When tackling tough cleaning tasks, having a reliable machine can make all the difference. Understanding the intricate design of such equipment is essential for optimal performance. This section delves into the various components that contribute to the functionality of these devices, helping users grasp the essential roles of each element.

The inner workings of these machines often include a variety of components that work in harmony. From the mechanism responsible for generating force to the various attachments that enhance cleaning efficiency, each part serves a specific purpose. By familiarizing oneself with these elements, users can troubleshoot issues effectively and maintain their equipment for prolonged use.

Moreover, comprehending how each section interacts allows for better decision-making when it comes to replacements or upgrades. Whether you’re a seasoned user or new to these cleaning devices, this knowledge empowers you to achieve the best results while ensuring the longevity of your equipment.

Key Components of the Pressure Washer

Understanding the essential elements of a cleaning device can enhance its effectiveness and longevity. Each component plays a vital role in ensuring the unit operates efficiently, delivering the desired results. From generating forceful jets to providing a comfortable grip, every part contributes to the overall functionality and user experience.

Main Assembly and Motor

The main assembly houses critical elements, including the motor, which drives the entire system. This mechanism transforms electrical energy into mechanical power, propelling the fluid through the device. A robust and efficient motor ensures reliable operation, enabling the user to tackle various cleaning tasks effectively.

Delivery System

This system comprises the hose and nozzle, responsible for directing the flow of the fluid. The hose transports the liquid from the reservoir to the nozzle, which can be adjusted to vary the spray pattern. A well-designed delivery system enhances precision and control, making it easier to clean diverse surfaces with varying degrees of intensity.

Exploring the Motor Mechanism

This section delves into the inner workings of the motor, a crucial component that drives performance and efficiency. Understanding its structure and functionality can provide valuable insights into the overall operation of the device.

Key Components of the Motor

- Stator: The stationary part that creates a magnetic field, essential for motor operation.

- Rotor: The rotating element that converts electrical energy into mechanical energy.

- Bearings: Support the rotor, ensuring smooth movement and reducing friction.

- Windings: Coils of wire that create electromagnetic forces when current flows through them.

How the Motor Functions

- Electricity flows into the windings, generating a magnetic field.

- The rotor spins due to the interaction between the magnetic field and the stator.

- This rotational movement powers the connected components, enabling their functionality.

By exploring the motor’s design and operation, users can better appreciate its role in delivering effective performance in various applications.

Function of the High-Pressure Hose

The high-pressure hose is a crucial component in a cleaning system, designed to facilitate the effective transfer of fluid from the machine to the surface being treated. Its role is essential in ensuring optimal performance during operations, contributing to both efficiency and safety.

This component has several key functions, including:

- Fluid Transport: The hose carries water or other cleaning solutions at elevated pressures, allowing for effective removal of dirt and debris.

- Durability: Constructed from robust materials, it withstands high pressures and environmental conditions, ensuring longevity and reliability.

- Flexibility: Designed to be flexible, it allows for ease of movement and maneuverability, enabling users to reach various areas without obstruction.

- Safety Features: Many hoses are equipped with safety features to prevent leaks and bursts, protecting both the user and the equipment.

Understanding the function of this essential component enhances the overall effectiveness of cleaning operations, making it a vital part of any cleaning setup.

Water Inlet and Outlet Details

This section provides essential insights into the components responsible for the flow of liquid into and out of the device. Understanding these elements is crucial for ensuring efficient operation and maintenance.

The water inlet and outlet are designed to facilitate the movement of fluid, contributing to the overall functionality of the system. The inlet allows water to enter, while the outlet ensures proper expulsion, maintaining the balance required for effective operation.

| Component | Description |

|---|---|

| Inlet Valve | Controls the entry of liquid into the assembly, allowing for regulated flow. |

| Outlet Hose | Conveys the expelled fluid to the desired location, designed for flexibility and durability. |

| Filters | Ensures that debris does not enter the system, preserving the integrity of internal components. |

| Fittings | Connects hoses and valves, ensuring a secure and leak-free assembly. |

Role of the Trigger Gun Assembly

The trigger gun assembly plays a crucial role in the operation of cleaning devices, serving as the main interface for the user. It enables effective control over the flow and intensity of the fluid, allowing for tailored cleaning experiences. This component is designed for ease of use and safety, ensuring that users can manage the device with minimal effort while maximizing performance.

This assembly typically consists of several key components, each contributing to its overall functionality:

| Component | Function |

|---|---|

| Trigger | Controls the release of the cleaning solution, allowing for immediate response during operation. |

| Safety Lock | Prevents accidental activation, enhancing user safety when the device is not in use. |

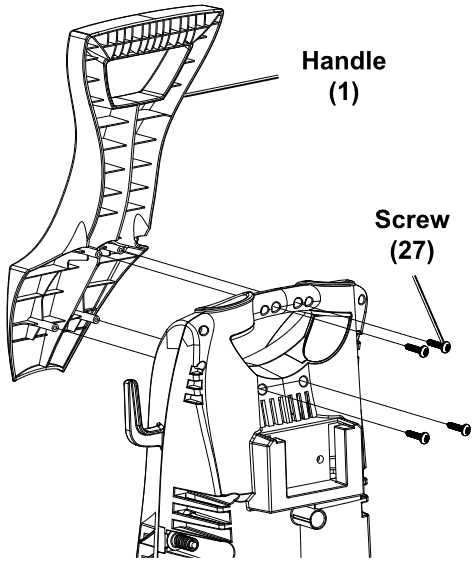

| Handle | Provides a secure grip, ensuring comfort and stability during operation. |

| Inlet Port | Facilitates the connection to the fluid source, ensuring a steady supply for effective cleaning. |

| Nozzle Adjustment | Allows users to modify the spray pattern for different cleaning tasks, optimizing results. |

Overall, the trigger gun assembly is essential for achieving efficient operation and user satisfaction in cleaning applications. Understanding its components and their functions can greatly enhance the effectiveness of the cleaning process.

Identifying the Nozzle Types Available

Understanding the variety of nozzle options is essential for achieving optimal cleaning results. Different types are designed to cater to specific tasks, allowing users to adapt their equipment for various surfaces and levels of dirt. Recognizing these distinctions can enhance effectiveness and efficiency during use.

Standard Spray Nozzles

Standard nozzles are commonly utilized for general cleaning purposes. These attachments offer a balanced spray pattern that efficiently removes dirt and grime from surfaces. Users can typically find options with varying spray angles, enabling adjustments based on the cleaning task.

Specialized Nozzle Variants

For more demanding cleaning challenges, specialized nozzles come into play. These include rotating or turbo nozzles, which combine pressure and rotation for intensified cleaning action. Additionally, some nozzles are tailored for gentle applications, making them ideal for delicate surfaces.

Understanding the Pump Assembly Features

The pump assembly is a critical component in any cleaning system, playing a vital role in the overall efficiency and effectiveness of the equipment. This section explores the various characteristics and functions of this essential unit, highlighting its significance in delivering optimal performance.

Here are some key features of the pump assembly:

- Material Quality: High-quality materials are essential for durability and longevity, ensuring that the assembly can withstand rigorous use.

- Pressure Regulation: The ability to control and maintain a specific output pressure is crucial for adapting to different cleaning tasks.

- Flow Rate: The flow rate of the assembly determines how quickly the cleaning solution is delivered, impacting the overall efficiency.

- Design: An ergonomic design facilitates easy maintenance and accessibility, allowing for straightforward repairs and adjustments.

- Sealing Mechanisms: Effective sealing systems prevent leaks and ensure the integrity of the assembly during operation.

Understanding these features can help users make informed decisions about maintenance and troubleshooting, leading to better care of their equipment and extended service life.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your cleaning equipment. By following a few straightforward practices, you can enhance the lifespan of your device and maintain its performance at optimal levels.

Regular Inspection: Periodically examine all components for any signs of wear or damage. Addressing issues early can prevent further complications and prolong the life of the equipment.

Cleaning After Use: After each use, clean the exterior and any attachments to remove dirt and debris. This simple step helps prevent clogs and maintains smooth operation.

Fluid Replacement: Regularly check and replace fluids as necessary, including any lubricants or cleaners recommended by the manufacturer. This practice ensures all moving parts function efficiently.

Storage Considerations: Store the equipment in a dry and protected area to prevent exposure to harsh elements. Using a protective cover can further safeguard it from dust and moisture.

By implementing these basic maintenance tips, you can enhance the functionality and lifespan of your cleaning device, ensuring it remains a reliable tool for your tasks.

Common Issues and Troubleshooting Steps

When operating cleaning devices, users may encounter a variety of challenges that can hinder performance. Understanding these common problems and their potential solutions is essential for maintaining optimal functionality and efficiency. This section provides an overview of typical issues and practical steps for troubleshooting.

One frequent problem is the lack of sufficient cleaning force. This can result from a clogged nozzle or a low water supply. To address this, check the nozzle for blockages and ensure the water source is adequate. Cleaning or replacing the nozzle may also be necessary.

Another issue could be irregular operation or failure to start. This might stem from electrical faults or low fuel levels. Inspect the power supply and connections, ensuring they are secure and functional. Additionally, verify the fuel tank is filled appropriately, as inadequate fuel can prevent proper operation.

Leaks in hoses or fittings are also common, often caused by wear and tear over time. Regularly inspect hoses for cracks or damage, and replace them as needed. Tightening fittings can also help mitigate minor leaks.

Lastly, vibrations or excessive noise during operation can indicate mechanical issues. Ensure all components are securely fastened and check for any signs of wear on moving parts. Lubrication may also be necessary to reduce friction and enhance performance.

Where to Find Replacement Parts

Locating suitable components for your cleaning equipment can be a straightforward process when you know where to look. There are various sources available that offer a wide selection of replacement items to ensure your device operates efficiently and effectively. Exploring these options will help you find the necessary components without unnecessary hassle.

Online Retailers are among the most convenient places to search for replacement items. Many websites specialize in offering a variety of components for cleaning devices, making it easy to compare prices and specifications. When shopping online, be sure to check for customer reviews and ratings to ensure the quality of the products.

Local Hardware Stores can also be valuable resources for finding components. Many stores carry a selection of items that may suit your needs. It’s advisable to call ahead to confirm the availability of specific items before visiting. In addition, staff members can provide helpful advice and recommendations based on your requirements.

Manufacturer’s Website often features a dedicated section for replacement items. Visiting the official site can provide you with accurate information regarding the specific components compatible with your equipment. Moreover, you may find helpful diagrams and guides that assist in the installation process.

By exploring these avenues, you can effectively track down the components needed for your cleaning device and ensure it continues to perform at its best.