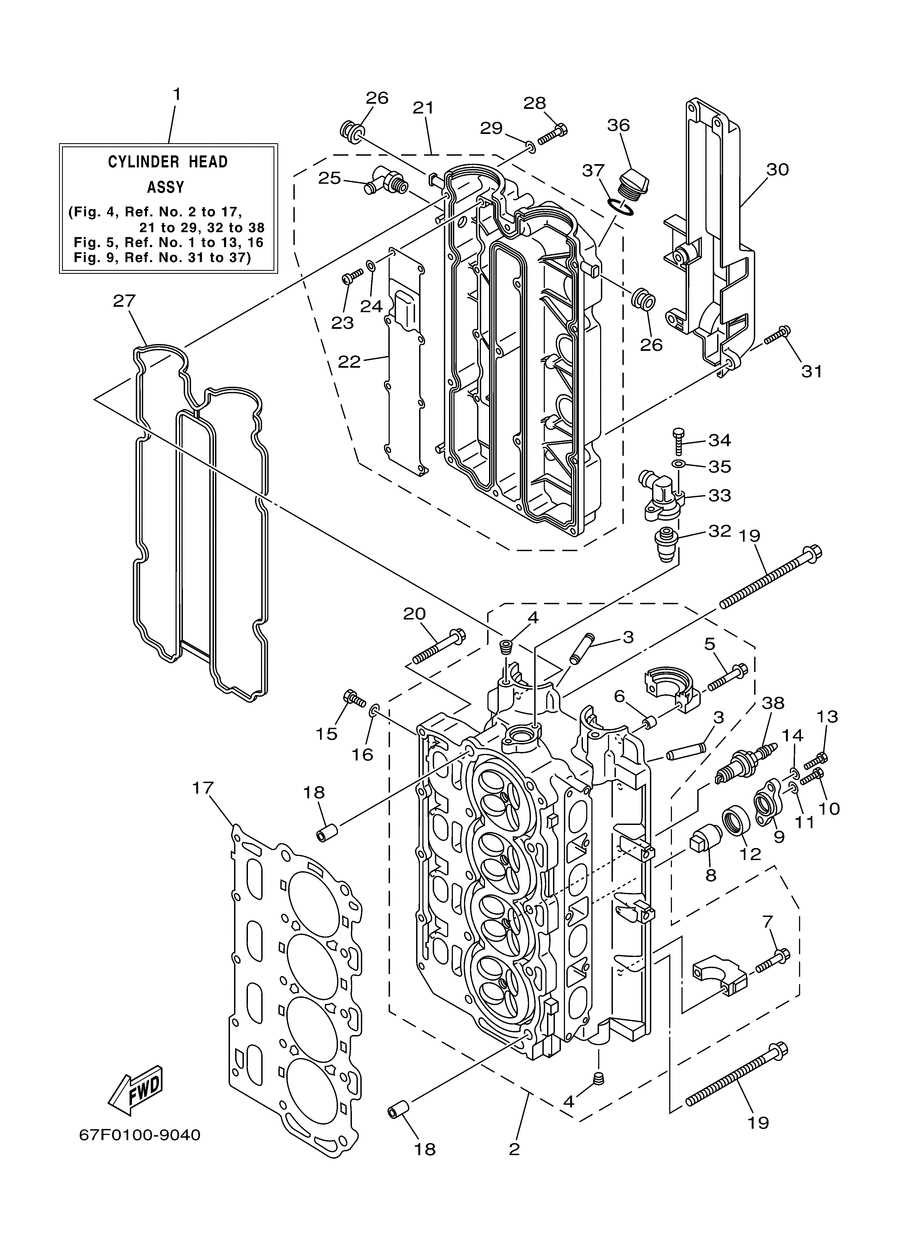

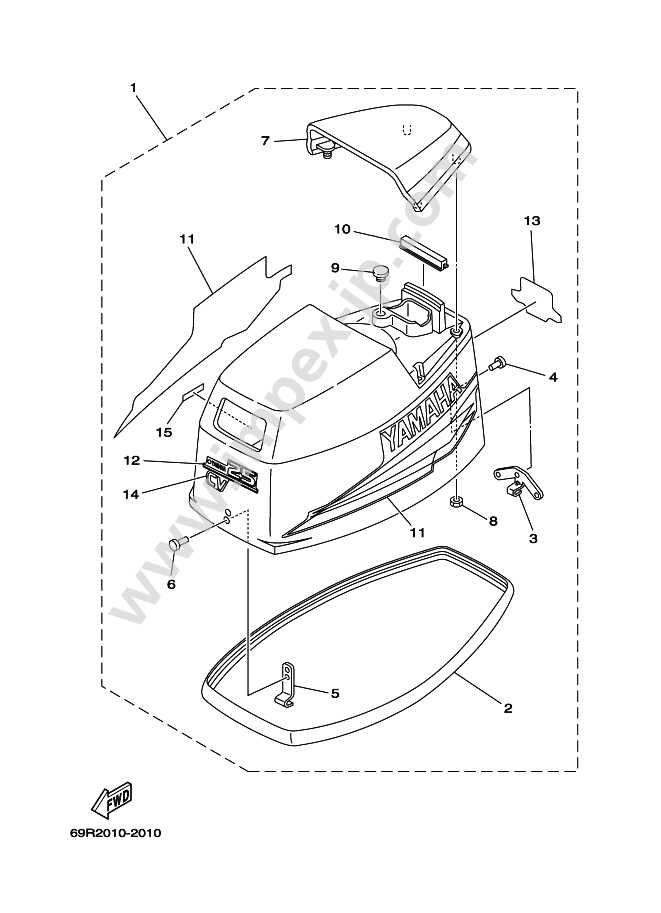

The intricate assembly of a 15 horsepower outboard engine plays a crucial role in its performance and reliability. A comprehensive exploration of this engine’s configuration reveals the various elements that contribute to its efficient operation. Each component is meticulously designed to work in harmony, ensuring the smooth functioning of the entire system.

Examining the layout of the engine allows enthusiasts and technicians alike to gain valuable insights into its mechanics. From the ignition system to the fuel delivery mechanisms, every part has a specific function that enhances overall performance. Understanding these components not only aids in maintenance but also fosters a deeper appreciation for marine engineering.

Furthermore, having a clear visual representation of the assembly can significantly simplify the repair and replacement process. By identifying each element and its relation to others, users can approach issues with confidence and precision. This knowledge is essential for anyone looking to optimize the longevity and efficiency of their outboard engine.

Understanding Key Components of a 15 HP Engine

The fundamental elements of a compact power unit play a crucial role in its performance and reliability. Each component is designed to work in harmony, contributing to the overall efficiency and functionality of the engine. Understanding these essential parts is vital for maintenance and troubleshooting.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel combustion occurs, generating power for the engine. |

| Piston | A moving part that compresses the fuel-air mixture and transmits force to the crankshaft. |

| Crankshaft | The rotating shaft that converts linear motion from the piston into rotational energy. |

| Fuel System | The assembly that delivers the appropriate mixture of fuel and air to the combustion chamber. |

| Ignition System | The mechanism that initiates combustion by creating a spark at the correct time. |

| Exhaust System | The setup that channels waste gases away from the engine, ensuring smooth operation. |

Familiarity with these key elements can greatly enhance one’s ability to maintain and operate a power unit effectively. Each part contributes uniquely to the overall functionality, making it essential to recognize their significance.

Examining the Fuel System Parts

The efficiency of any marine engine heavily relies on the intricacies of its fuel delivery mechanism. This system plays a crucial role in ensuring that the engine receives the appropriate mixture of fuel and air, facilitating optimal performance and reliability. A closer look at the components involved reveals their specific functions and the importance of their maintenance.

Key components of the fuel delivery system include:

- Fuel Tank: This reservoir holds the necessary fuel for operation, designed to prevent contamination and ensure a steady supply.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine, it ensures adequate pressure for efficient operation.

- Carburetor: This device mixes air with fuel in the correct ratio, crucial for the combustion process to take place effectively.

- Fuel Filter: It protects the engine by removing impurities from the fuel before it reaches critical components.

- Fuel Lines: These conduits transport fuel between the various components, requiring regular inspection for wear or leaks.

Understanding these elements and their interconnections can significantly enhance maintenance practices and troubleshooting efforts. Regular checks and timely replacements are vital to maintain the overall functionality and longevity of the system.

Exploring the Ignition Mechanism

The ignition system plays a crucial role in ensuring that an engine operates efficiently and reliably. This mechanism is responsible for generating the spark that ignites the fuel-air mixture, allowing for smooth combustion and optimal performance. Understanding its components and functioning is essential for effective maintenance and troubleshooting.

Key components of the ignition system include:

- Ignition Coil: Converts low voltage from the battery into high voltage needed to create a spark.

- Spark Plug: Initiates the combustion process by igniting the air-fuel mixture.

- Flywheel Magnet: Generates the necessary electrical energy to power the ignition coil.

- CDI Unit: Controls the timing and duration of the spark for optimal ignition.

Maintenance of the ignition system involves regular checks of these components. Here are some essential tips:

- Inspect spark plugs for wear and replace them if necessary.

- Test the ignition coil for proper functionality.

- Ensure connections are clean and secure to prevent voltage loss.

- Check the timing settings to ensure optimal performance.

By familiarizing oneself with the ignition mechanism, users can enhance the reliability and efficiency of the engine, ensuring smooth operation and prolonged life.

Essential Cooling System Elements

The cooling system of an outboard motor is crucial for maintaining optimal operating temperatures and preventing overheating. This system comprises several key components that work together to regulate engine temperature and ensure efficient performance.

Key Components of the Cooling System

- Water Pump: The primary component responsible for circulating water through the cooling system. It draws in water from the surrounding environment and forces it through the engine.

- Thermostat: This device regulates the flow of coolant by controlling the temperature within the engine. It opens and closes to allow coolant to flow only when necessary.

- Cooling Jacket: A series of passages around the engine where coolant flows to absorb excess heat, ensuring that the engine operates within a safe temperature range.

- Exhaust Manifold: This component helps expel exhaust gases while allowing cooling water to mix and dissipate heat effectively.

Maintenance Tips

- Regularly inspect the water pump for wear and tear to ensure it operates efficiently.

- Check the thermostat for proper functioning to prevent overheating issues.

- Flush the cooling system periodically to remove debris and salt buildup, which can obstruct water flow.

Overview of the Propeller Assembly

The propeller assembly is a crucial component that significantly influences the performance and efficiency of marine engines. It consists of various elements that work together to convert engine power into thrust, allowing vessels to move through the water smoothly. Understanding the configuration and functionality of this assembly is essential for maintenance and optimal operation.

Key Components

This assembly typically includes several integral parts, each serving a specific role in ensuring effective propulsion. The arrangement of these components affects both the handling and speed of the craft.

| Component | Description |

|---|---|

| Propeller Blades | Responsible for generating thrust through rotation, influencing speed and maneuverability. |

| Hub | The central part that connects the blades to the drive shaft, allowing for rotational motion. |

| Spanner Nut | Secures the assembly in place, ensuring stability during operation. |

| Washer | Provides additional support and prevents loosening of the components under stress. |

Maintenance Considerations

Regular inspection and maintenance of the propeller assembly are vital to prolonging its lifespan and enhancing performance. Issues such as damage to the blades or corrosion can adversely affect functionality. Proper care will ensure that the assembly operates efficiently, providing reliable propulsion for various watercraft.

Inspecting Carburetor Structure and Function

The carburetor plays a vital role in the overall operation of an outboard motor, ensuring the correct mixture of fuel and air is delivered to the combustion chamber. Understanding its design and functionality is crucial for effective maintenance and troubleshooting.

Key components of a typical carburetor include:

- Float Chamber: Regulates the fuel level, ensuring a consistent supply.

- Venturi: Creates a pressure drop, drawing fuel into the airstream.

- Jets: Control the amount of fuel entering the airflow, impacting performance and efficiency.

- Throttle Plate: Regulates airflow, affecting engine speed and power output.

To effectively inspect and maintain the carburetor, consider the following steps:

- Remove the carburetor from the engine.

- Clean all components using appropriate solvents to eliminate dirt and debris.

- Check the float for proper operation; it should rise and fall freely.

- Examine the jets for clogs or damage, replacing them as necessary.

- Inspect gaskets and seals for wear, ensuring no air leaks that could affect performance.

Regular checks of these elements can help maintain optimal performance and longevity of the motor. Understanding the intricacies of this component will significantly enhance overall efficiency and reliability.

Analyzing the Exhaust System Layout

The exhaust system plays a crucial role in the overall performance of a marine engine, influencing both efficiency and emissions. Understanding its configuration is essential for ensuring optimal operation and maintenance. This section will explore the various components and their arrangement within the exhaust framework, highlighting the importance of each element in facilitating effective exhaust gas flow.

At the heart of the exhaust assembly is the manifold, which collects gases from the engine cylinders and directs them towards the exhaust outlet. A well-designed manifold minimizes back pressure, allowing for smoother expulsion of exhaust gases. Following this, the exhaust pipe carries these gases away from the engine, often featuring bends and joints that can impact the flow dynamics. Proper alignment and sealing at these junctions are critical to prevent leaks that could affect performance.

Additionally, the presence of an exhaust expansion chamber can enhance engine efficiency. This component is designed to dampen noise and facilitate better gas flow by using the principles of pressure wave reflection. Analyzing the configuration of the expansion chamber reveals its significance in improving engine responsiveness and overall power output.

Finally, the exit point of the exhaust system is equally important. Whether through a through-hull fitting or an external outlet, the design should ensure that gases are released efficiently and safely, minimizing the risk of backflow into the engine compartment. A comprehensive understanding of these components and their layout allows for better troubleshooting, maintenance, and performance optimization of the engine.

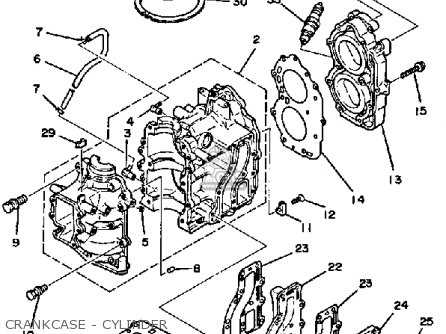

Crankshaft and Pistons: Role and Design

The crankshaft and pistons play a crucial role in the operation of internal combustion engines, facilitating the conversion of linear motion into rotational energy. This transformation is essential for generating power and ensuring the smooth functioning of the engine. Understanding their design and functionality provides valuable insights into engine performance and efficiency.

Functionality of the Crankshaft

The crankshaft serves as the central component that translates the vertical movement of the pistons into rotational motion. Its design includes several key features:

- Bearings: These support the crankshaft and allow it to rotate smoothly within the engine block.

- Counterweights: These help balance the crankshaft, reducing vibrations during operation.

- Crankpins: These connect the pistons to the crankshaft, enabling the conversion of motion.

Piston Design and Performance

Pistons are integral to the engine’s operation, moving up and down within the cylinder to compress the air-fuel mixture and transmit forces to the crankshaft. Key aspects of piston design include:

- Material: High-strength materials are utilized to withstand extreme pressures and temperatures.

- Shape: The design influences combustion efficiency and overall engine performance.

- Piston Rings: These create a seal between the piston and cylinder walls, preventing gas leaks and oil consumption.

In summary, the crankshaft and pistons are vital components that work together to ensure efficient power generation in internal combustion engines. Their design intricacies directly affect the engine’s performance, longevity, and overall functionality.

Identifying the Lubrication System Parts

The lubrication system plays a crucial role in ensuring optimal performance and longevity of any engine. Understanding its components is essential for maintenance and troubleshooting. Each element contributes to the overall functionality, helping to reduce friction and wear during operation.

Key components of the lubrication assembly include the oil reservoir, which stores the lubricant, and the pump, responsible for circulating the fluid throughout the engine. Additionally, the oil filter is vital for removing contaminants, ensuring that the lubricant remains clean and effective.

Another important part is the oil cooler, which helps to maintain the appropriate temperature of the lubricant, preventing overheating. The various hoses and fittings that connect these components also play a significant role, as they facilitate the proper flow of the lubricant throughout the system.

By familiarizing yourself with these elements, you can better appreciate the importance of a well-maintained lubrication system and its impact on the overall efficiency of the engine.

Lower Unit Components and Maintenance

The lower unit of an outboard motor plays a crucial role in delivering power and maneuverability to the vessel. Understanding its components is essential for effective maintenance and optimal performance. Regular inspection and upkeep can help prevent potential issues and extend the life of the motor.

Key Components

- Gearcase: Houses the gears that transmit power from the engine to the propeller.

- Propeller: Converts rotational energy into thrust, enabling movement through water.

- Driveshaft: Connects the engine to the gearcase, transferring power efficiently.

- Water Pump: Ensures proper cooling by circulating water through the engine and lower unit.

- Oil Seal: Prevents leakage of lubricant, maintaining proper function of internal components.

Maintenance Tips

- Regularly check the oil level in the gearcase and change it according to the manufacturer’s recommendations.

- Inspect the propeller for damage and ensure it is properly secured.

- Test the water pump to confirm it is functioning effectively and replace it if necessary.

- Examine seals and gaskets for wear to prevent leaks.

- Keep the lower unit clean and free from debris to ensure optimal performance.

Electrical Wiring and Control Systems

The effectiveness of a marine engine heavily relies on the integration of its electrical components and control systems. Proper wiring ensures that all parts communicate efficiently, allowing for optimal performance and reliability. Understanding the layout and function of these elements is crucial for maintenance and troubleshooting.

Key Components of Electrical Wiring

- Wiring Harness: A collection of wires and connectors that transmit electrical signals between different components.

- Power Supply: Supplies the necessary voltage and current to the engine’s electrical systems.

- Switches: Control the operation of various electrical devices, such as lights and ignition systems.

- Fuses: Protect the circuit by preventing overloads and short circuits.

Control System Overview

Control systems are designed to manage and regulate the operation of the engine. These systems include various sensors and actuators that work together to maintain performance and efficiency.

- Ignition Control: Manages the timing and firing of the spark plugs for optimal combustion.

- Fuel Management: Regulates fuel delivery to ensure the right mixture for combustion.

- Temperature Sensors: Monitor engine temperature to prevent overheating and ensure safe operation.

- Trim Control: Adjusts the angle of the motor for improved handling and fuel efficiency.

Thorough knowledge of these systems and their configurations can lead to better maintenance practices and enhanced performance.