When maintaining or repairing mechanical equipment, it is crucial to have a clear overview of its internal organization. This allows for easier identification of key elements and ensures efficient troubleshooting. Whether you are performing regular upkeep or addressing specific issues, having an organized reference helps streamline the process.

Every machine is built from numerous interconnected elements, each playing a specific role in its overall function. These components need to work in harmony to ensure smooth operation. A detailed view of these elements provides valuable insight into their arrangement and how they interact with each other.

Understanding the layout of these elements is essential for anyone involved in maintaining or servicing the equipment. Having access to well-organized data about the machine’s structure allows for accurate problem diagnosis, helping users quickly identify areas that require attention and providing a clear path to resolution.

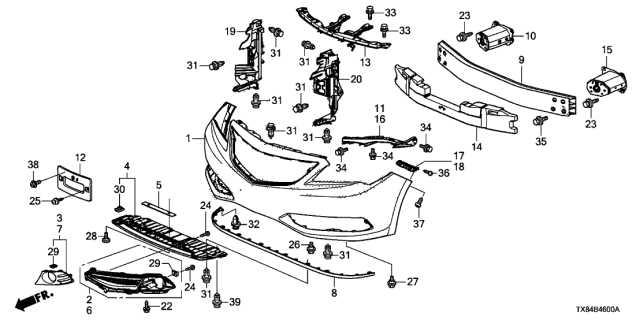

Understanding the 11a-a2rq563 Parts Layout

In this section, we will explore how the various elements within the assembly are arranged and interact with each other. By examining the layout, one can gain a deeper understanding of how each element contributes to the overall functionality. Understanding the design and positioning is crucial for maintenance, repairs, or upgrades.

Key Components Overview

- Primary mechanical elements responsible for movement and operation.

- Structural supports that ensure stability and alignment.

- Fasteners and connectors holding the entire configuration together.

Arrangement and Interaction

The layout is carefully designed to optimize efficiency and reliability. Each element has a specific position that ensures smooth operation and minimizes wear over time.

- Main structure forms the base for all interconnected pieces.

- Functional elements are aligned to facilitate seamless operation.

- Connections between moving parts are designed for easy adjustment and replacement.

Key Components of the 11a-a2rq563 Model

The internal structure of this model is built around a series of crucial elements, each playing a vital role in its overall operation. Understanding these essential components will help you maintain and troubleshoot the unit more efficiently. Below, we will explore the main elements that contribute to its functionality and durability.

Core Mechanical Elements

At the heart of this system lies the engine assembly, responsible for powering the entire mechanism. It is complemented by a set of transmission elements that ensure the efficient transfer of energy to other parts. Additionally, the frame and support structure provide the necessary stability, allowing the unit to operate smoothly under various conditions.

Auxiliary Systems

Beyond the primary mechanical systems, auxiliary components play a supporting role. These include control mechanisms, which allow for precise operation, and safety features designed to protect both the machine and the operator. Together, these systems ensure optimal performance and extended longevity.

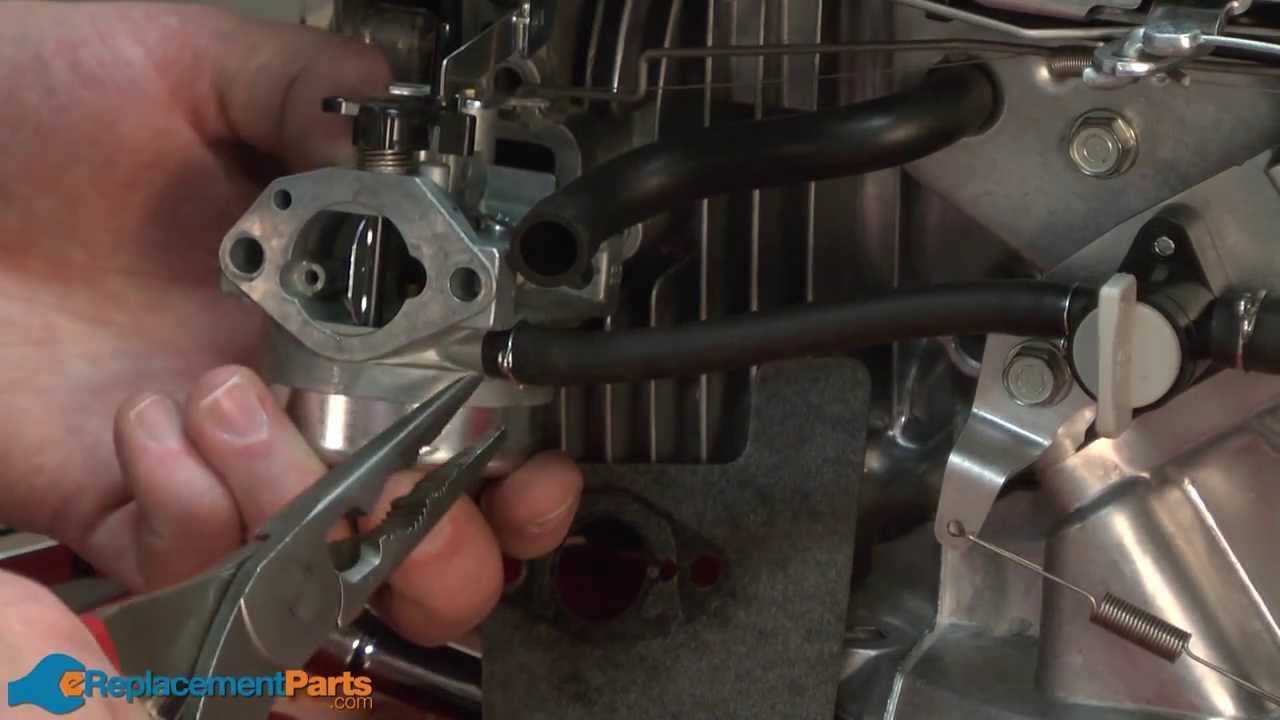

Engine Assembly Breakdown for 11a-a2rq563

The engine unit is a complex system of interconnected components that work in harmony to generate power. Understanding how each part functions within the system is key to maintaining its efficiency and ensuring longevity. This section provides a detailed look at the main elements that form the core of the engine, offering a comprehensive overview of their roles and relationships.

Key Components of the Engine

Several crucial elements come together to ensure the engine operates smoothly. These include the cylinder block, which houses the moving parts, and the crankshaft, responsible for converting linear motion into rotational energy. Each of these parts plays a vital role in the overall operation, and their precise interaction is what keeps the engine running efficiently.

Assembly and Function

The assembly of the engine follows a methodical process, ensuring that every part fits perfectly within its designated space. From the positioning of the pistons within the cylinder to the alignment of the valves and camshaft, each step is essential. The careful construction ensures the smooth transfer of energy, ultimately powering the machine with consistent performance.

Drive System Elements and Functions

The drive system is a crucial component responsible for transferring power to the moving parts of a machine, ensuring its efficient operation. Understanding the roles and interplay of various mechanical elements within this system is key to maintaining optimal performance.

| Component |

Function |

| Engine |

Generates the initial power required for movement and overall operation. |

| Transmission |

Adjusts the power output to ensure smooth operation across various speeds. |

| Drive Belt |

Connects the engine to the transmission, transferring power efficiently between components. |

| Axle |

Transfers rotational force from the transmission to the wheels, enabling movement. |

| Wheels |

Blade Mechanism and Its Parts

The cutting mechanism plays a crucial role in ensuring the effective functioning of lawn maintenance equipment. It is designed to deliver precision and durability, making it an essential component in the cutting process. This system consists of various elements working together to provide clean and accurate results.

Blade Assembly: At the core of the mechanism is the blade assembly, which is responsible for the actual cutting. Its design allows for both sharpness and balance, ensuring that grass is cut evenly without causing damage to the equipment.

Mounting Hub: The blade is securely attached to the central hub, which serves as the connection between the motor and the cutting surface. This ensures stability during operation, preventing unwanted vibrations that could lead to wear and tear.

Rotation Mechanism: The rotation system is driven by the motor, enabling the blade to spin at high speeds. Its efficiency determines the overall performance, ensuring that the equipment can handle various types of grass and terrain with ease.

Safety Guard: To protect both the user and the equipment

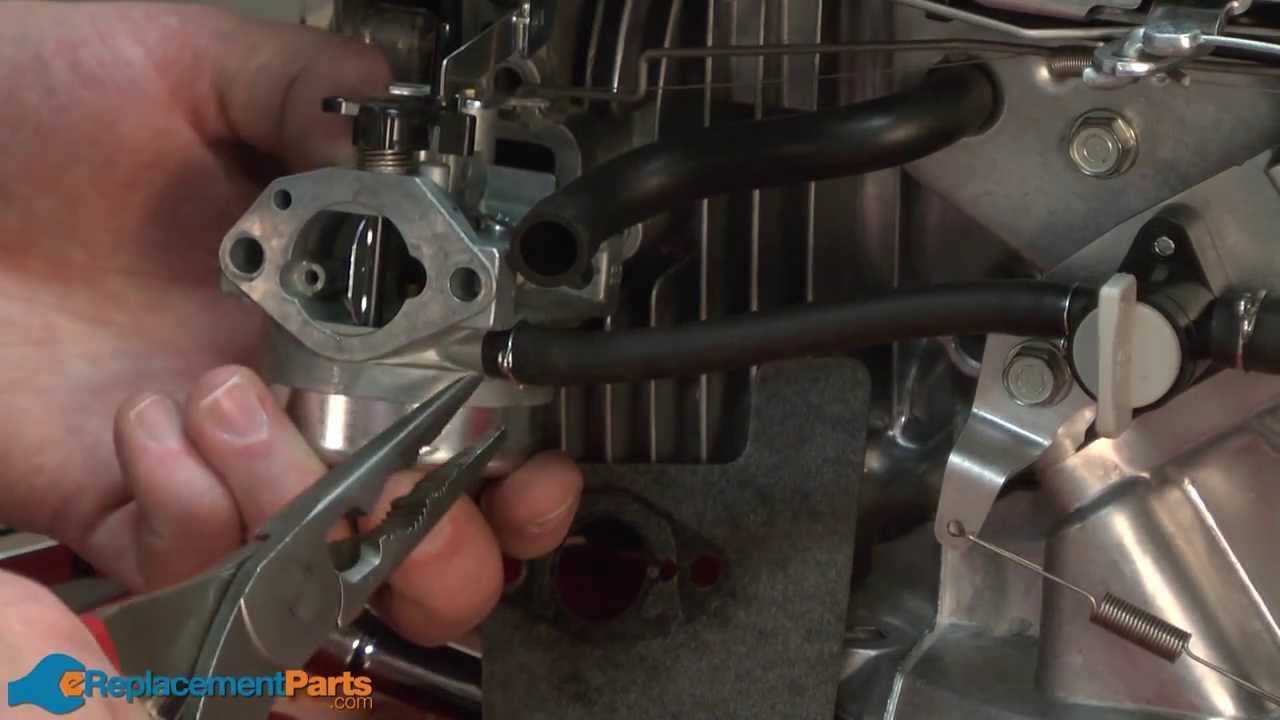

Fuel System Structure and Components

The fuel system is designed to efficiently deliver fuel to the engine, ensuring optimal performance and power output. Each element of the system works in harmony to transport fuel from the storage tank to the engine, where it is combined with air for combustion. The components must function seamlessly to maintain engine efficiency and reduce emissions.

| Component |

Function |

| Fuel Tank |

Stores fuel and supplies it to the rest of the system. |

| Fuel Pump |

Pressurizes and pushes fuel through the lines to the engine. |

| Fuel Filter |

Removes impurities and debris from the fuel before it reaches the engine. |

| Fuel Injectors |

Spray fuel into the engine’s combustion chambers in a precise manner for efficient burning. |

| Fuel Lines |

Transport fuel from the tank to the engine components. |

Transmission and Clutch Parts Overview

The transmission and clutch are crucial elements in ensuring efficient power transfer between the engine and wheels. Their interaction enables smooth gear shifts and effective control of vehicle movement, optimizing performance during acceleration and deceleration.

Below is a breakdown of the primary components involved in this system:

- Clutch Disc: Facilitates the engagement and disengagement of power from the engine to the transmission.

- Pressure Plate: Applies pressure to the clutch disc to ensure firm contact with the flywheel during operation.

- Flywheel: Provides a surface for the clutch disc to press against and stores rotational energy.

- Transmission Gears: Responsible for adjusting the speed and torque delivered to the wheels.

- Synchronizers: Assist in smooth gear shifting by aligning the speed of the gears during transitions.

- Throwout Bearing: Engages and disengages the clutch by applying pressure to the pressure plate.

- Shift Fork: Moves the throwout bearing and helps in disengaging the clutc

Electrical Wiring and Circuit Details

This section delves into the intricacies of electrical connections and circuit layouts that play a pivotal role in the functionality of the system. Understanding how components are interconnected is essential for troubleshooting and optimizing performance.

Wiring Configurations: The arrangement of wires determines the flow of electricity throughout the device. Each wire must be correctly positioned to ensure effective transmission and minimize potential failures. Proper insulation and routing of cables prevent short circuits and other electrical hazards.

Component Interactions: The way various elements interact within the circuitry can affect overall efficiency. Key components, such as resistors, capacitors, and switches, should be carefully integrated to achieve the desired functionality. Understanding their roles and how they influence one another is crucial for effective design.

Safety Considerations: Electrical safety must always be a priority when dealing with wiring and circuits. It’s essential to adhere to industry standards and best practices to protect both the equipment and personnel involved. Regular inspections and maintenance can help identify potential issues before they escalate.

By comprehensively analyzing these aspects, one can ensure that the electrical system operates smoothly and efficiently, minimizing downtime and enhancing reliability.

Handle Assembly and Control System

The handle assembly plays a crucial role in ensuring the efficient operation of the equipment, providing users with the necessary interface to manage various functionalities. This section delves into the intricate components and mechanisms that constitute the handle system, emphasizing their importance in achieving seamless control.

At the heart of the assembly lies the handle itself, designed for comfort and ease of use. It incorporates ergonomic features that enhance grip, allowing operators to maintain precise control during operation. Integrated buttons and switches within the assembly facilitate quick access to essential functions, enabling users to adjust settings or initiate actions with minimal effort.

The control system is interconnected with various sensors and feedback mechanisms, ensuring that the user’s inputs translate accurately into the machine’s responses. This includes proximity sensors that detect handle position and feedback indicators that inform users of the system status, enhancing overall operational efficiency.

Overall, understanding the intricacies of the handle assembly and control system is vital for troubleshooting and maintenance, as well as for optimizing performance in various applications.

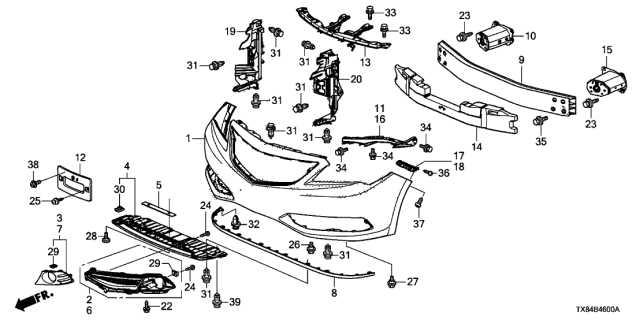

Chassis and Frame Assembly Breakdown

The chassis and frame serve as the foundational structure of any vehicle, providing stability and support for various components. This section explores the intricate details of the assembly process, highlighting the interrelationships among different elements that contribute to the overall integrity and performance of the machine.

The construction typically involves a combination of robust materials designed to withstand various stresses encountered during operation. Key components such as cross members, support beams, and mounting brackets play crucial roles in ensuring that the frame can handle dynamic loads while maintaining structural integrity.

Furthermore, proper alignment and secure fastening of these elements are essential for achieving optimal performance and longevity. Understanding how each part interacts within the assembly allows for more effective troubleshooting and enhances maintenance efforts, ultimately leading to a more reliable and efficient vehicle.

Air Intake and Exhaust Components

The air intake and exhaust systems play a crucial role in optimizing engine performance and efficiency. These systems ensure the proper flow of air into the engine for combustion while effectively expelling exhaust gases. Understanding their components is essential for maintaining the overall functionality and longevity of the machinery.

Air Intake System

The air intake system consists of several key elements that facilitate the flow of clean air into the engine. This includes air filters, intake manifolds, and throttle bodies. Each component works together to maximize airflow and enhance combustion efficiency, ultimately contributing to improved power output and fuel economy.

Exhaust System

The exhaust system is equally important, as it is responsible for directing harmful gases away from the engine and out of the vehicle. Key components include exhaust manifolds, catalytic converters, and mufflers. These parts not only help reduce emissions but also minimize noise, ensuring a smoother and quieter operation.