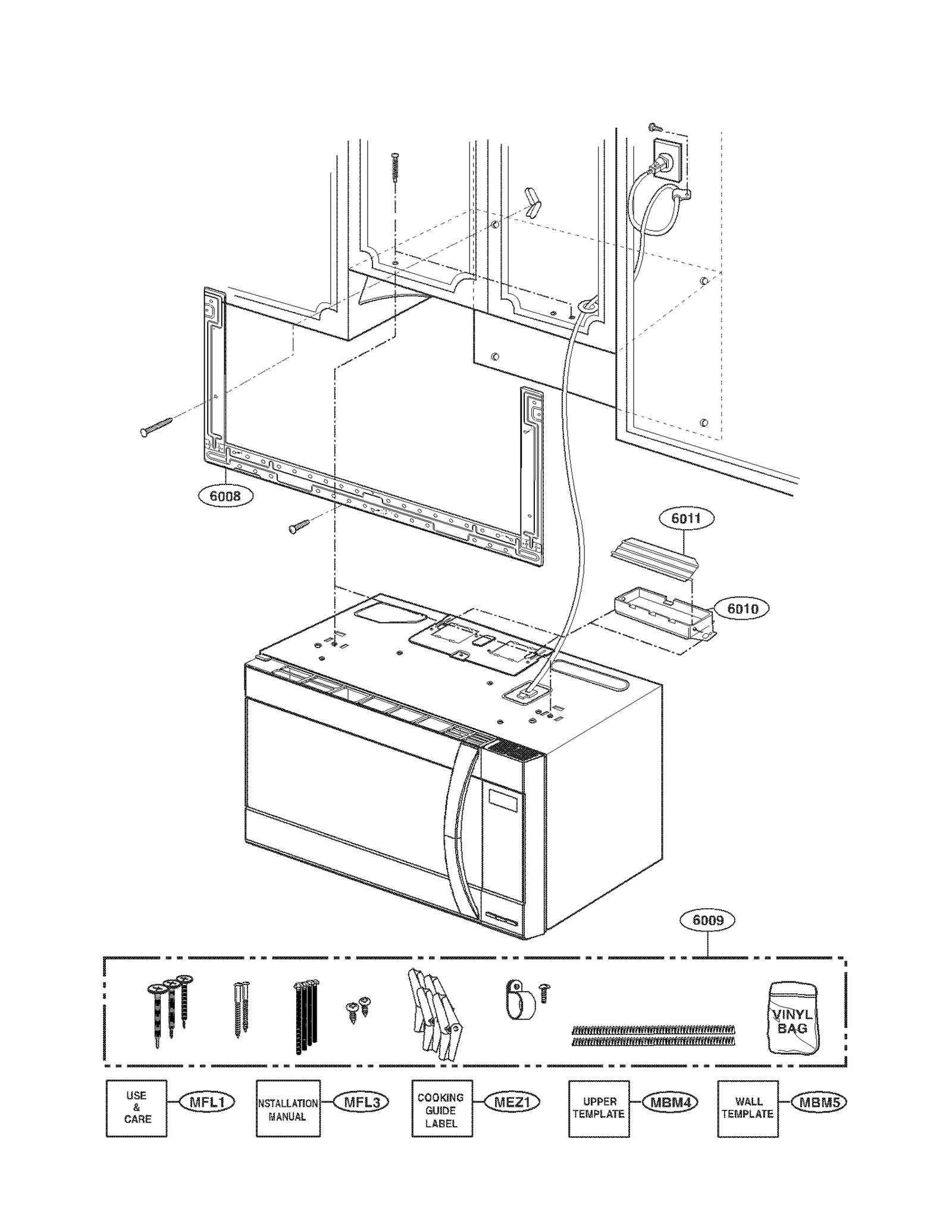

The inner workings of modern kitchen devices often go unnoticed, but understanding how each element functions can provide valuable insights for maintenance and troubleshooting. These household helpers consist of numerous components working in harmony, ensuring efficient performance. Knowing their layout can aid in identifying potential issues and streamlining repairs.

Each mechanism within these appliances is carefully engineered to fulfill a specific role. From cleaning systems to drying methods, every section contributes to the overall operation. By familiarizing yourself with the internal structure, it becomes easier to recognize when something may need attention or replacement, ensuring longer-lasting performance.

Whether you’re exploring this information out of curiosity or necessity, understanding the makeup of your home device can be a crucial step towards effective maintenance. With detailed information about each part’s location and role, tackling potential problems becomes significantly simpler.

Kenmore Elite Dishwasher Parts Overview

Understanding the various components of a high-end kitchen cleaning appliance is essential to ensure proper maintenance and longevity. Each element plays a unique role in the overall performance, contributing to efficiency and effective cleaning results. Below is an outline of key components involved in the system’s functionality.

- Control Unit – Manages different cycles and settings for optimal operation.

- Water Circulation – A system that ensures efficient water flow during washing phases.

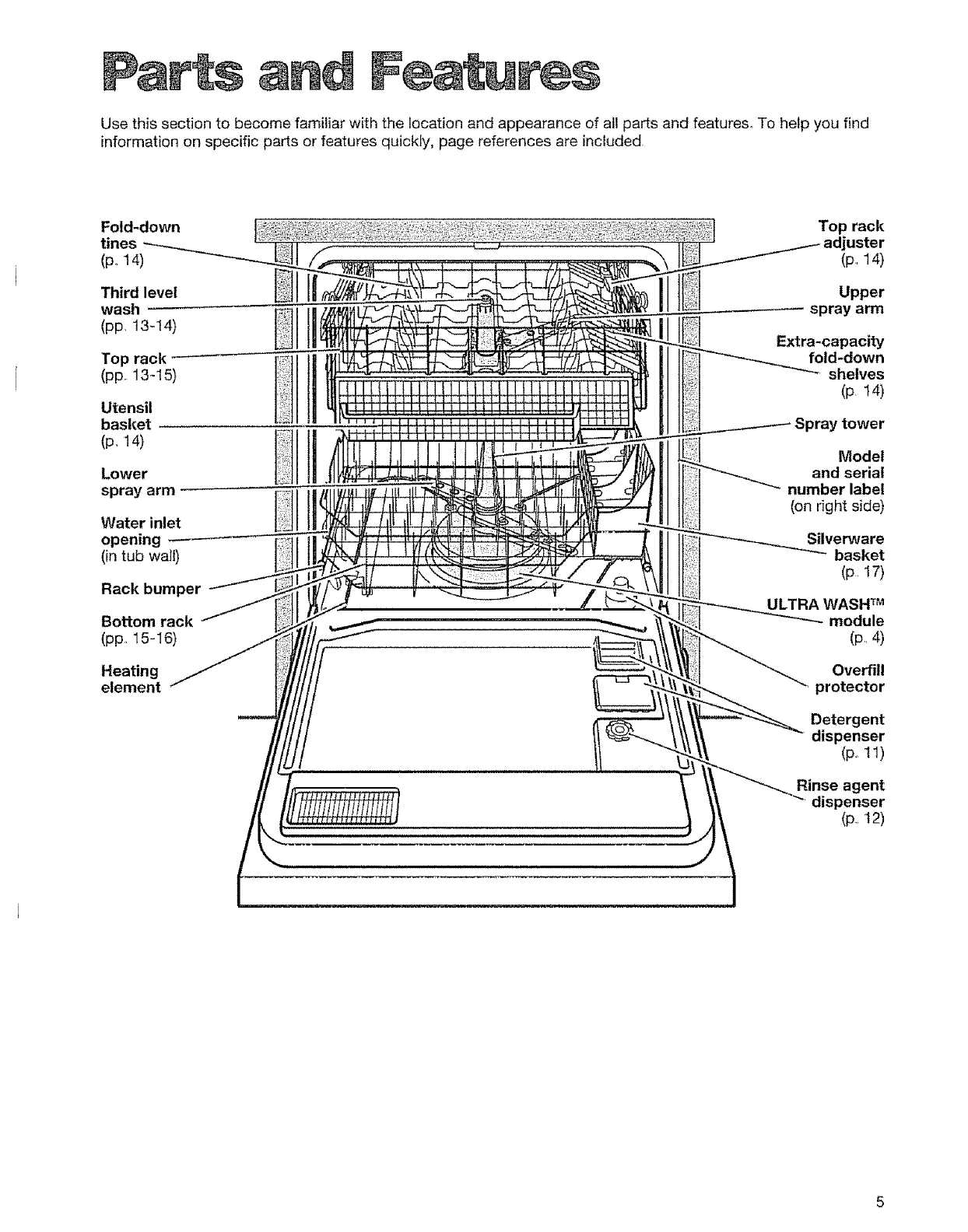

- Spray Arms – Responsible for distributing water evenly across all items in the machine.

- Filtration System – Keeps debris out of the water, ensuring clean dishes after every cycle.

- Heating Element – Regulates water temperature for better cleaning and drying performance.

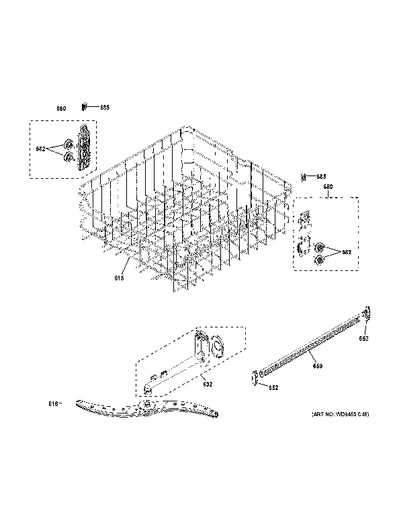

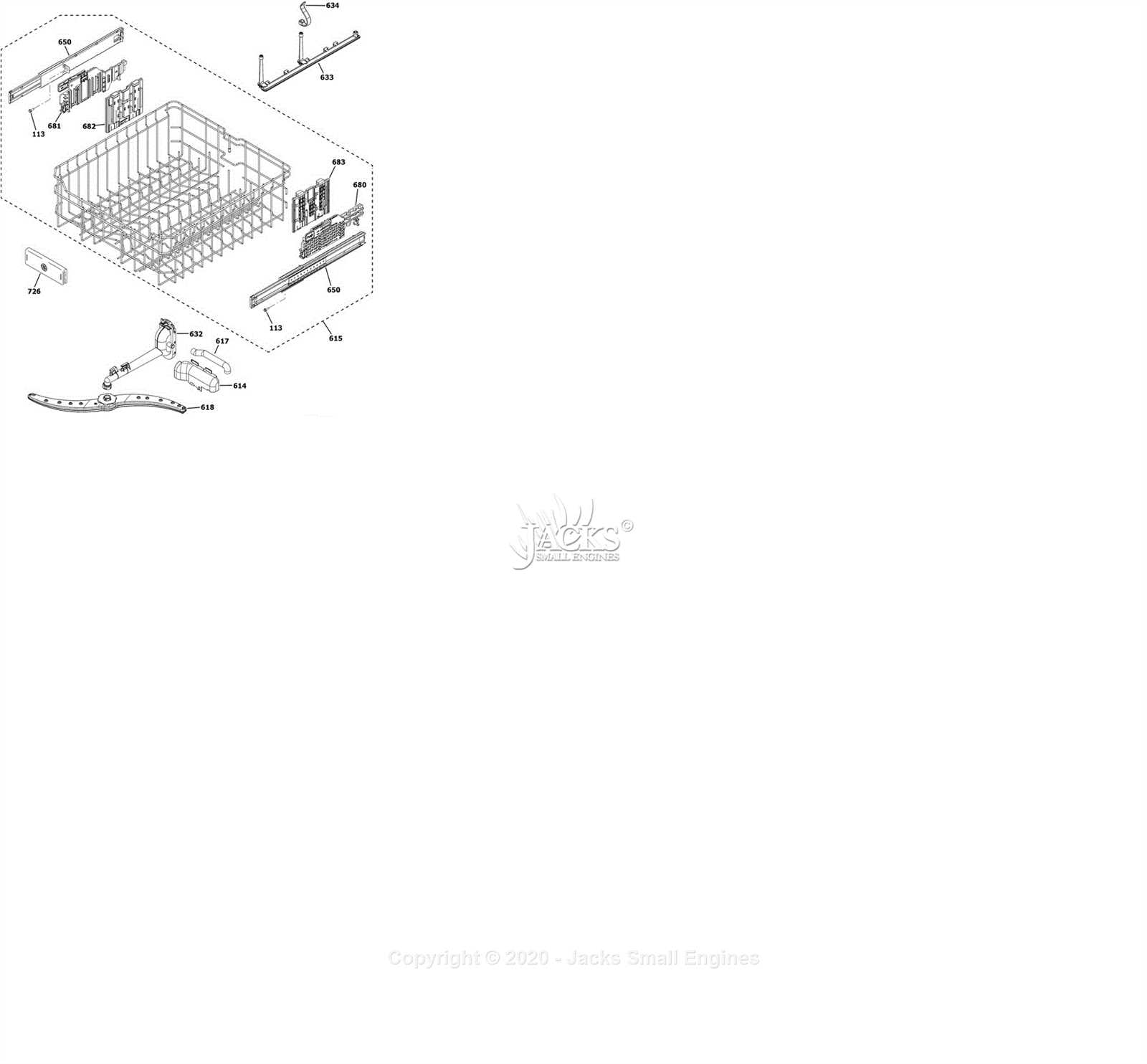

- Racks and Baskets – Customizable spaces designed for holding various kitchenware.

- Drainage System – Removes used water and prevents clogging during the cleaning process.

Main Components of the Dishwasher

The system responsible for cleaning dishes is composed of several interconnected units that ensure efficient operation. Each element plays a crucial role in making the process seamless, from water circulation to drying. Understanding these fundamental elements is key to maintaining the machine’s functionality over time.

Water Distribution and Spraying

The primary function of the cleaning device is achieved through its water distribution mechanism. This section includes various nozzles that spray water, ensuring thorough coverage during the cleaning process. The water flow is regulated and distributed across all levels, targeting every item placed inside.

Control and Operation System

The control unit governs the entire cleaning cycle, allowing the user to select different settings. It manages water temperature, cycle duration, and the intensity of the cleaning process. This component ensures that each load is handled according to specific needs, enhancing the efficiency and effectiveness of the machine.

Functions of the Control Panel

The control panel serves as the primary interface, allowing users to manage various settings and options of the device. It provides easy access to the machine’s key features, ensuring efficient and personalized operation based on individual needs.

Main Buttons and Their Roles

- Power Button: Activates or deactivates the device, controlling its operational state.

- Cycle Selection: Offers multiple program choices to adjust the cleaning process to specific requirements.

- Start/Pause: Initiates or temporarily halts the selected program, giving flexibility during operation.

Additional Features

- Delay Start: Allows scheduling the machine to run at a later time, optimizing energy use or convenience.

- Indicators: Visual signals inform about cycle status, completion, and potential issues,

Detailed Look at the Water Inlet Valve

The water inlet valve plays a critical role in controlling the flow of water into the cleaning system. It ensures that the correct amount of water enters the machine, depending on the selected cycle and settings. Proper functioning of this component is essential for optimal cleaning results and overall appliance performance.

How the Inlet Valve Operates

This valve is designed to open and close according to signals from the control system. When it’s time to fill the device with water, the valve opens, allowing water to flow through. After the required amount is reached, the valve shuts off to prevent overfilling. Its precise operation is vital to ensure efficient water use and avoid potential leaks or water damage.

Maintenance and Troubleshooting

Over time, mineral deposits or wear and tear can affect the valve’s efficiency. Regular inspection is recommended to prevent mal

Spray Arm Mechanism and Operation

The rotating arm system plays a critical role in ensuring water is distributed evenly throughout the cleaning cycle. By spinning, it directs streams of water to effectively rinse and clean the contents inside. This process helps achieve thorough cleaning coverage without leaving any areas untouched.

How the Rotating Arm Works

The system operates by using water pressure to rotate the arm. As water is forced through strategically placed nozzles, it causes the arm to spin, spraying water in all directions. The balance and angle of the nozzles are crucial for maintaining consistent movement and coverage.

Key Features of the Mechanism

Several elements are designed to ensure smooth operation of the arm, such as bearings that reduce friction and allow continuous rotation. In addition, the material and design of the arm are selected to resist corrosion and handle high water pressure.

Feature Description Rotation Bearings Enable smooth and consistent spinning of the arm during operation. How the Drain Pump Works

The drain pump is an essential component in any kitchen appliance designed for cleaning dishes. Its primary function is to remove water from the interior after the washing cycle is complete, ensuring efficient operation and preventing any water-related issues.

Mechanism of Operation

When the washing cycle concludes, the drain pump activates to expel residual water. This process begins with the pump drawing water through the filter and into its housing. Once inside, the motor drives the impeller, creating centrifugal force that propels the water out through the drainage hose. This mechanism is crucial for maintaining proper hygiene and efficiency in the cleaning process.

Importance of Maintenance

Regular maintenance of the drain pump is vital for optimal performance. Over time, debris and food particles can accumulate, hindering the pump’s effectiveness. Periodic cleaning of the filter and checking for blockages will help prevent issues and extend the lifespan of the appliance. Ensuring that the drainage system remains clear contributes to efficient water removal and enhances overall functionality.

Understanding the Role of the Heating Element

The heating component is essential in ensuring optimal performance and efficiency in cleaning processes. Its primary function involves regulating temperature, which is crucial for various operations within the appliance.

Here are some key aspects of its importance:

- Water Temperature Regulation: The heating element elevates the water temperature, enabling better removal of grease and food residues.

- Drying Efficiency: It plays a significant role in the drying cycle, helping to evaporate moisture from dishes effectively.

- Sanitization: Higher temperatures facilitate the elimination of bacteria, ensuring sanitized dishes.

- Energy Consumption: Proper functioning of the heating component can influence overall energy efficiency, impacting operational costs.

In conclusion, the heating element is a pivotal component that enhances the cleaning capabilities and efficiency of the appliance, contributing significantly to its overall functionality.

Door Seal and Its Importance

The seal around the access point of a cleaning appliance plays a crucial role in maintaining its efficiency. This component is designed to prevent leaks, ensuring that water remains contained during operation. A well-functioning seal enhances performance and contributes to the longevity of the device.

Functionality of the Seal

The primary function of the seal is to create a tight barrier that keeps water inside the unit. This not only optimizes cleaning results but also protects surrounding areas from potential water damage. When the seal is compromised, it can lead to various issues, including decreased efficiency and increased energy consumption.

Maintenance and Care

Regular inspection and maintenance of the seal are essential for optimal performance. Users should check for signs of wear or damage and replace the seal when necessary. Proper care extends the life of the appliance and ensures that it operates as intended.

Seal Condition Recommended Action Intact Regular inspection Worn Replace immediately Damaged Replace and check other components Exploring the Silverware Basket Design

The design of the silverware container plays a crucial role in optimizing the cleaning process for utensils. A well-thought-out structure ensures that each piece receives adequate water flow and detergent exposure, leading to superior cleanliness. This section delves into the features and functionalities that enhance the efficiency of this essential kitchen accessory.

Innovative Features of the Silverware Container

Modern silverware containers are equipped with various innovative features aimed at improving usability. For instance, adjustable compartments allow users to customize the layout according to their needs. Additionally, some models include protective elements to prevent scratching and ensure the longevity of the utensils. Durability is another key factor, as high-quality materials resist wear and tear over time.

Importance of Proper Placement

Correct placement of the silverware basket is vital for achieving optimal cleaning results. Positioning it in the designated area ensures that water can circulate freely around each item. This not only enhances the cleaning efficiency but also minimizes the risk of damage to delicate pieces. Understanding the best practices for placement can significantly impact the overall performance of the cleaning appliance.

Filter System Maintenance Tips

Proper upkeep of the filtration mechanism is essential for optimal performance and longevity of your cleaning appliance. Regular attention to this component helps ensure efficient operation and prevents common issues that may arise from neglect.

Here are some practical suggestions to keep the filtration system functioning effectively:

Tip Description Regular Inspection Check the filter routinely for debris buildup or blockages that could hinder performance. Cleaning Frequency Clean the filter at least once a month to maintain optimal functionality and prevent odors. Proper Removal Follow the manufacturer’s instructions for removing the filter to avoid damage. Use Mild Detergents When cleaning, opt for gentle cleaning agents that won’t harm the filter material. Reinstallation Ensure the filter is securely reattached after cleaning to avoid leaks or operational issues. Upper and Lower Rack Configurations

The arrangement of the upper and lower shelves plays a crucial role in maximizing the efficiency of your cleaning appliance. Understanding how to utilize these areas effectively can significantly enhance your experience and ensure optimal performance during each wash cycle.

Upper Shelf Setup

The upper shelf is designed to accommodate smaller items, providing flexibility in placement. It typically features adjustable tines, allowing for various configurations depending on the size and shape of your dishes. Utilizing this space wisely not only ensures that every item is thoroughly cleaned but also prevents potential damage.

Lower Shelf Organization

In contrast, the lower shelf is meant for larger and heavier cookware. Its robust design supports pots and pans while maintaining stability during operation. Arranging items with consideration to size and weight ensures an even wash and prevents blockage of spray arms, allowing for thorough rinsing.

Diagnosing Issues with the Motor Assembly

Identifying problems related to the motor unit is crucial for maintaining the proper functioning of the appliance. Common issues may manifest as unusual noises, inconsistent performance, or complete failure to operate. Understanding how to troubleshoot these situations can help restore efficiency and prolong the lifespan of the device.

Common Symptoms of Motor Malfunction

Several signs can indicate a malfunctioning motor assembly. If the machine fails to start, it may suggest an electrical issue or a problem with the motor itself. Unusual sounds, such as grinding or buzzing, often indicate that components are misaligned or worn out. Additionally, if the appliance is not completing cycles as expected, this may signal a deeper issue within the motor assembly.

Troubleshooting Steps

To diagnose the motor assembly, begin by ensuring that the appliance is properly plugged in and that there are no blown fuses or tripped circuit breakers. Next, inspect the motor for visible damage or debris that may hinder its operation. Testing the motor with a multimeter can help determine if it is receiving power. If all else fails, consider consulting a professional technician for a thorough evaluation and necessary repairs.

Replacing the Float Switch in a Dishwasher

The float switch is a crucial component that ensures the proper water level within the appliance. When this mechanism malfunctions, it can lead to improper filling or drainage issues. Understanding how to replace this switch is essential for restoring the efficiency of the cleaning unit.

Identifying the Problem

Common signs of a faulty float switch include the appliance not filling with water, excessive water accumulation, or continuous drainage. If these symptoms are observed, it may be necessary to inspect and potentially replace the float switch to maintain optimal functionality.

Replacement Process

To begin the replacement, disconnect the unit from the power source and water supply. Locate the float switch, usually found at the bottom of the tub. Remove any screws or clips holding it in place. Carefully disconnect the wiring harness and remove the old switch. Install the new component by reversing these steps, ensuring all connections are secure. Finally, restore the power and water supply to test the functionality.