The efficient operation of household cleaning appliances hinges on numerous intricate components working in harmony. These elements, often overlooked, play a crucial role in ensuring optimal functionality and longevity of the machine. By exploring their arrangement and interaction, one can appreciate the sophistication behind modern cleaning technology.

In this guide, we will delve into the essential mechanisms that drive these devices, focusing on key elements that contribute to their performance. Understanding these components can empower users to make informed decisions regarding maintenance and repairs, ultimately enhancing the lifespan of their equipment.

Through detailed illustrations and explanations, readers will gain insight into how each piece functions within the larger system. This knowledge not only aids in troubleshooting common issues but also provides a clearer perspective on the ultimate efficiency of the appliance in daily use.

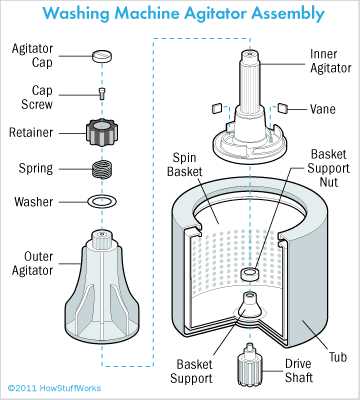

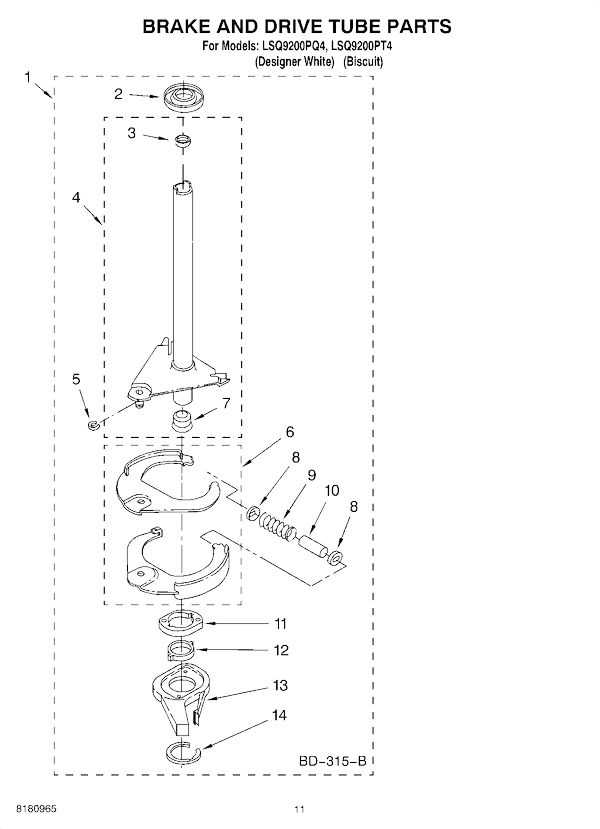

Understanding Whirlpool Washer Agitator Components

This section aims to provide insights into the various elements that contribute to the effective functioning of laundry appliances. Each component plays a crucial role in ensuring optimal performance and efficiency, facilitating the cleaning process through coordinated movements and interactions.

Key Elements of the System

Several essential components work together to create the desired agitation and movement within the drum. Understanding these elements can help users troubleshoot issues and maintain their equipment more effectively.

| Component | Function |

|---|---|

| Drive Shaft | Transmits power from the motor to create motion. |

| Agitator Cup | Secures and supports the central mechanism. |

| Fins | Enhance cleaning action by directing water and clothes movement. |

| Brake Assembly | Stops movement at the end of the cycle to prevent damage. |

Importance of Regular Maintenance

Regular inspection and upkeep of these components are vital for prolonging the lifespan of the appliance. Neglecting maintenance can lead to wear and tear, resulting in decreased efficiency and potential breakdowns.

Functions of the Agitator Assembly

The component responsible for movement within the cleaning appliance plays a crucial role in the overall effectiveness of the washing process. It orchestrates the action that ensures items are thoroughly saturated and agitated, facilitating the removal of dirt and stains from fabrics.

Mixing and Circulation

One of the primary functions of this assembly is to mix water and detergent efficiently. By creating a dynamic flow, it ensures that the cleaning solution reaches all areas of the load, enhancing the effectiveness of the cleaning process.

Fabric Movement and Care

This mechanism also promotes the gentle movement of textiles, reducing the risk of damage while ensuring that each item is treated equally. The careful action helps maintain the integrity of delicate materials, ultimately prolonging their lifespan.

Common Issues with Agitator Parts

When it comes to laundry appliances, certain components often experience wear and tear, leading to operational challenges. Understanding these typical problems can enhance performance and extend the lifespan of your machine.

Wear and Tear: Over time, essential components may become worn out, resulting in ineffective movement during cycles. Regular inspections can help identify such issues early.

Blockages: Accumulation of lint and debris can obstruct movement, causing uneven distribution of laundry. Ensuring cleanliness can mitigate this problem significantly.

Noise: Unusual sounds during operation often indicate misalignment or damage. Addressing these noises promptly can prevent further complications.

Failure to Engage: Sometimes, components may fail to connect properly, leading to incomplete cycles. Regular maintenance checks can help maintain optimal engagement.

Leaking: Any sign of moisture around the appliance may suggest seal deterioration. Timely repairs can prevent more extensive damage and costly repairs.

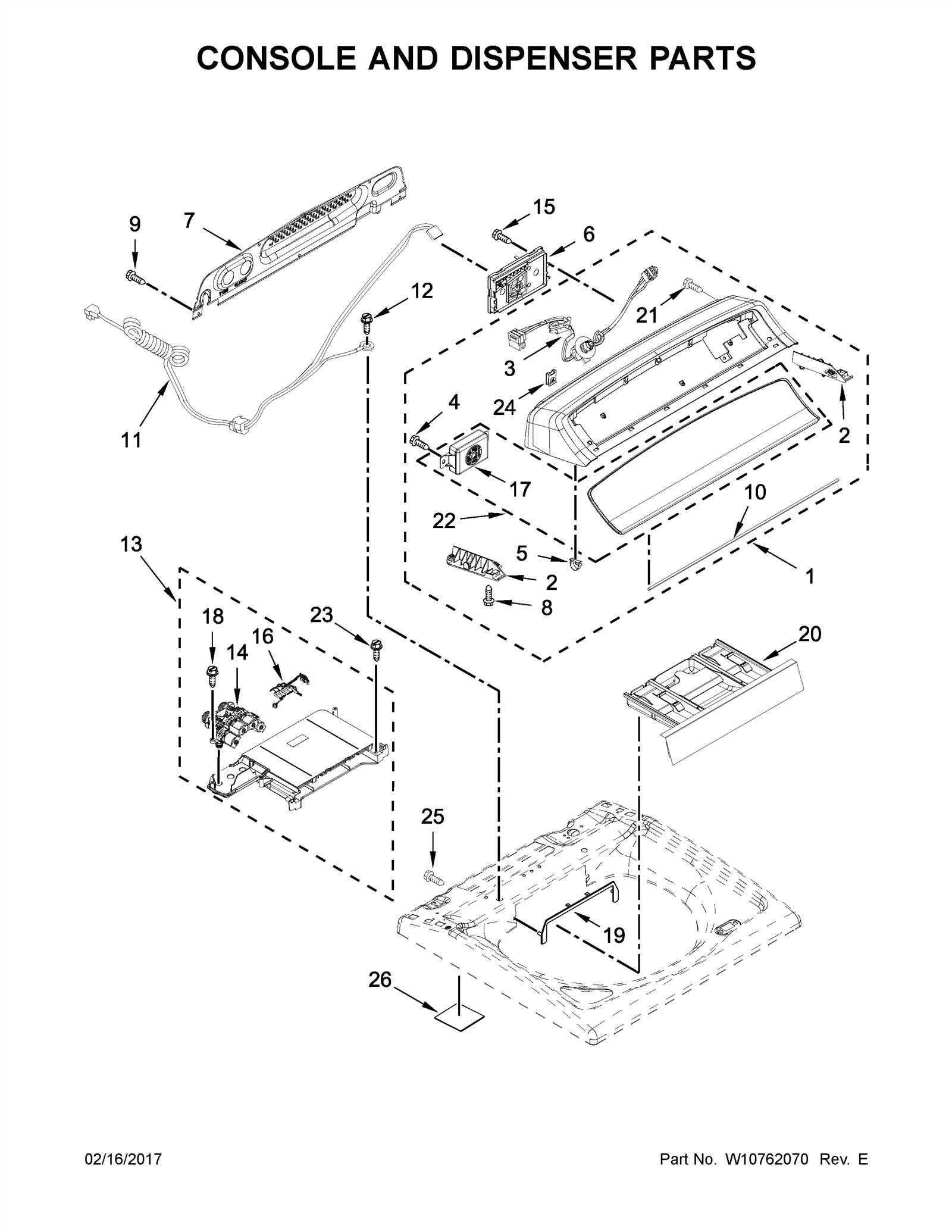

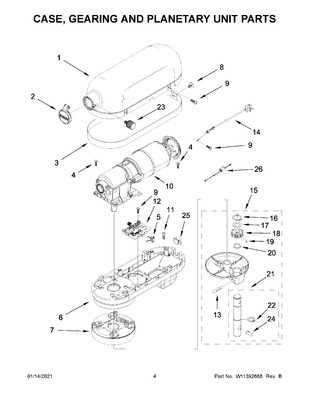

Identifying Parts on the Diagram

Understanding the components of your appliance is crucial for effective maintenance and troubleshooting. By familiarizing yourself with the various elements depicted in the schematic, you can better identify issues and perform repairs with confidence.

The following table outlines common components you may encounter, along with their descriptions and functions:

| Component | Description | Function |

|---|---|---|

| Drive Shaft | A cylindrical rod connected to the motor. | Transfers rotational motion to the main mechanism. |

| Cup Assembly | A circular container that holds the central mechanism. | Supports the inner workings and maintains alignment. |

| Agitator Dog | Small, movable pieces located within the central unit. | Engages and disengages to control motion. |

| Stator | A stationary part surrounding the rotor. | Generates a magnetic field to drive the system. |

| Base Plate | The bottom support structure. | Provides stability and foundation for the entire assembly. |

By referencing this information alongside the schematic, you can gain a clearer understanding of how each component interacts within the system, allowing for more efficient repairs and maintenance tasks.

Replacing a Worn Agitator Dog

Maintaining optimal performance in your laundry routine often involves addressing issues with essential components. One common problem is the wear of certain internal elements, which can lead to inefficient operation. Identifying and replacing these worn pieces can significantly enhance the effectiveness of your appliance.

To begin, gather the necessary tools and replacement components. You will typically need a socket wrench, pliers, and the new part designed to restore functionality. Make sure to disconnect the appliance from power to ensure safety during the process.

Step 1: Access the internal mechanism by removing the lid and the central assembly. Carefully detach any securing clips or screws to avoid damage.

Step 2: Once exposed, examine the current condition of the worn component. Take note of its position and how it interacts with other elements, as this will be important for proper installation of the new piece.

Step 3: Remove the old unit by gently prying it out, ensuring not to disrupt adjacent components. Install the new piece in the same orientation, pressing firmly to secure it in place.

Step 4: Reassemble the unit by reversing the disassembly steps. Ensure all connections are tight and secure before reconnecting to power.

After the replacement, test the functionality to confirm that the new component is working as intended. Regular maintenance and timely replacements will help prolong the lifespan of your equipment, ensuring reliable performance for years to come.

Tools Needed for Agitator Repair

Undertaking repairs on your laundry appliance requires a specific set of instruments to ensure a successful and efficient process. Proper tools not only facilitate the disassembly and reassembly of components but also enhance safety and precision during the task. Below are essential items that will assist you in performing repairs effectively.

Essential Hand Tools

Begin with a set of screwdrivers, including both flathead and Phillips types, to manage various fasteners. Additionally, a pair of pliers is crucial for gripping and manipulating smaller components. A wrench set will come in handy for loosening or tightening nuts and bolts that secure different parts. Lastly, consider having a hammer on hand for gentle tapping when necessary.

Specialized Equipment

In addition to standard tools, certain specialized instruments can make your repair tasks smoother. A socket set allows for easier access to hard-to-reach screws, while a torque wrench ensures that all connections are tightened to the manufacturer’s specifications. To improve visibility, a work light is invaluable, particularly in dimly lit areas. Finally, a toolbox will help you keep everything organized and readily accessible.

Maintenance Tips for Agitator Longevity

Ensuring the longevity of your laundry appliance’s movement system involves regular attention and care. Proper upkeep can enhance performance and prevent unnecessary breakdowns. Here are some essential practices to consider.

Regular Inspection

- Check for any visible wear or damage.

- Look for signs of rust or corrosion.

- Inspect connections and fasteners for tightness.

Routine Cleaning

- Remove debris and lint buildup after each use.

- Wipe down surfaces with a mild detergent.

- Run an empty cycle with vinegar occasionally to eliminate odors.

How to Diagnose Agitator Problems

Identifying issues with your laundry appliance can often seem daunting, but a systematic approach can simplify the process. Start by observing the machine’s behavior during operation, noting any unusual sounds, movements, or lack of agitation. Understanding the signs can lead you to the root cause of the malfunction.

First, check for any blockages or foreign objects that may be hindering movement. Next, inspect the drive system to ensure all components are functioning correctly. Look for signs of wear and tear, as these can significantly impact performance. Finally, consider the motor’s health; a malfunctioning motor could be the ultimate reason for inefficiency.

Taking these steps will help you delve deeper into the issue, leading to a more effective resolution and restoring your appliance’s functionality.

Exploring Agitator Models and Variants

In the realm of laundry appliances, the mechanisms responsible for movement and mixing are crucial for effective cleaning. Various models showcase distinct designs and functionalities, each tailored to enhance performance while addressing specific user needs. Understanding these differences can significantly impact maintenance and efficiency.

Types of Movement

Different models employ various methods for creating agitation. Some utilize a central post to generate a strong motion, while others feature a dual-action system that offers more versatility. Recognizing these mechanisms allows users to select an option best suited for their cleaning preferences.

Material and Durability

The construction of these mechanisms can vary significantly, affecting longevity and effectiveness. High-quality materials ensure better resistance to wear and tear, leading to enhanced performance over time. Choosing a robust design can ultimately lead to a more satisfying laundry experience.

Where to Find Replacement Parts

Locating the necessary components for your appliance can be a straightforward process if you know where to look. There are various resources available that cater to different needs and budgets. Understanding these options will help you find the right solutions efficiently.

Online Retailers: Numerous websites specialize in selling appliance components. These platforms often provide extensive catalogs, complete with detailed descriptions and images, making it easier to identify the required items. Ensure you check customer reviews to gauge the reliability of the retailer.

Local Appliance Repair Shops: Visiting a nearby repair shop can be beneficial, as they often stock essential components or can order them for you. Additionally, you might receive helpful advice from experienced technicians regarding installation and maintenance.

Manufacturer’s Website: The official site of the appliance manufacturer is an excellent place to start. They usually offer a comprehensive selection of components tailored for their products. You can also find installation guides and other valuable resources.

Second-Hand Marketplaces: Platforms that facilitate the buying and selling of used goods can be a treasure trove for those seeking affordable options. However, exercise caution and verify the condition of the items before purchasing.

By exploring these avenues, you can confidently source the necessary replacements for your appliance, ensuring its continued functionality.

DIY vs. Professional Repair Options

When faced with a malfunctioning appliance, homeowners often grapple with the decision to tackle repairs themselves or to enlist the help of a specialist. Each approach carries its own advantages and challenges, which can greatly influence the outcome and overall cost of the repair process.

DIY repairs can be a rewarding experience, allowing individuals to save money and gain valuable skills. Many online resources and tutorials provide step-by-step guidance, making it easier for those with a bit of technical know-how to handle minor issues. However, this route requires time, patience, and the right tools. Additionally, improper repairs can lead to further complications, potentially increasing the overall expense.

On the other hand, opting for professional services guarantees expertise and efficiency. Technicians possess the training and experience to diagnose problems accurately and implement effective solutions. While this option typically involves higher costs, it can provide peace of mind, particularly for more complex issues. Professionals also often offer warranties on their work, ensuring that any recurring problems are addressed without additional charges.

Ultimately, the choice between DIY and professional repair hinges on factors such as the severity of the issue, available resources, and personal comfort levels with home maintenance. Evaluating these elements can help homeowners make an informed decision that best suits their needs.