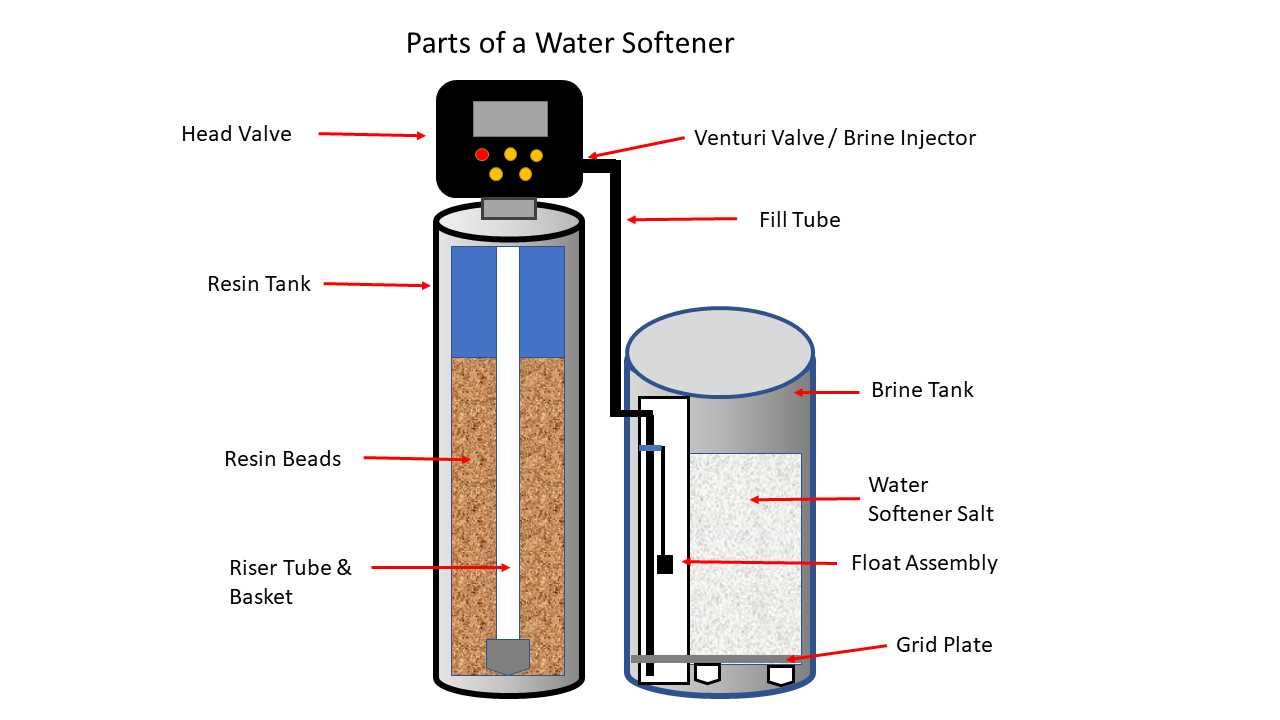

This section delves into the various elements that contribute to the effective functioning of a filtration apparatus. Understanding these components is essential for anyone looking to maintain or enhance the performance of their setup.

Identifying each element is crucial for troubleshooting and ensuring optimal operation. By familiarizing oneself with the different parts, users can better appreciate how they work together to achieve efficient results.

Additionally, recognizing the role of each component allows for informed decisions regarding upgrades or replacements, ultimately leading to improved longevity and effectiveness of the system.

The process of reducing hardness in fluids involves a series of steps that effectively alter the composition of minerals present. This method is essential for enhancing the quality of liquids used in various applications.

At the core of this process is the exchange of ions, where undesirable minerals are replaced with more manageable ones. Here are the primary components involved:

- Resin Beads: Small spheres that facilitate the ion exchange process.

- Brine Solution: A concentrated mixture that rejuvenates the resin beads, allowing them to function optimally.

- Control Valve: Regulates the flow and timing of the treatment stages.

The cycle begins when the liquid passes through the resin bed, where hardness minerals are captured and exchanged. Once the resin reaches its capacity, a brine solution is introduced to regenerate the beads. This cycle ensures a continuous supply of treated liquid, maintaining desired quality levels.

Understanding the mechanisms behind this process can help in optimizing performance and prolonging the life of the system. Regular maintenance and timely regeneration play crucial roles in achieving effective results.

Importance of Each Component

Understanding the significance of various elements within a treatment system is crucial for optimal functionality and performance. Each component plays a vital role in ensuring the effective operation and longevity of the system.

| Component | Function |

|---|---|

| Tank | Holds the medium that facilitates the removal of impurities. |

| Control Valve | Regulates the flow of liquid and manages regeneration cycles. |

| Media | Acts as the primary agent in the removal of unwanted elements from the fluid. |

| Brine Tank | Stores the salt solution necessary for regeneration of the medium. |

| Piping | Ensures the proper distribution of fluid throughout the system. |

Common Issues with Softener Parts

When it comes to the functionality of a treatment system, various components can encounter problems that hinder performance. Understanding these common challenges is essential for maintaining efficiency and ensuring a longer lifespan for the unit. Recognizing the signs of malfunction can lead to timely interventions, which are crucial for optimal operation.

Clogs and Blockages

One of the frequent issues faced is the buildup of residue in the system’s internal mechanisms. This accumulation can lead to reduced efficiency, as the flow of liquid is impeded. Regular inspections and cleanings can help mitigate these problems, ensuring smooth operation and preventing further complications.

Component Wear and Tear

Over time, the various elements of a treatment unit may experience degradation due to constant usage. This deterioration can manifest in leaks or diminished effectiveness. It’s important to monitor these components and replace them when necessary to maintain overall system integrity.

Maintenance Tips for Optimal Function

To ensure long-lasting efficiency and performance of your system, regular upkeep is essential. Simple practices can significantly enhance its functionality and prevent potential issues from arising.

First and foremost, routinely inspect the unit for any signs of wear or damage. Addressing minor concerns promptly can prevent more significant problems down the line. Additionally, keeping the area around the unit clean and free from debris will promote better airflow and reduce the risk of clogs.

Another vital aspect is monitoring the chemical levels used within the system. Ensuring that the appropriate substances are replenished regularly will maintain optimal performance. It is advisable to follow the manufacturer’s guidelines regarding the frequency and quantity of these substances.

Lastly, scheduling professional servicing at regular intervals can help identify underlying issues before they escalate. Experts can provide insights and solutions tailored to the specific needs of your setup, ensuring it continues to operate smoothly for years to come.

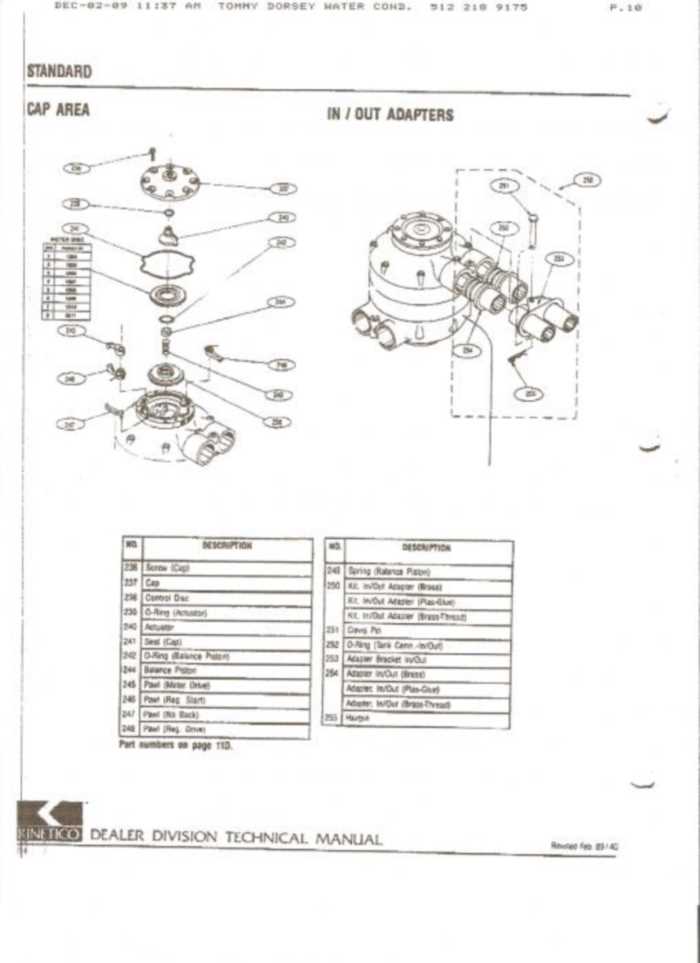

How to Read Parts Diagrams

Understanding the visual representation of components is crucial for effective maintenance and troubleshooting. These illustrations serve as a roadmap, guiding users through the intricate network of elements within a system. Mastering this skill can greatly enhance one’s ability to address issues efficiently.

Identifying Key Elements

When examining these visual aids, focus on recognizing the essential components. Here are some tips to help you:

- Look for labeled sections that indicate specific functions.

- Pay attention to the symbols used; they often represent particular features.

- Note the connections between elements, as these often reveal the flow of operation.

Understanding Color Codes and Symbols

Colors and symbols convey important information about the functionality of various elements. Consider the following:

- Different colors may indicate different materials or functions.

- Symbols often represent standardized features that can simplify interpretation.

- Refer to a legend if available, as it provides clarity on the meaning behind each symbol or color.

Comparing Manual and Automatic Systems

This section explores the distinctions between systems that require user intervention and those that operate independently. Each approach has unique advantages and limitations that cater to different user needs and preferences.

| Feature | User-Controlled Systems | Self-Regulating Systems |

|---|---|---|

| Ease of Use | Requires regular user adjustments | Operates without manual input |

| Maintenance | Potential for increased maintenance due to user oversight | Typically requires less frequent attention |

| Cost | Often more affordable upfront | Higher initial investment but potentially lower long-term costs |

| Customization | Allows for personalized settings | Limited customization options |

| Efficiency | May be less efficient due to user variability | Designed for optimal performance automatically |

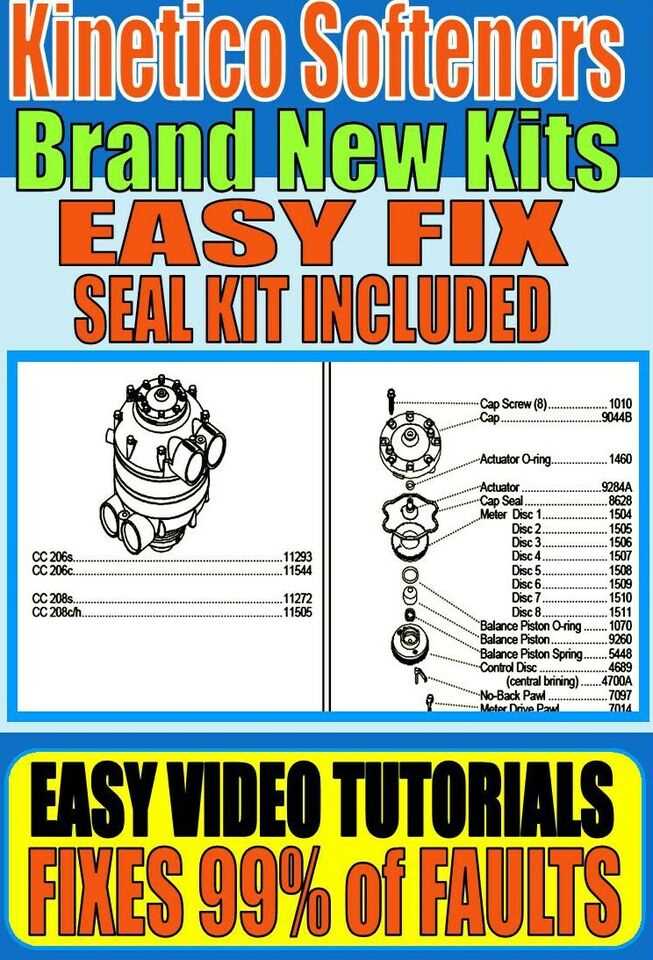

Identifying Replacement Parts

Recognizing components for a specific system is essential for effective maintenance and repairs. Understanding the different elements involved can significantly enhance the efficiency and longevity of the device. This section provides guidance on how to identify the necessary replacements for optimal functionality.

Here are some key points to consider when determining which elements may need to be swapped out:

- Functionality: Assess the role of each component within the overall structure.

- Compatibility: Ensure that the replacements match the specifications of the existing setup.

- Quality: Look for reliable and durable alternatives to maintain high performance.

To assist in the identification process, it is helpful to refer to a comprehensive guide or manual that outlines the various components and their functions. Additionally, visual aids can provide clarity on what to look for during inspections.

Consider the following methods for identifying components:

- Examine any available schematics or illustrations that highlight the structure.

- Consult with experts or professionals who specialize in the device.

- Utilize online resources or forums dedicated to similar systems for insights.

By following these steps, users can effectively pinpoint the necessary replacements and ensure their systems remain in peak condition.

Installation Guidelines for New Components

When integrating new elements into your system, following precise instructions is essential for optimal performance. Proper installation ensures efficiency and longevity, reducing the likelihood of future issues. This section will outline the key steps to facilitate a smooth installation process, ensuring all components function harmoniously.

Begin by gathering all necessary tools and materials required for the installation. It is advisable to review the specifications for each new component to understand its features and requirements. Below is a helpful table summarizing the essential tools and components:

| Item | Description |

|---|---|

| Wrench Set | For securing fittings and connections. |

| Screwdriver | For attaching and detaching various elements. |

| Sealant | To ensure leak-proof connections. |

| Instruction Manual | A guide for detailed installation procedures. |

Before beginning the installation, ensure the system is powered down to prevent any accidents. Carefully follow the outlined steps in the instruction manual to connect and secure each new element. Double-check all connections for tightness and alignment to maintain system integrity. Once the installation is complete, restore power and monitor the system for any irregularities.

Upgrades for Improved Efficiency

Enhancing the performance of a treatment system can lead to significant benefits in functionality and longevity. By implementing thoughtful modifications, users can optimize their setup for better results and resource management.

Several upgrades can be considered to achieve this goal:

- Advanced Control Systems: Incorporating smart technology can automate processes and provide real-time monitoring, ensuring optimal operation.

- High-Efficiency Resin: Switching to premium materials can enhance the effectiveness of the treatment process, reducing waste and improving overall performance.

- Energy-Efficient Pumps: Upgrading to more efficient pumps can decrease energy consumption, lowering operational costs while maintaining effectiveness.

- Enhanced Filtration Options: Adding additional filtration stages can improve water quality by removing more contaminants, providing a cleaner output.

- Regular Maintenance Kits: Investing in maintenance products can ensure the system operates smoothly and efficiently, preventing breakdowns and extending lifespan.

By focusing on these upgrades, users can significantly improve the efficiency of their systems, leading to long-term savings and better performance.

Frequently Asked Questions about Softener Parts

This section addresses common inquiries regarding components associated with treatment systems designed to enhance water quality. Understanding these elements is crucial for maintaining optimal functionality and ensuring longevity of the system.

What are the main components found in these systems?

The systems typically consist of a tank, resin, control valve, and brine container. Each component plays a vital role in the overall performance, contributing to the effective removal of undesirable minerals.

How often should the components be replaced?

Replacement frequency varies based on usage and the specific system employed. Regular maintenance checks can help identify when components require attention or replacement.

Can I install replacement parts myself?

While some individuals may choose to handle replacements independently, consulting with a professional is recommended to ensure proper installation and avoid potential issues.

What maintenance is necessary to keep these systems running smoothly?

Routine maintenance includes checking the brine levels, inspecting the control valve, and ensuring the resin is functioning correctly. Regular maintenance helps prolong the life of the entire system.