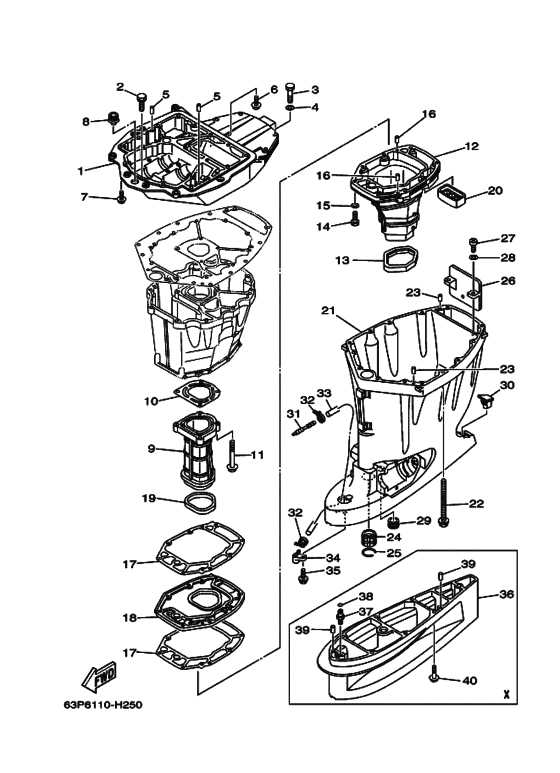

The intricate arrangement of engine components plays a crucial role in the overall functionality and efficiency of any watercraft. A thorough examination of these elements allows enthusiasts and technicians to grasp how each part contributes to performance. Understanding this structure is essential for effective maintenance and repairs.

Visual representations of these components enhance comprehension and facilitate identification during servicing. Such illustrations serve as valuable tools for both novice users and seasoned professionals, ensuring that everyone can navigate the complexities of their machinery with confidence. Additionally, these visuals help streamline the process of sourcing replacements or upgrades when necessary.

By delving into the specifics of engine assembly, one can better appreciate the engineering that drives watercraft forward. A detailed look at these configurations not only aids in troubleshooting but also fosters a deeper connection between the user and their vessel. Ultimately, mastering this knowledge equips individuals to keep their equipment in optimal condition.

Understanding the layout of components for your watercraft is essential for effective maintenance and repairs. A visual representation can greatly assist in identifying individual elements, facilitating quicker troubleshooting and replacement processes. Below are steps to effectively navigate and utilize this valuable resource.

- Familiarize Yourself with the Layout: Start by observing the overall structure. Note how different sections are organized and labeled, helping you quickly locate specific components.

- Identify Key Components: Focus on important items that require regular attention. Make a list of these parts to keep track of maintenance needs.

- Cross-Reference with Manuals: Utilize your repair manual alongside the visual guide. This combination provides detailed information about each part’s function and specifications.

- Seek Additional Resources: Explore online forums or manufacturer websites for more insights. Engaging with other users can enhance your understanding and provide practical tips.

- Organize Replacement Tasks: Create a plan for any needed replacements. Prioritize tasks based on urgency and availability of components.

By following these steps, you can maximize the effectiveness of the visual guide, ensuring your vessel remains in optimal condition.

Identifying Electrical Components

Understanding the various electrical elements within a marine engine is essential for ensuring optimal performance and reliability. Each component plays a critical role in the overall functionality of the system, and recognizing their specific characteristics can aid in effective troubleshooting and maintenance.

Key Electrical Elements

Electrical systems are composed of several key elements, each serving distinct purposes. Familiarity with these components enhances the ability to diagnose issues and implement appropriate solutions. Here are some of the primary elements found in a typical marine electrical setup:

| Component | Description |

|---|---|

| Battery | Stores electrical energy for starting and powering systems. |

| Fuse | Protects circuits by breaking the connection in case of overload. |

| Relay | Acts as a switch to control larger currents using a smaller signal. |

| Ignition Switch | Controls power supply to the engine’s ignition system. |

| Wiring Harness | Bundle of wires that connects various electrical components. |

Recognizing and Testing

Proper identification and testing of these components are vital for maintaining functionality. Using a multimeter, one can check for continuity, voltage, and resistance to ensure that each element is operating within its specified parameters. Regular inspections can prevent unexpected failures and prolong the lifespan of the electrical system.

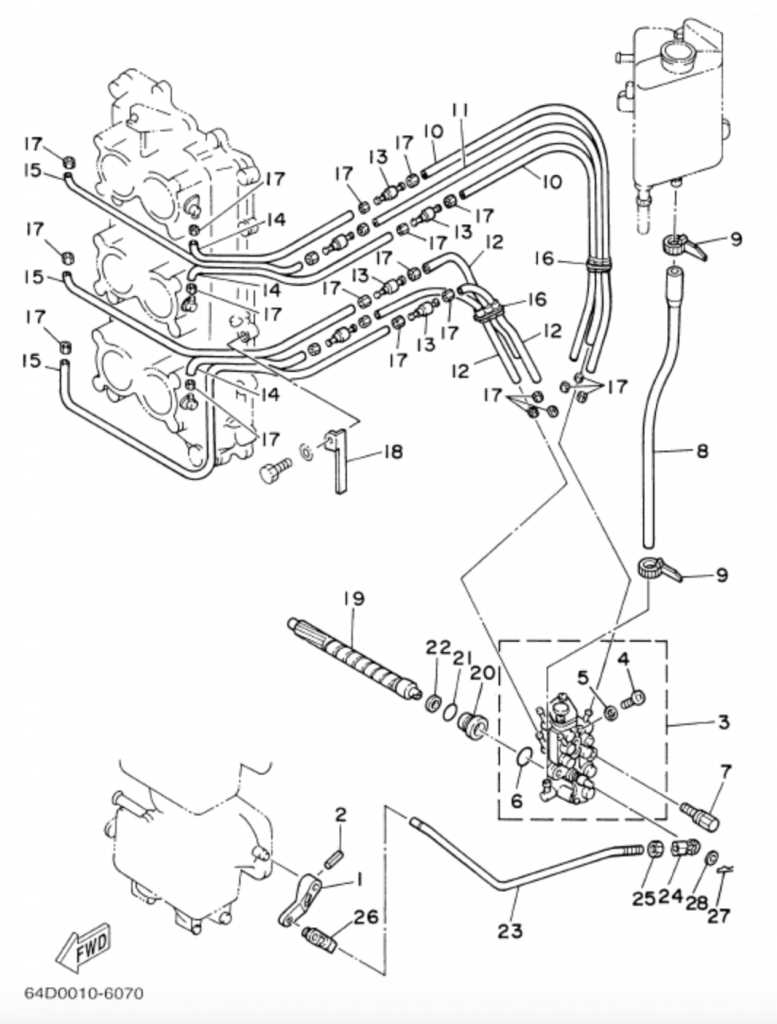

Fuel System Parts Explained

The fuel system in a marine engine plays a crucial role in ensuring optimal performance and efficiency. It consists of various components that work together to deliver fuel to the engine in a precise manner. Understanding these elements is essential for maintaining the functionality of the engine and addressing any potential issues that may arise.

Fuel Pump: This component is responsible for transferring fuel from the tank to the engine. It ensures a steady flow under varying conditions, which is vital for engine performance.

Fuel Filter: This part removes impurities and contaminants from the fuel before it reaches the engine. A clean fuel filter is essential for preventing damage and maintaining engine health.

Fuel Injectors: These devices spray a precise amount of fuel into the combustion chamber. They play a significant role in ensuring efficient combustion, which affects both power output and fuel economy.

Fuel Lines: These tubes transport fuel from the tank to the engine. Properly functioning fuel lines are critical to avoid leaks and ensure the system operates efficiently.

Fuel Pressure Regulator: This component maintains the correct pressure within the fuel system. It adjusts the pressure based on the engine’s requirements, ensuring optimal performance.

In summary, each component of the fuel delivery system contributes to the overall effectiveness of the engine. Regular inspection and maintenance of these parts can prevent issues and enhance the longevity of the marine engine.

Cooling System Components Overview

The cooling system plays a vital role in maintaining the optimal operating temperature of an engine, preventing overheating and ensuring efficient performance. This section provides an overview of the essential components that make up the cooling system, highlighting their functions and significance in overall engine operation.

Key Components of the Cooling System

Several critical elements contribute to the effective functioning of the cooling system. Understanding these components is essential for proper maintenance and troubleshooting.

| Component | Function |

|---|---|

| Thermostat | Regulates the engine temperature by controlling coolant flow. |

| Radiator | Dissipates heat from the coolant to the surrounding air. |

| Water Pump | Circulates coolant throughout the system to maintain flow. |

| Coolant | Transfers heat away from the engine and prevents freezing. |

| Cooling Hoses | Transport coolant between various components. |

Importance of Regular Maintenance

Ensuring the cooling system operates efficiently is crucial for prolonging engine life and optimizing performance. Regular inspections and maintenance of these components can prevent costly repairs and improve overall reliability.

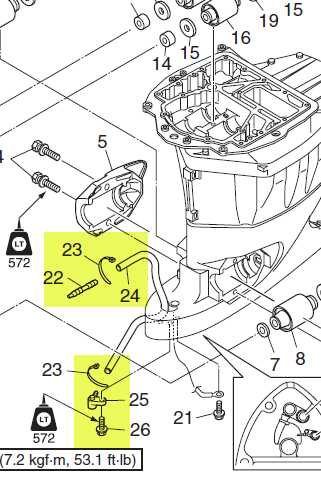

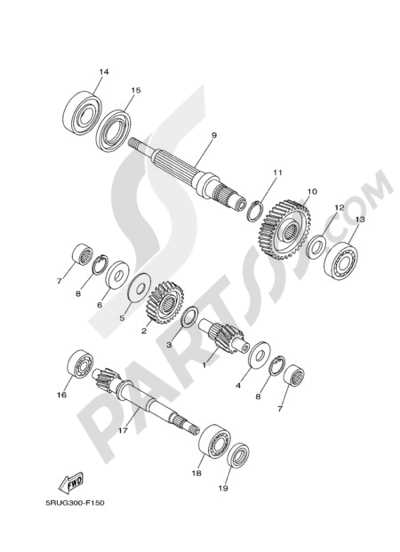

Gearbox and Drive Train Insights

The gearbox and drive train are essential components of marine propulsion systems, playing a crucial role in transferring power from the engine to the propeller. Understanding their functionality and maintenance can enhance performance and longevity.

Key aspects to consider include:

- Types of Gearboxes: Various designs are available, each suited for specific applications, affecting torque and speed.

- Maintenance Tips: Regular inspections and timely replacements of lubricants can prevent wear and ensure optimal operation.

- Common Issues: Symptoms such as unusual noises or vibrations may indicate underlying problems that require immediate attention.

By familiarizing oneself with these elements, users can better manage their marine systems, ensuring efficient and reliable performance during operations.

Safety Features of Yamaha F150

The importance of safety features in marine engines cannot be overstated. These elements play a crucial role in ensuring the protection of both the operator and the vessel during operation. Advanced safety systems enhance reliability and contribute to a more secure boating experience.

Emergency Cut-Off Switch

Emergency cut-off switches are essential for maintaining safety on the water. This feature automatically shuts off the engine in case the operator falls overboard, preventing potential accidents and ensuring the safety of everyone on board.

Overheat Protection System

The overheat protection system serves as a vital safeguard, monitoring the engine’s temperature and preventing damage. If the temperature exceeds safe limits, the system automatically reduces power or shuts down the engine, ensuring optimal performance and longevity.

Aftermarket Parts Options and Considerations

Exploring alternative components can enhance performance, reliability, and customization in marine engines. This section delves into various aftermarket options available for your vessel’s needs, highlighting key factors to consider when making a choice.

Types of Aftermarket Components

- Performance Enhancements: Upgrades that improve speed and efficiency.

- Maintenance Supplies: Replacement items to ensure longevity and functionality.

- Customization Options: Unique parts that allow for personalization of the engine.

Factors to Consider

- Quality: Ensure the components are made from durable materials and are tested for performance.

- Compatibility: Verify that the alternative components fit well with existing systems.

- Warranty: Check if the aftermarket options come with a warranty for peace of mind.

- Reviews: Look for feedback from other users to gauge reliability and satisfaction.

Frequently Asked Questions on F150 Parts

This section addresses common inquiries regarding components associated with specific models. Understanding the various elements and their functions can assist in making informed decisions and enhance overall satisfaction.

General Inquiries

- What types of components are available for my model?

- How can I identify the correct part for my needs?

- Are there aftermarket options for specific elements?

Maintenance and Care

- How often should I inspect various components?

- What are the signs that a part needs replacement?

- Are there recommended practices for prolonging the life of my equipment?