The functionality and efficiency of any printing system depend heavily on the precise arrangement and interaction of various internal elements. Understanding how individual modules fit together ensures smooth operation and helps troubleshoot potential issues effectively.

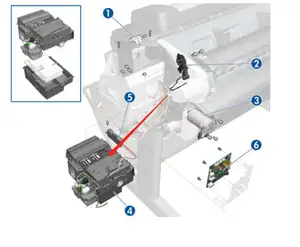

This section explores the internal structure of a widely used large-format printing machine, breaking down its essential elements. From control units to moving mechanical sections, each piece plays a critical role in achieving high-quality results.

A closer look at the internal assembly provides clarity on how these systems are built for durability and ease of maintenance. Knowing the proper configuration also supports accurate repairs and upgrades, enhancing long-term performance and minimizing downtime.

Overview of Component Arrangement

The internal structure of complex printing equipment relies on the precise alignment of various mechanical and electronic elements. Understanding how these elements interact ensures smooth operation, minimizes downtime, and facilitates efficient troubleshooting.

Key Functional Areas

Each section within the device has distinct responsibilities. The mechanical section handles material feed and movement, while the control units manage signals between internal systems. Proper synchronization between these areas is essential for optimal performance.

Interconnection of Elements

Wiring assemblies, sensors, and motors work in harmony to maintain seamless operations. Signal flow from control boards to actuators ensures precision during each task. Monitoring points embedded throughout the system help detect irregularities, allowing for quick intervention when needed.

Analyzing Internal Mechanisms

The inner structure of complex printing devices involves multiple coordinated components working in harmony. Each element within the system serves a specific function, contributing to seamless operations and ensuring precision output. This section explores how different internal modules interact to deliver accurate results.

Key Operational Components

- Drive Assembly: Controls the movement of essential elements, ensuring smooth transitions during operation.

- Ink Delivery System: Regulates the distribution of ink or toner for consistent output quality.

- Control Board: Acts as the brain of the machine, managing communication between internal parts.

Synchronization and Troubleshooting

The coordination between mechanical and electronic systems ensures proper functionality. When disruptions occur, identifying misalignments or faulty modules is critical to restoring efficiency. Routine inspections and targeted maintenance extend the lifespan of individual units and improve overall performance.

- Inspect moving assemblies regularly to prevent wear and tear.

- Monitor fluid distribution to detect blockages early.

- Keep software up to date for optimal system communication.

Display Module and Control Interface

The visual and command center plays a crucial role in managing operations, offering feedback, and enabling user interaction. It consists of a screen that provides essential system information and input mechanisms that allow configuration adjustments and monitoring.

This section includes both the visual output and the interactive elements. The display showcases key operational statuses, error messages, and maintenance alerts, ensuring smooth performance. The controls consist of tactile buttons or touch-sensitive areas, designed to facilitate easy access to settings and diagnostics.

Proper understanding of the interface ensures efficient navigation through system options and helps users quickly respond to any notifications. Regular checks and familiarity with the layout contribute to effective management and reduce downtime.

Understanding User Interaction Elements

This section focuses on the essential components that enhance the experience of individuals interacting with a system. Such elements play a critical role in ensuring smooth operation, offering clarity in processes, and reducing the potential for errors.

- Input Mechanisms: These are tools that allow individuals to provide instructions or information to the system, ensuring precise control over its functions.

- Display Interfaces: These components convey essential information back to the user, helping them monitor status and make informed decisions.

- Connection Points: Physical or software-based links that facilitate communication between different modules, ensuring seamless data exchange.

- Status Indicators: Visual cues that keep users informed about the current state of processes or potential issues that require attention.

The combination of these elements creates a system that is easy to use and highly efficient. An optimal setup ensures users have quick access to the information they need, minimizing downtime and improving overall workflow.

Media Feed and Paper Handling System

The mechanism responsible for moving printing materials ensures smooth and accurate flow, minimizing disruptions. This system maintains alignment and stability to achieve consistent results, crucial for any high-precision printing environment.

Various components work together to guide sheets or rolls, preventing misalignment and reducing mechanical stress during operations. Efficient control of material input and output plays a key role in optimizing performance.

| Component | Function |

|---|---|

| Roller Assembly | Facilitates smooth movement of the media through the system, ensuring even pressure distribution. |

| Feed Sensors | Detect the presence and position of the material, preventing jams and ensuring proper loading. |

| Adjustment Levers | Allow fine-tuning of media alignment to maintain precision during operations. |

| Collection Tray | Organizes output materials, preventing curling or damage upon exit. |

This arrangement supports uninterrupted processes by balancing movement speed and handling accuracy. Together, these elements form an essential part of the overall system’s reliability and efficiency.

Troubleshooting Material Flow Issues

Addressing challenges in the movement of resources is crucial for maintaining efficiency in any operation. Various factors can impede the seamless transfer of materials, leading to delays and inefficiencies. Understanding these obstacles is essential for implementing effective solutions.

Begin by examining the pathways and mechanisms involved in the material movement process. Check for any blockages or misalignments that may disrupt the flow. Inspecting the relevant components for wear and tear can also provide insights into potential failures.

Additionally, consider the role of external influences such as temperature fluctuations and humidity, which can affect the performance of materials and equipment. Regular maintenance and timely interventions are vital to ensure optimal functioning and to prevent recurring issues.

Lastly, documenting any patterns or recurring problems can help identify root causes and facilitate more efficient troubleshooting in the future. By taking a proactive approach, operations can significantly reduce downtime and enhance overall productivity.

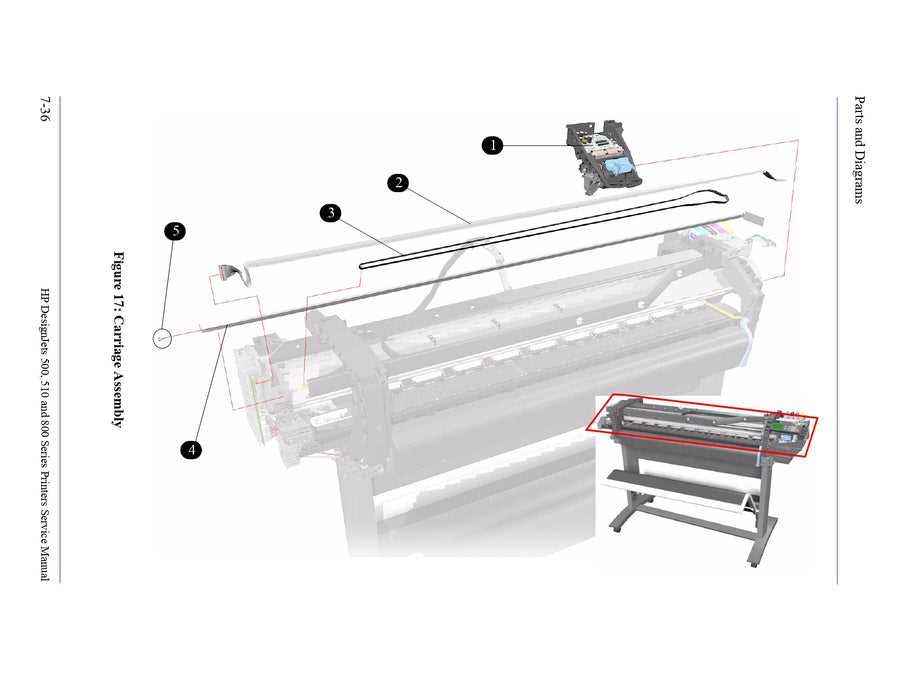

Carriage and Printhead Assembly

The assembly responsible for housing the printing mechanism plays a crucial role in the overall functionality of large-format printers. This component is integral to the movement of the printing elements and the application of ink onto the media. Understanding its design and operation is essential for effective maintenance and troubleshooting.

Key aspects of this assembly include:

- Movement Mechanism: The assembly incorporates a system that enables precise lateral movement, ensuring accurate positioning during the printing process.

- Ink Delivery: It features pathways for ink transfer from cartridges to the printing nozzles, facilitating consistent ink flow.

- Printhead Maintenance: Integrated systems for cleaning and servicing the printing elements help maintain optimal performance and print quality.

Regular inspections of the carriage and printhead assembly are vital. Users should be aware of common issues, such as:

- Clogs in the ink pathways, which can lead to inconsistent print quality.

- Wear and tear on the movement components, affecting the precision of the print process.

- Alignment problems that may result in misprints or artifacts on the media.

By keeping the carriage and printhead assembly in optimal condition, users can ensure longevity and reliability in their printing operations.

Maintenance Tips for Smooth Operation

Ensuring the reliable performance of large-format printing devices requires regular upkeep and attention. Proper maintenance not only prolongs the lifespan of the equipment but also enhances the quality of output. Here are some essential practices to keep your machine running efficiently.

- Regular Cleaning: Periodically clean the internal and external surfaces to remove dust and debris that can interfere with performance.

- Check Ink Levels: Monitor ink levels frequently to prevent running out during critical jobs, and replace cartridges promptly.

- Update Firmware: Keep the device’s software up to date to benefit from the latest features and performance enhancements.

- Inspect Cables and Connections: Ensure all connections are secure and inspect cables for any signs of wear or damage to prevent communication issues.

- Calibrate Regularly: Perform routine calibration to maintain print accuracy and quality.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommended maintenance schedule for optimal performance.

By implementing these maintenance strategies, users can ensure the consistent operation of their large-format printing systems, leading to better productivity and high-quality results.

Ink Supply and Delivery Path

This section outlines the crucial processes involved in the provision and transport of coloring fluid within the printing apparatus. Understanding this pathway is essential for ensuring optimal performance and print quality, as it directly influences the efficiency of ink utilization and the overall functionality of the device.

The pathway of fluid delivery encompasses various components that work in concert to ensure precise distribution. From reservoirs to dispensing mechanisms, each part plays a pivotal role in maintaining a steady flow and preventing issues such as clogging or inconsistencies in color saturation.

| Component | Description |

|---|---|

| Reservoir | A container that holds the coloring fluid, providing a reliable source for the system. |

| Pump | Mechanism that moves the fluid from the reservoir to the dispensing units, ensuring proper pressure and flow rate. |

| Hoses and Tubing | Flexible channels that transport the fluid between various components, designed to minimize leakage and contamination. |

| Print Head | Critical component that applies the fluid onto the medium, controlling the release of the fluid for accurate image reproduction. |

| Filter | Device that removes impurities from the fluid before it reaches the print head, ensuring clear and consistent output. |

Ensuring Consistent Print Quality

Achieving reliable output quality is vital for any printing operation, particularly when precision and detail are paramount. A systematic approach to maintenance and care can significantly enhance the longevity of the equipment and the accuracy of printed materials. Implementing best practices for upkeep not only contributes to optimal performance but also minimizes the likelihood of errors during the printing process.

Regular Maintenance Practices

Routine inspections and cleaning of the printing mechanism play a crucial role in sustaining print quality. Periodically checking for dust, debris, and wear on moving parts helps ensure smooth operation. Additionally, recalibrating the machine as recommended by the manufacturer can maintain alignment and color accuracy, resulting in vibrant and precise prints.

Using Quality Consumables

The selection of high-grade materials, such as inks and media, directly influences the final output. Utilizing compatible and high-quality supplies reduces the risk of clogs and inconsistencies. Furthermore, keeping an inventory of essential items ensures that the printing process remains uninterrupted, promoting a steady flow of production.

Power Management and Circuit Layout

This section delves into the essential aspects of energy regulation and the organization of electrical pathways within a particular system. Effective management of energy consumption and optimal arrangement of circuit components are crucial for enhancing performance and reliability. Understanding these elements allows for improved functionality and longevity of the overall assembly.

Energy Distribution Strategies

The distribution of energy within electronic systems is paramount. Properly configured circuits ensure that power is allocated efficiently, minimizing waste and preventing overheating. Several strategies can be employed to achieve optimal energy management, including the use of voltage regulators and power supply modules.

Circuit Configuration Techniques

When designing the layout of electrical pathways, various techniques are applied to facilitate efficient operation. A well-organized circuit can significantly reduce interference and enhance signal integrity. Utilizing layered designs and careful placement of components can lead to improved performance and simpler troubleshooting processes.

| Component | Function | Importance |

|---|---|---|

| Voltage Regulator | Maintains stable output voltage | Prevents damage from voltage fluctuations |

| Capacitor | Stores and releases energy | Helps smooth out voltage variations |

| Fuse | Protects against overcurrent | Ensures safety and prevents circuit damage |

Identifying Key Electrical Components

Understanding the essential electrical elements within a large-format printing device is crucial for optimal performance and troubleshooting. Recognizing these components allows users to maintain functionality and address potential issues effectively.

Main Electrical Elements

- Power Supply Unit: This component delivers the necessary electrical energy to all parts of the system.

- Control Board: The central hub for managing operations and communication between various elements.

- Stepper Motors: These devices drive the movement of the printing head and paper feed, ensuring precision in printing.

- Sensors: Various sensors monitor paper position, ink levels, and other critical parameters, facilitating smooth operation.

- Wiring Harness: A network of cables that connects and transmits power and signals between different components.

Importance of Component Identification

Being able to identify these key electrical components aids in performing routine maintenance and repairs. Familiarity with each element’s location and function contributes to enhanced troubleshooting efficiency and prolongs the life of the device.

Connectivity Ports and Data Interfaces

This section explores the various communication access points and data transfer mechanisms that facilitate the interaction between the device and external systems. Understanding these interfaces is crucial for optimizing performance and ensuring seamless connectivity with peripheral equipment.

Devices typically feature a range of connection types, enabling versatile integration with different technologies. Common ports include those designed for wired connections, allowing direct interaction with computers and other machinery. Additionally, wireless options provide flexibility, catering to modern operational needs and minimizing cable clutter.

Data transmission is often governed by specific protocols, ensuring reliable information exchange. These protocols dictate the manner in which data packets are formatted and sent, impacting the speed and efficiency of communication. Familiarity with these standards can greatly enhance troubleshooting and maintenance efforts, leading to improved overall functionality.

Incorporating multiple connectivity options can enhance the device’s adaptability to varying workflows. Whether it’s through USB, Ethernet, or alternative means, ensuring compatibility with diverse devices fosters a more dynamic operational environment, allowing for the incorporation of innovative solutions.