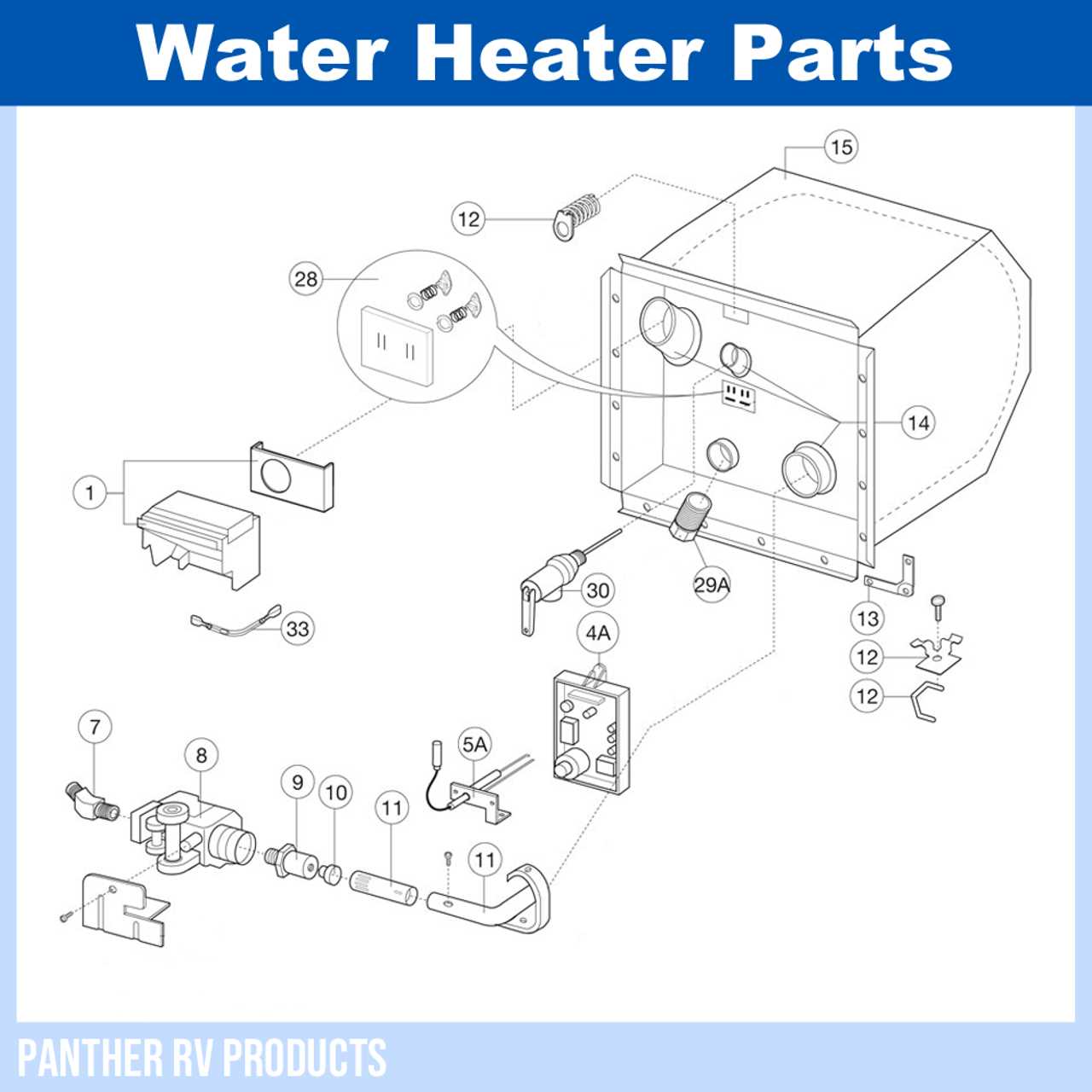

The core function of any modern system designed for heating is based on the interaction of various essential elements. Each element plays a vital role in ensuring efficiency and durability. Whether you’re looking to repair or upgrade, knowing the specific functions of these components can save time and effort. In this section, we will explore the key elements that keep your heating system running smoothly.

To maintain optimal performance, it’s crucial to understand how different pieces of the system connect and operate together. Recognizing the importance of each part, from the ignition mechanisms to the control units, is the first step in addressing potential issues or planning replacements. By gaining a comprehensive overview of these systems, you can better manage their upkeep and ensure consistent operation.

In the following sections, we’ll delve into the specifics, detailing the individual components that work harmoniously to provide consistent heating. This guide will serve as a foundation for those seeking to familiarize themselves with the mechanics and structure of these systems.

Atwood Water Heater: Key Component Overview

Understanding the essential elements of a modern heating device is crucial for efficient use and maintenance. Each component plays a role in ensuring the unit operates smoothly, delivering warmth and comfort while maintaining energy efficiency. Below is a breakdown of the most important mechanisms and systems that ensure reliable performance.

Main Heating Mechanism

The core element responsible for generating heat is the burner assembly. This section includes the ignition system and flame sensors, both crucial for safe and efficient operation. Proper maintenance of these components can prevent issues such as uneven heating or complete malfunction.

Control Systems

Control units regulate the entire process, from adjusting the temperature to monitoring safety protocols. These systems typically include thermostats and limit switches, which prevent overheating and ensure the device functions within safe parameters. Regular inspection of these controls is essential for long-term performance and safety.

Understanding the Function of the Main Valve

The main valve plays a crucial role in the overall operation of the system by regulating the flow of fuel. It is responsible for controlling the energy supply that enables the system to function effectively. Without a properly working valve, the unit may experience issues with energy distribution, leading to performance problems.

Key Components of the Main Valve

The valve consists of several essential elements that work together to ensure a smooth operation. These parts include the inlet and outlet sections, a control mechanism, and safety features that prevent overheating or overpressure.

| Component | Function |

|---|---|

| Inlet Section | Regulates the entry of fuel into the system. |

| Control Mechanism | Adjusts the flow of fuel to maintain consistent operation. |

| Safety Features | Prevents malfunctions by monitoring pressure and temperature levels. |

Maintenance and Troubleshooting

Regular inspections of the valve are essential to ensure optimal performance. Checking for blockages or leaks can prevent potential issues. If any irregularities are found, it is

Ignition System and Its Role

The ignition system plays a critical role in the functionality of many thermal appliances, ensuring that the combustion process starts reliably. Without a well-functioning ignition mechanism, the heating element cannot operate efficiently, resulting in a failure to provide the desired warmth. This component is essential for converting fuel into energy through a controlled ignition process.

Main Components of the Ignition System

- Spark Electrode: This component generates a spark that ignites the fuel mixture, allowing the system to begin heating.

- Control Board: The control board sends signals to activate the ignition process and regulates the overall system operation.

- Ignition Switch: This part initiates the process, acting as the trigger that engages the system.

How It Contributes to Efficiency

Proper ignition not only ensures consistent heating but also helps maintain energy efficiency. A malfunctioning ignition system can lead to increased fuel consumption or incomplete combustion, reducing the overall performance. Regular maintenance and inspection of this system are essential for optimal operation.

Thermostat: Regulating Water Temperature

The thermostat plays a crucial role in managing the temperature of the fluid. It ensures that the level of warmth is consistently maintained, offering both safety and efficiency. By adjusting the settings, users can control the balance between energy consumption and comfort, avoiding overheating or unnecessary energy use.

Below is a table outlining the key components and their functions:

| Component | Function |

|---|---|

| Thermostat Sensor | Monitors the fluid temperature and sends signals to the control unit. |

| Adjustment Dial | Allows manual setting of the desired temperature range. |

| Control Unit | Receives input from the sensor and adjusts the heat source accordingly. |

Proper regulation of temperature is essential to ensure the system operates within safe and efficient parameters, reducing the risk of malfunction.

Burner Assembly: Heat Generation Process

The burner assembly plays a crucial role in transforming fuel into heat, which is essential for creating a warm environment. This component works by igniting a fuel source, causing a controlled flame that transfers energy to the system. Understanding how this part operates allows for better maintenance and efficient use of the entire heating setup.

Key Components of the Burner Assembly

The burner assembly consists of several interconnected parts that contribute to its functionality. These include the burner tube, ignition system, and gas valve. Together, these components work in harmony to initiate the combustion process and regulate the amount of fuel used.

Heat Production Mechanism

Once the ignition system activates, gas flows through the burner tube, where it meets a spark or pilot flame. This ignition produces a controlled flame, which heats the surrounding elements. The gas valve ensures that the correct amount of fuel is supplied, optimizing both safety and energy efficiency.

| Component | Function | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Burner Tube |

| Stage | Description |

|---|---|

| Normal Operation | The valve stays closed, allowing the system to function without interruption. |

| Pressure Buildup | As pressure rises due to heat, the valve remains on standby, monitoring the levels inside. |

| Relief Activation | When the pressure reaches the safety limit, the valve opens, releasing pressure to prevent damage. |

| Pressure Release | The valve stays open until the pressure drops to a manageable level, then closes to resume normal function. |

Importance of the Anode Rod in Maintenance

The anode rod plays a crucial role in extending the lifespan of your system by preventing internal corrosion. This small yet essential component helps protect the internal surfaces from damage caused by rust and other corrosive elements. By acting as a sacrificial element, the rod attracts corrosive agents, ensuring that the internal parts remain intact and function efficiently for a longer time.

Regular inspection and replacement of the anode rod are key steps in maintaining optimal performance. Over time, the rod wears down as it continuously absorbs corrosive elements. Failing to replace it when needed can result in significant damage to the system, leading to costly repairs or replacements. Proper care of this component ensures that your equipment operates smoothly and effectively.

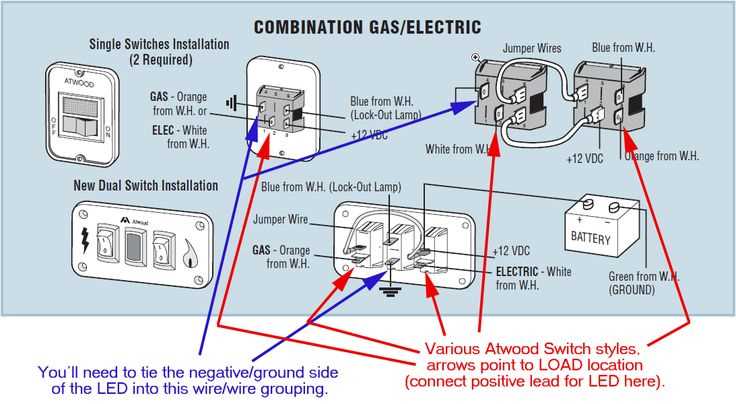

Wiring and Electrical Parts of the System

The electrical framework of this system is essential for maintaining optimal functionality. Understanding its components and how they interact is critical for troubleshooting or any necessary adjustments. This section will explore the primary elements involved in powering the system, including connections, cables, and key control units.

| Component | Description |

|---|---|

| Main Wiring Harness | The central connection point for all electrical circuits, ensuring the system operates efficiently and safely. |

| Control Board | Responsible for managing and coordinating the electrical signals to ensure proper system operation. |

| Thermostat | Regulates the system’s temperature by controlling the power flow based on user settings and environmental conditions. |

| Fuse and Circuit Breaker | Provides protection against electrical overloads or faults by interrupting the current when necessary. |

Control Board: Managing Water Heater Operations

The control board serves as the central hub for overseeing the functionality of heating devices, orchestrating various operations to ensure optimal performance. This component interprets signals from sensors and user inputs, making real-time adjustments to maintain the desired temperature and efficiency. By effectively coordinating these elements, the control board plays a vital role in enhancing the overall reliability and usability of the heating system.

Functions of the Control Board

One of the primary functions of the control board is to process information from temperature sensors, allowing for precise regulation of the heating cycle. This capability ensures that the system operates within safe parameters, minimizing the risk of overheating or energy wastage. Additionally, the control board may integrate diagnostic features, alerting users to potential issues and facilitating timely maintenance.

Importance of Proper Calibration

Accurate calibration of the control board is crucial for maintaining system efficiency. Regular adjustments and updates based on usage patterns can optimize performance and prolong the lifespan of the entire assembly. Properly calibrated systems not only enhance user satisfaction but also contribute to energy savings, making them a valuable investment for any owner.

Water Tank Structure and Insulation

The design of a storage unit plays a crucial role in maintaining optimal thermal efficiency and longevity. Properly structured compartments ensure effective heat retention, preventing unnecessary energy loss. Additionally, the choice of insulating materials significantly influences the overall performance and durability of the system.

Construction Materials: The selection of robust and resilient materials is essential for the unit’s integrity. Commonly used substances include stainless steel and aluminum, which provide excellent resistance to corrosion and physical wear. These materials are often preferred due to their lightweight properties and ability to withstand varying temperatures.

Insulation Techniques: Effective insulation minimizes heat transfer, ensuring that the stored contents remain at the desired temperature for extended periods. Common methods include foam insulation and fiberglass, which are applied to the exterior surfaces of the tank. This barrier significantly reduces energy consumption and enhances efficiency.

Design Considerations: Engineers must consider various factors when designing the structure, such as the tank’s capacity, intended use, and environmental conditions. A well-designed unit will not only meet performance standards but also offer ease of maintenance and accessibility for repairs or inspections.

Commonly Replaced Components and Upgrades

In the realm of portable heating systems, certain components frequently require replacement or enhancement to ensure optimal functionality and efficiency. Understanding these elements can aid in maintaining performance and prolonging the lifespan of the system.

One of the most commonly replaced items is the thermostat. This device regulates temperature and can wear out over time, leading to inconsistent heating. Upgrading to a more advanced model can improve accuracy and energy efficiency.

Another vital component is the ignition system. An outdated ignition mechanism may hinder the unit’s ability to start efficiently. Investing in a modern ignition system can enhance reliability and reduce the chances of ignition failure.

The tank itself is also a critical aspect. Corrosion and sediment build-up can compromise its integrity, necessitating replacement. Opting for a more durable, corrosion-resistant material can significantly improve longevity.

Additionally, upgrading the insulation can lead to better heat retention, minimizing energy consumption. Ensuring that all connections and fittings are secure can also prevent heat loss and improve overall performance.