Understanding the structure of high-performance personal watercraft requires a detailed look at how various elements are positioned and interact with one another. The arrangement of these components ensures optimal functionality and smooth operation during demanding conditions on the water.

In this section, we will explore the essential systems that make these machines reliable and efficient. From propulsion units to control mechanisms, each part plays a crucial role in delivering peak performance. Recognizing how these systems connect can significantly aid in maintenance and customization efforts.

A focus on individual sections–such as engine compartments, steering assemblies, and exhaust pathways–allows for a clear understanding of the craft’s internal workings. With proper insights into their layout, operators can achieve better troubleshooting results and enhance the overall riding experience.

Yamaha Superjet Assembly Overview

This section provides a structured overview of the assembly process for a high-performance watercraft designed for speed and agility. The content covers the arrangement of critical components, highlighting how various mechanical and electrical elements come together to ensure optimal functionality.

The assembly involves key modules such as the propulsion unit, control mechanisms, and support systems. Each of these segments plays a specific role, working in unison to maintain stability, responsiveness, and durability during operation. Understanding how these modules interconnect is essential for both maintenance and modifications.

Special attention is given to ensuring proper alignment between the propulsion system and the control elements. This coordination is critical for achieving smooth handling and efficient power transfer. Additionally, an organized layout simplifies troubleshooting, enabling swift identification of any issues that may arise.

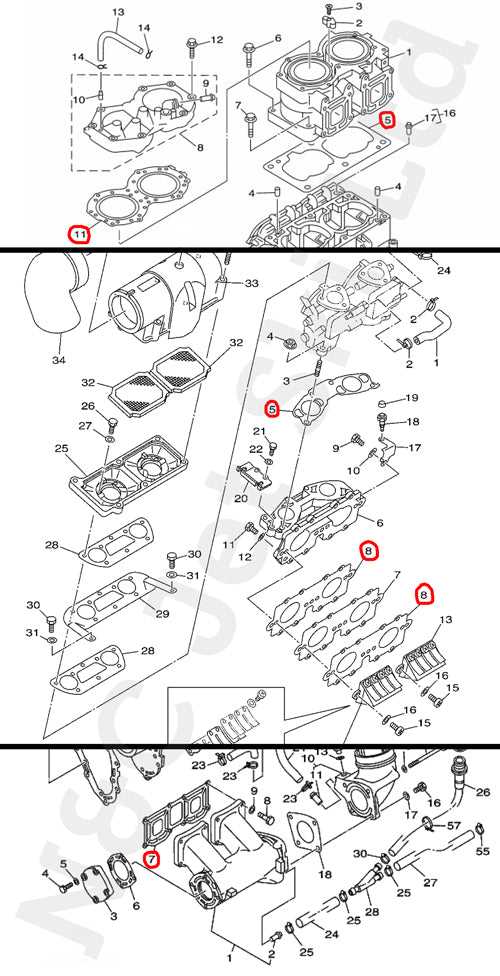

Engine Components Breakdown

The heart of any propulsion system relies on a seamless interplay of mechanical elements. Each component, whether large or small, plays a crucial role in generating power and ensuring smooth operation. This section delves into the primary structures within the motor, offering a closer look at how they interact to deliver reliable performance.

Main Sections of the Assembly

- Cylinder Block: The core housing that contains the combustion chambers, facilitating power generation.

- Pistons and Crankshaft: These elements convert energy from expanding gases into rotational motion.

- Cooling Mechanism: A network that prevents overheating, ensuring stable operation during extended use.

- Intake and Exhaust Paths: Channels that manage the flow of air and gases, optimizing fuel combustion and emission release.

Support Components and Controls

- Fuel Delivery System: Manages the precise supply of fuel into the chambers for efficient combustion.

- Ignition Unit: Sparks the air-fuel mixture at the right moment to initiate movement.

- Lubrication Circuit: Reduces friction between

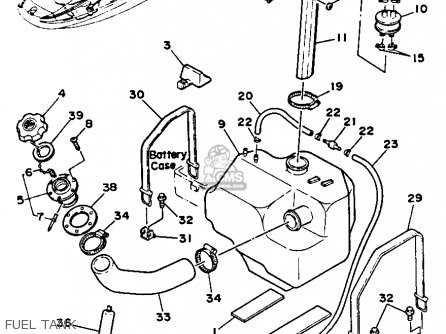

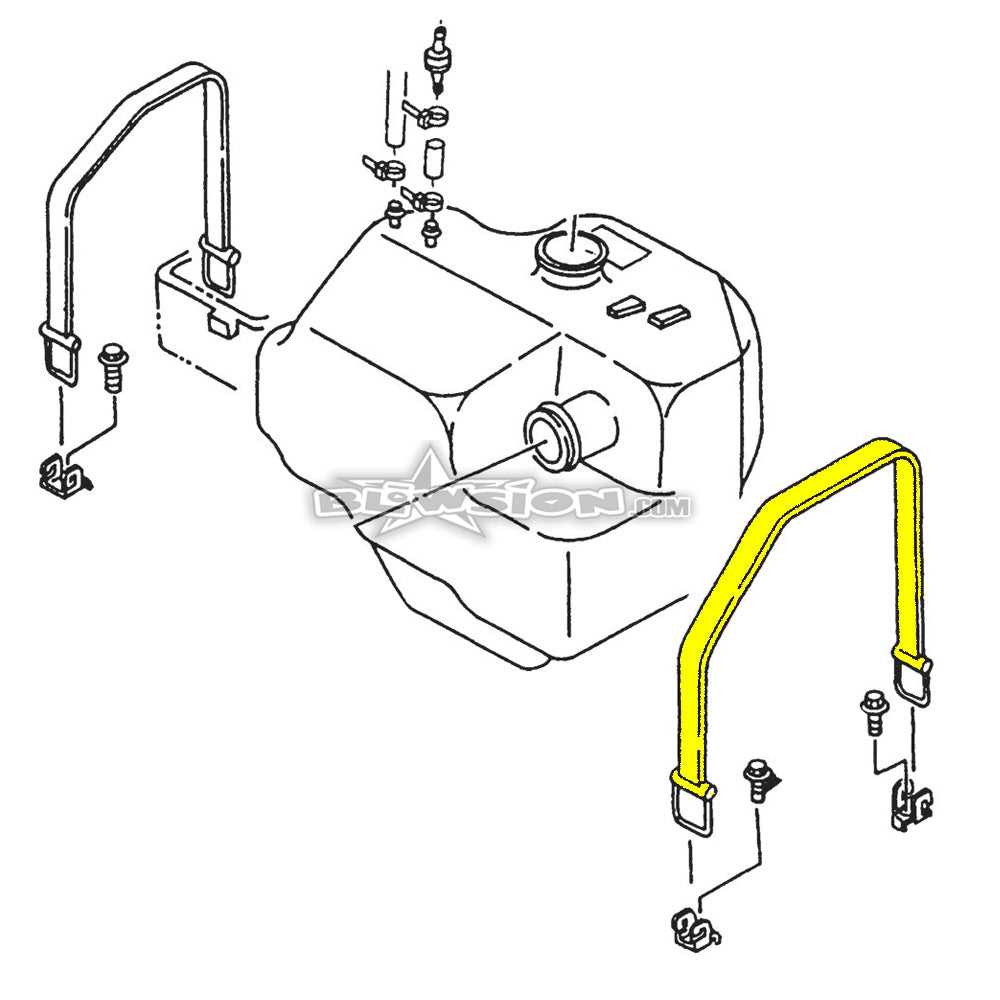

Fuel System Configuration

The arrangement of the fuel delivery components ensures efficient flow and proper combustion. This section explores the key elements involved in maintaining a steady supply of fuel, optimizing performance under varying conditions.

Pumps and Lines: The fuel pump facilitates the transfer of fuel from the reservoir to the engine, ensuring consistent pressure. Lines and hoses connect various parts, creating a smooth pathway for fluid movement.

Filters: Integrated filters prevent contaminants from entering the system, protecting sensitive components and ensuring long-term reliability. Regular maintenance of these filters is essential to prevent clogging.

Control Mechanism: Valves and regulators adjust flow rates based on demand, balancing fuel delivery with engine requirements. This mechanism plays a critical role in both performance optimization and fuel efficiency.

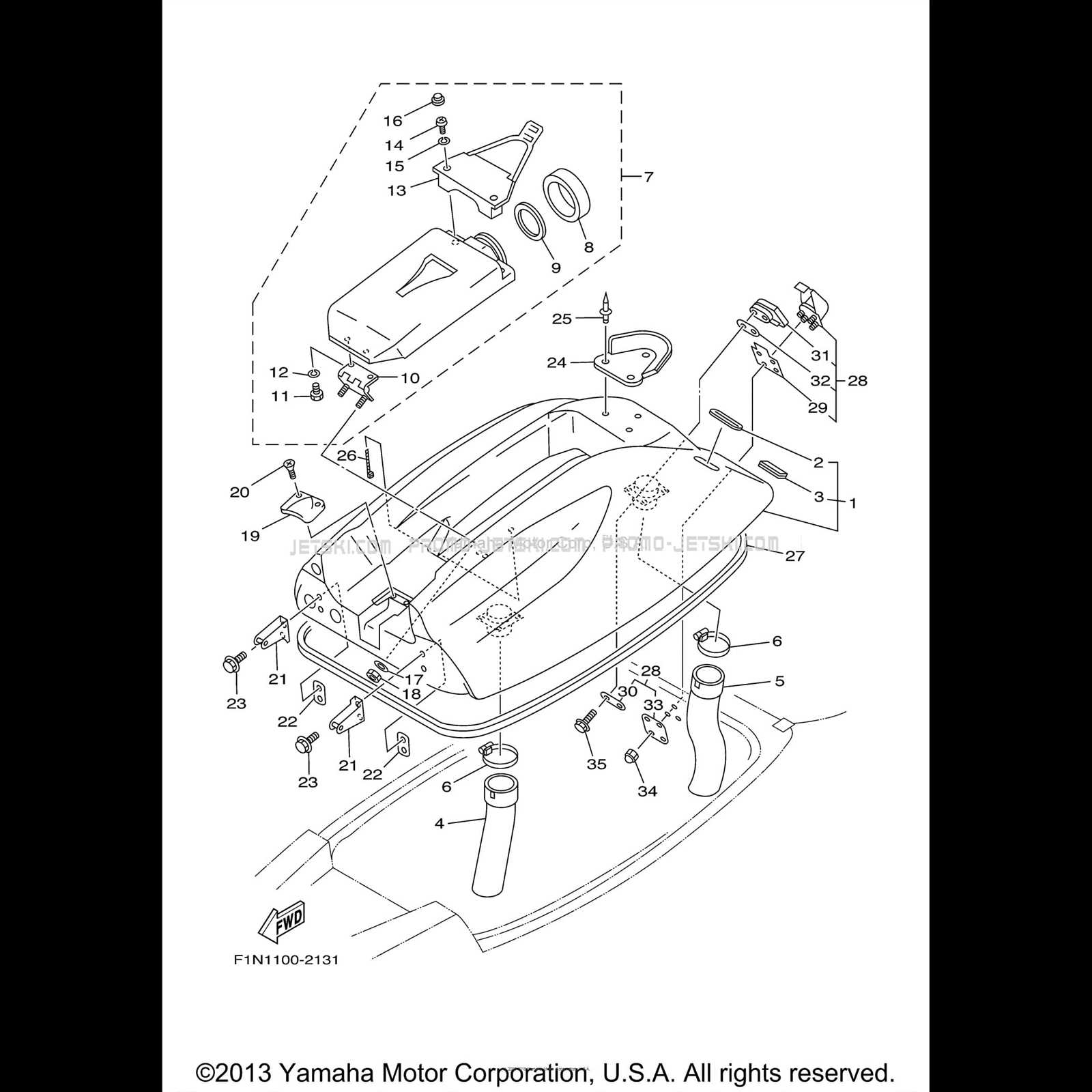

Hull Structure and Materials

The body design and composition of watercraft play a crucial role in determining both performance and durability. Crafted to endure continuous exposure to aquatic environments, the external frame must balance weight, rigidity, and hydrodynamic efficiency. Each element of the framework contributes to ensuring a smooth ride, stability in motion, and resistance to wear over time.

Below is a breakdown of the typical materials and components used in constructing such watercraft structures:

Component Material Purpose Outer Shell Fiberglass or Composite Provides a lightweight and impact-resistant surface Reinforcement Layers Carbon Fiber or Kevlar Enhances rigidity and structural strength Internal Framework Aluminum Alloy Supports load distribution and stabilizes the vessel Coating Gelcoat or Marine Paint Protects against corrosion and UV exposure The combination of these materials ensures optimal performance across a range of conditions, contributing to the watercraft’s longevity and reliability i

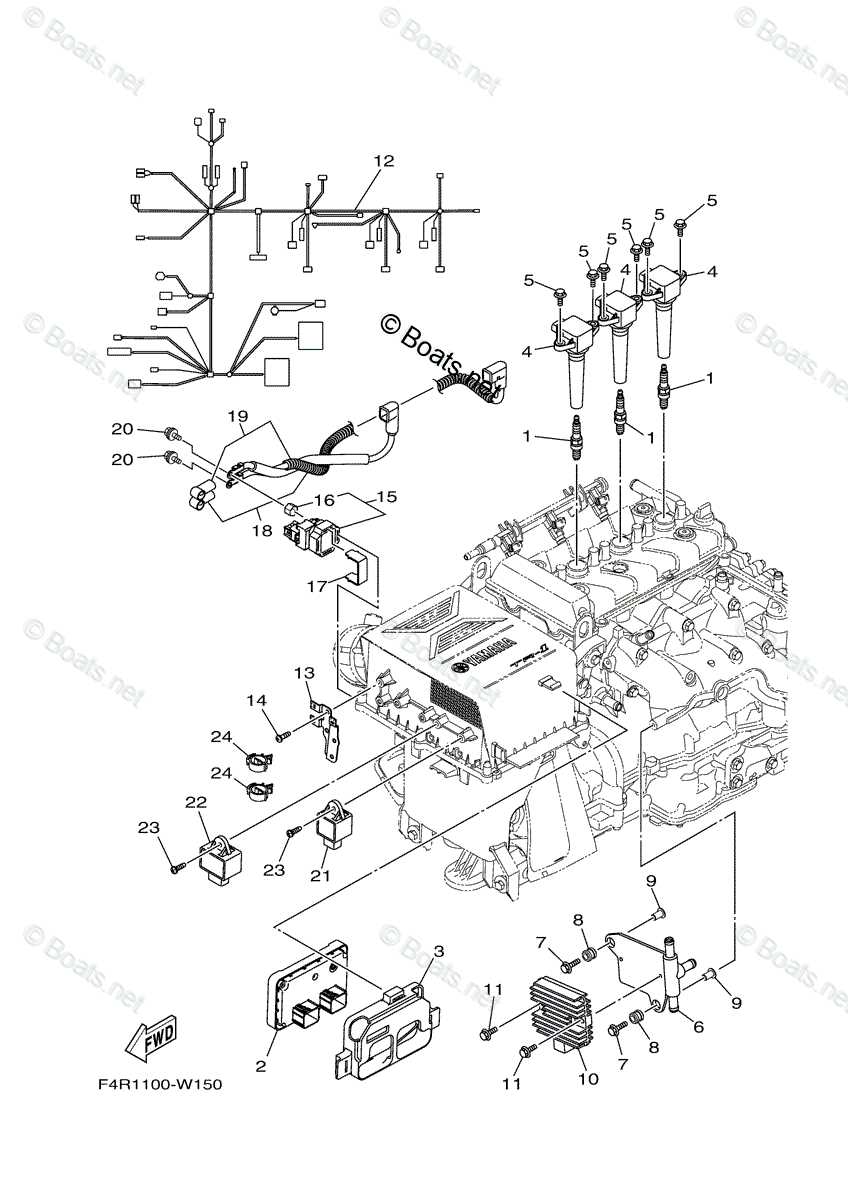

Electrical Wiring Layout

The arrangement of conductive pathways ensures that power and signals are distributed efficiently throughout the system. Understanding this structure is essential for troubleshooting, upgrades, and ensuring optimal performance.

Main Circuit Elements

- Control Unit: Central component managing signals between various sections.

- Power Distribution: Channels energy from the primary source to secondary units.

- Switching Mechanisms: Allow activation or deactivation of specific sections on demand.

Connector Types and Routing

- Inline Connectors: Maintain continuity between distant sections without compromising signal strength.

- Grounding Paths: Ensure safe discharge of excess electrical energy.

- Color-Coded Wires: Facilitate easy identification and reduce the risk of misconnection.

Cooling System Pathways

The efficiency of a watercraft’s cooling mechanism is essential for maintaining optimal performance and preventing overheating. This system operates by directing fluid through various channels, ensuring that heat generated by the engine is effectively dissipated. Understanding these pathways is crucial for ensuring the longevity and reliability of the machinery.

Typically, the cooling system comprises several key components, including hoses, water inlets, and exhaust outlets. These elements work in harmony to circulate coolant, which absorbs excess heat and transports it away from critical areas. Proper routing of these conduits is vital, as any obstructions or leaks can significantly hinder the system’s effectiveness.

In addition, regular maintenance of the cooling pathways helps to prevent the buildup of debris and mineral deposits, which can impede fluid flow. By ensuring that these passages remain clear and functional, operators can enhance the overall efficiency of their vessel’s thermal management system.

Steering Mechanism Details

The steering apparatus in aquatic vehicles is essential for ensuring precise navigation and maneuverability. It consists of several components that work in tandem to provide responsiveness and control during operation. Understanding these elements can enhance the overall experience and functionality of the vessel.

At the core of the steering system is the helm, which allows the operator to direct the craft with ease. This mechanism typically incorporates a linkage system connecting the helm to the rudder or jet nozzle, facilitating smooth transitions and turns. The design of the linkage plays a crucial role in the responsiveness of the steering, influencing how quickly and accurately the vessel can react to the operator’s inputs.

Additionally, the system may include various types of bearings and pivot points that support movement and reduce friction. The integration of these components ensures durability and longevity, allowing for a seamless interaction between the operator and the vehicle. Regular maintenance of the steering apparatus is vital for optimal performance and safety during navigation.

Control Handlebar Setup

Establishing an effective configuration for the steering mechanism is essential for optimal performance and handling. This section outlines the critical components and considerations necessary for ensuring that the control system is responsive and comfortable for the operator.

Essential Components

- Throttle Control: Responsible for regulating speed and acceleration.

- Steering Mechanism: Allows the rider to navigate and maneuver the vessel effectively.

- Safety Features: Includes lanyard systems and emergency shut-off switches to enhance rider safety.

Setup Guidelines

- Ensure that all controls are positioned within easy reach to minimize distractions.

- Adjust the throttle for a smooth and gradual response to input.

- Test the steering mechanism for smooth operation and proper alignment.

- Incorporate safety features that are functional and accessible during operation.

Regular inspection and maintenance of the control setup contribute significantly to the overall efficiency and safety of the experience. Adhering to these guidelines will help achieve a reliable and enjoyable ride.

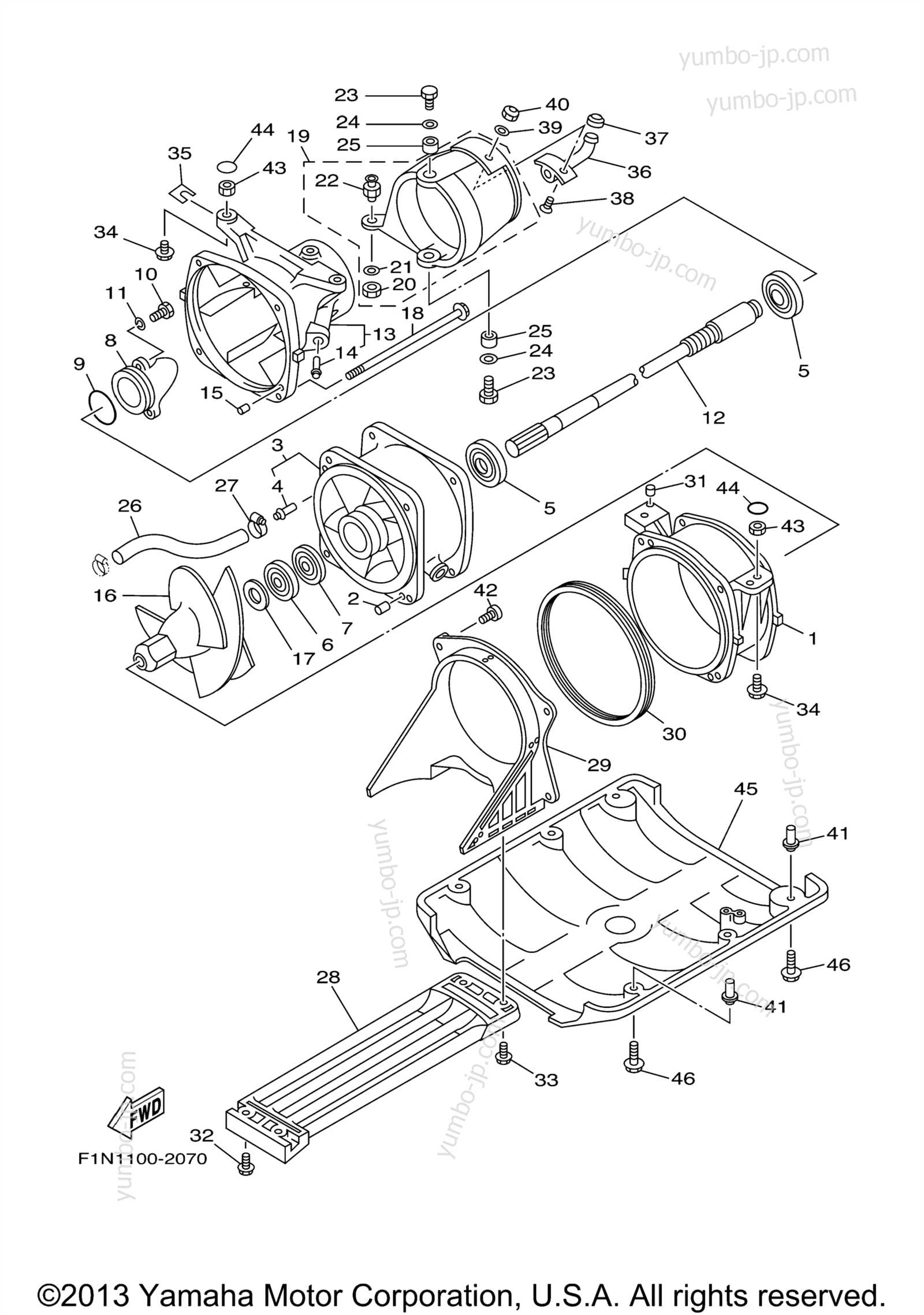

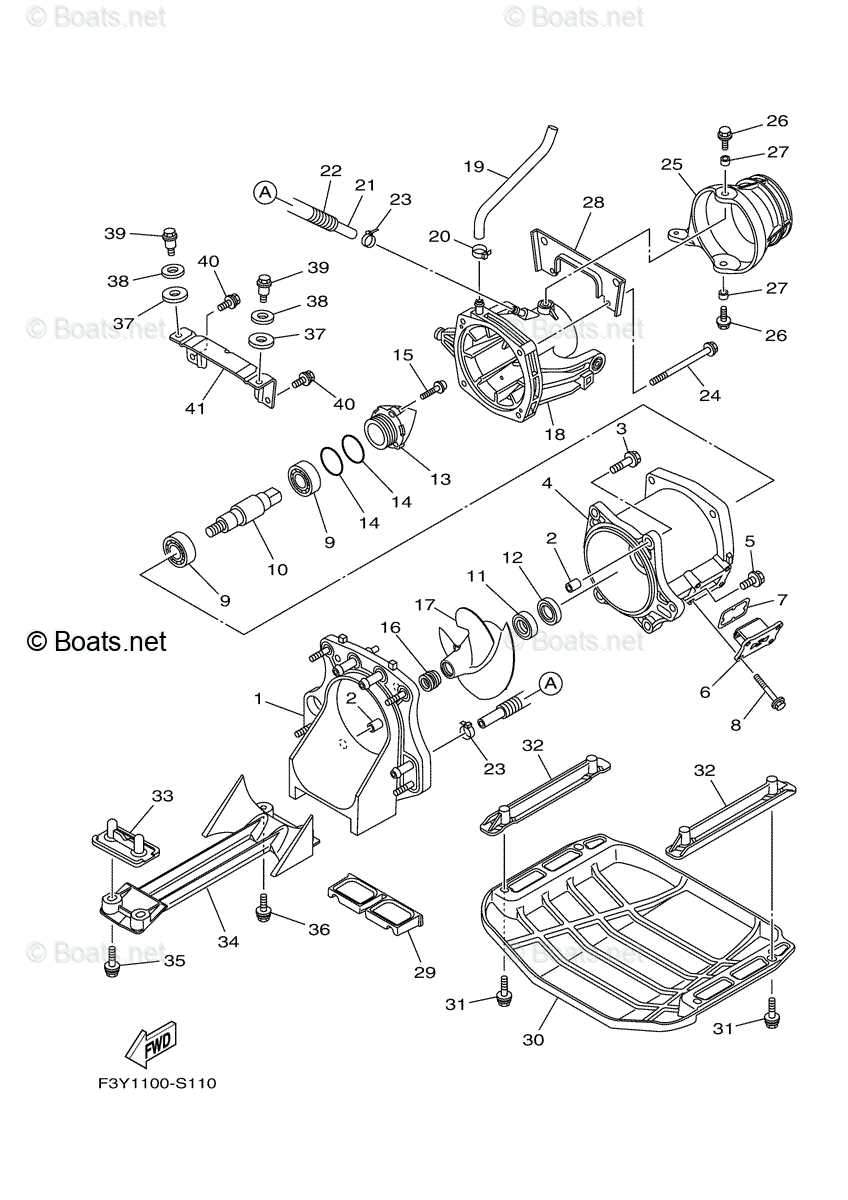

Jet Pump Assembly

The jet propulsion mechanism is a crucial component in watercraft, ensuring efficient movement through water. This assembly encompasses various elements that work together to create thrust, significantly impacting performance and maneuverability. Understanding the intricacies of this assembly is essential for maintenance and upgrades.

Key Components

Within the propulsion system, several integral parts contribute to its overall functionality. The main housing serves as the foundation, housing essential elements such as the impeller and nozzle. The impeller, a vital component, rotates at high speeds to draw in water and expel it forcefully, generating thrust. The nozzle directs the flow of water, allowing for controlled acceleration and deceleration.

Maintenance Considerations

Regular inspection of the jet propulsion mechanism is essential to ensure optimal performance. Wear and tear can affect the efficiency of the impeller and housing, potentially leading to reduced speed and maneuverability. Routine cleaning and timely replacement of worn parts can enhance longevity and reliability, making it critical for enthusiasts to understand this assembly’s importance.

Propulsion Nozzle Arrangement

The configuration of the propulsion nozzle plays a crucial role in enhancing the overall efficiency and performance of aquatic vehicles. This assembly is designed to direct the flow of water expelled from the propulsion system, allowing for improved maneuverability and thrust generation. Understanding the layout and mechanics of this component is essential for optimizing speed and agility in various water conditions.

Components of the Nozzle System

The nozzle system typically consists of several key elements, including the housing, directional fins, and the control mechanism. The housing is engineered to withstand high-pressure water flow, while the fins are strategically placed to facilitate precise steering. The control mechanism enables the operator to adjust the angle of the nozzle, allowing for dynamic responses to steering inputs.

Performance Implications

Proper arrangement of the propulsion nozzle can significantly impact acceleration and handling characteristics. A well-designed system can lead to quicker turns and enhanced stability, ensuring that the vehicle performs optimally in various aquatic environments. By fine-tuning the nozzle’s layout, users can achieve desired performance metrics tailored to specific usage scenarios.

Exhaust System Routing

The arrangement of the exhaust apparatus is crucial for ensuring optimal performance and efficiency in watercraft. Proper routing not only aids in effective expulsion of exhaust gases but also contributes to the overall functioning of the engine. A well-designed pathway minimizes back pressure and enhances engine responsiveness.

When examining the routing of the exhaust system, consider the following key components:

- Exhaust manifold: Connects to the engine and directs exhaust gases away.

- Flexible hoses: Provide flexibility and absorb vibrations during operation.

- Exhaust pipe: Transports gases from the manifold to the outlet, often designed to maintain optimal flow.

- Water lock: Prevents water from entering the exhaust system, protecting the engine from potential damage.

- Outlet: The final section where exhaust gases are expelled into the surrounding environment.

It is important to ensure that all connections are secure and free from leaks to maintain system integrity. Regular inspections can help identify any potential issues that may affect performance.

Adhering to the recommended routing guidelines will result in improved efficiency and longevity of the engine. Proper maintenance and awareness of the system’s components play a vital role in sustaining the operational health of the watercraft.

Replacement Parts Compatibility

Ensuring the proper functioning of any watercraft often hinges on the selection of suitable components. Compatibility among replacement elements is crucial for maintaining performance and longevity. It is essential to understand how different components interact and fit together within the assembly to avoid issues that may arise from mismatched items.

When considering alternative components, one must evaluate specifications, design similarities, and material quality. Many manufacturers offer cross-reference charts, allowing enthusiasts to identify which items can serve as viable substitutes. Additionally, consulting with professionals can provide insights into the reliability and performance of these alternatives.

Ultimately, selecting compatible replacements not only ensures a seamless integration into the existing framework but also enhances overall efficiency and safety.

Maintenance Tools and Requirements

Proper upkeep of your watercraft involves a variety of specialized instruments and essential supplies. Ensuring that you have the right tools not only facilitates effective servicing but also enhances the longevity and performance of the machine. Understanding the necessary items is crucial for both novice and experienced enthusiasts.

Basic Tools: A well-equipped toolkit should include basic hand tools such as wrenches, screwdrivers, and pliers. These items are vital for performing routine checks and minor repairs. Additionally, having a torque wrench on hand is recommended for tasks requiring precise tightening of fasteners.

Maintenance Supplies: It is essential to stock up on quality lubricants and cleaning agents. Regularly applying appropriate lubricants can help reduce wear on moving components, while cleaners are crucial for maintaining the appearance and functionality of the exterior surfaces.

Safety Gear: When undertaking maintenance tasks, safety should be a priority. Wearing gloves, goggles, and protective clothing minimizes the risk of injury and ensures a safe working environment. Additionally, ensuring proper ventilation while working with chemicals is critical for health and safety.

Storage Solutions: Organizing your tools and supplies is important for efficiency. Using a sturdy toolbox and labeled storage bins can help keep everything accessible and in order, making your maintenance tasks smoother and more enjoyable.