and high water temperatures. Its shape and structure contribute to optimizing water circulation and minimizing wear on fabrics during the washing cycle.

Function Description Water Retention The tub holds the water and detergent mixture, allowing for effective soaking and cleaning of fabrics. Agitation It facilitates the movement of garments through mechanical action, promoting the removal of dirt and stains. Drainage The tub is designed to allow water to exit efficiently during the draining phase of the cycle. Support It provides a stable environment for clothes, minimizing the risk of damage during operation. By understanding these functions, users can better appreciate how the tub contributes to overall cleaning performance, leading to cleaner clothes and a more efficient washing experience.

Common Issues with the Shock Absorbers

Shock absorbers play a critical role in the stability and efficiency of any appliance designed for laundry tasks. Over time, these components can face a variety of challenges that may affect their performance, leading to noticeable issues during operation.

One of the most frequent problems encountered is leakage. This can occur due to wear and tear, causing fluid to escape and resulting in reduced damping ability. As a result, vibrations may increase, leading to excessive noise and potential damage to other internal components.

Another common concern is wearing out of the rubber mounts or bushings that connect the shock absorbers to the chassis. When these components deteriorate, they can lead to improper alignment, which may cause an imbalance during cycles and further exacerbate vibration issues.

Additionally, users may experience noise disturbances, such as banging or thumping sounds during operation. This could indicate that the shock absorbers are not effectively managing the drum’s movements, often due to insufficient resistance or complete failure of the units.

It is essential to routinely inspect these components to ensure optimal performance. Addressing issues with the shock absorbers promptly can help prevent further damage and maintain the efficiency of the appliance.

How the Dispenser System Distributes Detergent

The distribution mechanism for cleaning agents plays a crucial role in ensuring effective laundry results. This system is designed to deliver the right amount of detergent at the appropriate time during the washing cycle, optimizing cleaning performance and minimizing waste. Understanding its operation can help users make informed choices about detergent types and usage.

Components of the Dispensing Mechanism

At the core of the dispensing system are several key components, including the reservoir, channels, and control valves. The reservoir holds the detergent and fabric softener, while the channels guide these substances to the drum when needed. Control valves regulate the flow, ensuring that the cleaning agents are dispensed precisely at the right moment, whether during the initial wash or rinse phases.

Operational Process

When the cycle begins, water enters the dispenser, dissolving the detergent and softener. As the machine progresses, sensors trigger the control valves to open, allowing the mixed solution to flow into the drum. This timely distribution ensures that the cleaning agents interact effectively with the fabrics, enhancing stain removal and fabric care.