The intricate design of automotive systems involves numerous essential elements that work harmoniously to ensure optimal performance. An in-depth exploration of these components reveals their unique roles and the importance of each part in maintaining efficiency and reliability.

For enthusiasts and professionals alike, grasping the layout and function of these mechanisms is crucial. By examining detailed schematics, one can identify how various units interact, facilitating a deeper comprehension of automotive engineering.

Ultimately, this knowledge empowers individuals to make informed decisions regarding maintenance and upgrades, enhancing the longevity and capability of vehicles. A comprehensive grasp of these intricate systems serves as the foundation for any successful endeavor in automotive care.

Understanding Delphi DP200 Components

Grasping the intricacies of these mechanical elements is essential for optimal functionality and maintenance. Each component plays a pivotal role in the overall system, contributing to its efficiency and reliability.

Key Elements

- Fuel Pump: Ensures proper fuel delivery to the engine.

- Injectors: Atomize fuel for efficient combustion.

- Filters: Keep contaminants at bay, prolonging system life.

Functionality Overview

- Fuel Supply: Components work together to maintain a steady fuel flow.

- Combustion Efficiency: Precision in injector function enhances performance.

- Maintenance: Regular checks on filters and pumps can prevent failures.

Overview of Delphi DP200 Functionality

This section explores the capabilities and features of a specific fuel management system designed to optimize engine performance and efficiency. The technology integrates various components to ensure precise control over fuel delivery and enhance overall vehicle operation.

At the core of this system lies an advanced control unit that monitors real-time data from multiple sensors. This information is processed to adjust fuel injection rates, ensuring optimal combustion and reducing emissions. The system’s ability to adapt to changing conditions plays a crucial role in maintaining engine responsiveness and reliability.

| Feature | Description |

|---|---|

| Fuel Injection Control | Ensures accurate timing and quantity of fuel delivered to the engine, enhancing efficiency. |

| Real-time Monitoring | Continuously tracks performance metrics and adjusts parameters to optimize operation. |

| Emissions Reduction | Minimizes harmful outputs through improved combustion processes. |

| Adaptability | Adjusts settings based on driving conditions, ensuring consistent performance. |

Understanding the functionalities of this innovative system is essential for those involved in vehicle maintenance and performance enhancement. Its integration of technology not only improves engine output but also contributes to environmental sustainability.

Common Issues with DP200 Parts

Understanding the frequent challenges associated with various components is essential for maintaining optimal performance and longevity. These difficulties can arise from manufacturing defects, wear and tear, or improper installation, leading to significant operational issues.

Wear and Tear

Components often experience gradual degradation due to prolonged use, which can manifest in reduced efficiency or malfunction. Regular inspections can help identify these issues early, preventing more extensive damage.

Installation Errors

Incorrect installation can lead to misalignment or improper functioning. It’s crucial to follow guidelines carefully to ensure all elements work together seamlessly, thereby avoiding unnecessary complications.

Benefits of Using Genuine Parts

Opting for original components in maintenance and repairs can greatly enhance the overall performance and longevity of machinery. While alternatives may seem attractive due to lower costs, the advantages of using authentic items far outweigh any initial savings.

Quality Assurance

Genuine components are manufactured to stringent quality standards, ensuring that they meet the specifications set by the original equipment manufacturer. This commitment to quality offers several benefits:

- Improved performance and reliability

- Consistent durability over time

- Enhanced compatibility with existing systems

Cost-Effectiveness

While the upfront cost may be higher, using authentic items can lead to significant savings in the long run. Here’s how:

- Reduced frequency of replacements due to superior durability

- Lower repair costs associated with fewer breakdowns

- Increased resale value of equipment that uses original components

In conclusion, investing in genuine items not only supports optimal functionality but also contributes to long-term financial benefits and peace of mind.

Key Features of the DP200 Model

This section highlights the standout characteristics of the advanced model, emphasizing its innovative design and operational efficiency. Understanding these features provides insight into its effectiveness and versatility in various applications.

- Robust Construction: Engineered with high-quality materials to ensure durability and reliability under challenging conditions.

- Efficiency: Optimized for performance, resulting in lower operational costs and reduced environmental impact.

- User-Friendly Interface: Intuitive controls that simplify operation, making it accessible for users of all skill levels.

- Advanced Technology: Incorporates cutting-edge systems for improved functionality and precision.

- Versatile Applications: Suitable for a wide range of uses, enhancing its appeal in various industries.

These features collectively contribute to the model’s reputation as a reliable and efficient choice for professionals seeking high-performance equipment.

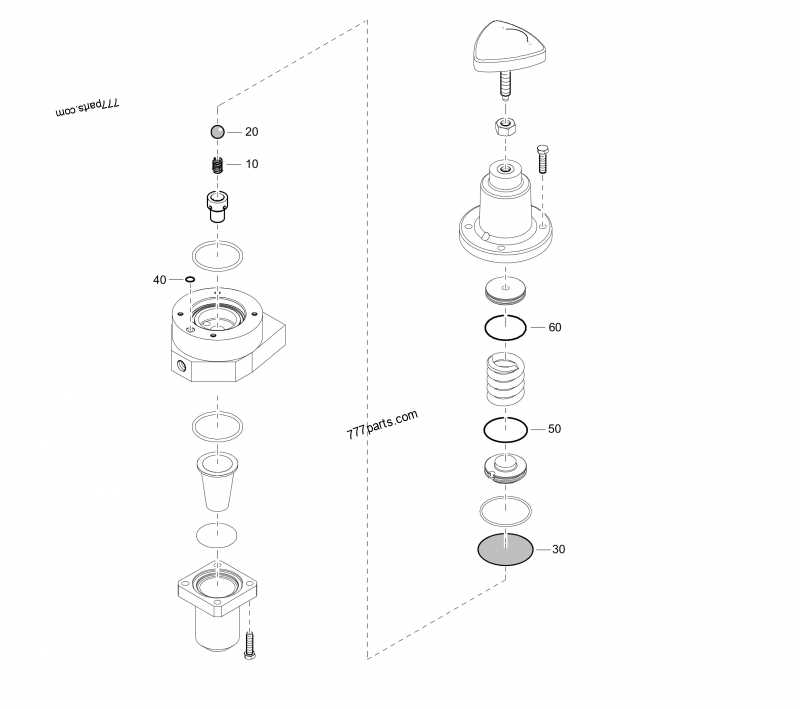

How to Read Parts Diagrams

Understanding the layout and components of a technical illustration is essential for effective maintenance and repair. This section aims to guide you through the process of interpreting these visuals, enabling you to identify and locate each element with confidence.

Key Elements to Look For

When analyzing these visuals, focus on specific symbols and notations. Each component is typically labeled, and you’ll often find a legend that explains these markings.

Tips for Interpretation

Take your time to familiarize yourself with the various sections of the illustration. Cross-reference with technical manuals for additional clarity, ensuring a comprehensive understanding of the assembly.

| Symbol | Description |

|---|---|

| A | Connector type |

| B | Fastening point |

| C | Assembly sequence |

Maintenance Tips for Delphi DP200

Regular upkeep of automotive components is essential for optimal performance and longevity. Implementing systematic maintenance practices can prevent common issues, enhance efficiency, and ensure safe operation. Here are some crucial recommendations to keep your system in peak condition.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct frequent checks to identify wear and tear, ensuring all components function correctly. |

| Fluid Changes | Replace fluids at recommended intervals to maintain proper lubrication and cooling properties. |

| Component Cleaning | Keep all parts free of dirt and debris to prevent blockages and reduce wear. |

| Software Updates | Ensure that any electronic systems have the latest software to enhance performance and fix bugs. |

| Professional Servicing | Schedule regular visits to a qualified technician for comprehensive inspections and repairs. |

Replacement Procedures for DP200 Parts

Maintaining optimal performance in your equipment involves understanding the steps necessary for substituting components effectively. Proper procedures ensure that new elements fit seamlessly, minimizing downtime and enhancing reliability. This section outlines the essential practices to follow when replacing specific elements, highlighting critical points and offering guidance for a successful transition.

Preparation Steps

Before initiating the replacement process, ensure you have the appropriate tools and components ready. It’s vital to create a clean workspace to prevent contamination and damage. Begin by disconnecting power and removing any barriers to access the area needing attention. Documentation of the existing setup can aid in reassembly.

Replacement Process

Follow these steps for effective substitution:

| Step | Description |

|---|---|

| 1 | Remove the old component carefully, noting the orientation and connections. |

| 2 | Clean the mounting surface to ensure proper adhesion and fit for the new element. |

| 3 | Install the new component, making sure it aligns with the existing configuration. |

| 4 | Reconnect any wiring or attachments, double-checking for secure connections. |

| 5 | Conduct a thorough inspection to confirm the installation meets specifications. |

Following these guidelines will enhance the longevity and efficiency of your system, ensuring it operates at peak performance.

Identifying Part Numbers in Diagrams

Understanding the various components and their associated identifiers is crucial for effective troubleshooting and maintenance. This section explores the methods used to recognize specific codes within illustrative representations, enabling users to locate the necessary elements swiftly.

When navigating these visual aids, consider the following strategies:

- Color Coding: Many illustrations utilize color differentiation to group similar items. Pay attention to these hues as they often signify related components.

- Label Placement: Identifiers are frequently positioned near their respective elements. Familiarize yourself with the layout to enhance your recognition skills.

- Numbering Systems: Sequential numbering is a common practice. Understanding the numbering logic can assist in quickly locating specific items.

- Reference Keys: Often, a reference key is provided, correlating identifiers with detailed descriptions. Always check for this tool, as it can save time.

By applying these techniques, users can navigate complex visuals with confidence and precision, facilitating a more efficient approach to component management.

Common Upgrades for the DP200

Enhancing the performance and reliability of a particular engine component can significantly improve overall vehicle efficiency. Various modifications can be undertaken to optimize functionality, boost power output, and ensure a smoother driving experience. Understanding these upgrades can help enthusiasts and professionals make informed decisions to enhance their systems.

Performance Enhancements

One of the most sought-after improvements involves upgrading the fuel injection system. This can lead to better fuel atomization and increased power. Additionally, installing a higher-flow fuel pump may provide the necessary fuel volume for more demanding applications. Moreover, tuning the engine management software can maximize performance by adjusting parameters such as air-fuel ratios and ignition timing.

Durability and Reliability Improvements

To ensure longevity and dependability, many users opt for reinforced components. Upgrading to more robust seals and gaskets can help prevent leaks and maintain optimal pressure. Furthermore, utilizing high-quality filters can protect sensitive parts from contaminants, prolonging their lifespan. Regular maintenance practices, combined with these enhancements, can lead to a significant reduction in the risk of failures.

Expert Recommendations for Troubleshooting

When faced with operational challenges, having a systematic approach is crucial for effective resolution. This section provides insights that can guide users through common issues, helping to restore functionality efficiently.

Identify Common Issues

- Check for unusual noises or vibrations.

- Inspect fluid levels and potential leaks.

- Monitor performance metrics for anomalies.

Step-by-Step Troubleshooting

- Begin by isolating the problem area.

- Refer to technical manuals for specific guidance.

- Utilize diagnostic tools to gather data.

- Replace any faulty components identified during checks.

- Test the system thoroughly after repairs.

Resources for Further Learning

Expanding your knowledge in the field of automotive components and their intricacies can significantly enhance your skills and understanding. Here are various resources that can guide you through the essentials and advanced concepts related to these intricate systems.

-

Online Courses:

- Platforms like Coursera and Udemy offer courses on automotive engineering and design.

- Look for specialized programs that focus on mechanical systems and electronic integrations.

-

Books:

- “Automotive Technology: A Systems Approach” provides comprehensive coverage of various automotive systems.

- “Understanding Automotive Electronics” delves into the electronic aspects of modern vehicles.

-

Technical Journals:

- Access journals such as the “Journal of Automotive Engineering” for the latest research and developments.

- Explore articles on mechanical innovations and their applications in the industry.

-

Forums and Online Communities:

- Join platforms like Reddit or specialized automotive forums to engage with professionals and enthusiasts.

- Participate in discussions to share knowledge and troubleshoot common challenges.

-

Webinars and Workshops:

- Attend virtual workshops that focus on new technologies and methodologies in the automotive sector.

- Seek out webinars hosted by industry experts to gain insights into current trends.

Utilizing these resources can empower you to deepen your expertise and stay updated in this ever-evolving field.