In the realm of maintenance equipment, comprehending the intricate arrangements of various elements is crucial for effective operation and repair. The organization of these components not only enhances functionality but also simplifies troubleshooting and upgrades. Familiarity with how each piece interconnects can lead to improved efficiency and longevity of the device.

Visual aids play a significant role in grasping the complex structures of these machines. They serve as invaluable resources, guiding users through the assembly and disassembly processes. By studying these illustrations, operators can gain insights into the workings of their equipment, empowering them to tackle issues independently.

Furthermore, a thorough understanding of the configuration can assist in identifying wear and tear or potential failures before they escalate. Whether you are a novice or an experienced user, having a clear representation of the machine’s components can significantly enhance your maintenance skills, ultimately leading to a more reliable and efficient cleaning experience.

Understanding Pressure Washers

Cleaning machines are essential tools for tackling tough grime and dirt in various settings. They utilize high-velocity streams of water to remove unwanted substances from surfaces, making them invaluable for both residential and commercial applications. A comprehensive grasp of their functionality can enhance your cleaning experience and extend the lifespan of the equipment.

Components play a crucial role in the operation of these machines. Each element, from the motor to the nozzle, contributes to the overall effectiveness and efficiency of the cleaning process. By familiarizing yourself with these elements, you can troubleshoot issues and maintain optimal performance.

Maintenance is another vital aspect that cannot be overlooked. Regular checks and timely replacements of worn-out components can prevent major breakdowns and ensure that your cleaning tasks are executed seamlessly. Understanding the intricacies of these machines empowers users to achieve the ultimate results in their cleaning endeavors.

Importance of Quality Parts

The reliability and longevity of any machine heavily depend on the quality of its components. When every element is crafted to high standards, the overall performance improves, leading to enhanced efficiency and reduced risk of failure. Investing in superior components not only ensures optimal functioning but also extends the lifespan of the equipment.

Benefits of High-Quality Components

Using top-tier materials provides numerous advantages. These include better durability, reduced maintenance needs, and improved safety. Here are some key benefits:

| Benefit | Description |

|---|---|

| Durability | Quality materials withstand wear and tear, ensuring longevity. |

| Efficiency | High-grade components enhance overall operational effectiveness. |

| Safety | Reliable elements reduce the risk of accidents and malfunctions. |

Conclusion

In summary, the significance of investing in high-quality components cannot be overstated. By ensuring that every part is made to last, users can enjoy peace of mind and superior performance from their equipment. This approach ultimately leads to greater satisfaction and a more productive experience.

Common Components of Pressure Washers

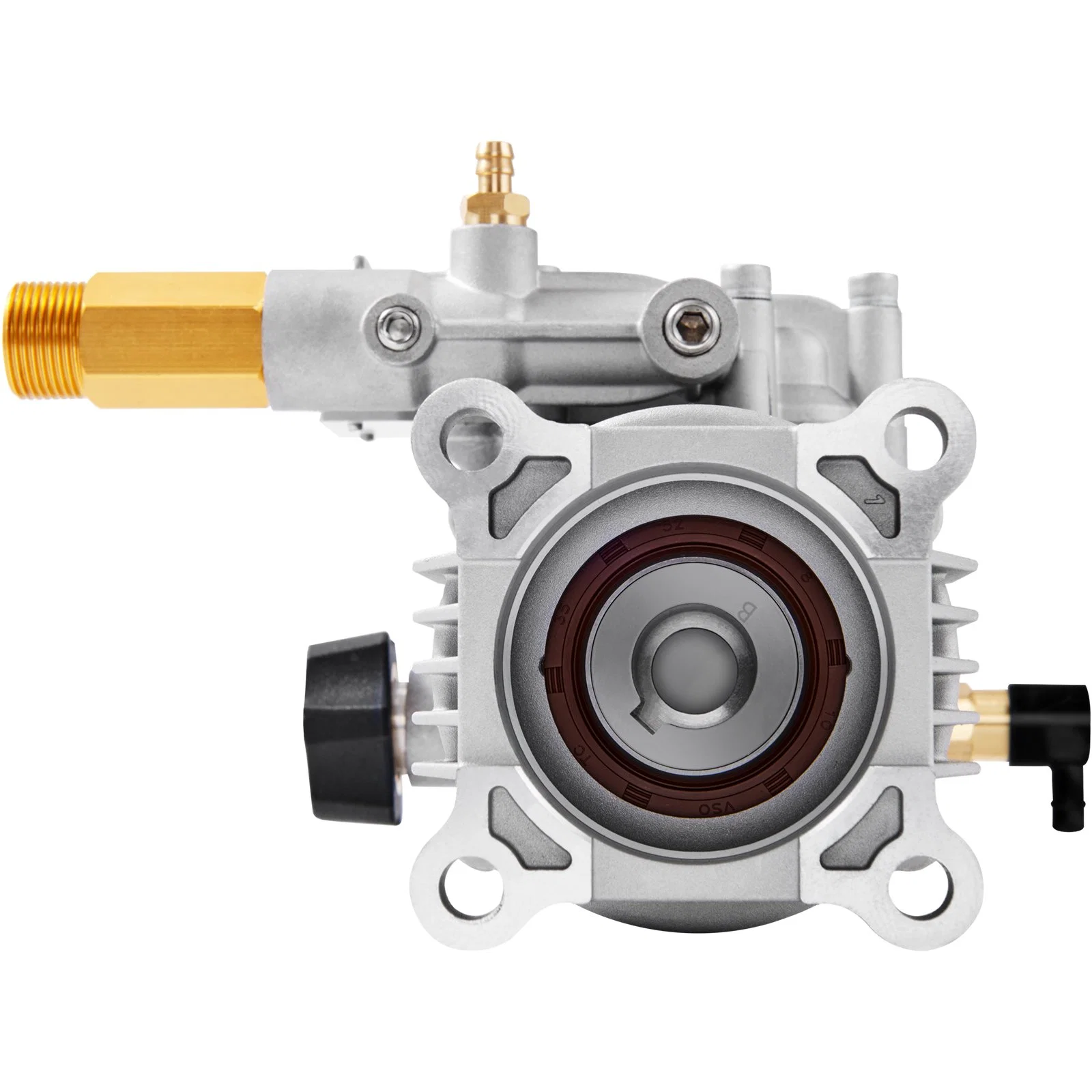

Understanding the key elements of a cleaning machine is essential for optimal performance and maintenance. Each component plays a crucial role in the functionality and efficiency of the equipment, contributing to its overall effectiveness in tackling tough cleaning tasks.

Motor: The heart of the system, providing the necessary power to drive the entire operation.

Pump: This mechanism increases water pressure, enabling the flow needed to effectively remove dirt and grime.

Nozzle: A vital attachment that directs the high-velocity stream, allowing for versatile cleaning options tailored to different surfaces.

Hose: Serving as the conduit for water, its durability and flexibility are key for maneuverability and ease of use.

Detergent Tank: An optional feature that holds cleaning solutions, enhancing the effectiveness of the cleaning process.

Trigger Gun: This user-controlled device allows for easy operation, providing a safe way to start and stop the flow of water.

By familiarizing yourself with these fundamental components, you can better maintain and troubleshoot your cleaning equipment, ensuring it remains in peak condition for all your cleaning needs.

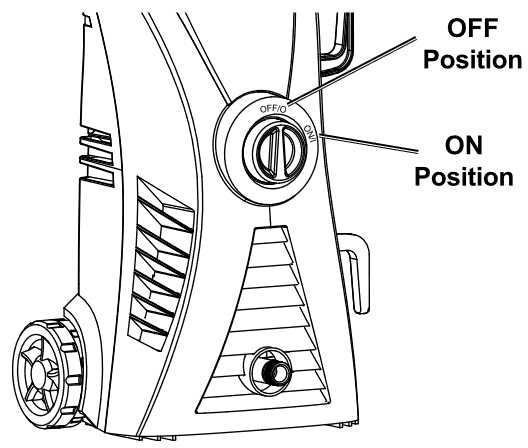

Portland Pressure Washer Overview

This section provides a comprehensive look at the equipment designed for cleaning and maintaining outdoor surfaces. Understanding the components and functionalities is essential for effective usage and upkeep.

Key Features

- Powerful motor for efficient cleaning

- Variety of nozzles for different tasks

- Durable construction for long-lasting performance

- Compact design for easy storage and transport

Common Applications

- Cleaning driveways and sidewalks

- Washing vehicles and outdoor furniture

- Restoring decks and patios

- Preparing surfaces for painting or staining

Utilizing this equipment can significantly enhance the efficiency and effectiveness of outdoor cleaning tasks. Familiarity with its components and functions ensures optimal performance and longevity.

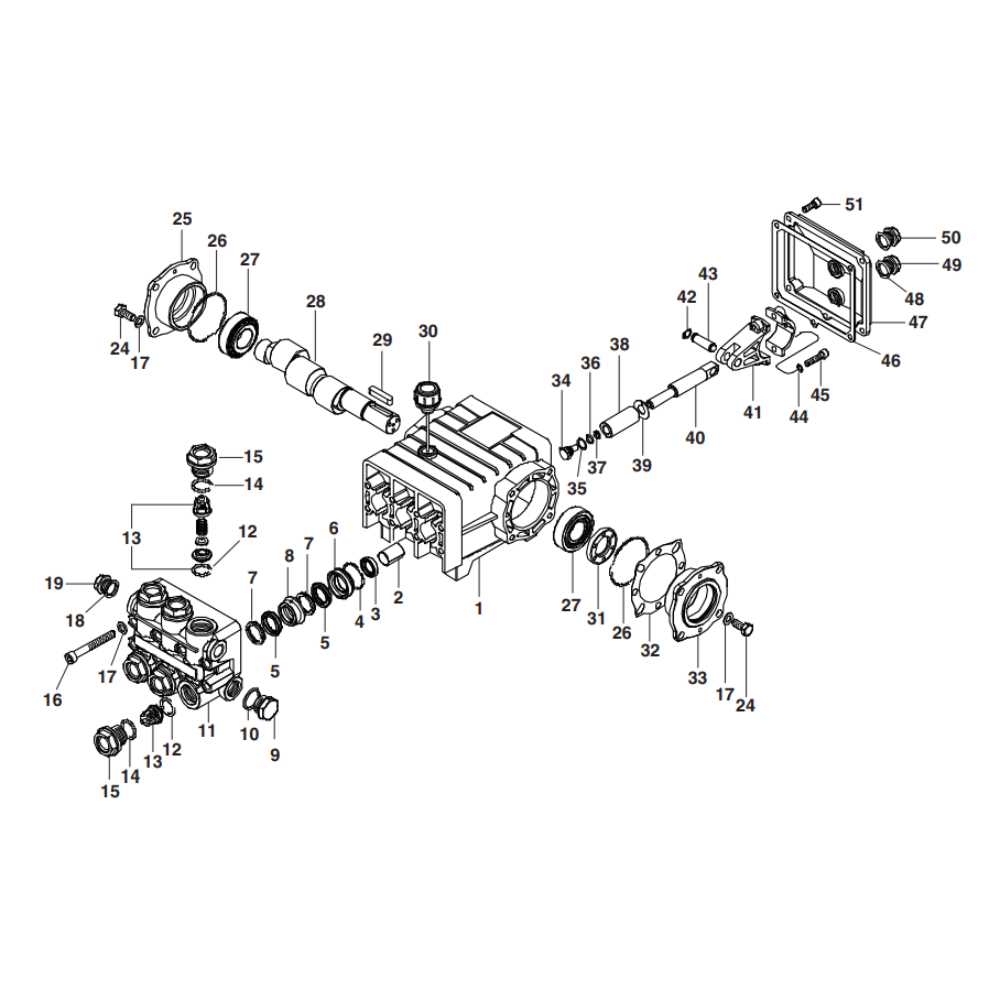

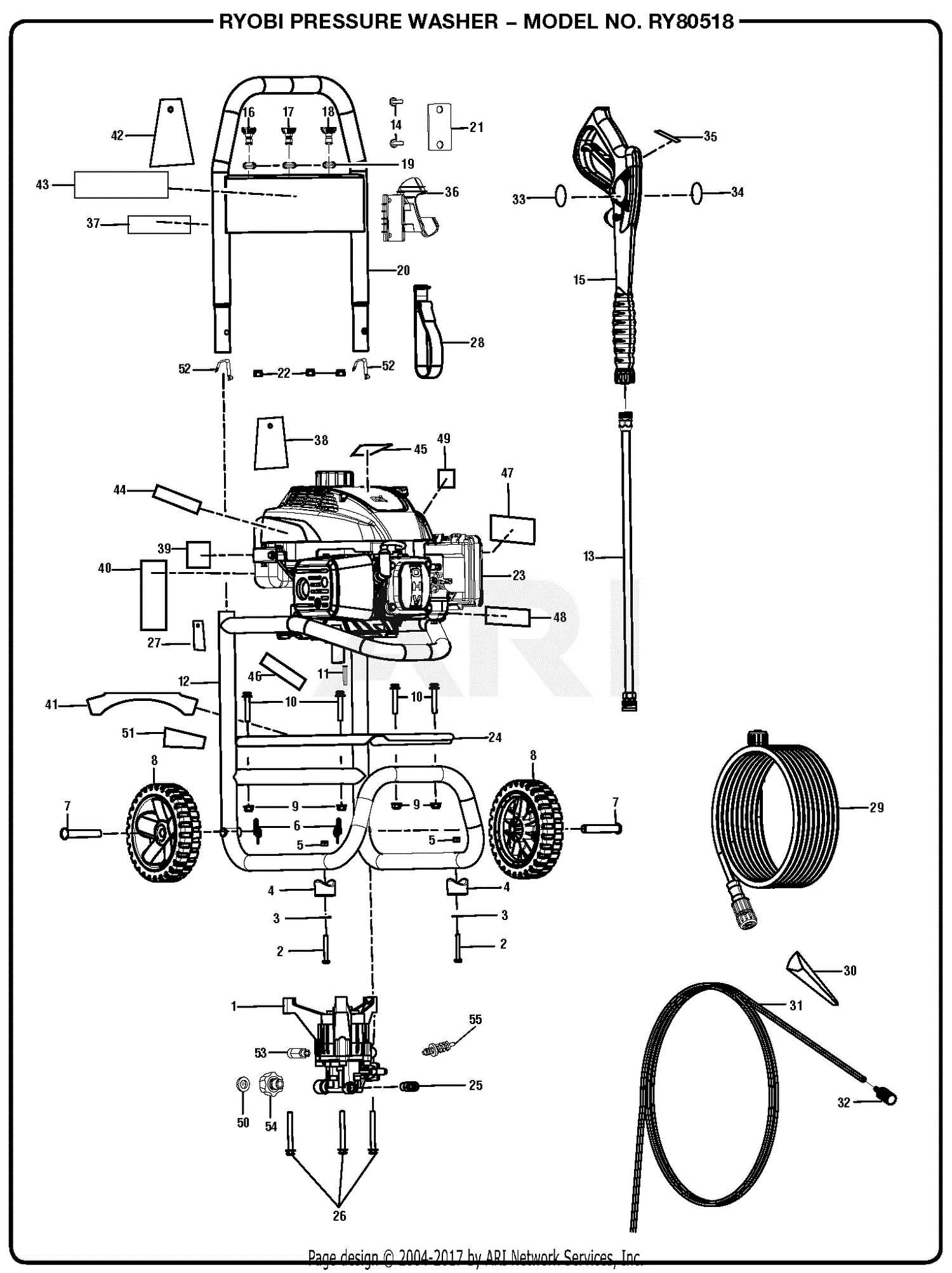

Identifying Key Diagrams

Understanding the essential visuals related to equipment assembly can greatly enhance maintenance and repair efficiency. These representations serve as vital guides, helping users navigate the complexities of their machinery.

Recognizing Components

To effectively manage repairs, it’s crucial to identify each element within the schematic. Key illustrations highlight specific areas, ensuring that all necessary components are easily discernible.

Utilizing Visual Aids

Employing these visuals can streamline the troubleshooting process. Comprehending the layout not only aids in identification but also fosters a deeper understanding of the equipment’s functionality.

How to Read Diagrams

Understanding visual representations is essential for interpreting complex information effectively. These illustrations often convey relationships, components, and workflows in a clear and concise manner, enabling users to grasp intricate systems quickly.

Here are some key steps to enhance your diagram-reading skills:

- Familiarize with Symbols: Different visuals use specific icons and symbols. Recognizing these can greatly aid in comprehension.

- Identify the Legend: Many visuals come with a key that explains the symbols used. Always check this section first for clarity.

- Trace the Flow: Follow the lines or arrows to understand the connections and directions between different elements.

- Pay Attention to Labels: Read any annotations or descriptions. They provide context and essential details that enhance understanding.

- Break it Down: If the visual is complex, divide it into smaller sections. Analyze each part individually before looking at the whole.

By practicing these techniques, you will become more adept at interpreting various visual layouts and improve your overall comprehension of technical material.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor cleaning equipment requires consistent care and attention. By following a few essential maintenance practices, you can enhance the performance and extend the lifespan of your device, keeping it in optimal working condition for years to come.

Regular Cleaning

- Clean the exterior after each use to remove dirt and debris.

- Inspect and clear any obstructions from the nozzle to maintain efficiency.

- Wipe down hoses to prevent buildup that can cause damage over time.

Routine Inspections

- Check connections for leaks and tighten as necessary.

- Examine hoses for signs of wear and replace if needed.

- Monitor motor and components for unusual noises that may indicate issues.

Implementing these simple yet effective practices will help you keep your equipment running smoothly, ensuring you can tackle outdoor tasks effortlessly for an extended period.

Replacing Worn-out Parts

Over time, certain components of your cleaning equipment may experience wear and tear, leading to decreased performance and efficiency. Addressing these issues promptly can ensure your device operates optimally, saving you both time and resources.

Identifying the Issue: Regular inspection is essential to spot damaged or degraded elements. Look for signs like unusual noises, leaks, or a decline in functionality.

Choosing the Right Replacement: When selecting new components, consider compatibility with your equipment. Refer to your user manual for specifications and recommendations to avoid any mismatches.

Installation Tips: Proper installation is crucial for the longevity of new components. Follow the manufacturer’s guidelines carefully, and use the appropriate tools to ensure a secure fit.

Maintenance and Care: After replacement, regular maintenance will help prolong the life of your new components. Keep the equipment clean and perform routine checks to catch potential issues early.

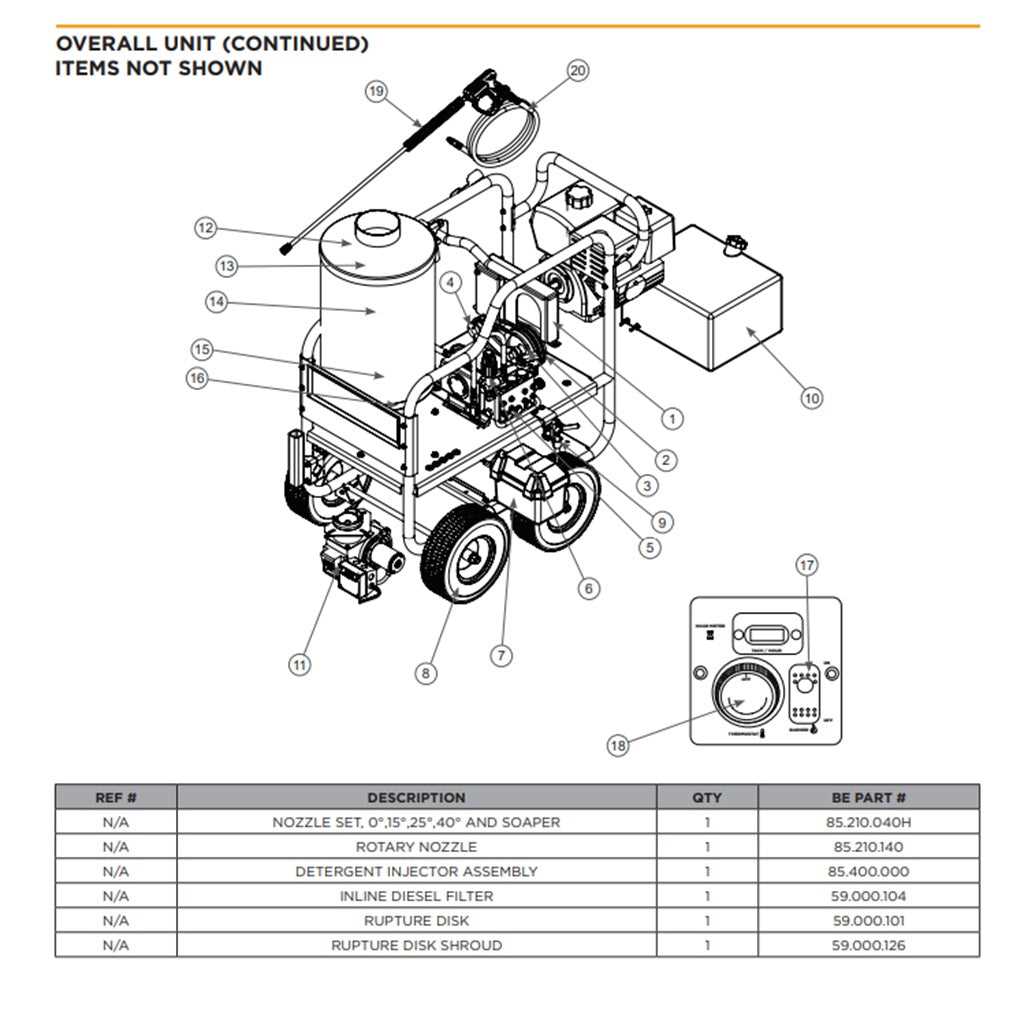

Finding Compatible Parts Easily

Locating suitable components for your equipment can be a straightforward process if approached methodically. Understanding the model and specifications is essential, as this knowledge streamlines the search for the right elements. Utilizing reliable sources and resources will enhance your ability to find what you need efficiently.

Start by consulting the manufacturer’s documentation or official website, which often provides detailed information about compatible items. Online marketplaces can also be invaluable, allowing you to filter results based on your model. Community forums and discussion groups may offer insights and recommendations from fellow users who have faced similar challenges.

When you identify potential replacements, verify their specifications to ensure a proper fit. Keeping track of the details, such as dimensions and performance ratings, can prevent compatibility issues later on. By employing these strategies, you can navigate the search for essential components with confidence and ease.

Common Issues and Solutions

In any equipment relying on high fluid dynamics, various challenges may arise that can hinder performance. Understanding these frequent problems and their corresponding remedies is essential for maintaining optimal functionality and longevity of the machinery.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Lack of power | Clogged filters, low fluid levels | Clean or replace filters; check and refill fluid |

| Unusual noises | Loose components, worn-out bearings | Tighten screws and bolts; inspect and replace bearings |

| Inconsistent flow | Damaged hoses, air leaks | Inspect hoses for damage; tighten or replace as necessary |

| Overheating | Blocked vents, prolonged use | Ensure proper ventilation; allow for cooldown periods |

| Leaks | Worn seals, loose connections | Replace seals; check and tighten all connections |

Safety Precautions During Repairs

When engaging in maintenance tasks on any mechanical device, prioritizing safety is essential. Ensuring a secure working environment not only protects the individual but also enhances the overall efficiency of the repair process. By following certain guidelines, one can minimize risks and avoid accidents.

Essential Safety Measures

Before beginning any repair work, it is crucial to take the necessary precautions. This includes wearing appropriate protective gear, ensuring proper ventilation, and being aware of potential hazards associated with the equipment. Always have a first aid kit nearby in case of emergencies.

Work Area Organization

A well-organized workspace can significantly reduce the likelihood of accidents. Keep tools and components neatly arranged and ensure that the area is free from clutter. Proper lighting and the absence of obstructions can enhance visibility and accessibility.

| Precaution | Description |

|---|---|

| Protective Gear | Wear gloves, goggles, and masks to shield against debris and chemicals. |

| Ventilation | Ensure adequate airflow to avoid inhaling harmful fumes. |

| Tool Inspection | Check tools for damage before use to prevent malfunctions. |

| Clear Space | Maintain a tidy work area to minimize tripping hazards. |

| Emergency Kit | Keep a first aid kit within reach for quick response to injuries. |

Upgrading Your Equipment

Enhancing your tools can significantly boost performance and efficiency. By investing in superior components, you not only improve the longevity of your apparatus but also elevate the quality of your tasks. This proactive approach ensures that you remain competitive and effective in your endeavors.

Consider exploring advanced technology that offers enhanced features, such as improved energy efficiency and better durability. Upgrading can also include accessories that maximize versatility, allowing for a wider range of applications. Evaluating your current setup and identifying areas for improvement is essential for optimal results.

Ultimately, a well-thought-out upgrade can transform your workflow, making it smoother and more productive. Embrace the opportunity to delve into the latest innovations, ensuring you are well-equipped to tackle any challenge that comes your way.

Where to Buy Quality Parts

Finding reliable components for your equipment is essential for maintaining its performance and longevity. Ensuring you select the right retailer can make a significant difference in the quality and durability of the items you purchase. Below are some key places to consider when looking for high-grade replacements.

Local Retailers

- Home improvement stores: These often carry a wide range of items suitable for various equipment.

- Specialty shops: Look for stores that focus on outdoor tools and machinery; they typically have knowledgeable staff.

- Automotive supply stores: Some components overlap with those used in vehicles, providing additional options.

Online Options

- Manufacturer websites: Purchasing directly from the maker ensures authenticity and quality.

- Reputable e-commerce platforms: Look for well-reviewed sellers with a solid return policy.

- Marketplace sites: Check for customer feedback and ratings to avoid subpar items.

In summary, whether you prefer shopping locally or online, exploring these avenues can lead you to the quality components you need for your equipment.