The functionality of a vehicle’s stopping system is crucial for safe operation on the road. It comprises several essential components that work together to ensure effective deceleration and control. Mastering the intricacies of this system enhances both safety and performance.

In this section, we will explore the various elements involved in this vital mechanism. From the interactions between different components to the significance of their arrangement, we will delve into how these parts contribute to the overall efficiency and reliability of the system.

By understanding the layout and operation of these mechanisms, vehicle owners and enthusiasts can gain insight into maintenance and potential upgrades. This knowledge is not only beneficial for repair purposes but also helps in appreciating the engineering behind modern automotive technology.

Understanding Ford F150 Brake Systems

Comprehending the mechanics behind the stopping systems of a popular truck model is essential for both safety and maintenance. These systems are complex, involving multiple components that work together to ensure effective deceleration and control of the vehicle. Knowledge of these elements aids in troubleshooting and performing necessary repairs or upgrades.

The stopping mechanism generally consists of various assemblies that play distinct roles in the overall operation. Recognizing how these components interact can significantly enhance your ability to maintain the vehicle’s performance and ensure safety on the road.

| Component | Description |

|---|---|

| Rotors | Disks that rotate with the wheels and provide a surface for the pads to clamp against, creating friction. |

| Pads | Friction material that presses against the rotors to slow down the vehicle. |

| Calipers | Devices that house the pads and contain the hydraulic pistons, applying pressure to the pads. |

| Lines | Hoses that transport hydraulic fluid from the master cylinder to the calipers, enabling the system to function. |

| Master Cylinder | Part that converts the force applied to the pedal into hydraulic pressure for the system. |

Understanding these components and their functions provides a clearer picture of how the system operates, ultimately leading to more informed decisions regarding maintenance and repairs.

Key Components of Brake Assemblies

Understanding the essential elements that contribute to a vehicle’s stopping system is crucial for maintaining safety and performance. Each component plays a significant role, working in harmony to ensure reliable functionality and responsiveness when needed.

| Component | Description |

|---|---|

| Rotor | The circular disc that rotates with the wheel, allowing for friction to be applied. |

| Pads | The material that presses against the rotor to create the necessary friction for deceleration. |

| Caliper | The device that houses the pads and applies pressure to them during operation. |

| Master Cylinder | The component that converts the force from the pedal into hydraulic pressure. |

| Lines | The tubes that transport hydraulic fluid from the master cylinder to the calipers. |

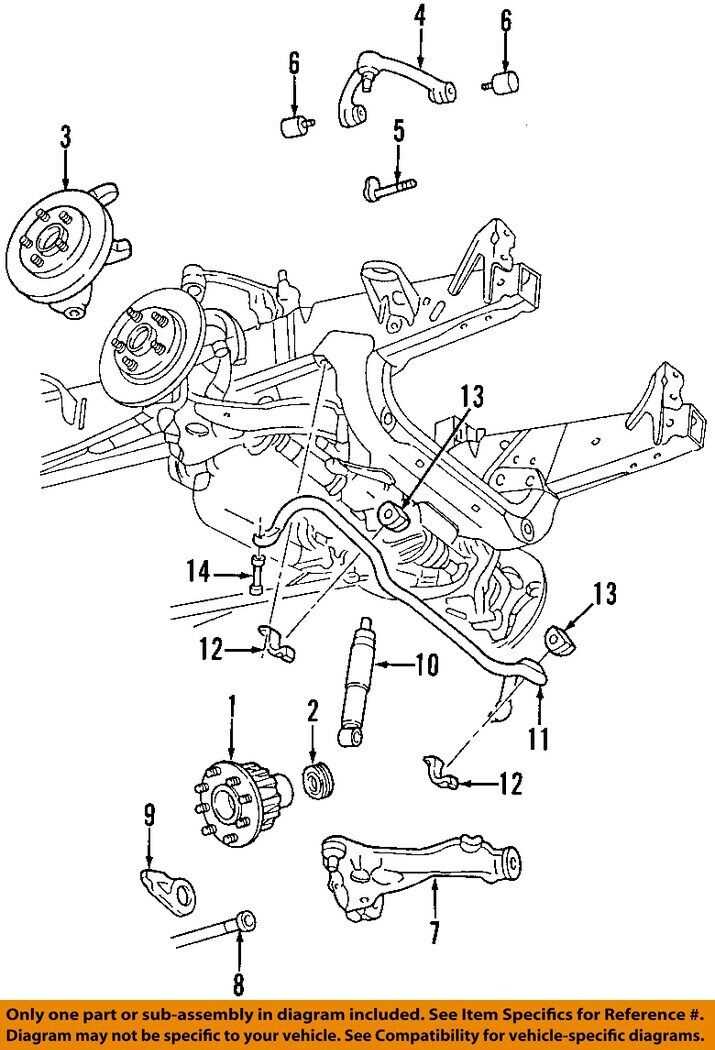

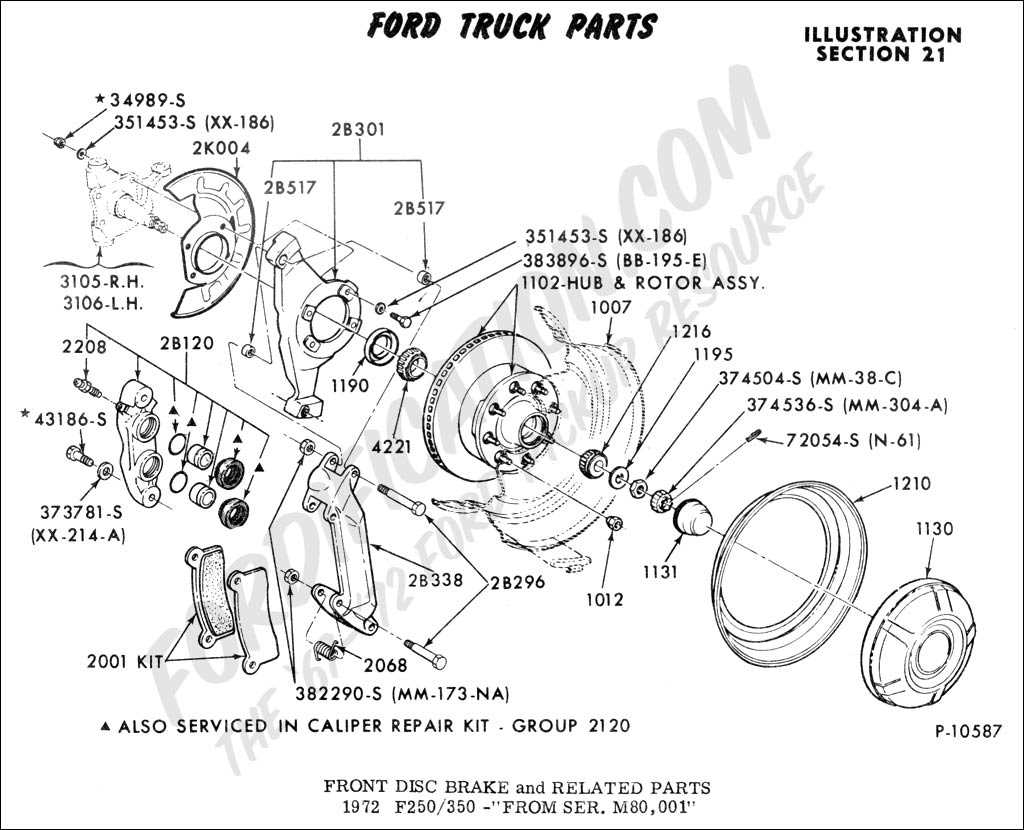

Brake Diagram Overview for Ford F150

This section provides a comprehensive examination of the essential components involved in the stopping mechanism of a popular pickup truck. Understanding these elements is crucial for both maintenance and repair, ensuring optimal performance and safety on the road.

Key Components

The stopping system consists of various integral pieces, including discs, calipers, and pads. Each element plays a vital role in the overall functionality, contributing to effective deceleration and vehicle control.

Maintenance Tips

Regular inspection of these components is essential for longevity and reliability. Ensuring that everything is in good condition can prevent unexpected failures and enhance driving safety.

Importance of Regular Brake Maintenance

Ensuring the functionality of stopping mechanisms is crucial for vehicle safety and performance. Consistent upkeep can prevent unexpected failures, enhancing both reliability and driver confidence. Neglecting these essential components can lead to costly repairs and increased risk on the road.

Safety First

Regular inspections and servicing significantly reduce the likelihood of accidents. Properly maintained systems respond promptly, allowing for safer driving conditions and minimizing the chances of malfunctions.

Cost Efficiency

Investing time in maintenance can save money in the long run. Addressing minor issues early on prevents them from escalating into major problems, which can be expensive to resolve. Ultimately, this proactive approach is beneficial for both your wallet and your vehicle’s longevity.

How to Read Brake Parts Diagrams

Understanding visual representations of vehicle components is essential for effective maintenance and repair. These illustrations provide a clear layout of various elements, allowing enthusiasts and technicians to identify and comprehend the relationships between each component.

Familiarize Yourself with Symbols

Each representation includes unique symbols and labels that denote specific elements. Take time to study the key or legend, as this will enhance your ability to interpret the visual language used.

Identify Key Components

Focus on the main elements illustrated, such as those responsible for function and support. By recognizing these crucial parts, you can delve deeper into the assembly and understand the ultimate workings of the system.

Common Issues with Brake Parts

When it comes to stopping systems, various complications can arise that impact performance and safety. Understanding these prevalent issues is crucial for maintaining vehicle reliability and ensuring smooth operation.

Wear and Tear: Over time, components can deteriorate due to regular usage. This leads to reduced efficiency and may result in a lack of responsiveness.

Fluid Leaks: Any loss of hydraulic fluid can severely compromise functionality. Identifying the source of these leaks is essential for proper repairs.

Noisy Operation: Unusual sounds during engagement often indicate underlying problems. This can be caused by misalignment or debris interfering with the mechanism.

Vibration: Excessive shaking when in use may signal issues such as uneven wear or imbalanced components, requiring immediate attention.

Corrosion: Exposure to moisture can lead to rust, affecting the integrity of the system. Regular inspections can help catch this early.

Being aware of these challenges allows for timely interventions, ultimately enhancing the overall safety and performance of the vehicle.

Upgrading Your F150 Brake Components

Enhancing the stopping mechanisms of your vehicle can significantly improve performance and safety. This process not only boosts responsiveness but also ensures durability under various driving conditions. By selecting superior components, you can tailor your ride to meet personal preferences and demands.

Choosing Quality Components

When it comes to selecting new components, it’s crucial to consider materials and designs that optimize function. High-performance options can provide better heat dissipation and increased longevity.

Installation Tips

Proper installation is key to maximizing the benefits of your upgrades. Following manufacturer guidelines and using the right tools can make the process smoother and more effective.

| Component | Benefits |

|---|---|

| Pads | Enhanced grip and reduced fade |

| Rotors | Improved heat management and longevity |

| Calipers | Increased clamping force for better stopping power |

Essential Tools for Brake Repairs

Having the right instruments is crucial for effective maintenance and repair tasks. A well-equipped workspace enhances efficiency and ensures safety during the process. Below is a list of necessary tools that will help streamline your repair work.

Basic Tools

- Socket set

- Wrenches

- Torque wrench

- Jack and jack stands

- Brake fluid

Specialized Instruments

- Piston tool

- Caliper hanger

- Brake pad spreader

- Micrometer for measuring thickness

- Diagnostic scanner

Identifying Brake Problems Early

Recognizing issues with your vehicle’s stopping system at an early stage can prevent more severe complications and ensure safety. Various signs can indicate when something is amiss, allowing drivers to take proactive measures before it escalates.

Common Warning Signs

Unusual noises, such as squeaking or grinding, often signal wear and tear. Additionally, a noticeable change in response time or pulling to one side while halting can indicate underlying issues. Monitoring these symptoms is crucial for timely interventions.

Regular Maintenance Checks

Routine inspections play a vital role in identifying potential problems. Keeping an eye on fluid levels and visual wear can help maintain optimal function. Early detection not only enhances performance but also extends the lifespan of critical components.

Step-by-Step Brake Replacement Guide

Replacing the components responsible for slowing down your vehicle is essential for safety and performance. This guide will walk you through the necessary steps to ensure a successful installation and optimal functionality. By following these instructions carefully, you can enhance your driving experience and prolong the lifespan of your system.

Gathering the Necessary Tools

Before starting, ensure you have all required tools at hand. This typically includes a jack, jack stands, a wrench set, and a torque wrench. Having quality tools is crucial for a smooth process, as they allow you to work efficiently and safely.

Replacement Process

Begin by securely lifting the vehicle and removing the wheels to access the components. Next, detach the old items by loosening any fasteners. After that, clean the area to eliminate dust and debris, which can affect performance. Install the new components carefully, ensuring everything is aligned properly. Finally, reassemble the wheels, lower the vehicle, and test the system to confirm everything operates as intended.

Maintenance Tips: Regular checks can prevent future issues. Ensure to monitor wear and tear and replace any components as necessary to maintain safety.

Safety Tips for Brake Work

Ensuring safety during maintenance tasks is crucial for effective vehicle operation. Proper precautions not only protect the individual working on the system but also enhance the reliability of the components involved.

- Always wear appropriate personal protective equipment, such as gloves and safety glasses.

- Work in a well-ventilated area to avoid inhaling harmful substances.

- Use jack stands and wheel chocks to secure the vehicle before beginning any work.

- Be aware of your surroundings and keep tools organized to prevent accidents.

Before commencing, familiarize yourself with the specific components you will be handling to mitigate risks effectively.

Resources for Further Brake Information

Understanding the intricacies of your vehicle’s stopping mechanisms is essential for maintenance and safety. A variety of resources are available to enhance your knowledge and support your efforts in keeping these systems in optimal condition. Whether you are a seasoned mechanic or a car enthusiast, accessing reliable information can significantly improve your understanding of how these components function.

Online forums and automotive communities offer a wealth of shared experiences and troubleshooting advice. Websites dedicated to car maintenance often feature detailed articles and videos that cover installation techniques, common issues, and tips for upgrades. Additionally, official manufacturer manuals provide comprehensive specifications and guidelines tailored to specific vehicle models.

For those who prefer a more hands-on approach, local workshops and automotive classes can be invaluable. Many community colleges and organizations offer courses focused on vehicle maintenance, allowing participants to learn from experienced professionals while gaining practical skills. Supplementing these resources with textbooks on automotive engineering can further deepen your understanding of vehicle systems.