Understanding the internal structure and various elements of machinery is crucial for ensuring its smooth operation. This section provides a detailed look at the key components and how they work together to maintain optimal performance. With the right knowledge, you can keep your equipment running efficiently and address any potential issues before they escalate.

Each mechanism consists of several interconnected elements that require regular checks and replacements over time. Recognizing how these elements are assembled and function as a unit is important for both routine upkeep and unexpected repairs.

In this guide, we will explore the different sections, providing a comprehensive overview of the essential components. This knowledge will help you better navigate the maintenance process and ensure longevity for your machine.

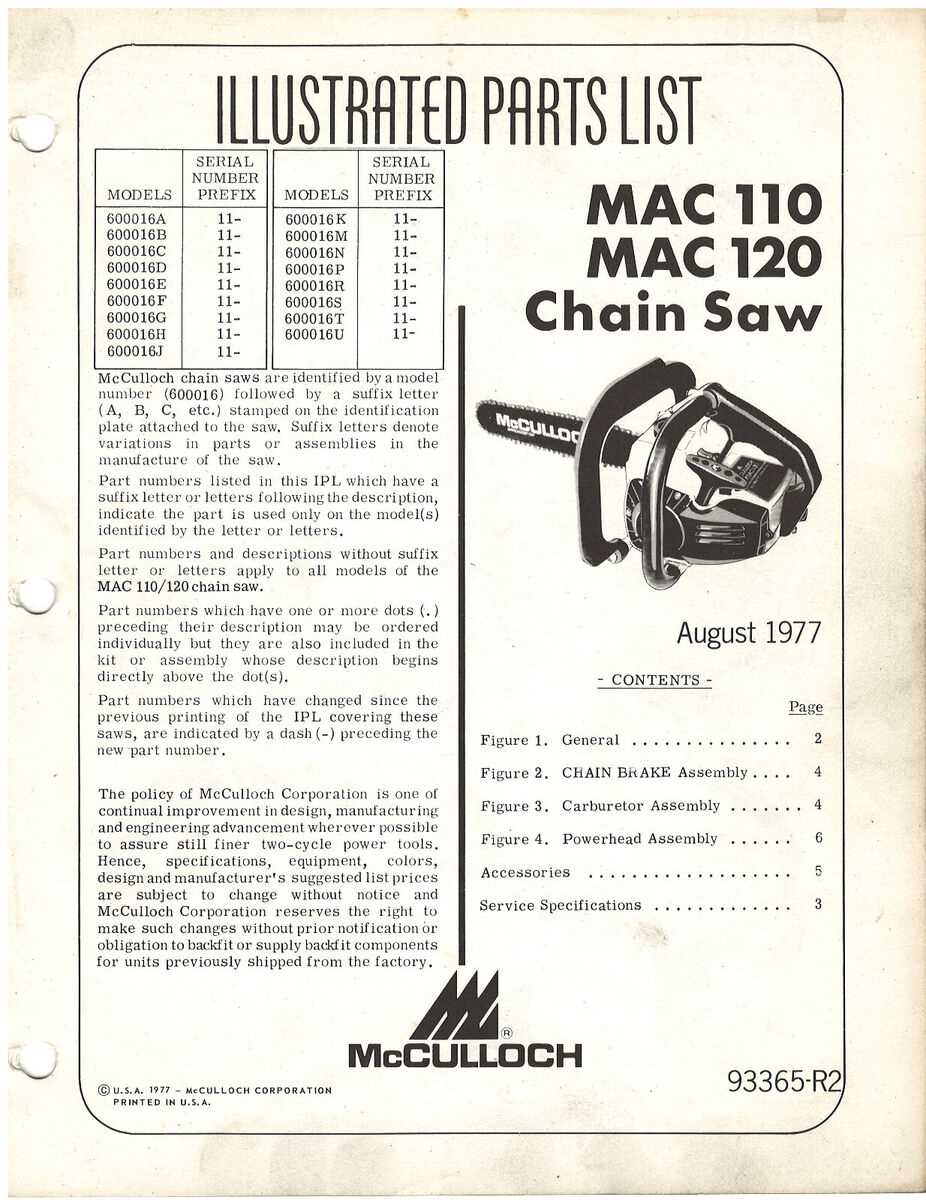

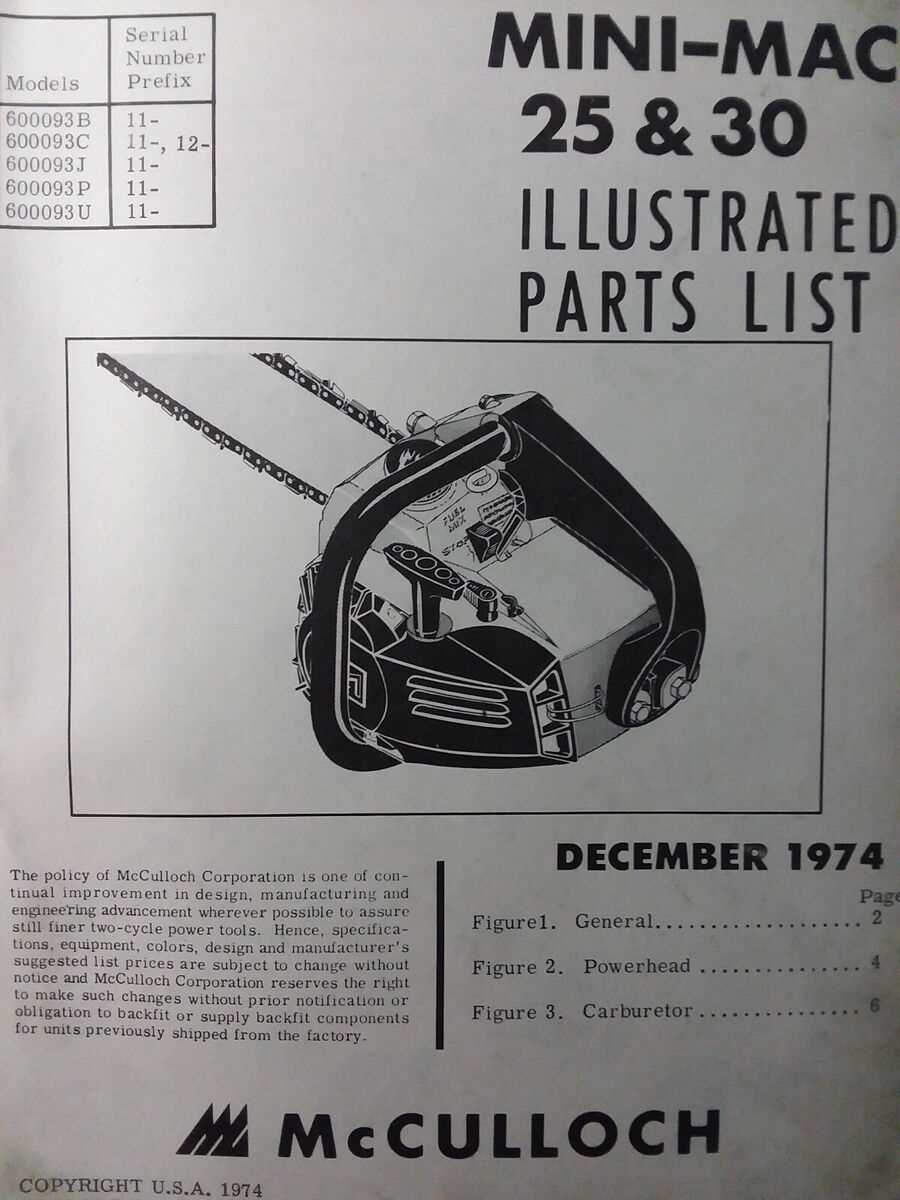

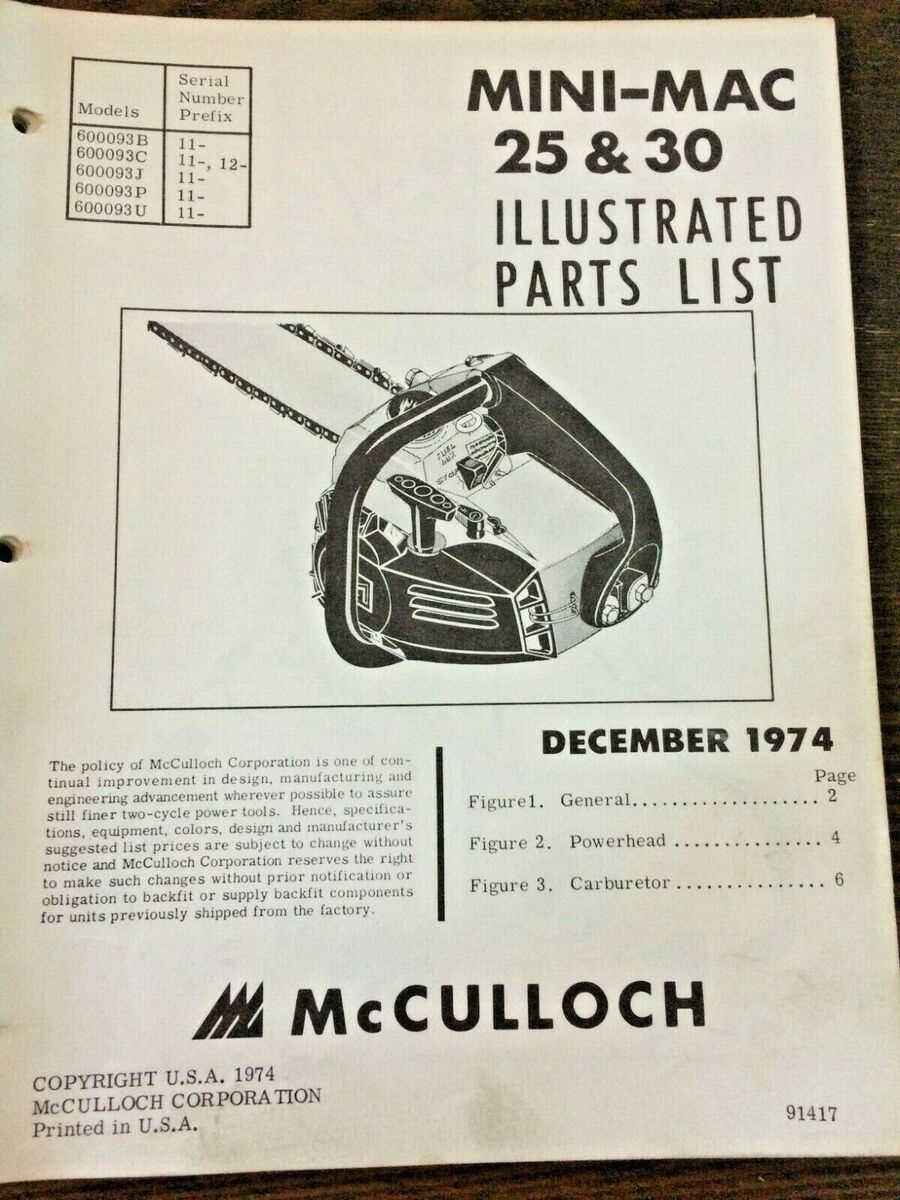

Understanding the Components of McCulloch Mini Mac 25

Exploring the intricacies of a small engine reveals a range of essential elements that contribute to its efficient operation. Each component plays a pivotal role in ensuring the overall functionality and performance of the device. By examining these individual parts, users can gain valuable insights into the mechanics of the engine, leading to better maintenance and troubleshooting practices.

Key Elements of the Engine

Among the vital components are the fuel system, ignition system, and air intake system. The fuel system is responsible for delivering the necessary energy for operation, while the ignition system initiates combustion, ensuring that the engine runs smoothly. Additionally, the air intake system allows for optimal airflow, enhancing efficiency and performance.

Maintenance and Care

Proper care and regular maintenance of these components can significantly extend the lifespan of the engine. Routine inspections and timely replacements of worn parts are essential to maintaining optimal performance. Understanding how each element interacts within the engine provides users with the knowledge needed to keep their equipment running effectively.

Key Features of the McCulloch Mini Mac 25

This section highlights the essential characteristics of a compact and efficient outdoor power tool designed for various tasks. Its design prioritizes user comfort and operational efficiency, making it a valuable asset for both homeowners and professionals. The integration of advanced technologies ensures that it performs effectively across different applications.

Lightweight and Portable

The tool is notably lightweight, allowing for easy maneuverability during use. Its compact structure enables effortless transportation, making it ideal for tackling tasks in tight spaces or on uneven terrain.

Powerful Performance

Equipped with a robust engine, this equipment delivers impressive power for a wide range of applications. Users can expect consistent performance, ensuring that even challenging jobs are completed efficiently. The combination of strength and agility enhances overall productivity.

Guide to Chainsaw Bar and Chain Assembly

Assembling the cutting components of a chainsaw is essential for optimal performance and safety. This section provides a comprehensive overview of the process, highlighting the key elements involved in attaching the guide and chain to ensure efficient operation.

Essential Tools and Materials

- Wrench or socket set

- Chainsaw chain

- Guide bar

- Bar nuts

- Chain oil

Steps for Assembly

- Begin by disconnecting the spark plug to prevent accidental starting.

- Remove the old chain and bar if necessary.

- Position the new guide bar onto the chainsaw frame, ensuring it aligns with the sprocket.

- Thread the new chain around the guide bar, following the correct orientation (the cutting edges should face forward).

- Place the chain over the sprocket and ensure it is properly seated.

- Secure the guide bar and chain using the bar nuts, tightening them firmly but not excessively.

- Fill the oil reservoir with chain oil before testing the chainsaw.

Regular maintenance and proper assembly of the cutting components will enhance the efficiency and lifespan of your equipment. Ensure to follow safety guidelines and consult the user manual for specific details related to your chainsaw model.

Exploring the Engine Parts of McCulloch Mini Mac 25

This section delves into the essential components that constitute the heart of this compact power tool. Understanding the key elements is crucial for effective maintenance and troubleshooting. Each component plays a significant role in ensuring optimal performance and efficiency, making it vital for users to familiarize themselves with these parts.

Key Components Overview

The engine features various integral components, including the cylinder, piston, and spark plug. The cylinder is where combustion occurs, converting fuel into energy. The piston moves within the cylinder, generating the power needed for operation. Additionally, the spark plug ignites the fuel-air mixture, initiating the combustion process.

Importance of Maintenance

Regular maintenance of these components is essential to prolong the lifespan of the engine. Neglecting routine checks can lead to reduced efficiency and potential damage. Users should pay attention to signs of wear or malfunction in these parts, ensuring timely replacements or repairs to keep the equipment functioning at its best.

How to Identify Common Replacement Parts

Understanding the components of your equipment is essential for effective maintenance and repair. Familiarity with various elements can aid in recognizing when a replacement is necessary, ensuring optimal performance. This section outlines key strategies to help you identify frequently needed components and their characteristics.

Visual Inspection Techniques

One of the first steps in identifying replacement components is conducting a thorough visual examination. Look for signs of wear, damage, or corrosion. This method can often reveal which parts may require attention. Pay close attention to critical areas that endure the most stress during operation.

Consulting Manufacturer Resources

Utilizing the resources provided by the manufacturer, such as user manuals or online databases, can significantly enhance your ability to identify necessary components. These resources typically contain detailed descriptions and images, making it easier to locate the specific parts needed for replacement.

| Component Type | Common Issues | Replacement Indicators |

|---|---|---|

| Blades | Dullness, Chips | Poor Cutting Performance |

| Filters | Clogs, Dirt Buildup | Reduced Efficiency |

| Fuel Lines | Leaks, Cracks | Fuel Leaks |

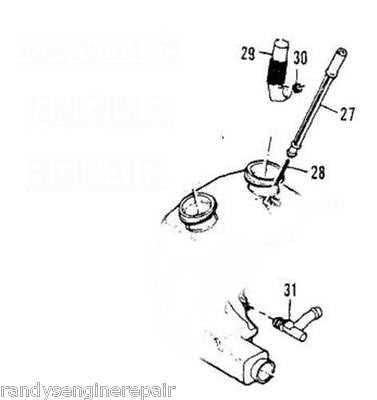

Understanding the Fuel System Components

The fuel system plays a crucial role in the efficient operation of small engine machinery. It is responsible for delivering the right amount of fuel to the engine for combustion, ensuring optimal performance. A well-functioning fuel system can significantly enhance the machine’s reliability and longevity.

Key elements within this system include the fuel tank, lines, filter, and carburetor. Each component serves a specific function, contributing to the overall effectiveness of the fuel delivery process.

| Component | Function |

|---|---|

| Fuel Tank | Stores fuel for the engine |

| Fuel Lines | Transport fuel from the tank to the engine |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine |

| Carburetor | Mixes fuel with air for combustion |

Maintaining the McCulloch Mini Mac 25

Proper care and regular upkeep are essential for ensuring optimal performance and longevity of your equipment. Following a structured maintenance routine can prevent potential issues and enhance efficiency. Below are key practices to consider.

Routine Checks

- Inspect the fuel system for leaks or blockages.

- Check the air filter for dirt and replace it if necessary.

- Examine the spark plug for wear and clean or replace as needed.

Cleaning Procedures

- Clear debris from the exterior, especially around the air intake.

- Clean the fuel tank to avoid contamination.

- Ensure all moving parts are free from dirt and grime.

Storage Tips

When not in use, store the unit in a dry, cool location. Drain the fuel to prevent degradation, and cover it to protect against dust and moisture.

Air Filter and Carburetor Setup Overview

Proper maintenance and configuration of the air intake and fuel delivery systems are essential for optimal performance and efficiency. These components play a vital role in ensuring that the engine operates smoothly, providing the necessary power for various tasks. Understanding how to set up and maintain these parts can significantly enhance the overall functionality of the equipment.

Air Filter Functionality

The air filter is crucial for preventing contaminants from entering the engine. A clean and well-maintained filter allows for optimal airflow, which is necessary for efficient combustion. Regular inspection and replacement of the air filter are recommended to maintain engine health and performance.

Carburetor Adjustments

Adjusting the carburetor is vital for ensuring the correct fuel-to-air ratio. This balance affects the engine’s efficiency and power output. Proper tuning can enhance throttle response and overall performance, allowing the engine to run smoothly under various operating conditions.

| Component | Purpose | Maintenance Tips |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine | Check regularly; replace when dirty |

| Carburetor | Controls the mixture of air and fuel | Adjust for optimal performance; clean periodically |

Handle Assembly and Safety Mechanisms

The handle assembly plays a crucial role in the functionality and user experience of handheld tools. It ensures that the device can be operated comfortably and safely, minimizing the risk of accidents during use. Understanding the components of the handle and their respective safety features is essential for proper maintenance and effective operation.

Components of the Handle Assembly

The handle assembly typically consists of various components that work together to provide stability and control. These may include the grip, trigger mechanism, and protective covers. Each part is designed to enhance user comfort while maintaining a secure hold on the equipment.

Safety Mechanisms

Safety mechanisms are integral to preventing unintended operation and ensuring the user’s protection. Features such as safety locks, ergonomic designs, and anti-slip grips are commonly implemented. These mechanisms not only improve safety but also contribute to overall efficiency during operation, allowing users to focus on their tasks with confidence.

Troubleshooting Parts for Better Performance

Ensuring optimal functionality of your equipment involves identifying and addressing potential issues with its components. By understanding how each element operates, you can enhance overall efficiency and longevity.

Here are some common problems you might encounter and how to resolve them:

- Air Filter:

- Check for blockages or excessive dirt buildup.

- Replace if it appears worn or clogged.

- Fuel Lines:

- Inspect for leaks or cracks that may impede fuel flow.

- Replace damaged sections to maintain proper function.

- Spark Plug:

- Examine for corrosion or deposits that can affect ignition.

- Replace if necessary to ensure reliable starting.

By regularly maintaining these elements, you can significantly improve the performance and durability of your machine.

Finding Compatible Parts for McCulloch Mini Mac 25

When it comes to maintaining and enhancing the functionality of your equipment, sourcing the right components is crucial. Ensuring compatibility with your machine can significantly improve its performance and longevity. This section focuses on how to identify and acquire suitable replacements and upgrades for your specific model.

Start by consulting the user manual or online resources that provide detailed specifications for your device. These documents typically list compatible components, including measurements and materials. Additionally, reputable online retailers and local stores often offer guidance on which items work best with your machine.

It is also beneficial to engage with online forums and communities dedicated to similar equipment. Users often share their experiences, recommendations, and insights regarding which components are effective and reliable. Leveraging these resources can help you make informed decisions and ensure that your equipment operates at its best.

Lastly, keep an eye out for warranties or guarantees provided by manufacturers or sellers. These assurances can offer peace of mind, knowing that the components you purchase are designed to meet specific standards and will function effectively with your machine.