In the realm of heavy machinery, having a clear understanding of the various elements that contribute to the overall functionality of an engine is crucial. Each individual piece plays a significant role in ensuring optimal performance, and comprehending how these components interact can enhance maintenance practices and troubleshooting efforts.

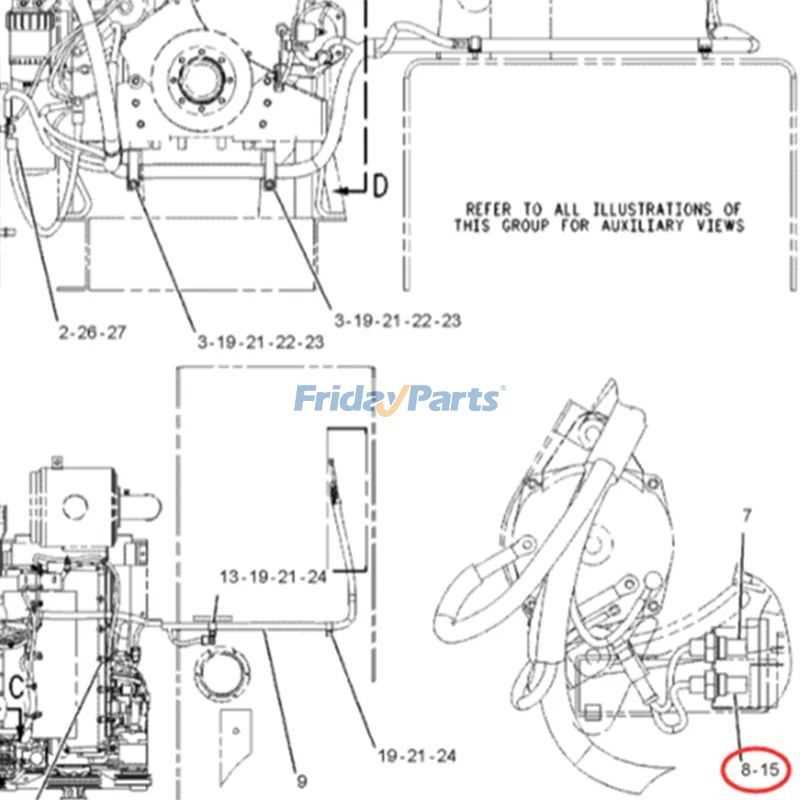

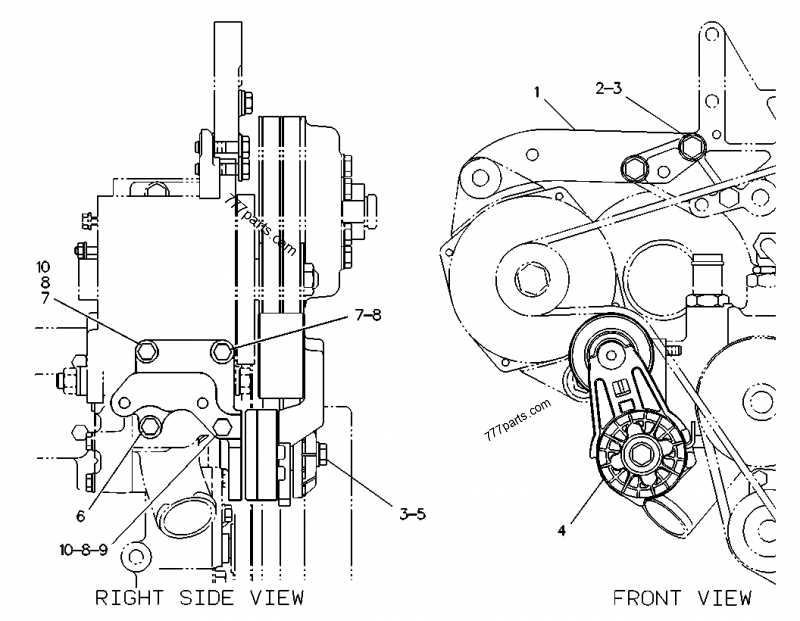

Visual representations that illustrate the arrangement and relationship between these essential elements can be invaluable. Such illustrations provide a roadmap, guiding technicians through the complexities of mechanical systems. By familiarizing oneself with these layouts, one can efficiently diagnose issues and carry out repairs, leading to improved machinery longevity and reliability.

For those involved in the upkeep of industrial engines, knowledge of how different components fit together is paramount. This understanding not only facilitates effective maintenance but also empowers operators to make informed decisions regarding repairs and upgrades, ultimately enhancing the efficiency of the equipment.

Overview of Cat 3116 Engine Parts

The intricate machinery of a particular engine encompasses numerous components, each serving a distinct purpose. Understanding the functionality and layout of these elements is crucial for maintenance and repair. This section provides a comprehensive look at the main constituents that contribute to the overall performance of this engine.

Key Components

Several essential elements are integral to the efficient operation of this engine. Each component plays a vital role, and familiarity with them can enhance repair efforts and maintenance routines. Below are the primary components:

- Cylinder Block: The core structure housing the cylinders.

- Pistons: Components that convert fuel energy into mechanical motion.

- Crankshaft: Transforms the linear motion of the pistons into rotational force.

- Fuel Injection System: Delivers fuel to the combustion chamber in a precise manner.

- Exhaust System: Directs exhaust gases away from the engine.

Additional Elements

In addition to the primary components, various supplementary parts contribute to the overall functionality and reliability of the engine:

- Oil Pump: Ensures adequate lubrication throughout the system.

- Timing Belt: Coordinates the timing of the engine’s internal operations.

- Cooling System: Maintains optimal operating temperatures.

- Air Filter: Prevents contaminants from entering the combustion chamber.

Each element, from the main constituents to the supplementary parts, works harmoniously to ensure the engine operates efficiently and effectively.

Importance of Accurate Parts Diagram

Having a precise representation of components is essential for effective maintenance and repair operations. Such illustrations not only facilitate understanding but also ensure that each element is correctly identified and utilized, leading to enhanced performance and longevity of machinery.

Accurate component representations serve several critical functions:

- Efficiency in Repairs: Clear visuals allow technicians to quickly locate and address issues, minimizing downtime.

- Reduced Errors: Proper identification of parts reduces the likelihood of mistakes during replacement, ensuring compatibility and functionality.

- Enhanced Training: Visual aids support training programs by providing new technicians with a clear reference, improving their understanding of the machinery.

- Cost Savings: By preventing errors and streamlining the repair process, businesses can save significant amounts on labor and replacement costs.

In summary, maintaining accuracy in representations of components is vital for efficient maintenance, reducing errors, and saving costs in the long run. The benefits extend beyond immediate repairs, contributing to overall operational effectiveness.

Common Issues with Cat 3116 Parts

The machinery’s components can encounter various challenges over time, impacting overall functionality and performance. Understanding these common difficulties is essential for effective maintenance and troubleshooting. By addressing these issues promptly, operators can ensure smoother operation and extend the lifespan of their equipment.

Frequent Wear and Tear

Regular usage often leads to significant wear on critical elements, causing them to degrade faster than expected. Components such as gaskets, seals, and bearings may experience deterioration due to constant friction and pressure. Operators should routinely inspect these elements to identify signs of damage and replace them as necessary to maintain optimal performance.

Fuel System Concerns

Problems within the fuel delivery system can lead to inefficient combustion and reduced power output. Clogs in filters or issues with injectors are common culprits that can result in subpar performance. It is crucial to regularly clean and replace fuel filters to prevent debris from obstructing the flow and to ensure that the machinery operates at peak efficiency.

How to Interpret the Parts Diagram

Understanding an illustration that showcases components is essential for anyone working with machinery. These visuals provide crucial insights into the various elements and their interconnections, enabling users to troubleshoot issues effectively and ensure proper maintenance.

To make sense of these illustrations, consider the following steps:

- Familiarize Yourself with Symbols: Each element typically has a specific symbol or label. Learning these symbols helps in recognizing what each part represents.

- Study the Layout: Observe how components are arranged. The layout often indicates the relationship between different parts, such as which ones work together.

- Check Reference Numbers: Many illustrations include reference numbers. These are crucial for identifying parts in catalogs or ordering replacements.

- Consult the Manual: A manual accompanying the illustration can provide additional context and details about maintenance procedures or assembly instructions.

By following these guidelines, individuals can enhance their understanding of the machinery and ensure more effective maintenance and repairs.

Key Features of the Cat 3116

This section highlights the essential characteristics of a popular diesel engine model known for its reliability and efficiency in various applications. Understanding these attributes is crucial for users looking to optimize performance and maintenance.

- Durable Design: Engineered for longevity, this model features robust construction that withstands demanding operating conditions.

- High Power Output: Delivers impressive horsepower, making it suitable for heavy-duty tasks and machinery.

- Efficient Fuel Consumption: Designed to maximize fuel efficiency, it helps reduce operational costs over time.

- Advanced Technology: Incorporates modern innovations that enhance performance and reduce emissions.

- Versatile Applications: Suitable for a wide range of industries, including construction, agriculture, and transportation.

These key features contribute to the overall functionality and appeal of this engine, ensuring it meets the demands of various users effectively.

Replacement Parts for Cat 3116

When it comes to maintaining heavy machinery, ensuring the availability of quality components is crucial for optimal performance and longevity. Having access to suitable alternatives can significantly enhance the efficiency of the equipment and minimize downtime.

Essential Components: A variety of essential components are available to replace worn or damaged items. These include items such as filters, gaskets, and belts, which play a vital role in the overall functionality of the engine.

Quality Considerations: It’s important to choose high-quality replacements to ensure durability and reliability. Quality components can help avoid frequent repairs and maintain the machinery’s operational integrity.

Aftermarket Options: Numerous aftermarket options are also available, often at competitive prices. These alternatives can provide a cost-effective solution while still meeting the necessary performance standards.

Conclusion: Whether sourcing original or aftermarket components, having a reliable supply is key to ensuring your machinery continues to operate smoothly. Investing in quality replacements not only prolongs the life of your equipment but also enhances its efficiency.

Maintenance Tips for Cat 3116 Engine

Ensuring the longevity and optimal performance of a heavy machinery engine requires regular attention and care. Adopting effective maintenance practices can significantly enhance the reliability and efficiency of your equipment. This section outlines essential tips for keeping your engine in excellent working condition.

One of the most critical aspects of engine upkeep is routine inspections. Regularly checking for signs of wear, leaks, or unusual noises can help identify potential issues before they escalate. Additionally, adhering to the manufacturer’s service schedule is crucial for maintaining warranty coverage and ensuring all components function harmoniously.

Another vital maintenance tip is to monitor fluid levels consistently. Proper lubrication is essential for reducing friction and preventing overheating. Regularly changing oil and filters, along with coolant checks, will keep the engine running smoothly and efficiently.

Additionally, cleanliness plays a significant role in engine maintenance. Keeping the engine compartment free from debris and dirt can prevent overheating and ensure proper airflow. Using protective covers during downtime can also safeguard against contaminants.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Oil Change | Every 500 hours | Use manufacturer-recommended oil |

| Filter Replacement | Every 1000 hours | Check for signs of clogging |

| Fluid Level Check | Weekly | Include coolant and hydraulic fluids |

| Visual Inspection | Monthly | Look for leaks and wear |

Comparing Cat 3116 to Other Models

This section explores the differences and similarities between a specific engine model and its counterparts. Understanding these distinctions can provide valuable insights for users considering various options for their machinery or vehicles.

When evaluating different engine models, several factors should be taken into account:

- Performance: Each model may exhibit unique capabilities regarding horsepower and torque, affecting overall efficiency.

- Fuel Efficiency: Variations in fuel consumption can lead to significant cost differences over time.

- Maintenance Requirements: Some engines may demand more frequent or specialized servicing than others, impacting operational downtime.

- Parts Availability: The accessibility of components for repairs or upgrades can vary, influencing the decision-making process for potential users.

By examining these aspects, users can better determine which engine model aligns with their specific needs and preferences.

In summary, a thorough comparison reveals that while there may be commonalities among various engine types, critical differences often dictate their suitability for particular applications.

Finding Quality Parts Suppliers

When seeking reliable sources for engine components, it’s crucial to ensure that the chosen providers offer high-quality products and services. A well-informed decision can significantly impact the performance and longevity of your machinery, making it essential to thoroughly evaluate potential suppliers.

Begin by researching various distributors and manufacturers, focusing on their reputation within the industry. Online reviews, testimonials, and ratings can provide valuable insights into their reliability and customer service. Engaging with fellow enthusiasts or professionals can also yield recommendations for trustworthy vendors.

Additionally, consider the range of products offered by each supplier. A diverse inventory indicates a robust network and a commitment to meeting various customer needs. Look for suppliers that provide detailed specifications, compatibility information, and clear return policies, as these factors reflect their dedication to quality assurance.

Lastly, don’t overlook the importance of pricing. While finding competitive rates is vital, prioritizing quality over cost can prevent future issues. Establishing a relationship with a reputable supplier will ultimately lead to better outcomes and peace of mind for your projects.

Resources for Cat 3116 Owners

For individuals managing their machinery, having access to the right materials and support is crucial. This section outlines various resources available to ensure that owners can maintain optimal performance and troubleshoot effectively. Utilizing these tools can enhance the understanding and longevity of the equipment.

Online Forums and Communities

Engaging with online communities can provide valuable insights and support. Numerous platforms allow users to share experiences, tips, and solutions to common issues. Participating in discussions can foster connections with fellow enthusiasts and experts, making it easier to find answers to specific queries.

Technical Manuals and Documentation

Comprehensive manuals and technical documentation are essential for understanding the inner workings of the machinery. These resources typically offer detailed instructions, maintenance schedules, and troubleshooting guides. Having access to these documents can empower owners to perform repairs and maintenance confidently.