An adjustable setting that allows the user to vary the blade’s movement speed,

Tools Required for Jigsaw Repair

For successful restoration and maintenance of power tools, having the correct set of instruments is essential. Each repair process involves specific equipment that ensures the device functions smoothly and is reassembled correctly. Proper preparation will make the task efficient and reduce the chances of errors during the procedure.

Basic Repair Instruments

- Screwdrivers: Both flathead and Phillips screwdrivers are commonly needed for opening the housing and accessing internal components.

- Allen wrenches: These are necessary to loosen and tighten any hexagonal screws securing key parts.

- Pliers: Useful for holding small parts, cutting wires, or adjusting components that may be difficult to handle.

Additional Equipment

- Multimeter: This tool helps check the electrical continuity and ensure proper circuit connections within the device.

- Lubricants: Applying lubricant to moving parts prevents friction and ensures smoother operation.

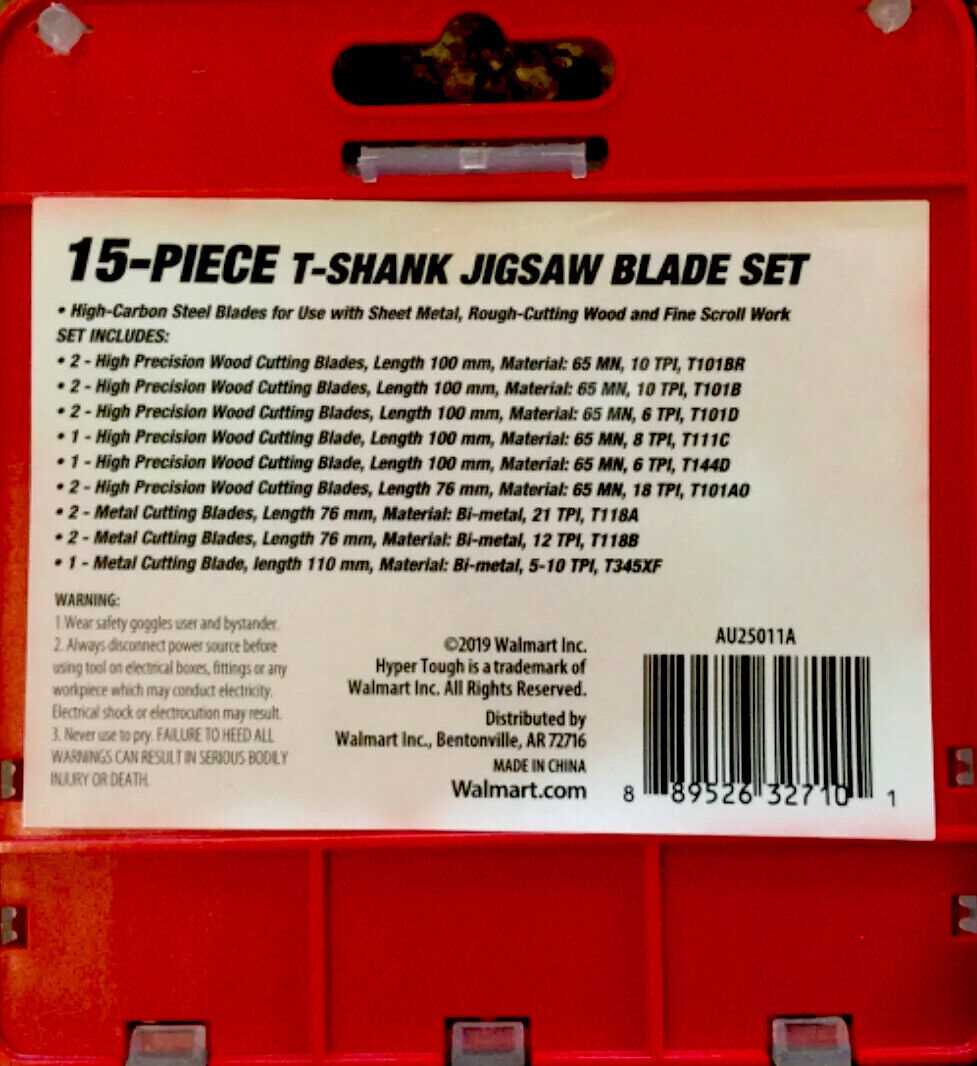

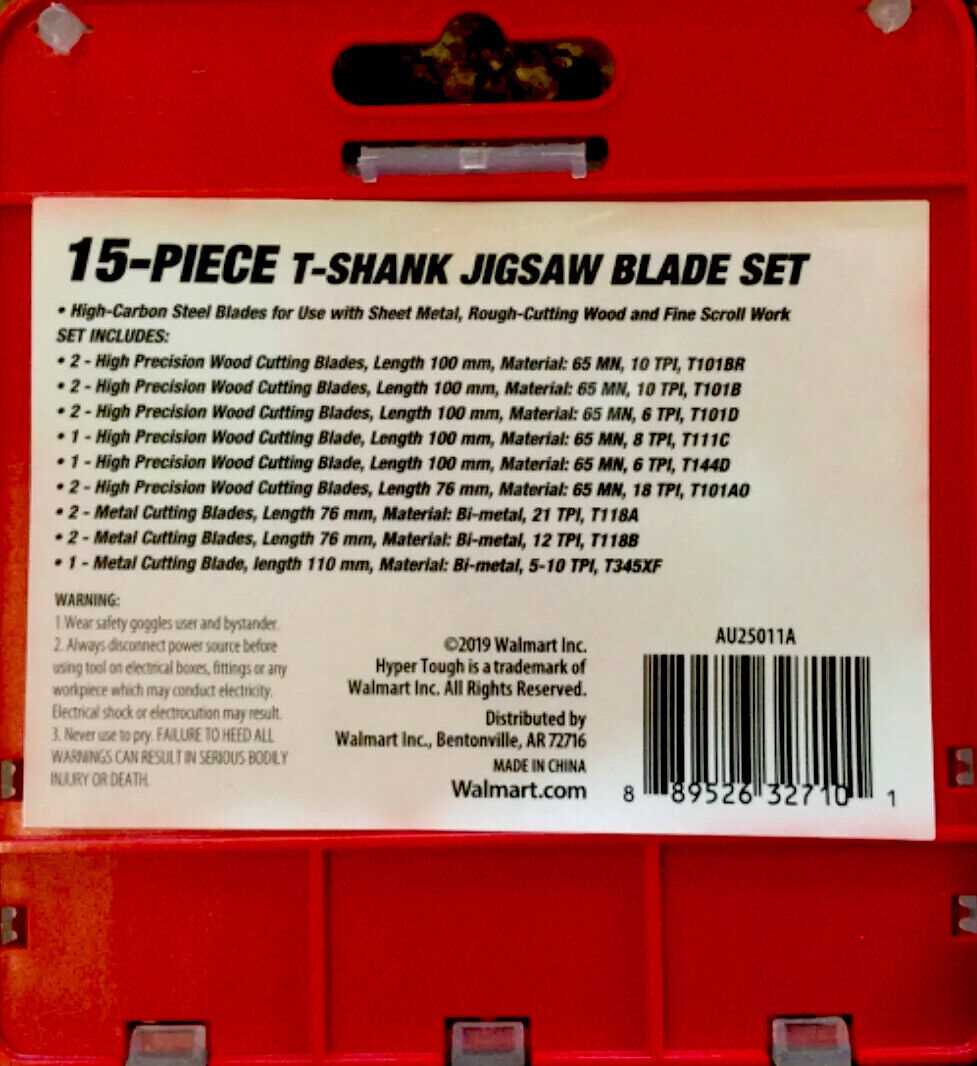

- Replacement blades or components: It’s often necessary to have new parts ready, in case old ones are worn or broken during the repair.

Maintenance Tips for Jigsaw Longevity

Proper care and regular upkeep of your cutting tool are essential to ensure its performance and extend its lifespan. By following simple maintenance practices, you can keep the device in top condition, allowing for more accurate and efficient work over time. These guidelines will help prevent wear and tear while optimizing its operation.

Regular Cleaning

- After each use, make sure to remove dust and debris from the cutting mechanism to avoid clogging.

- Wipe down the surfaces with a dry cloth to eliminate any remaining particles.

- For more thorough cleaning, use compressed air to access tight spaces.

Lubrication and Blade Care

- Ensure all moving parts are properly lubricated to reduce friction and prevent overheating.

- Regularly inspect the blades for any signs of wear or damage, and replace them if needed to maintain cutting efficiency.

- Store blades in a dry place to avoid rusting and corrosion.

By integrating these maintenance steps into your routine, your tool will remain in excellent working condition, delivering consistent results for years to come.

Replacing Worn Jigsaw Components

Over time, frequent use of cutting tools can lead to wear and tear on various essential components, making maintenance and timely replacement crucial for maintaining optimal performance. Recognizing the signs of deterioration early can prevent more significant issues and ensure the device continues functioning smoothly.

Blade Replacement: One of the first parts to show wear is the cutting edge. A dull or damaged blade can affect precision and make the operation more difficult. Regularly inspect and swap out the blade to maintain accuracy and efficiency.

Maintaining the Drive Mechanism: The internal motion system can suffer from friction and debris build-up, causing reduced performance. Periodically clean and lubricate this mechanism to extend the life of the tool and keep it running smoothly.

Handle and Grip Maintenance: Comfort is key during long periods of use. If the handle shows signs of damage or wear, replacing it will improve control and reduce fatigue. Proper upkeep ensures safer and more comfortable use over time.

Where to Find Replacement Parts

When your tool needs new components, knowing where to look for quality replacements can save both time and money. Whether you are dealing with wear and tear or a malfunction, finding the right pieces is essential for maintaining the functionality and extending the life of your equipment.

Below are some reliable sources to explore when searching for the items you need:

- Manufacturer’s Website: Many companies offer a wide range of accessories and repair kits directly on their official sites, often with detailed product specifications.

- Authorized Dealers: Check with certified sellers who specialize in distributing original supplies. They can often provide both the parts and expert advice.

- Local Hardware Stores: Some smaller stores carry a selection of universal components that may fit various brands of tools, providing a convenient solution.

- Online Marketplaces: Websites like Amazon or eBay host a variety of options from third-party vendors, offering competitive prices and user reviews.

- Specialty Repair Shops: If you’re looking for specific items, visiting a shop dedicated to repairs can give you access to rare or hard-to-find components.

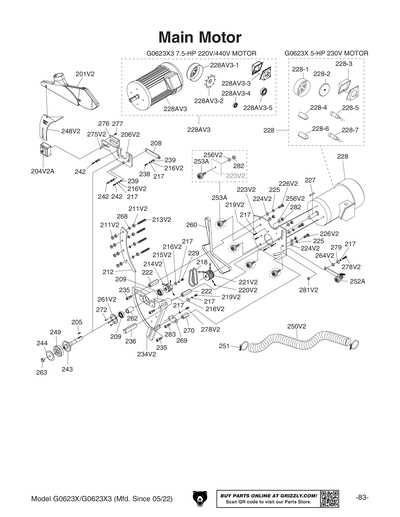

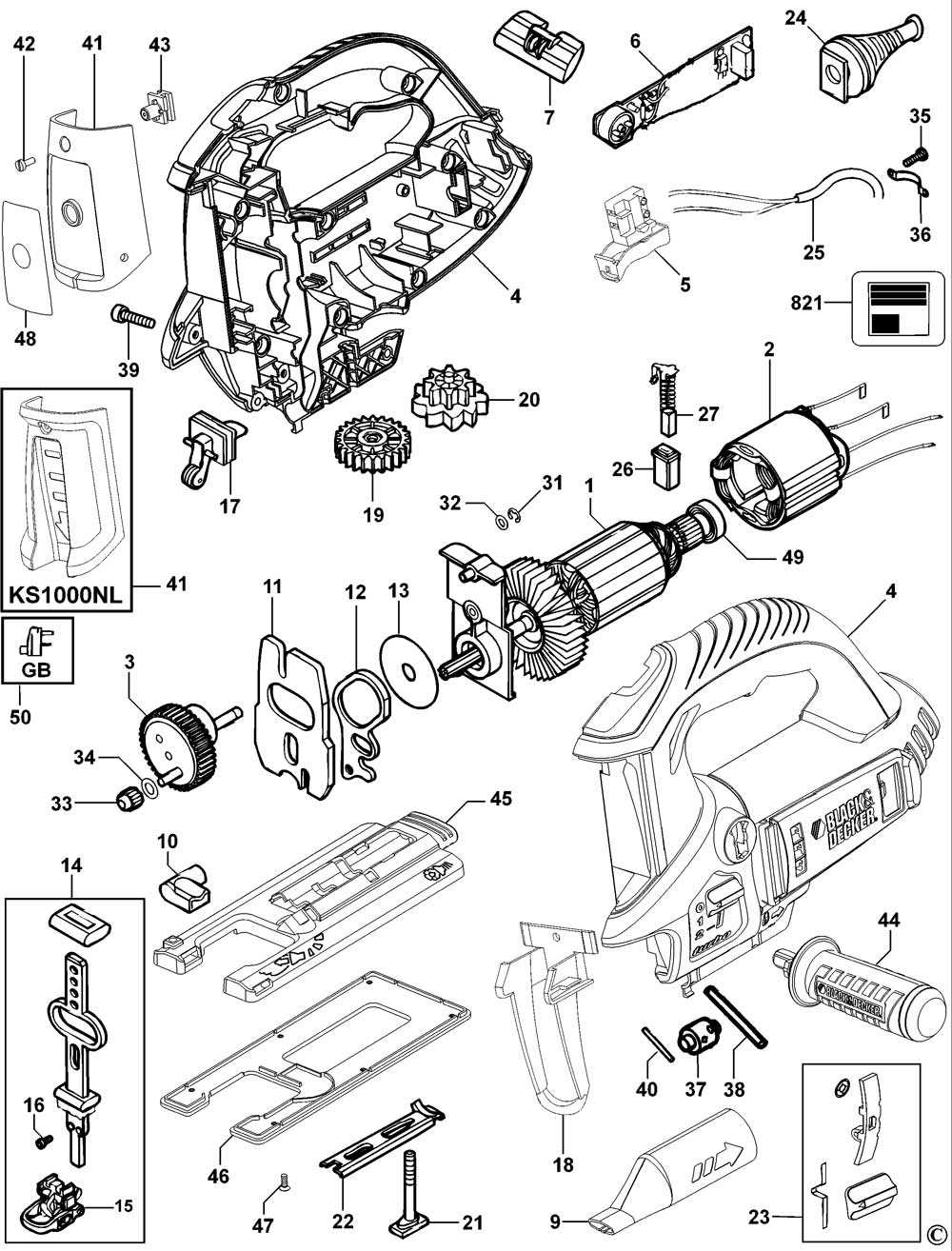

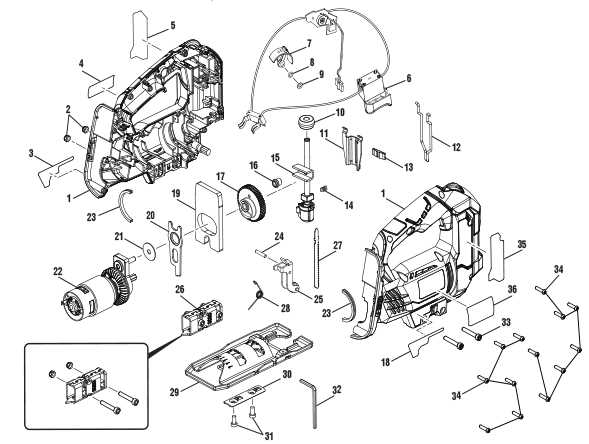

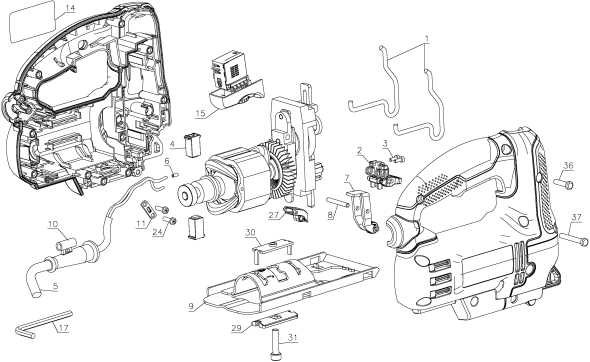

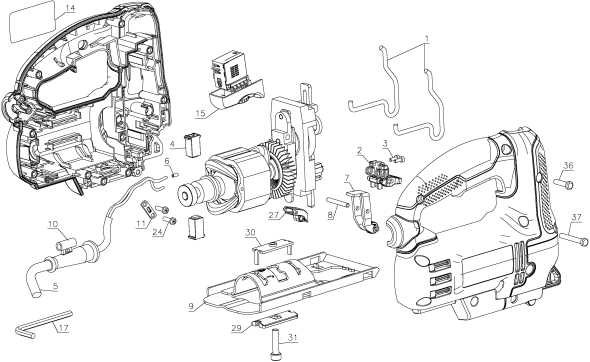

Understanding Jigsaw Assembly Process

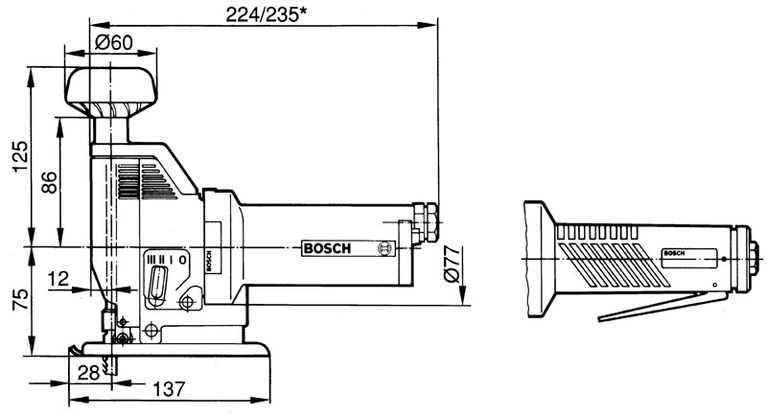

Assembling a cutting tool requires precision and attention to detail. Each component plays a crucial role in ensuring the device functions smoothly and safely. From connecting the motor to aligning the blade mechanism, understanding the placement and interaction of each piece is essential for proper assembly.

Key Components and Their Roles

When putting together the tool, it’s important to recognize the role of various parts, such as the power source, cutting blade, and control elements. Each of these elements works in unison to deliver accurate performance. The alignment of the drive mechanism and proper blade attachment ensures seamless cutting action without unnecessary strain on the device.

Step-by-Step Assembly Tips

Begin by securing the main body of the tool, ensuring the motor and electrical connections are firmly in place. Next, attach the blade system, making sure it is aligned correctly to prevent any wobbling during operation. Finally, check all screws and fasteners to guarantee the stability of the entire tool. Following these steps ensures a reliable and safe assembly process.

Benefits of Using Original Parts

When maintaining or repairing equipment, opting for genuine components brings several advantages that significantly enhance performance and reliability. Genuine items are designed to work seamlessly with the device, ensuring long-term durability and consistent operation.

- Increased Longevity: Authentic components are crafted with precision, ensuring they meet the highest standards. This results in a longer operational lifespan and reduced wear and tear.

- Optimal Compatibility: Original replacements are tailored to fit perfectly, minimizing the risk of damage caused by improper installation or poor alignment.

- Enhanced Safety: Using certified parts reduces the chance of malfunctions, protecting both the user and the equipment from potential hazards.

- Warranty Protection: Many manufacturers offer warranties that require the use of original components to remain valid, ensuring that repairs and replacements are covered.

- Consistent Performance: Genuine items maintain the intended performance levels, allowing the device to function as efficiently as possible without compromising quality.

DIY Tips for Jigsaw Users

Utilizing a versatile cutting tool can greatly enhance your crafting and construction projects. Whether you’re a seasoned artisan or a novice, understanding the best practices can lead to better results and increased safety. Here are some essential recommendations to consider.

Choose the Right Blade: Selecting an appropriate blade for your material is crucial. Different blades are designed for various surfaces such as wood, metal, or plastic. Ensure you have the right type to achieve clean and precise cuts.

Secure Your Workpiece: Always stabilize the material you are working on. Using clamps or a sturdy workbench will prevent movement, leading to more accurate cutting and reducing the risk of injury.

Maintain a Steady Pace: Rushing through the cutting process can compromise both safety and precision. Keep a consistent speed to allow the blade to do its job effectively, ensuring smoother cuts and a better finish.

Practice Safe Techniques: Always wear appropriate safety gear, such as goggles and gloves. Familiarize yourself with the tool’s operation and features before beginning your project to avoid accidents.

Regular Maintenance: Keep your cutting tool in top condition by regularly checking for wear and tear. Clean the blades and ensure all parts are functioning correctly to maintain optimal performance.

|