In the realm of small machinery, a thorough grasp of the various elements that contribute to functionality is essential for optimal operation. Knowing how these components interact can enhance performance and ensure longevity. This guide delves into the intricate assembly of a specific engine-driven device, focusing on its essential features.

Recognizing the significance of each individual segment allows users to diagnose issues more effectively and maintain their equipment with greater ease. By exploring the structural arrangement, one can identify crucial links between different sections, which facilitates informed decision-making when it comes to repairs and upgrades.

This article aims to provide a detailed overview of the configuration, highlighting the relationships among the various elements involved. Whether you are a seasoned technician or a novice enthusiast, understanding this schematic will empower you to maximize the efficiency of your machinery.

Understanding Honda GX160 Water Pump

This section provides an in-depth look at a specific type of machinery designed for fluid transfer, exploring its essential components and functionality. Understanding the intricacies of this equipment can enhance performance and maintenance practices.

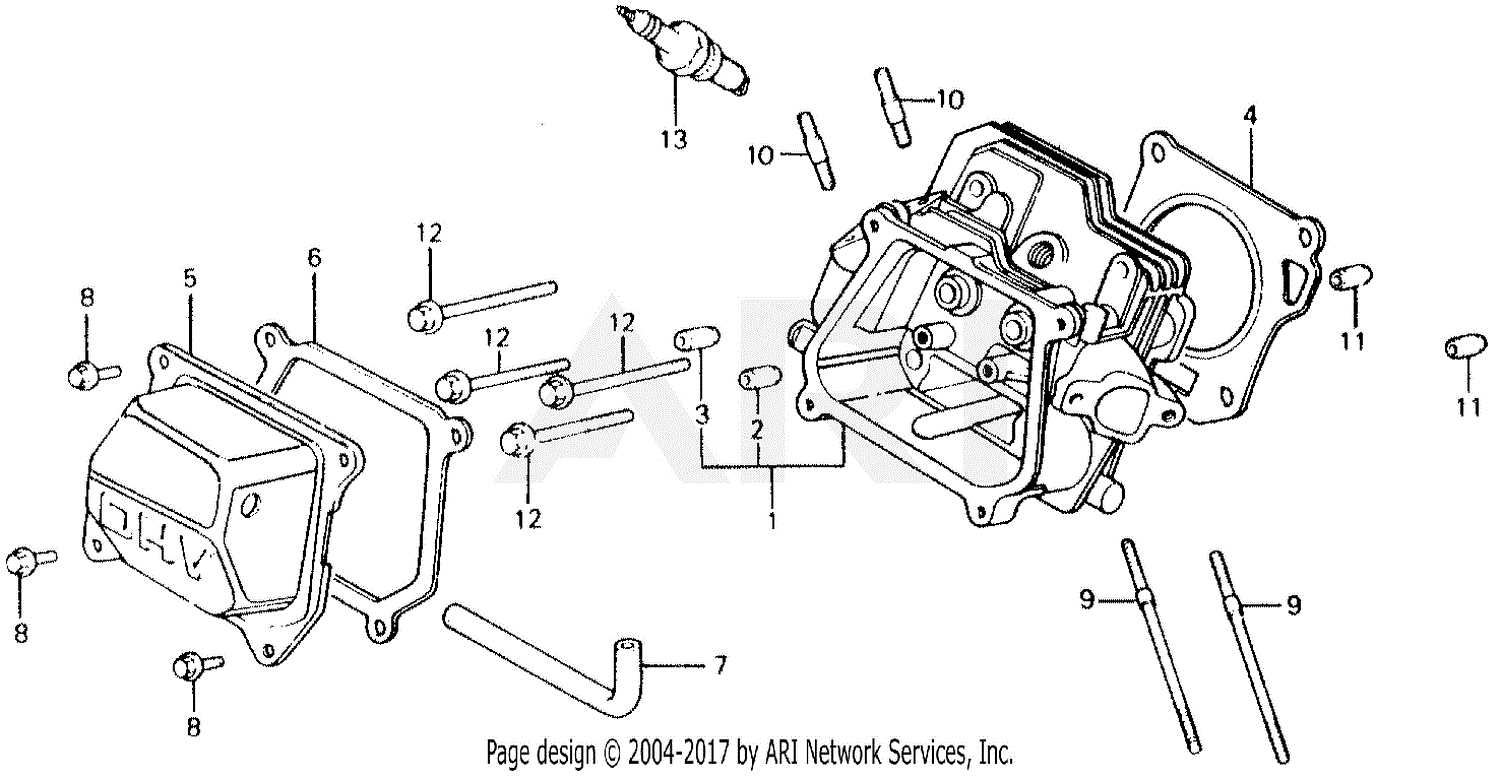

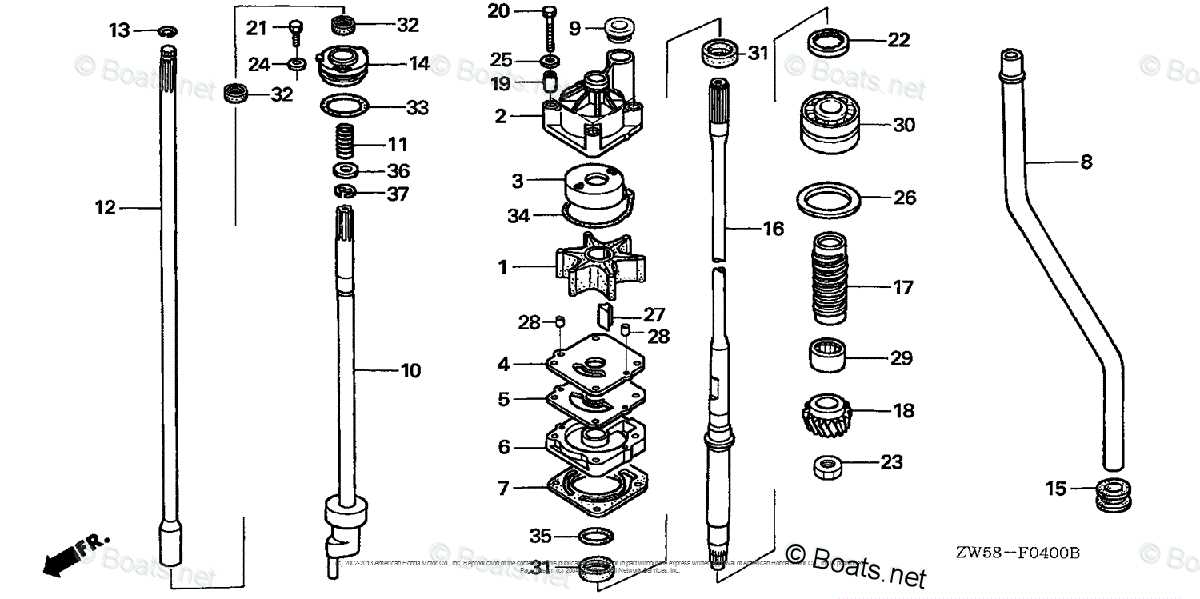

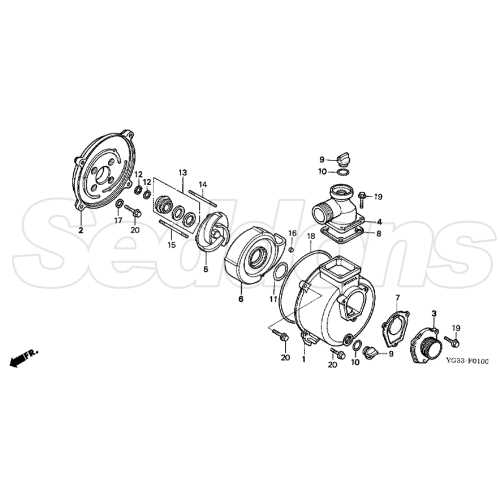

Key Components

Every unit comprises several crucial elements that work in harmony to ensure efficient operation. Recognizing these components is vital for troubleshooting and repair.

| Component | Description |

|---|---|

| Engine | Power source that drives the entire mechanism. |

| Impeller | Rotating part that facilitates fluid movement. |

| Housing | Encases internal components and directs fluid flow. |

Maintenance Tips

Regular upkeep is essential for longevity and reliability. Focus on checking fluid levels, inspecting seals, and ensuring all connections are secure to avoid malfunctions.

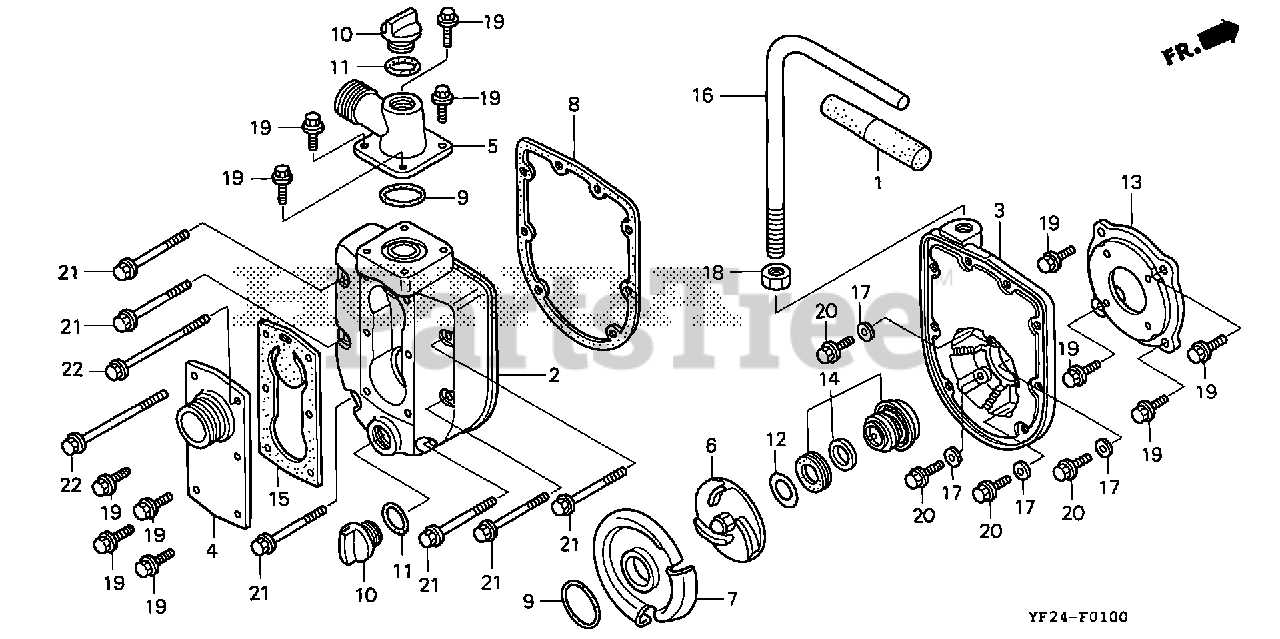

Key Components of the Water Pump

Understanding the essential elements of a fluid transfer system is crucial for effective operation and maintenance. Each component plays a vital role in ensuring efficiency and reliability, making it important for users to familiarize themselves with these critical features.

Impeller

The impeller is a fundamental part that generates flow by converting rotational energy into kinetic energy. Its design can significantly impact the system’s performance, with variations in size and shape affecting the volume and speed of the fluid movement.

Casing

The casing encases the impeller and directs the fluid flow, creating a pressure differential that facilitates movement. Proper sealing and structural integrity of the casing are essential to prevent leaks and ensure optimal functionality.

Other important components include the shaft, bearings, and seals, which work together to maintain efficiency and reduce wear. Regular inspection and maintenance of these elements are vital for the longevity of the system.

Common Issues and Troubleshooting Tips

When dealing with various types of machinery, it’s not uncommon to encounter specific challenges that can hinder performance. Understanding these issues is crucial for effective resolution and maintaining optimal function. Here are some prevalent problems and strategies to address them.

Performance Issues

One frequent concern is reduced efficiency. This can be attributed to factors such as blockages or wear in critical components. Regular inspections and cleanings can significantly improve functionality. Always ensure proper maintenance to avoid complications.

Starting Difficulties

Another common challenge is trouble starting the engine. This may stem from fuel supply issues or electrical malfunctions. Check the fuel level and connections, and consider testing the ignition system to pinpoint the issue effectively. Keeping a troubleshooting checklist handy can streamline this process.

Maintenance Practices for Longevity

Ensuring the durability and efficiency of any mechanical device requires regular care and attention. Implementing effective maintenance routines not only prolongs the lifespan of the equipment but also enhances its performance, reducing the risk of unexpected breakdowns.

Regular Inspections

Conduct frequent checks on all components to identify wear and tear early. This proactive approach can save time and resources in the long run.

Proper Cleaning Techniques

Keep the machinery clean from dirt and debris to prevent damage and maintain optimal functionality. A clean environment promotes better performance.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect components | Monthly | Identify issues early |

| Clean filters | Bi-weekly | Improves efficiency |

| Change lubricants | Every 50 hours | Reduces friction |

How to Identify Genuine Parts

Identifying authentic components is essential for maintaining the performance and longevity of your machinery. The market is flooded with imitations that may look similar but can lead to subpar functionality and safety issues. Ensuring you have the correct items can save you from costly repairs and replacements in the future.

First, examine the packaging. Genuine items typically come in high-quality packaging with clear branding and labels. Look for holograms or other security features that indicate authenticity.

Next, check the product itself. Authentic components are made with superior materials and exhibit precise craftsmanship. Compare the weight and finish with known genuine items.

Finally, purchase from reputable suppliers. Research the vendor’s history and customer reviews to ensure they provide genuine offerings. Trustworthy retailers often provide guarantees or warranties for their items.

Step-by-Step Repair Guide

This section aims to provide a clear and concise method for addressing common issues encountered in small engine machinery. Following these steps will help ensure optimal performance and longevity.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and pliers.

- Ensure you have replacement components on hand.

- Review the equipment manual for specific guidelines.

Repair Steps

- Disconnect the engine from the power source to ensure safety.

- Remove any covers or guards to access internal mechanisms.

- Inspect components for wear and damage; replace as needed.

- Reassemble all parts securely, following the reverse order of disassembly.

- Test the machinery for functionality before regular use.

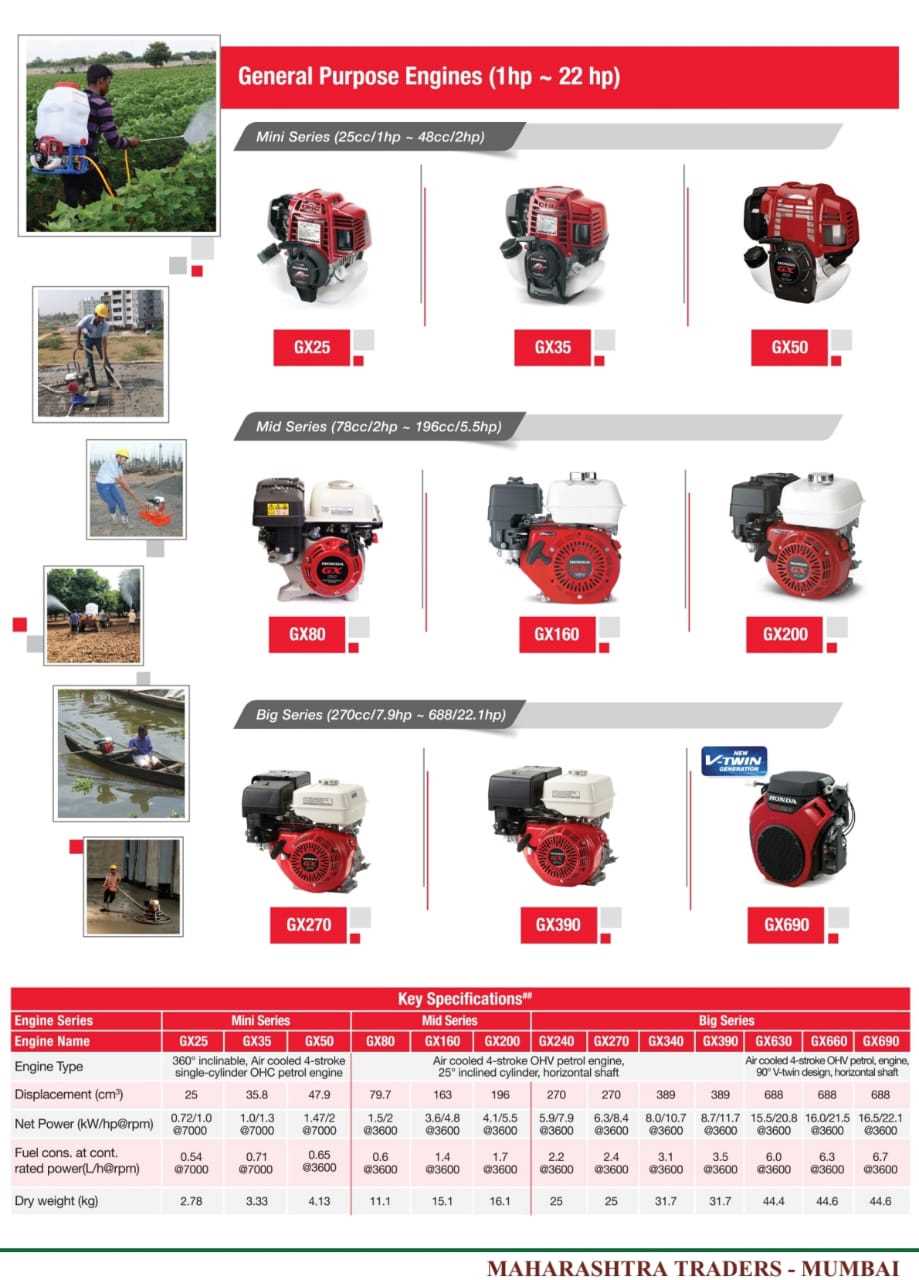

Comparison with Other Water Pumps

In exploring the realm of fluid transfer devices, it becomes essential to evaluate the distinct features that set each model apart. Various options on the market offer unique benefits tailored to different applications and user needs.

Performance: Some models excel in efficiency, delivering higher flow rates or pressure, making them ideal for large-scale tasks. Others prioritize fuel consumption, providing prolonged operation without frequent refueling.

Durability: When examining longevity, certain devices are crafted with robust materials, ensuring they withstand harsh conditions better than their competitors. In contrast, lighter units may sacrifice durability for portability.

Maintenance: The ease of upkeep varies significantly. Some require regular servicing and replacement of components, while others are designed for minimal intervention, appealing to users seeking convenience.

Ultimately, choosing the right device involves a careful consideration of these attributes, allowing users to select the model that best aligns with their specific needs and circumstances.

Importance of Proper Installation

Correct assembly and setup of machinery components are crucial for optimal performance and longevity. Neglecting this aspect can lead to various operational issues, resulting in inefficiency and potential damage.

Key Benefits of Proper Assembly

- Ensures efficient operation and energy use.

- Reduces the risk of mechanical failures.

- Extends the lifespan of the equipment.

Common Issues from Improper Setup

- Increased wear and tear on components.

- Frequent maintenance and repair requirements.

- Higher operational costs due to inefficiency.

Adhering to installation guidelines not only enhances performance but also promotes a safer working environment.

Parts Replacement Frequency Recommendations

Maintaining optimal performance in machinery requires a keen understanding of when components need to be replaced. Regular inspections and timely substitutions not only extend the life of the equipment but also enhance operational efficiency. This section provides guidelines on how often various elements should be checked and changed to ensure seamless functionality.

| Component | Recommended Replacement Interval | Notes |

|---|---|---|

| Seals | Every 6 months | Inspect for wear and tear, replace if leaks occur. |

| Filters | Every 3 months | Replace regularly to prevent clogging and ensure efficiency. |

| Hoses | Annually | Check for cracks and signs of deterioration; replace as necessary. |

| Fasteners | Every 6 months | Ensure tightness; replace if rusted or stripped. |

| Gaskets | As needed | Monitor for leaks; replace when sealing ability diminishes. |

Where to Buy Replacement Parts

Finding quality components for your equipment can significantly enhance performance and longevity. Various options are available to acquire these essentials, ensuring you keep your machinery in top condition.

Online Retailers

Many platforms offer a vast selection of components at competitive prices. Shopping online allows for easy comparison and access to customer reviews, which can guide your decision.

Local Stores

Visiting nearby hardware or specialty shops can be beneficial for immediate needs. Staff can often provide valuable advice on compatibility and alternatives.

| Source | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, competitive pricing | Shipping time, return policies |

| Local Stores | Immediate availability, expert advice | Limited stock, potentially higher prices |

FAQs About Honda GX160 Pumps

This section addresses common inquiries related to a specific engine model used for fluid transfer applications. Here, we aim to clarify typical concerns and provide essential information for users seeking guidance on maintenance, operation, and troubleshooting.

What is the typical lifespan of this engine?

The durability of this engine largely depends on usage and maintenance. Proper care can extend its life significantly, often exceeding several years with regular servicing.

How do I know if my engine is functioning properly?

Signs of proper operation include smooth performance, consistent output, and the absence of unusual noises or vibrations. Regular checks can help identify issues early.

What maintenance is required for optimal performance?

Routine tasks include oil changes, air filter replacements, and inspecting seals and hoses. Adhering to a maintenance schedule ensures longevity and efficiency.

Can I use this engine for different types of liquids?

While it is designed primarily for water, it can handle various liquids. However, it’s essential to check compatibility to avoid damage or inefficiency.

What should I do if it won’t start?

If starting issues arise, first check fuel levels and spark plug condition. Additionally, inspect the air filter and ensure there are no blockages in the fuel line.

Are replacement components readily available?

Yes, replacement components are widely accessible from numerous suppliers, ensuring that users can find what they need to maintain functionality.