In the realm of agricultural and industrial equipment, comprehending the layout of various components is crucial for maintenance and repair. A well-structured representation of individual elements can significantly enhance the efficiency of troubleshooting processes. This visual guide serves as a valuable resource for operators and mechanics alike, enabling them to identify and locate essential parts swiftly.

Effective maintenance relies on a clear understanding of how each segment interconnects within the larger framework of machinery. By exploring a detailed schematic, users can gain insights into the arrangement and function of specific units, which ultimately aids in performing repairs with confidence. Knowing where each piece fits not only streamlines the service process but also minimizes downtime.

Furthermore, familiarizing oneself with these representations can lead to improved operational safety. Recognizing potential wear points or failure zones becomes more straightforward when one has access to a comprehensive layout. This proactive approach ensures that all components function harmoniously, thereby extending the lifespan of the equipment and enhancing productivity.

Understanding Kubota T1400H Components

Exploring the intricate elements of machinery is essential for grasping its overall functionality and efficiency. Each component plays a vital role in the operation, contributing to the seamless performance of the equipment. Recognizing how these parts interact can significantly enhance maintenance practices and troubleshooting efforts.

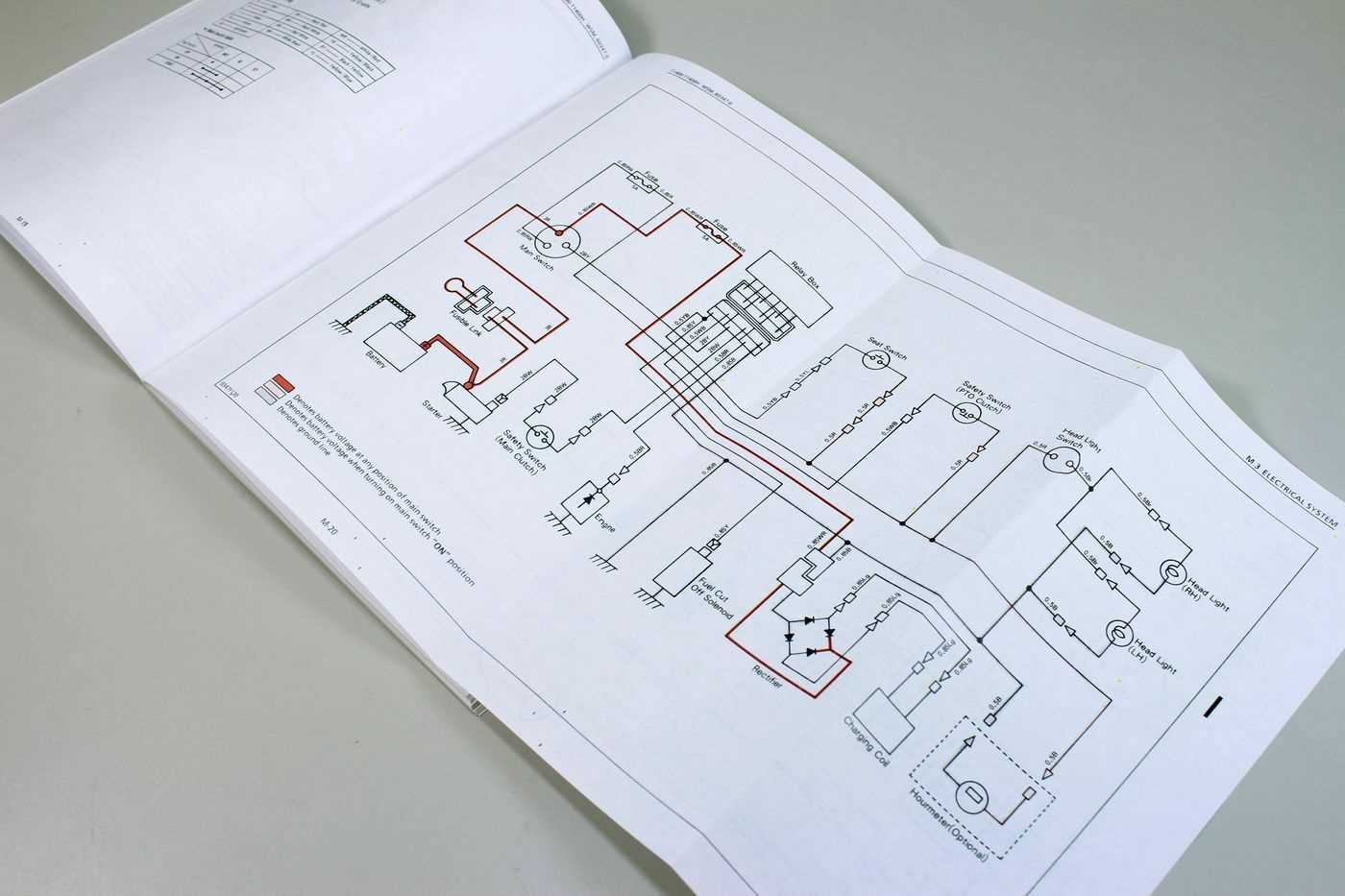

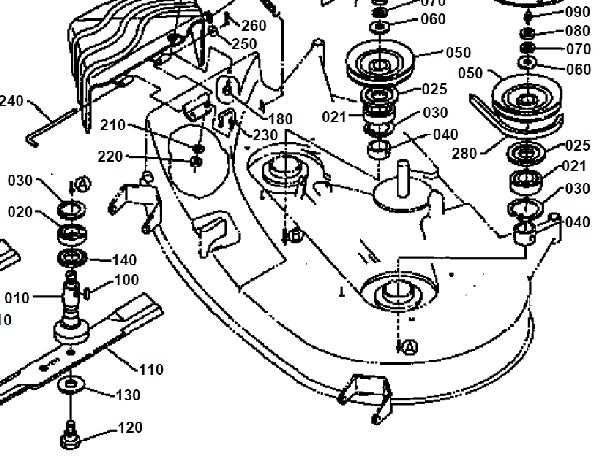

Key sections include the powertrain, which drives performance, and the steering mechanism, which ensures maneuverability. The hydraulic system is crucial for facilitating various operations, while the electrical components govern control and functionality. A comprehensive understanding of these segments aids in optimizing both performance and longevity.

Moreover, familiarity with the specific functions of each element allows for timely identification of issues, leading to effective solutions. This knowledge ultimately empowers users to maintain their equipment in peak condition, ensuring reliability in every task.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, enabling users to identify each element and comprehend how they fit together. This knowledge streamlines troubleshooting and ensures that replacements are accurately sourced.

Enhanced Clarity

Visual aids provide clarity that textual descriptions often lack. They help users quickly locate specific elements, making it easier to assess conditions and identify issues. This can significantly reduce downtime during maintenance tasks.

Efficiency in Repairs

Having a visual reference accelerates the repair process. Users can follow step-by-step procedures with greater confidence, leading to quicker resolutions and improved operational efficiency.

| Benefit | Description |

|---|---|

| Improved Understanding | Facilitates better comprehension of the machine’s structure. |

| Faster Troubleshooting | Enables quicker identification of problems. |

| Accurate Sourcing | Aids in finding the correct replacement components. |

Common Issues with Kubota T1400H

Understanding the typical challenges faced by users of this particular machine can enhance maintenance and improve performance. Many owners encounter similar problems that can often be traced back to specific components or operating conditions.

Engine Performance

One of the primary concerns involves the engine, which may exhibit issues such as reduced power or stalling. These symptoms can result from fuel quality, air intake obstructions, or ignition problems.

Hydraulic System Failures

The hydraulic system is crucial for operation and can face various difficulties, including leaks and poor responsiveness. Regular inspection of hoses and fluid levels is essential to mitigate these issues.

| Issue | Potential Cause | Solution |

|---|---|---|

| Reduced power | Poor fuel quality | Use high-quality fuel |

| Stalling | Air intake blockage | Clean air filters |

| Hydraulic leaks | Worn hoses | Replace damaged hoses |

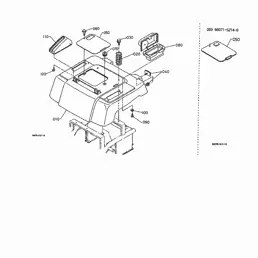

How to Read Parts Diagrams

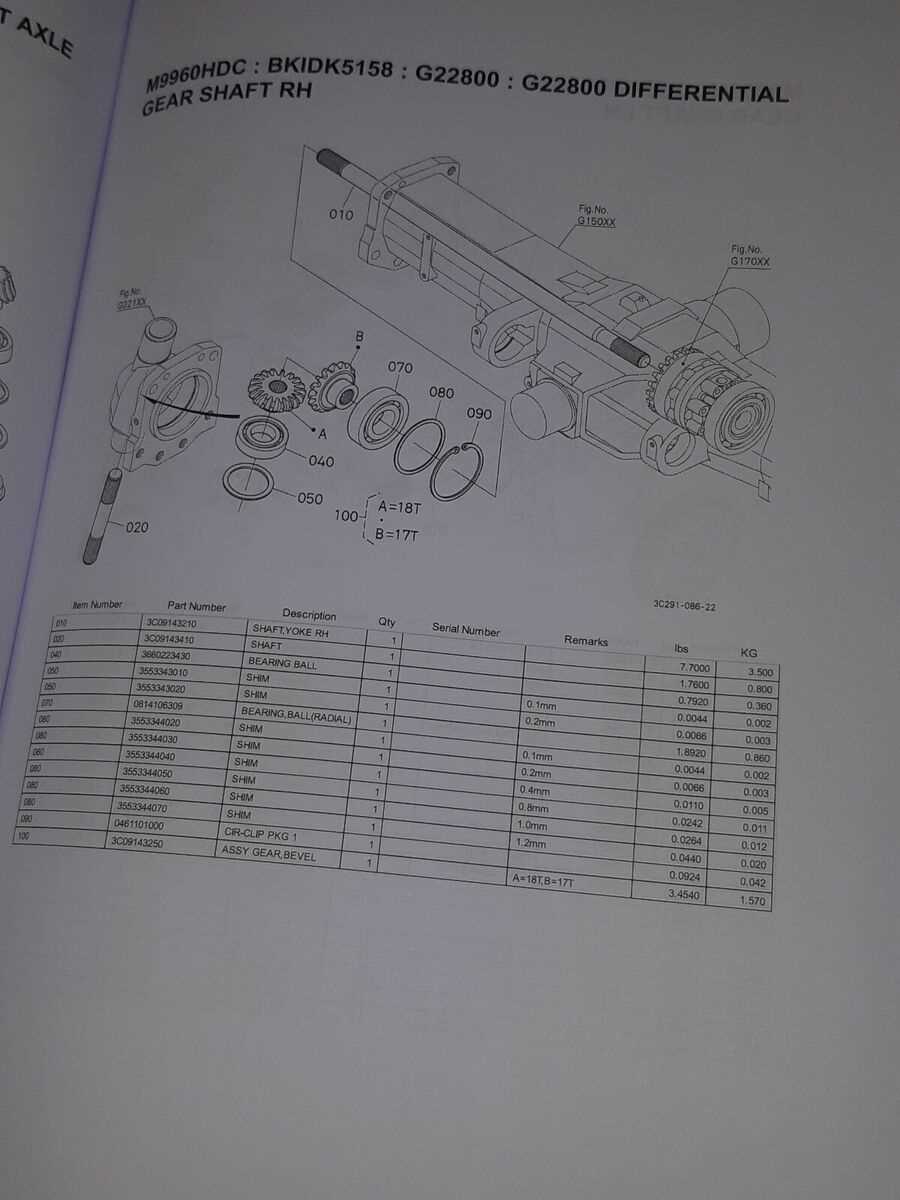

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear overview of various elements, their interconnections, and specific details that aid in identifying necessary replacements.

When examining these visuals, consider the following key aspects:

| Aspect | Description |

|---|---|

| Legend | Look for symbols that explain the meaning of various markings and codes. |

| Numbering | Check the numerical references that correspond to the components, which simplify ordering and identification. |

| Sections | Note how the illustration is divided into segments, each representing a different area of the assembly. |

| Orientation | Pay attention to the direction and layout, ensuring you understand how parts fit together. |

By mastering these elements, you can efficiently interpret these essential visuals and streamline your repair process.

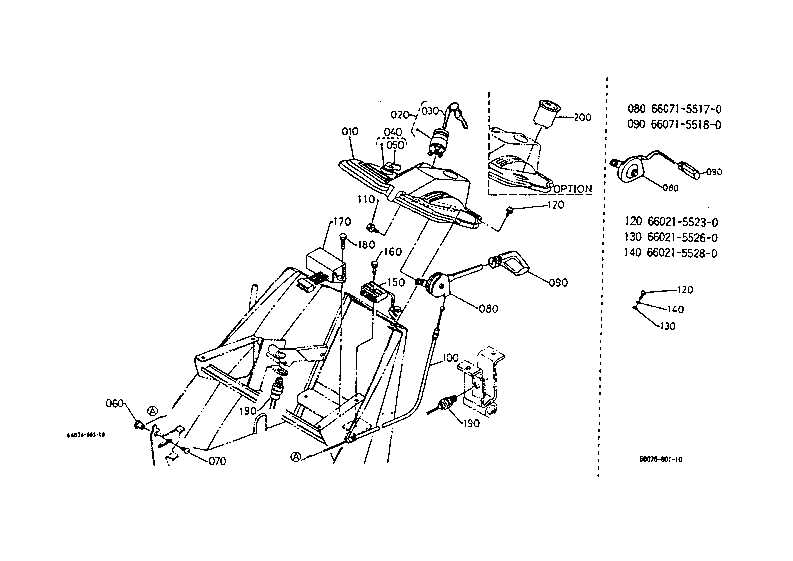

Identifying Key Components

Understanding the essential elements of machinery is crucial for effective maintenance and operation. Recognizing these components allows users to troubleshoot issues and ensure optimal performance.

- Engine: The heart of the machine, providing necessary power.

- Transmission: Responsible for transferring power from the engine to the wheels.

- Hydraulic System: Enables various functions through fluid power.

- Chassis: The frame that supports all other components.

Familiarity with these parts enhances understanding and promotes efficient upkeep.

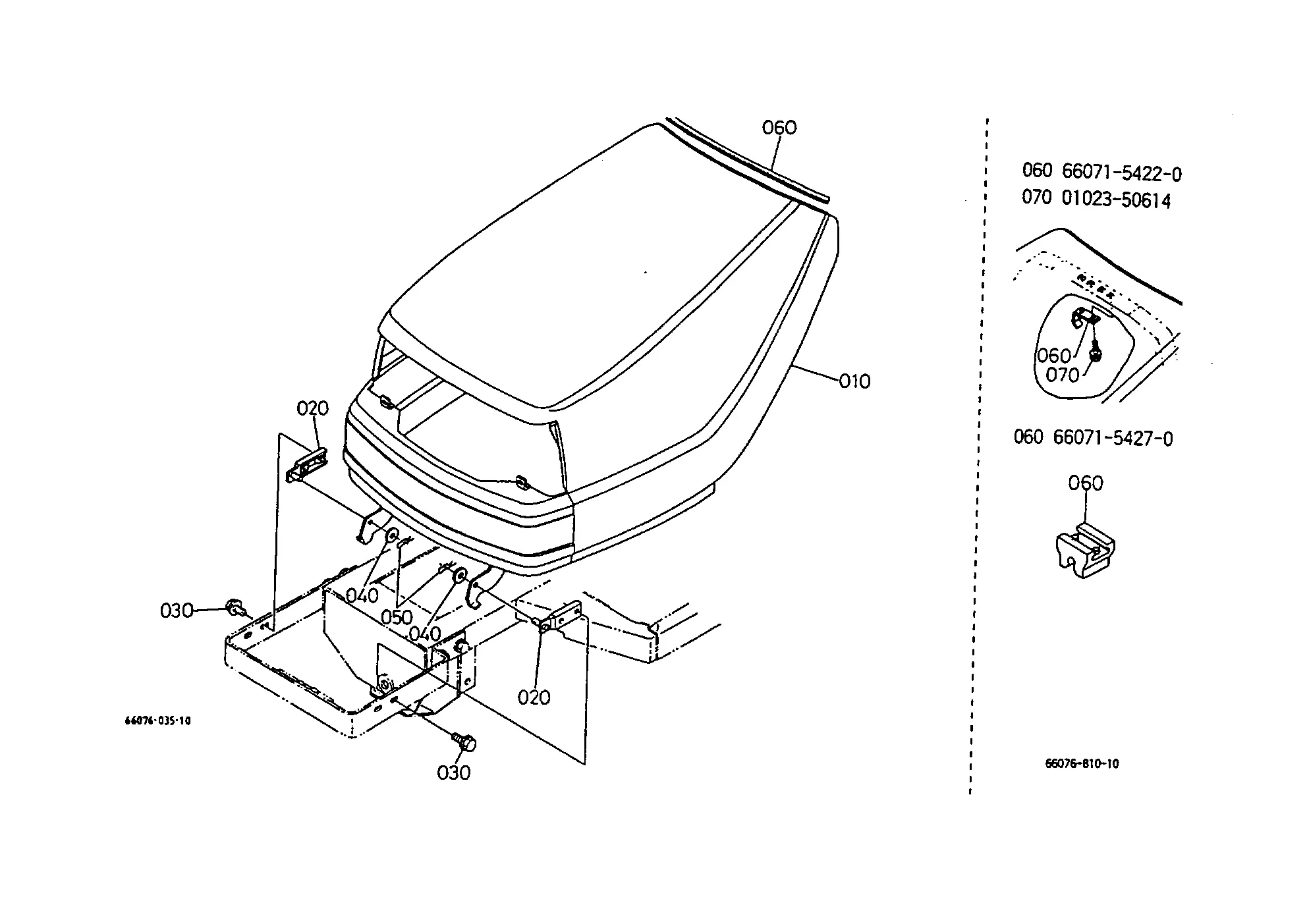

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. By implementing effective maintenance strategies, you can significantly extend the lifespan of your equipment while optimizing its performance. A proactive approach not only prevents potential issues but also enhances overall productivity.

Regular Inspection and Cleaning

Conducting routine inspections allows you to identify wear and tear before they escalate into serious problems. Check all components for signs of damage or deterioration. Regular cleaning is equally important, as debris and dirt can hinder functionality. Focus on key areas where dust and grime tend to accumulate, ensuring everything operates smoothly.

Timely Lubrication and Fluid Checks

Proper lubrication is crucial for minimizing friction and preventing premature wear. Follow the manufacturer’s guidelines for oil changes and fluid levels. Regularly check hydraulic fluids, engine oil, and other essential liquids to ensure optimal performance. Keeping these fluids at the recommended levels not only enhances efficiency but also protects vital components from damage.

Where to Find Replacement Parts

Finding suitable components for your machinery is essential for maintaining its efficiency and longevity. Whether you are looking for OEM options or aftermarket alternatives, there are several reliable sources to consider when searching for the right items to restore your equipment to optimal working condition.

Authorized Dealers

One of the most dependable avenues for sourcing components is through authorized dealerships. These establishments often carry a comprehensive inventory of genuine items, ensuring quality and compatibility. Engaging with a local dealer allows you to receive expert advice and assistance in identifying the correct pieces for your specific model.

Online Retailers and Marketplaces

The internet offers a plethora of options for acquiring components. Reputable online retailers provide vast catalogs and user reviews, making it easier to compare choices. Additionally, large marketplaces facilitate transactions between individual sellers and buyers, often featuring competitive pricing. However, it’s important to verify the credibility of the sellers to avoid counterfeit or subpar products.

In summary, whether you opt for local dealerships or online platforms, a thoughtful approach to sourcing essential components can significantly enhance your machinery’s performance and lifespan.

Upgrading Your T1400H Model

Enhancing the performance of your machinery can lead to improved efficiency and longevity. By focusing on specific components and features, you can significantly elevate its capabilities, ensuring a smoother operation and greater productivity in the field.

Key Components to Consider

When contemplating upgrades, pay attention to essential elements such as the engine, transmission, and hydraulic systems. Upgrading these parts not only boosts power but also enhances responsiveness and overall functionality. Additionally, investing in quality attachments can expand your machine’s versatility, allowing it to tackle a wider range of tasks.

Benefits of Upgrading

Implementing enhancements can lead to increased reliability and reduced maintenance costs. By upgrading to high-quality components, you ensure better performance and can enjoy a more enjoyable user experience. Furthermore, an upgraded model often retains higher resale value, making it a wise investment for the future.

Comparison with Other Kubota Models

This section explores the unique features and functionalities of various agricultural machinery, focusing on how one specific model stands out against its counterparts. Understanding these differences can help users make informed decisions based on their specific needs and operational requirements.

When comparing models, factors such as engine power, efficiency, and maintenance ease become essential. For instance, while some variants may excel in maneuverability, others might offer superior durability or advanced technology integrations. Evaluating these aspects allows potential users to pinpoint which equipment aligns best with their farming practices.

Additionally, performance metrics, such as fuel consumption and load capacity, can significantly vary between models. This diversity means that specific machinery can be better suited for different tasks, whether it be heavy-duty farming or precision gardening. Analyzing these elements enables a comprehensive understanding of available options.

Ultimately, assessing how each piece of equipment compares can guide users toward choosing the right machine that enhances productivity while meeting their operational goals effectively.

DIY Repairs and Troubleshooting

Engaging in do-it-yourself repairs can significantly enhance your understanding of machinery while saving time and money. By addressing common issues yourself, you not only become more self-reliant but also gain insight into the inner workings of your equipment. This section will guide you through basic troubleshooting techniques and repair strategies to help maintain optimal performance.

Common Issues and Solutions

One of the most frequent challenges users encounter is engine starting failure. To troubleshoot, first check the fuel level and battery connections. Ensure that all switches are in the correct position. If the engine still won’t start, inspect the ignition system for faults.

Preventive Maintenance Tips

Regular upkeep can prevent many problems from arising. Clean air filters and check oil levels routinely. Inspect belts and hoses for wear and tear, replacing them as necessary. Keeping a maintenance log can also help you track your efforts and identify any recurring issues.

Resources for Further Learning

For those looking to deepen their understanding of machinery components and maintenance, a wealth of resources is available. These materials can enhance both practical skills and theoretical knowledge, helping enthusiasts and professionals alike to navigate complex systems effectively.

Below is a table highlighting various types of resources, including books, online courses, and forums, that can serve as valuable tools in your learning journey.

| Resource Type | Description | Link/Source |

|---|---|---|

| Books | Comprehensive guides covering machinery operation and repair techniques. | Find Books |

| Online Courses | Structured learning modules that cover various aspects of machinery maintenance. | Explore Courses |

| Forums | Community-driven platforms for sharing knowledge and troubleshooting advice. | Join Forums |

| Videos | Tutorials and demonstrations on machinery handling and repairs. | Watch Videos |