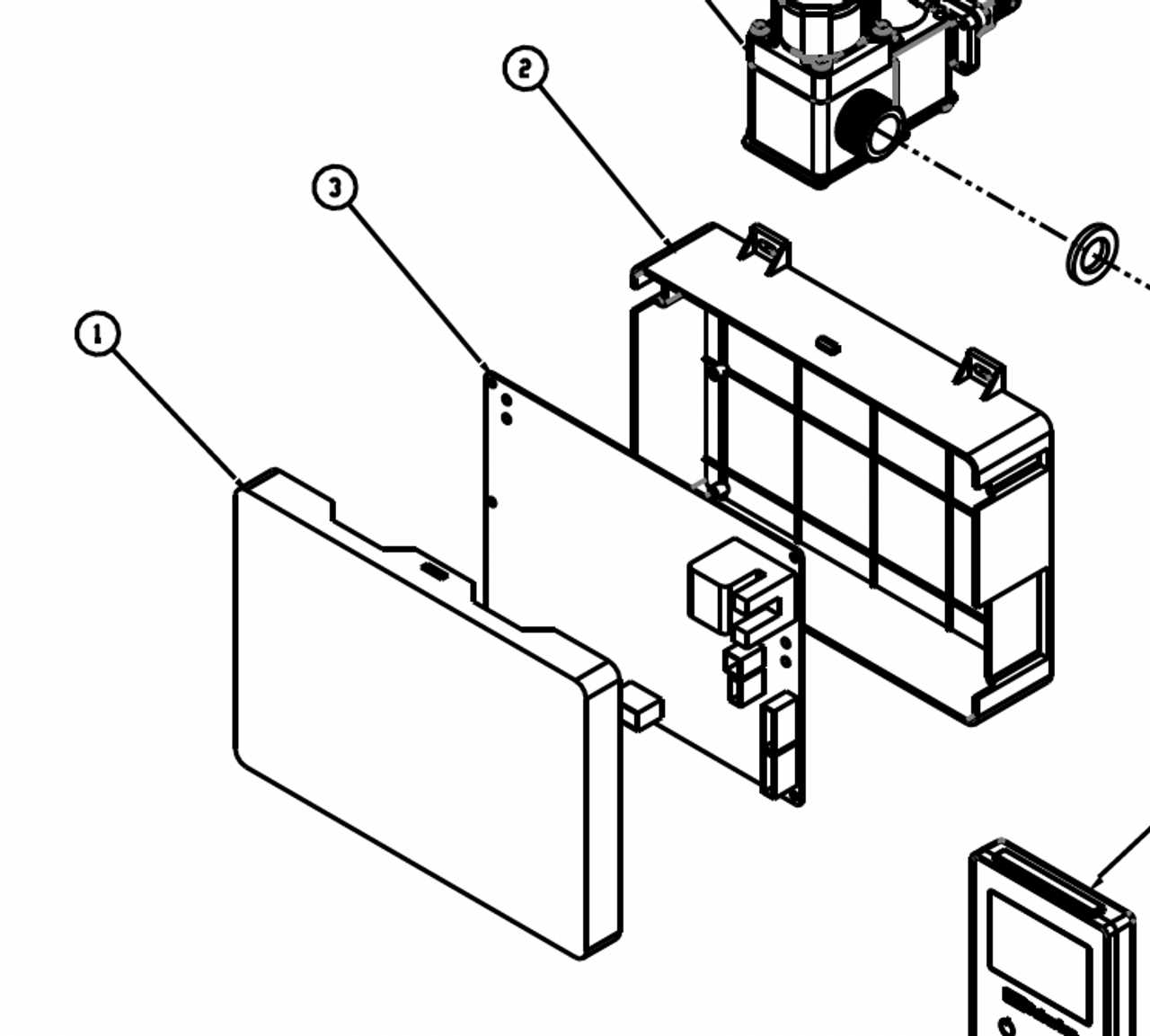

In every mechanical system, there are numerous interconnected elements that work in harmony to ensure smooth functionality. Whether it’s for daily convenience or more complex applications, understanding how these components operate together is key to maintaining and troubleshooting the unit effectively. Each part has a specific role, and when combined, they form a reliable and efficient mechanism that serves its purpose over time.

To gain a deeper insight into how such systems function, it’s important to explore the individual elements and their placement within the overall structure. By doing so, you can better identify potential issues and ensure that everything operates at peak efficiency. Knowing the layout of these essential components is crucial for anyone looking to enhance performance or perform routine maintenance on their equipment.

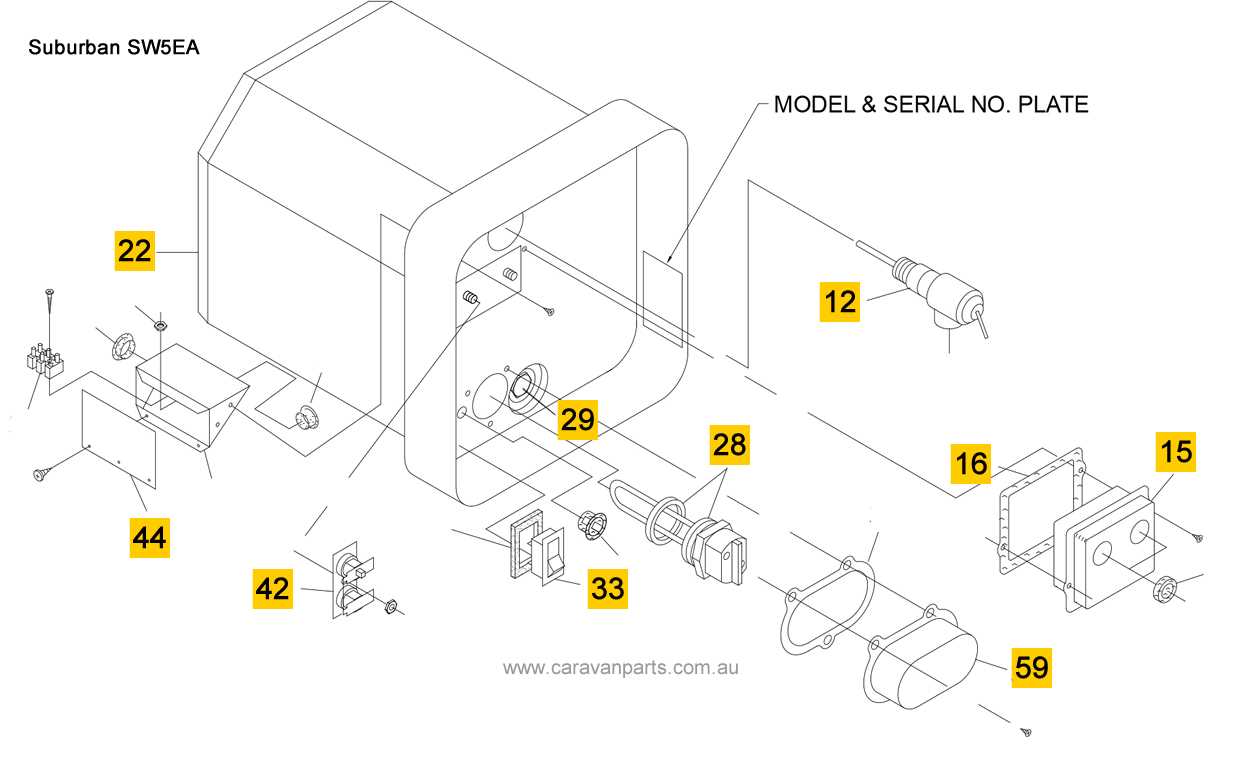

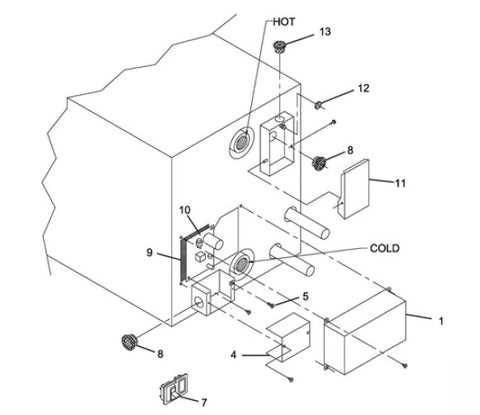

In any heating system, several essential elements work together to ensure smooth operation and reliable performance. Recognizing these components can help in identifying potential issues and performing necessary maintenance. Each part serves a unique function, contributing to the efficiency and longevity of the system.

The core assembly contains several key units responsible for generating and regulating warmth. The combustion chamber, for example, is where fuel is transformed into heat, while the heat exchanger ensures the transfer of energy to the surrounding medium. Additionally, the control panel allows users to adjust the temperature and monitor system performance.

To maintain safety and improve functionality, modern heating units incorporate a number of protective features. Pressure relief valves prevent excess buildup within the system, while the thermocouple monitors the flame, cutting off the gas supply in case of malfunction. These elements not only safeguard the equipment but also enhance energy efficiency

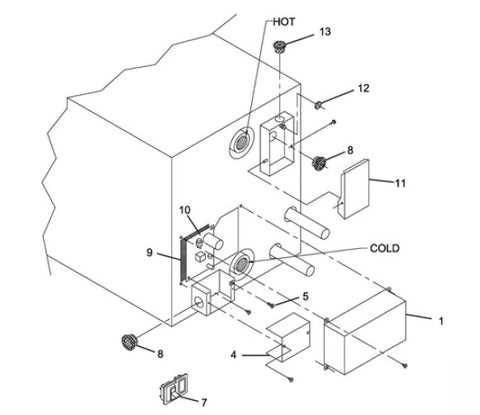

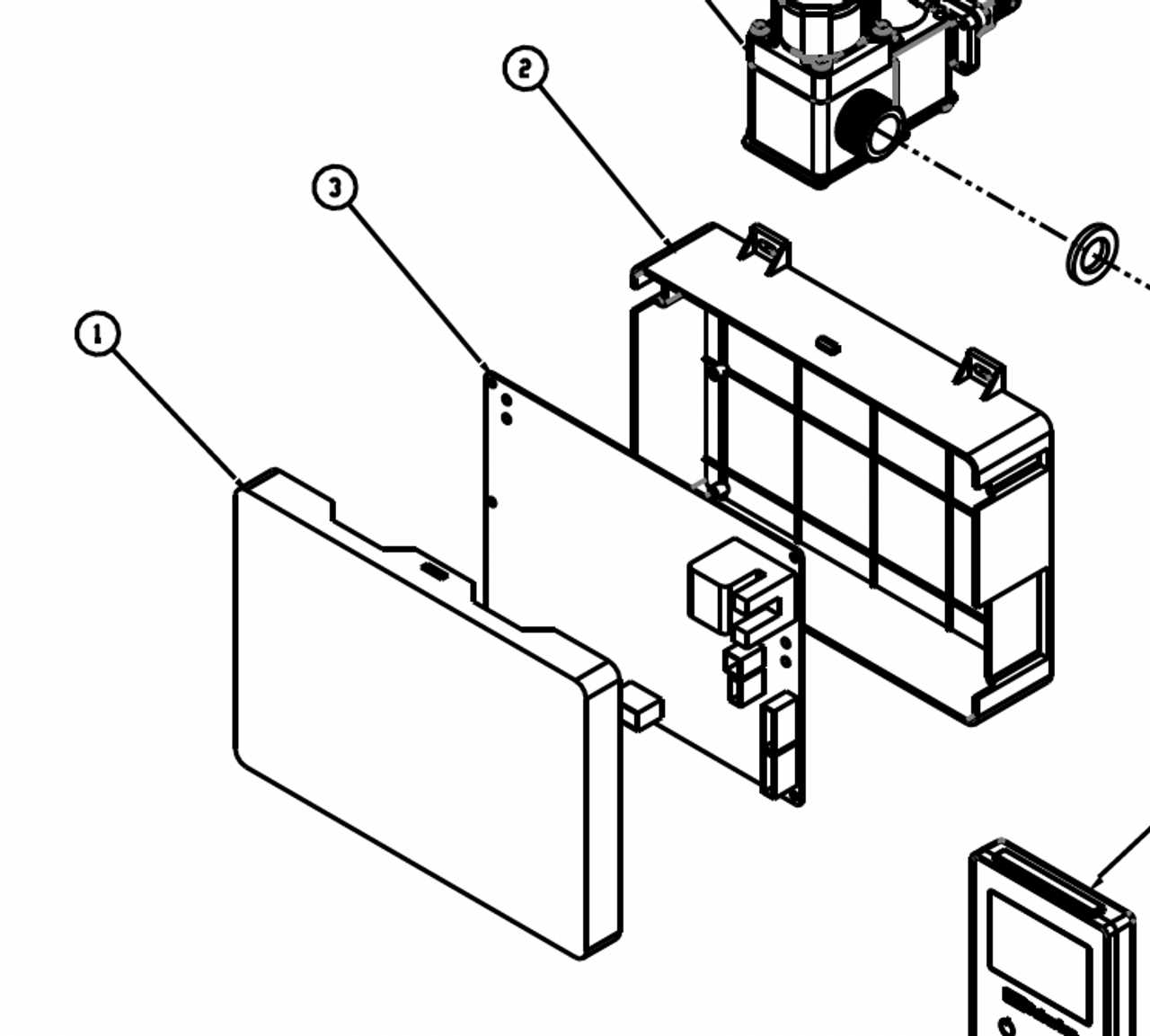

The system responsible for creating warmth relies on a variety of interconnected components, each playing a vital role in maintaining a consistent temperature. Understanding the functionality of these elements helps in ensuring efficient operation and identifying potential issues. Below, we’ll explore the most important components involved in the process.

At the core of the system lies the regulation mechanism, which controls and monitors the desired temperature. This component responds to changes and ensures that the system adjusts to provide the optimal level of warmth, preventing overheating or insufficient heating.

An essential part of the operation is the power connection, which fuels the entire process. Whether it runs on electricity or another energy source, the stability and reliability of this connection directly impact the system’s performance, ensuring it remains operational for extended periods.

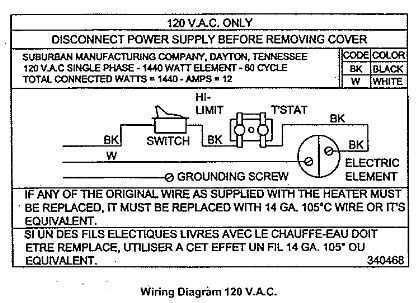

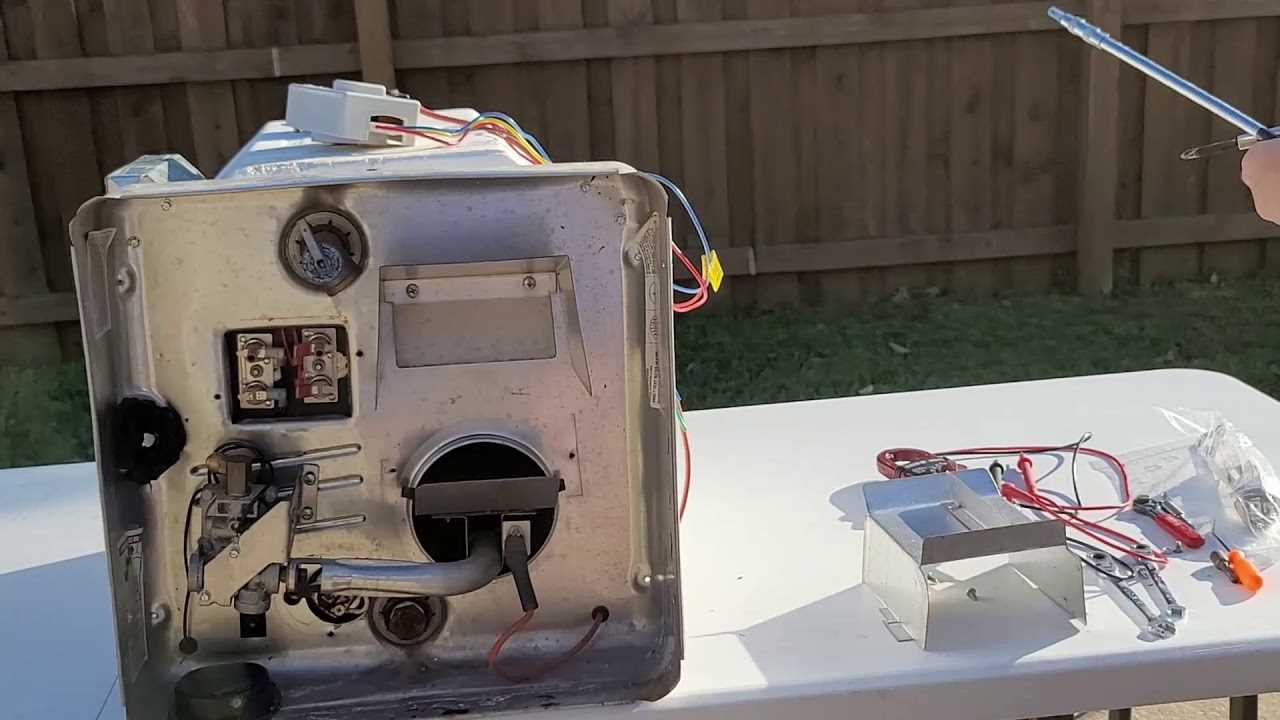

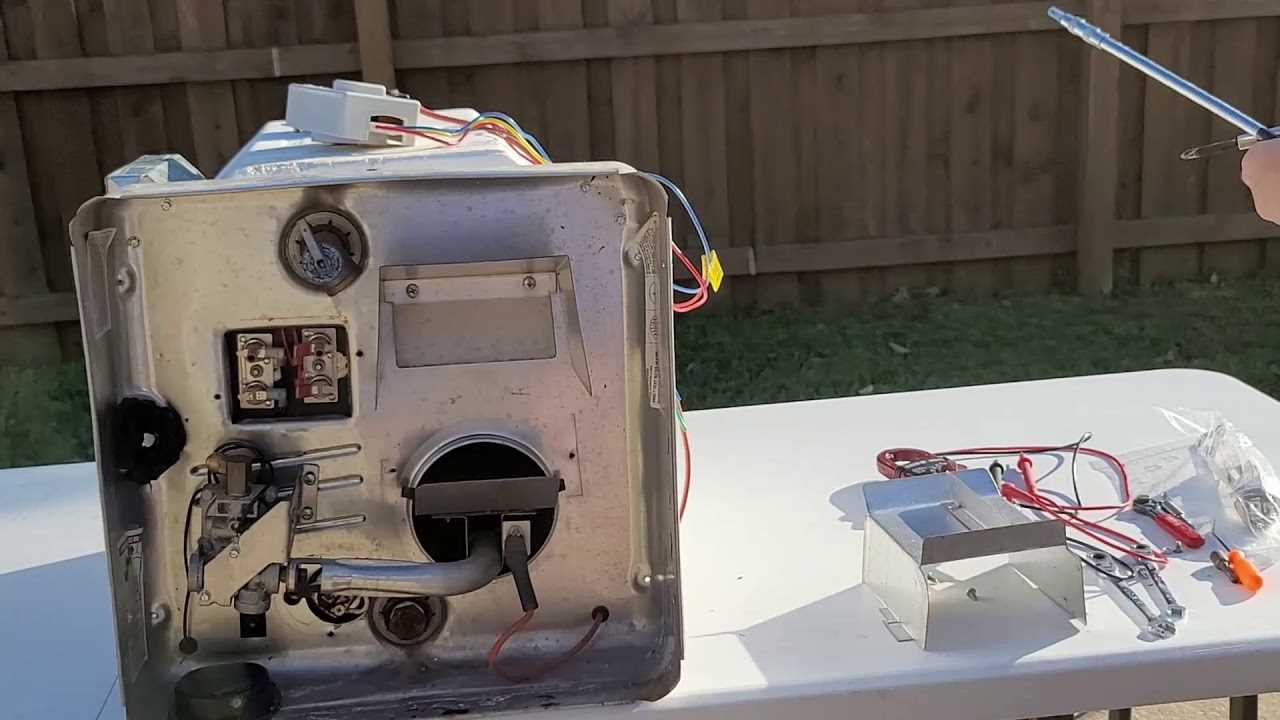

Understanding the arrangement of electrical pathways inside a heating device is crucial for proper installation and maintenance. The internal wiring connects various components, ensuring they function harmoniously. This section provides a comprehensive look at the key connections within the unit, highlighting their roles in the overall system.

| Component |

Connection Point |

Purpose |

| Thermostat |

Control Circuit |

Regulates temperature based on settings. |

| Heating Element |

Main Power Line |

Generates the necessary heat for the device. |

| Control Board |

Power Distribution |

Manages the flow of electricity to each part. |

How the Thermostat Regulates Temperature

The control mechanism is vital in maintaining a consistent and safe thermal level within the system. This device continuously monitors the environment, adjusting the heat output to ensure stability. Without this component, managing thermal conditions would be difficult, leading to potential issues with overheating or inefficiency.

Monitoring and Adjusting Heat Levels

The thermostat functions by sensing changes in the surrounding environment. When the temperature drops below a set threshold, the system activates the heating element to raise the heat. Conversely, once the desired level is reached, the device pauses the heating process, maintaining the optimal range.

Safety and Efficiency

Beyond providing comfort, this component also plays a critical role in energy efficiency. By preventing the system from running continuously, it helps conserve energy, reducing operational costs. Additionally, it ensures safety by

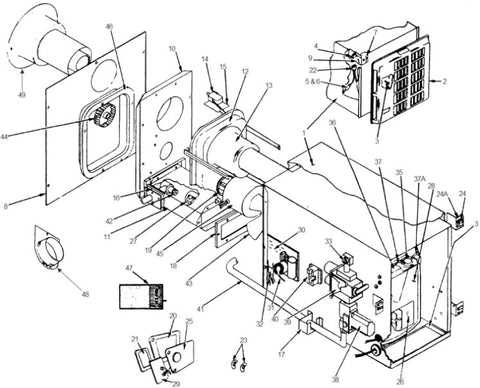

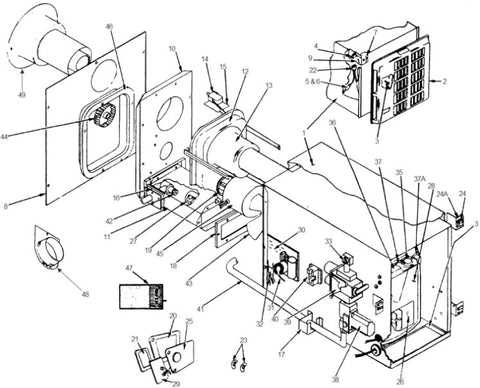

Burner Assembly: A Breakdown of Its Parts

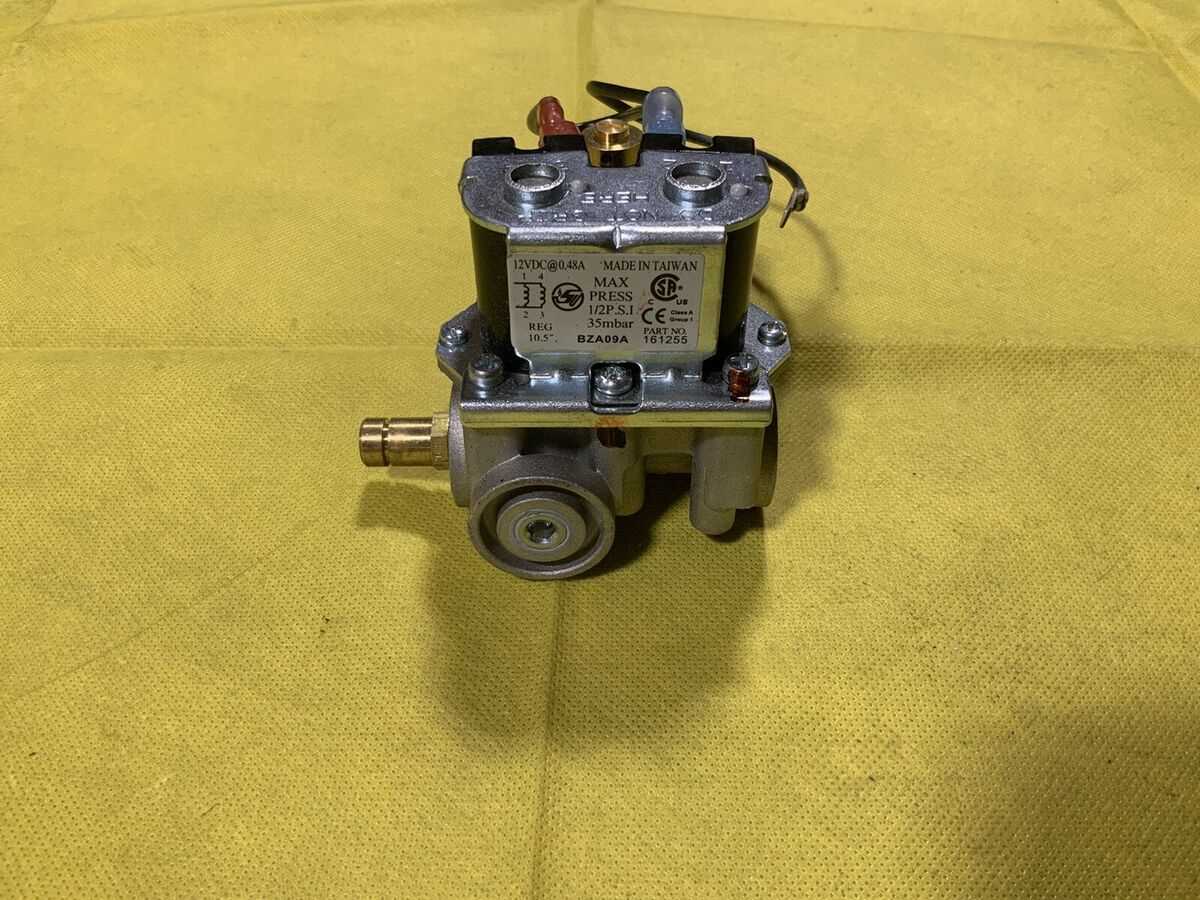

The combustion system plays a crucial role in the overall function of the device, ensuring efficient operation by producing the necessary heat. This system consists of multiple interconnected components, each serving a distinct function to ensure safe and effective ignition and flame management.

At the heart of the assembly is the ignition mechanism, responsible for sparking the fuel mixture. This is followed by the distribution section, which channels the fuel evenly to sustain a consistent flame. Surrounding the flame is a protective barrier, designed to contain the heat and direct it where it’s most needed.

Another key component is the regulator, which controls the flow of gas, ensuring the correct balance for optimal combustion. Finally, various safety features are integrated to monitor performance and shut off the system if irregularities are detected, protecting the unit from potential malfunctions.

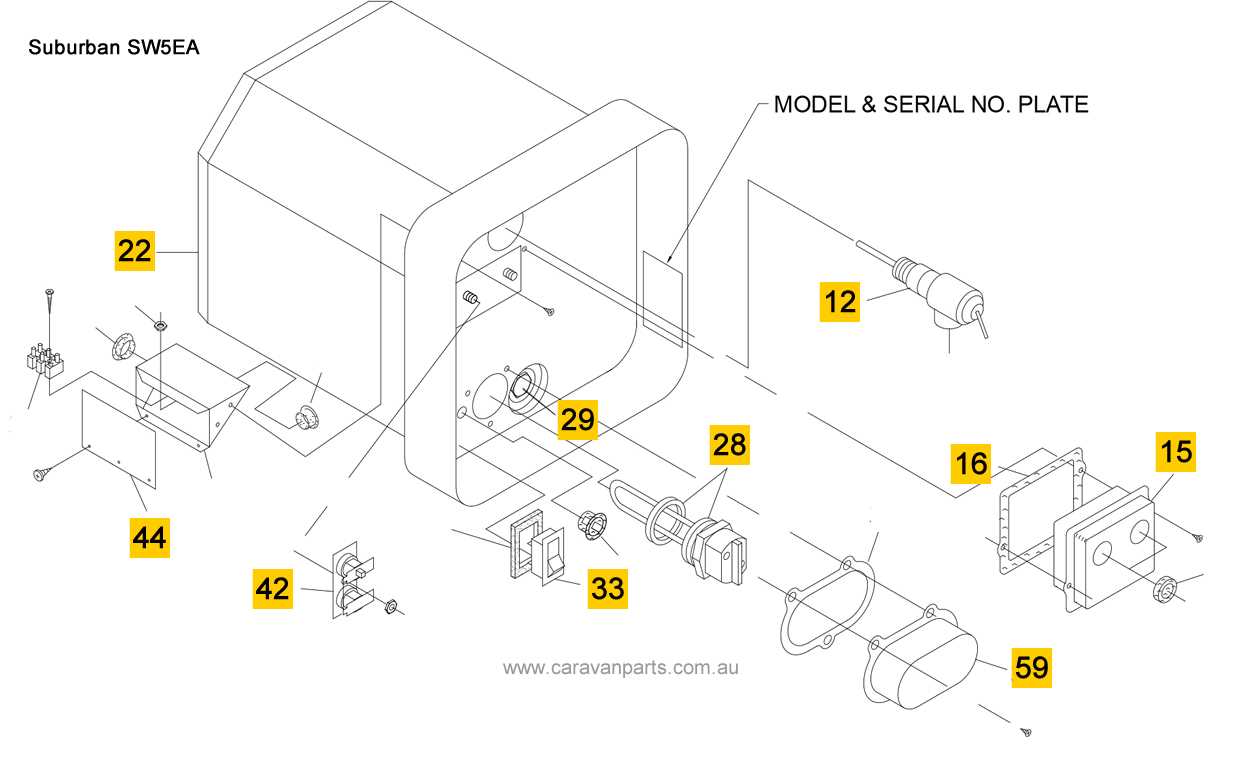

Pressure Relief Valve: Function and Maintenance

The pressure relief valve plays a crucial role in ensuring safety and efficiency in heating systems. This component is designed to regulate and maintain optimal pressure levels, preventing excessive buildup that could lead to catastrophic failures. Understanding its function and the importance of regular upkeep is essential for the longevity of the entire system.

This device operates by releasing excess pressure, thereby safeguarding the system from potential damage. When the internal pressure exceeds a predetermined threshold, the valve opens, allowing steam or fluid to escape. This process not only protects the integrity of the system but also ensures efficient operation by maintaining the correct pressure range.

Regular maintenance of the pressure relief valve is vital to ensure its proper functioning. Users should periodically inspect the valve for signs of wear or corrosion, as well as test it to verify that it opens at the specified pressure. If any issues are detected, it is advisable to replace the valve to avoid risks associated with pressure anomalies.

In summary, the pressure relief valve is an indispensable safety feature that requires attention and care. By understanding its role and committing to routine maintenance, users can enhance the reliability and performance of their heating systems.

Electric Element and Its Role in Heating

The core component responsible for thermal generation in a heating appliance is crucial for its efficient operation. This essential unit transforms electrical energy into heat, facilitating the warming of fluids within a designated system. Understanding its functionality provides insight into how temperature control is achieved and maintained in various applications.

Functionality of the Heating Component

This vital unit operates by passing an electrical current through a resistive material, which then generates heat. The heat produced is subsequently transferred to the surrounding medium, ensuring that the desired temperature is reached and sustained. The efficiency of this process is influenced by factors such as the material’s conductivity and the design of the component itself.

Importance of Maintenance

Regular upkeep of the heating element is essential for optimal performance. Over time, buildup of mineral deposits or corrosion can hinder its effectiveness, leading to inefficiencies or complete failure. Routine inspections and timely replacements ensure the longevity of the system and maintain its operational efficiency.

Anode Rod: Preventing Corrosion in the Tank

The anode rod plays a crucial role in extending the lifespan of a storage container by combating the damaging effects of rust and corrosion. This component acts as a sacrificial element, drawing corrosive elements toward itself and away from the surrounding materials.

Understanding the function of this vital component can help users maintain their system effectively. Here are some key points about the anode rod:

- Material Composition: Typically made from magnesium or aluminum, the anode rod is designed to corrode more easily than the tank’s interior.

- Installation Location: It is usually found at the top of the tank, making it easily accessible for inspection and replacement.

- Signs of Degradation: Regular checks for corrosion or depletion can indicate when the rod needs to be replaced to ensure optimal protection.

- Replacement Frequency: Depending on the water quality and usage, it is recommended to inspect the anode rod every one to three years.

By prioritizing the maintenance of this essential part, users can significantly enhance the durability of their storage unit and avoid costly repairs down the line.

Ignition System: Ensuring Safe Startup

The ignition mechanism plays a crucial role in the initiation process of any heating apparatus. It is designed to facilitate a reliable and efficient startup while prioritizing user safety. A properly functioning ignition system is essential for preventing hazardous situations, ensuring that the equipment operates smoothly from the moment it is activated.

Key Components of the Ignition Mechanism

Several vital elements contribute to the overall functionality of the ignition setup. These include an electronic control unit, ignition source, and safety sensors. The electronic control unit regulates the activation sequence, ensuring that all components work harmoniously. The ignition source, typically a spark or glow element, ignites the fuel mixture, while safety sensors monitor operational parameters to prevent malfunctions.

Importance of Regular Maintenance

Regular inspections and maintenance of the ignition system are vital to ensure consistent performance and safety. Neglecting these components can lead to inefficiencies, increased emissions, and potential safety hazards. Therefore, routine checks and timely replacements of worn parts are recommended to maintain optimal functionality. By prioritizing maintenance, users can enjoy peace of mind, knowing that their heating system will operate safely and effectively.

Examining the Drain Valve Operation

The functionality of the discharge mechanism plays a crucial role in maintaining the efficiency and longevity of heating appliances. This component is designed to allow for the removal of accumulated sediments and debris, which can hinder performance over time. Understanding its operation can aid in effective maintenance practices.

Components of the discharge mechanism typically include a valve handle, a sealing element, and the outlet for draining. When activated, the handle opens the valve, enabling the contents to flow out through the designated outlet. Regular inspection of these components is essential to ensure they are free from blockages and are operating correctly.

Maintenance of the discharge mechanism involves periodic checks for leaks and corrosion. A well-functioning valve helps prevent pressure buildup and potential damage, ensuring safe operation. By understanding how this mechanism works, users can take proactive steps to address any issues that may arise, thus prolonging the life of their heating appliance.

Thermocouple and Its Importance for Safety

The thermocouple is a critical component designed to monitor temperature changes within a system. By providing accurate readings, it ensures that the appliance operates efficiently and safely. This device plays a vital role in preventing potential hazards that may arise from overheating or malfunctioning systems.

How It Works

This sensor functions by generating a small voltage in response to temperature differences between two dissimilar metals. The resulting electrical signal is then interpreted by the system’s control mechanisms, allowing for precise regulation of the operating environment.

Safety Benefits

One of the primary advantages of this device is its ability to shut down the system in case of a malfunction. If the temperature exceeds a predetermined threshold, the thermocouple triggers a safety response, cutting off the fuel supply. This feature significantly reduces the risk of fires or other dangerous situations, making it an indispensable element in maintaining operational safety.

Heat Exchanger: Maximizing Energy Efficiency

The effectiveness of thermal transfer devices plays a crucial role in enhancing the overall performance of heating systems. By optimizing the transfer of thermal energy, these components significantly contribute to reduced energy consumption and improved operational efficiency.

To achieve maximum energy efficiency, consider the following factors:

- Material Selection: Choosing high-conductivity materials can enhance heat transfer rates.

- Design Configuration: Implementing designs that increase surface area promotes better thermal exchange.

- Regular Maintenance: Keeping the device clean and free from deposits ensures optimal performance.

- Temperature Management: Operating at the ideal temperature range prevents excessive energy use.

Implementing these strategies can lead to significant improvements in efficiency, resulting in lower energy bills and a reduced environmental impact.

Vent System: Managing Exhaust and Airflow

The venting mechanism plays a crucial role in ensuring the efficient operation of a heating appliance. Properly designed systems not only facilitate the removal of harmful gases but also maintain optimal airflow, contributing to overall efficiency and safety.

Effective exhaust management involves several key components and considerations:

- Exhaust Path: The route taken by flue gases to exit the system should be unobstructed and well-insulated to prevent heat loss.

- Air Intake: Adequate air supply is essential for combustion; the design must account for external air sources.

- Fan Functionality: In some configurations, fans are used to assist in expelling exhaust and drawing in fresh air, enhancing performance.

Regular maintenance and inspection of the venting assembly are necessary to avoid blockages or leaks, which can lead to dangerous situations. A well-maintained system promotes longevity and reliable function.

In conclusion, a properly functioning venting system is vital for the safety and efficiency of heating equipment. By understanding its components and ensuring regular upkeep, users can achieve optimal performance.