In the world of agricultural machinery, a comprehensive grasp of individual components is crucial for effective maintenance and repair. Each element plays a significant role in the overall functionality of the equipment, ensuring optimal performance in the field. By exploring these components in detail, operators can enhance their understanding and extend the lifespan of their machinery.

Visual aids can be invaluable tools for anyone looking to familiarize themselves with the intricate workings of a specific machine. They provide a clear representation of how different pieces fit together, making it easier to identify potential issues and understand the assembly process. Such illustrations not only serve as a guide for troubleshooting but also facilitate a smoother workflow during repairs.

For those keen on maximizing the efficiency of their equipment, having access to an organized overview of components is essential. This knowledge empowers users to conduct preventative maintenance, thereby reducing the likelihood of unexpected breakdowns. Ultimately, a deeper understanding of the machinery enhances productivity and contributes to the success of farming operations.

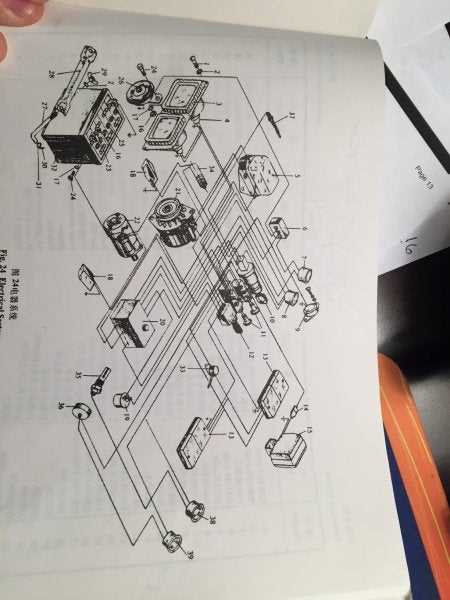

Understanding the Jinma 284 Parts Diagram

Grasping the intricate layout of a machinery component assembly is essential for effective maintenance and troubleshooting. A detailed visual representation serves as a valuable tool for operators and technicians alike, providing insights into the various elements that contribute to the overall functionality of the equipment.

Key Elements of the Assembly

Each section within the visual guide highlights specific components, illustrating their roles and interconnections. Recognizing these relationships can ultimately enhance your understanding of how to address issues or carry out repairs.

Benefits of Familiarity

Being well-acquainted with the assembly’s structure not only aids in efficient problem-solving but also fosters confidence in executing maintenance tasks. This knowledge empowers users to keep their equipment running smoothly and extends its operational lifespan.

Overview of Jinma 284 Specifications

This section provides a comprehensive examination of the key characteristics and features of a popular agricultural machine. Understanding the specifications is essential for both potential buyers and current owners to ensure optimal performance and maintenance. The highlighted aspects reflect the design, capabilities, and intended use of this versatile equipment.

Engine and Performance

The engine is a crucial component that determines the overall power and efficiency of the machine. With a robust output, it is designed to handle various tasks, from plowing to hauling. The combination of horsepower and torque plays a significant role in its ability to perform under challenging conditions, ensuring reliability and effectiveness in the field.

Dimensions and Weight

Dimensions and weight are vital for maneuverability and transport. The size of the machine impacts its ability to navigate different terrains, while the weight influences stability during operation. A well-balanced structure contributes to the overall performance, making it suitable for various agricultural applications.

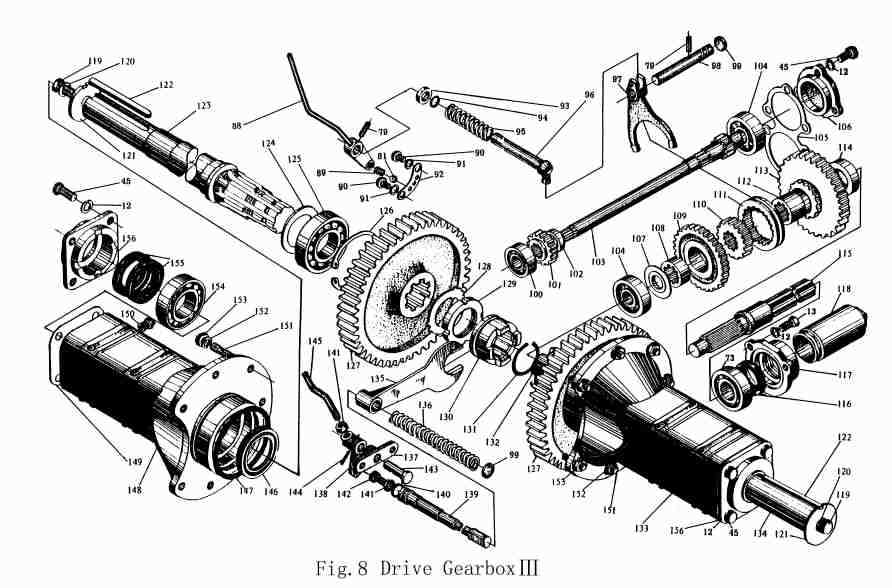

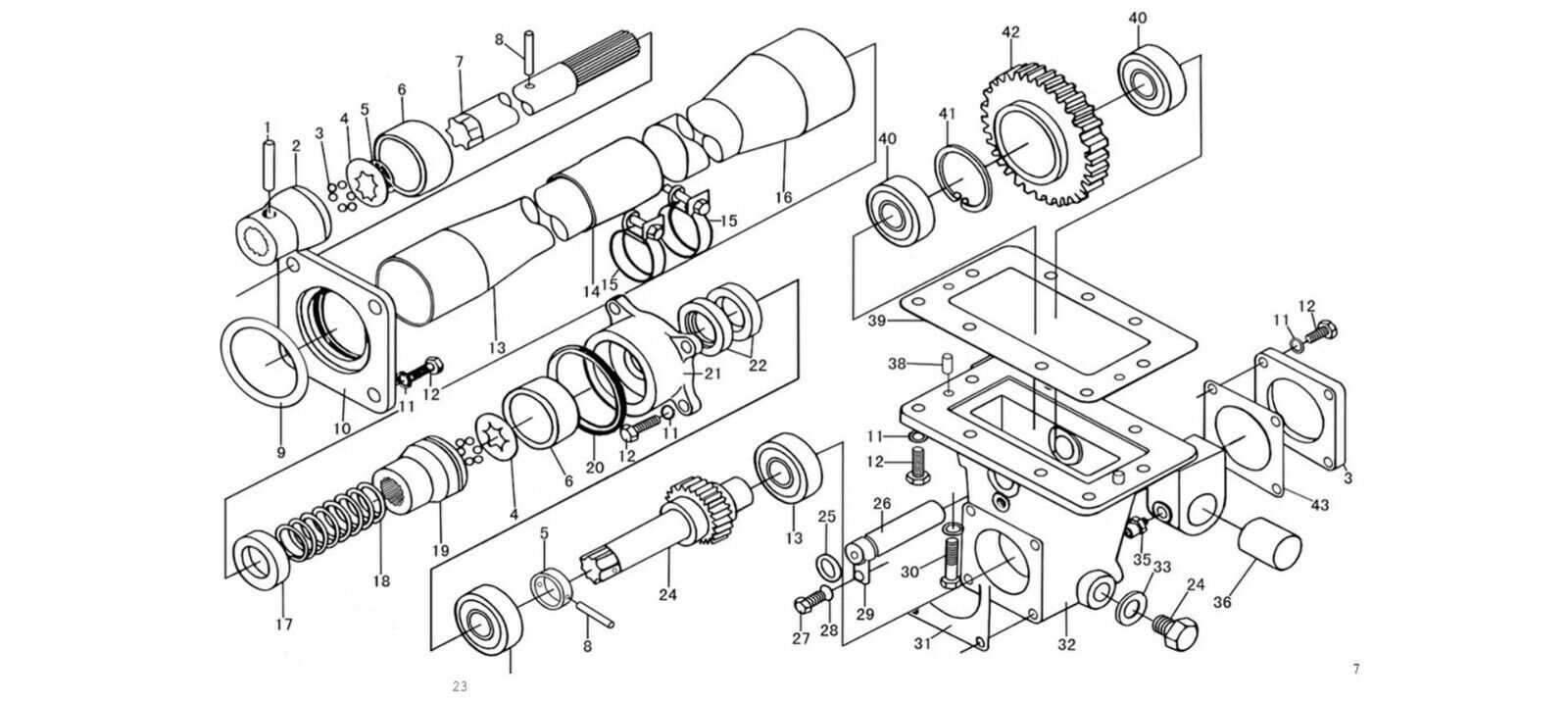

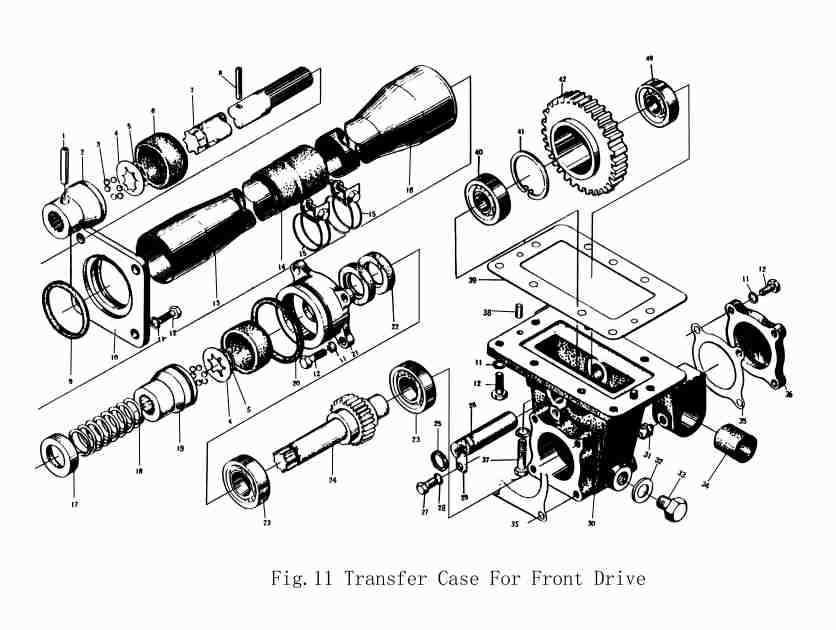

Key Components of Jinma 284

This section explores essential elements of a specific agricultural machine, focusing on the critical parts that contribute to its functionality and efficiency. Understanding these components is vital for maintenance, repairs, and enhancing performance.

Engine and Transmission

The powerhouse of the machine consists of a robust engine designed for durability and efficiency. Coupled with an advanced transmission system, it ensures smooth operation and optimal power delivery, making it suitable for various agricultural tasks.

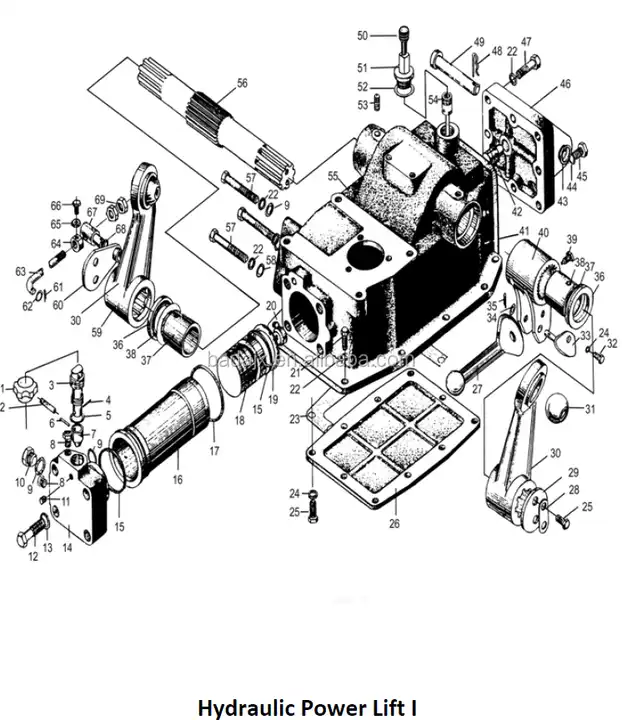

Hydraulic System

The hydraulic system plays a crucial role in enabling dynamic operations. Its design facilitates powerful lifting capabilities, allowing for seamless attachment and detachment of implements, which significantly enhances productivity on the field.

Importance of Accurate Diagrams

In the realm of machinery and equipment maintenance, precision visuals serve as essential tools for understanding complex systems. These illustrations provide a clear representation of components and their interrelationships, enabling technicians to troubleshoot issues effectively and streamline repairs.

Clarity is crucial; accurate visuals reduce the risk of errors during assembly and maintenance. By offering detailed views, they guide users in identifying parts, ensuring that each component is correctly understood and handled.

Furthermore, consistency in these representations fosters confidence among operators and technicians. When everyone relies on the same detailed visuals, communication improves, leading to quicker resolutions and enhanced operational efficiency.

Ultimately, investing time in creating and using precise visuals can save time and resources, reinforcing their significance in any technical field.

Common Issues with Jinma 284 Parts

When operating machinery, certain components may experience challenges that can affect overall performance. Identifying and addressing these common problems is crucial for maintaining efficiency and longevity. This section explores typical issues encountered with various elements of these vehicles, offering insights into their causes and potential solutions.

Wear and Tear of Components

Over time, frequent use can lead to significant wear on essential elements. Parts such as the transmission and engine may show signs of deterioration, leading to reduced functionality. Regular inspections can help detect early signs of damage, allowing for timely replacements that prevent further complications.

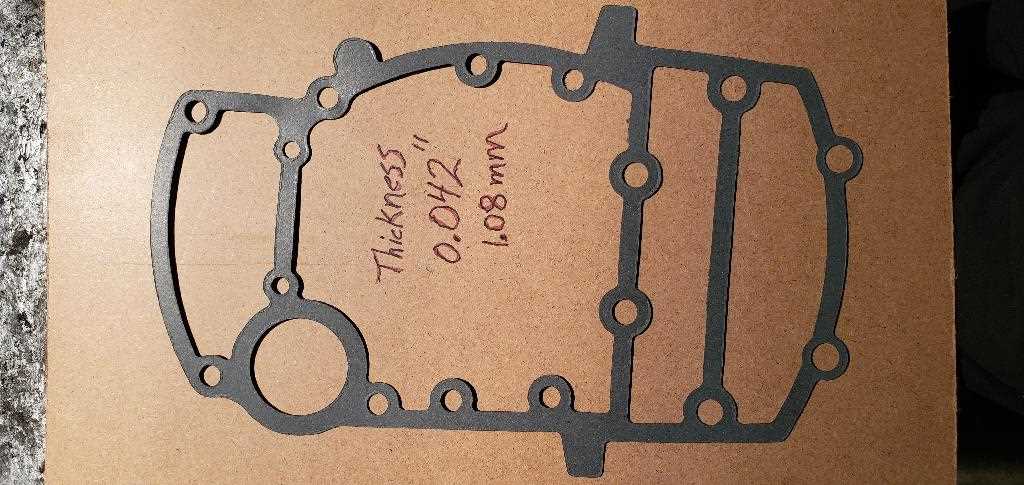

Fluid Leaks and Maintenance Challenges

Another prevalent concern involves fluid leaks, which can arise from seals and gaskets that have degraded. These leaks not only pose environmental risks but also threaten the efficiency of the machine. Keeping a regular maintenance schedule and monitoring fluid levels can mitigate these issues, ensuring smoother operation.

How to Use Parts Diagrams Effectively

Understanding visual representations of components is crucial for efficient maintenance and repair tasks. These illustrations not only enhance comprehension but also streamline the process of identifying necessary elements. By familiarizing oneself with the layout and symbols used, one can significantly improve their workflow.

Benefits of Visual Guides

- Facilitates quick identification of components

- Reduces the risk of errors during assembly

- Enhances communication among team members

- Simplifies troubleshooting processes

Tips for Effective Usage

- Familiarize yourself with the legend and symbols used.

- Cross-reference the visual guide with actual components.

- Keep the guide accessible during repair tasks.

- Regularly update your knowledge as new models or versions are released.

Maintenance Tips for Jinma 284 Owners

Proper upkeep is essential for maximizing the performance and longevity of your agricultural machinery. Regular maintenance not only ensures smooth operation but also helps in identifying potential issues before they escalate into costly repairs. By following a few key practices, you can keep your equipment running efficiently for years to come.

Regular Inspections

Cleaning and Lubrication

Maintaining cleanliness is vital in preserving the functionality of your machinery. Regularly clean the exterior and interior components to remove dirt and debris that may cause wear. Additionally, ensure all moving parts are adequately lubricated to reduce friction and prevent overheating. This simple step can significantly extend the life of various systems within your equipment.

Where to Find Replacement Parts

When it comes to sourcing essential components for your machinery, it’s crucial to know the best avenues to explore. Whether you’re looking to maintain performance or replace worn-out items, various resources can provide what you need efficiently.

Online Retailers

Numerous online platforms specialize in selling machinery components. These sites often offer extensive catalogs, allowing you to search for specific items by model or category. Look for retailers with positive reviews and reliable customer service to ensure a smooth purchasing experience.

Local Dealerships

Visiting local dealerships can also yield valuable results. Many of these establishments stock common items and can order specialized components. Additionally, staff members typically possess in-depth knowledge about the equipment, offering assistance in selecting the correct parts.

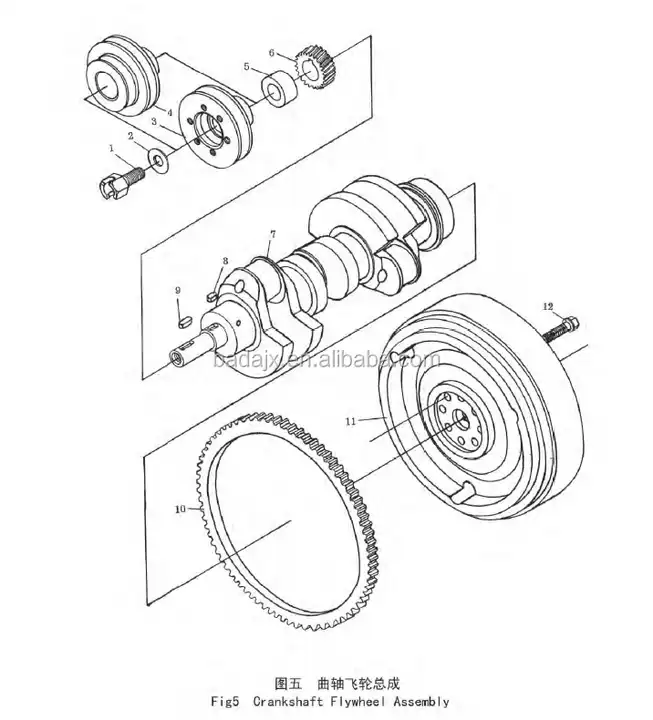

Exploring Jinma 284 Engine Components

This section delves into the intricate elements of a specific power unit, focusing on its essential mechanical parts and their functionalities. Understanding these components is crucial for anyone interested in maintenance or enhancements, as they play a pivotal role in the overall performance of the machinery.

Key Mechanical Elements

The core structure of the engine comprises various vital components that work in harmony to ensure optimal efficiency. Each part contributes uniquely to the engine’s operation, and familiarizing oneself with these elements is beneficial for troubleshooting and upgrades.

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders, providing strength and support. |

| Piston | A moving element that compresses fuel and air within the cylinder. |

| Crankshaft | Transforms linear motion from the pistons into rotational energy. |

| Camshaft | Regulates the timing of valve openings and closings for optimal airflow. |

| Fuel Injector | Delivers fuel directly into the combustion chamber for efficient ignition. |

Understanding Their Interactions

The synergy between these mechanical elements is crucial for effective performance. Each component interacts with others, creating a complex system where precision and coordination are essential. Knowledge of these relationships aids in effective diagnostics and repairs, ensuring longevity and reliability of the equipment.

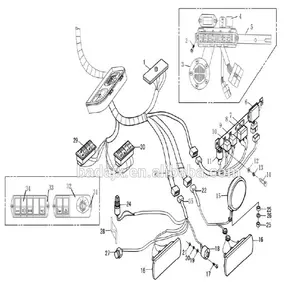

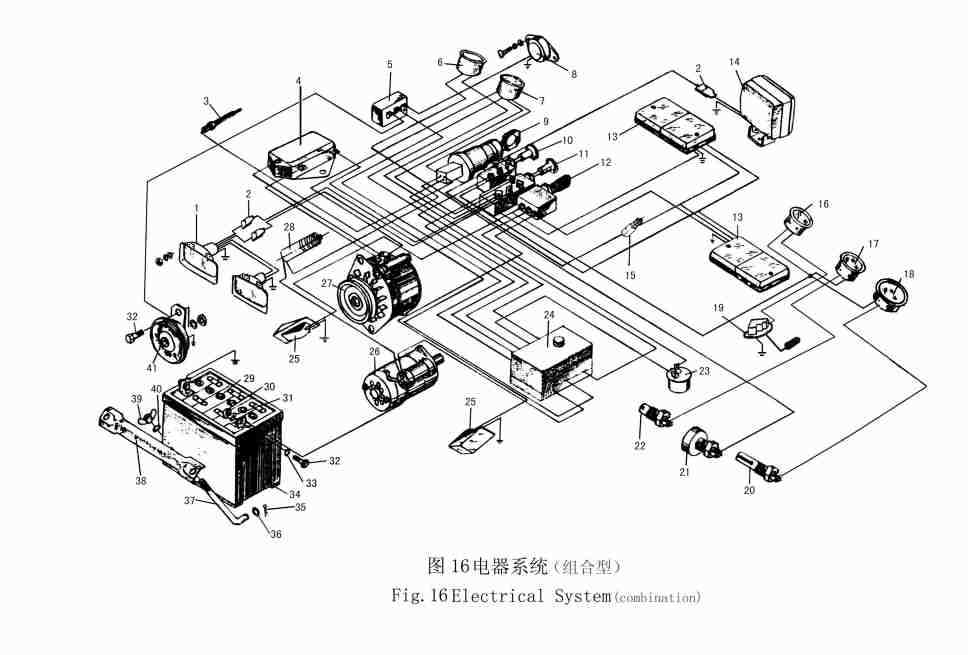

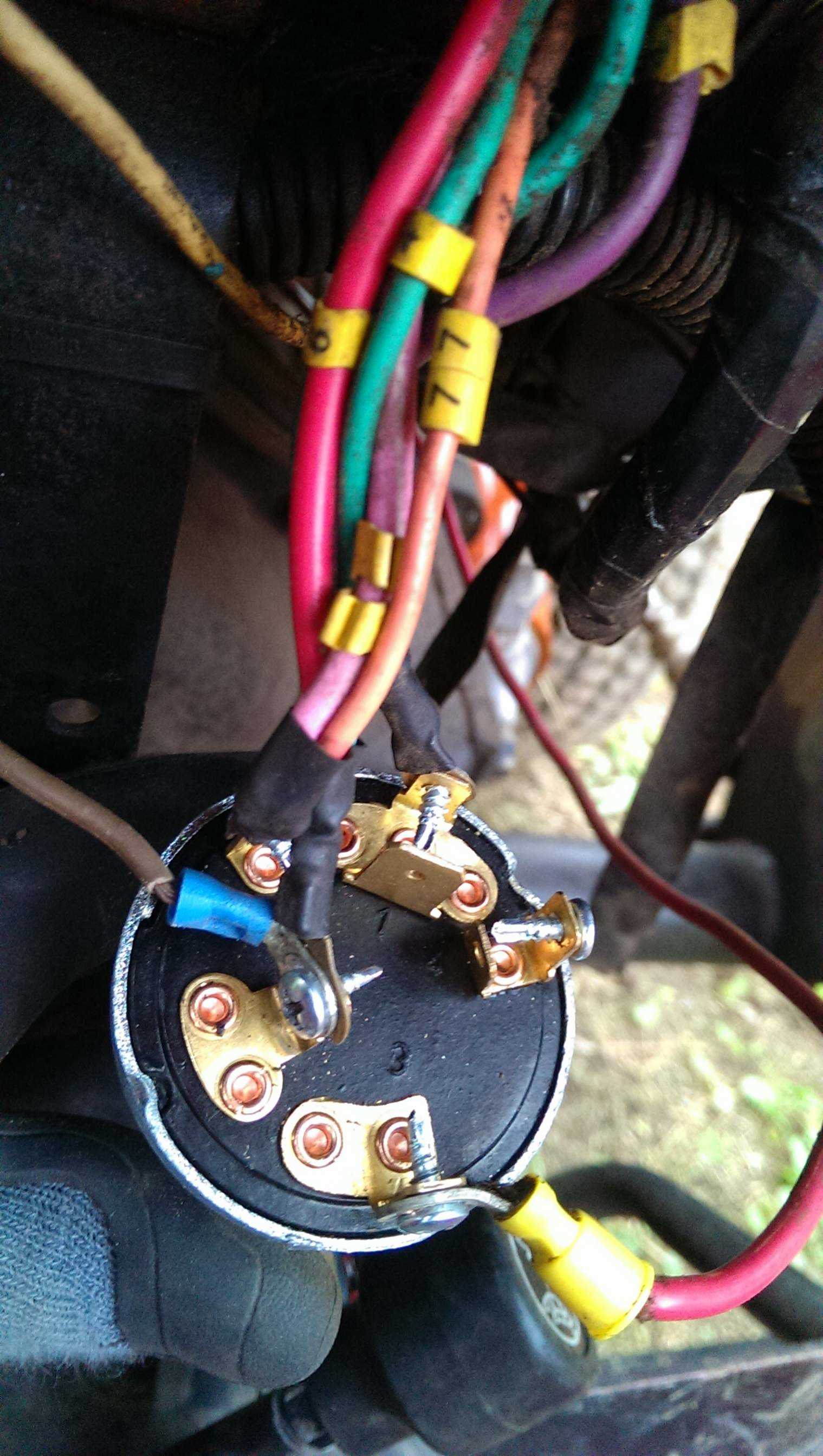

Identifying Electrical System Parts

Understanding the components of an electrical system is essential for effective maintenance and troubleshooting. Each element plays a crucial role in ensuring optimal performance, and recognizing these parts can greatly enhance the overall functionality of machinery.

Key Components

Several vital components include batteries, alternators, and wiring harnesses. Batteries store energy, while alternators convert mechanical energy into electrical energy, powering various systems. The wiring harness acts as the nervous system, connecting all parts and facilitating communication.

Common Issues

Recognizing common issues such as corrosion or loose connections can help in early detection and prevention of more severe problems. Regular inspections of these components can ensure the system remains functional and efficient.

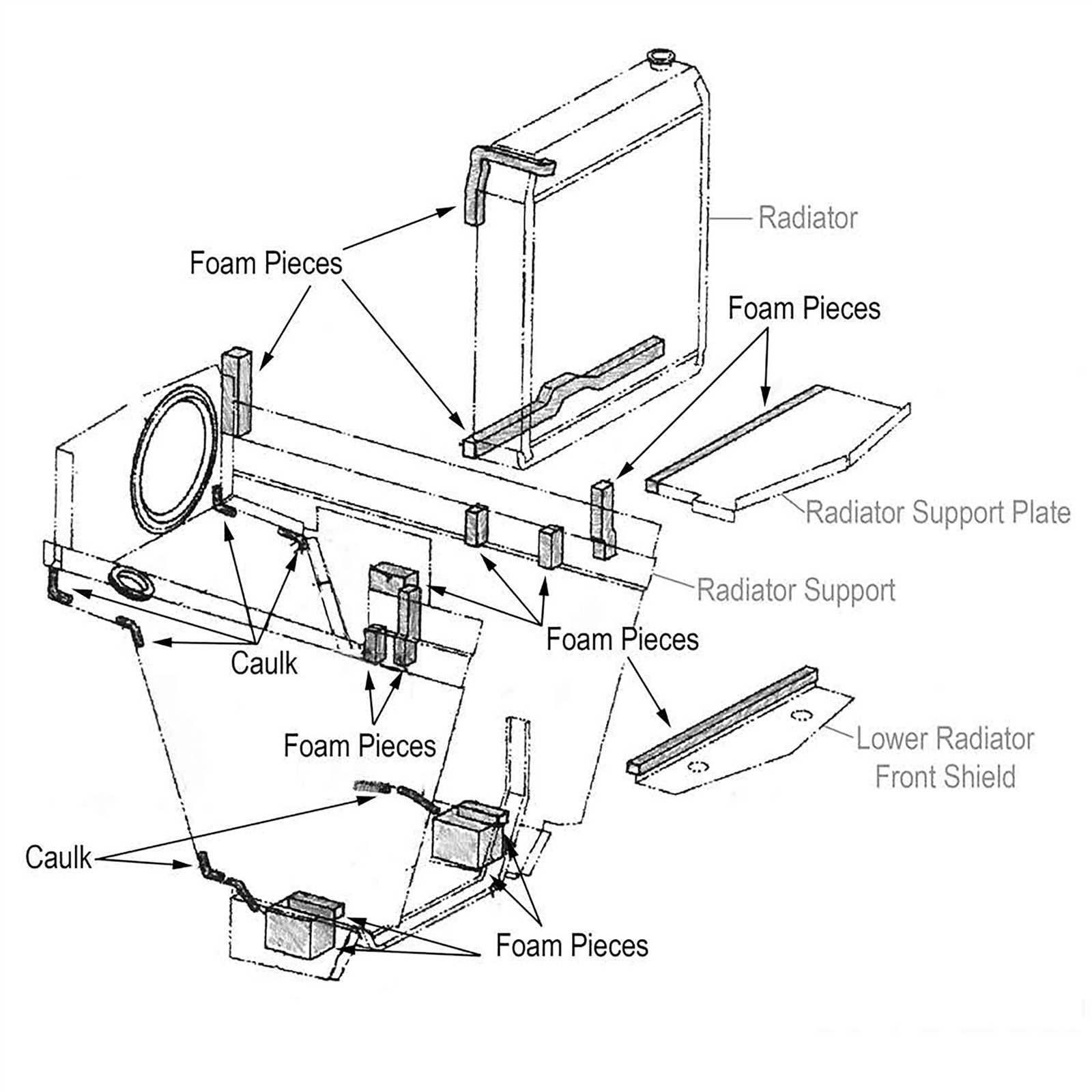

Hydraulic System Overview for Jinma 284

The hydraulic system of a compact tractor plays a crucial role in enhancing its efficiency and versatility. This system utilizes fluid power to perform various tasks, enabling the machine to operate attachments and perform heavy lifting with ease. Understanding the components and functioning of this system is essential for optimal performance and maintenance.

At the heart of this system lies the hydraulic pump, which generates the necessary pressure to move fluid through the circuit. The fluid travels through hoses and lines, connecting to different actuators such as cylinders and motors, which convert hydraulic energy into mechanical work. This enables the tractor to accomplish a range of functions, from lifting and lowering implements to steering and controlling attachments.

Additionally, the hydraulic reservoir plays a vital role in storing fluid, ensuring a steady supply to the system. Regular maintenance, including checking fluid levels and inspecting for leaks, is essential for preventing issues that could lead to inefficient operation or damage to components.

In summary, the hydraulic system is a fundamental aspect of compact tractor operation, providing the necessary power and control for various tasks. Familiarity with its components and upkeep can significantly enhance the machine’s performance and longevity.

Safety Precautions for Repairs

When undertaking any mechanical maintenance or restoration work, prioritizing safety is essential to prevent accidents and injuries. A systematic approach to ensuring a secure environment can significantly enhance the efficiency of the repair process.

First and foremost, always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. This gear serves as a barrier against potential hazards and minimizes the risk of injury.

Additionally, ensure that the workspace is well-lit and organized. A clutter-free area helps maintain focus and reduces the likelihood of tripping or mishandling tools.

Furthermore, it is vital to disconnect power sources before commencing any work. This precaution helps avoid electrical shocks and accidental activation of machinery during repairs.

Finally, familiarize yourself with the equipment’s safety features and operational guidelines. Understanding these aspects can prevent mishaps and ensure a safer repair experience.

Resources for Jinma 284 Enthusiasts

For those passionate about their favorite agricultural machinery, finding reliable information and support can significantly enhance the ownership experience. A wealth of resources exists to assist owners in maintaining, repairing, and enhancing their equipment.

Online Communities: Engaging with fellow enthusiasts through forums and social media groups can provide invaluable insights and practical advice. These platforms often feature discussions on common issues and solutions.

Manuals and Guides: Accessing comprehensive manuals is essential for understanding machinery specifications and maintenance procedures. Many websites offer downloadable resources that cover everything from basic upkeep to advanced repairs.

Parts Suppliers: Establishing connections with trusted suppliers ensures that you can find the necessary components for your machine. Online retailers often have user reviews to help gauge reliability.

Local Workshops: Visiting nearby repair shops that specialize in agricultural machinery can offer hands-on assistance and expert advice, making it easier to tackle any issues that arise.

Events and Meetups: Participating in local gatherings or trade shows allows enthusiasts to share experiences, exchange tips, and learn about the latest innovations in the industry.