The effective operation of a portable flame device relies on a harmonious interaction among its various elements. Each component plays a vital role, contributing to the overall functionality and safety of the tool. A thorough understanding of these elements can enhance both performance and user experience.

Exploring the intricate layout and mechanics of this tool reveals the engineering prowess behind its design. From the fuel chamber to the ignition system, each section is meticulously crafted to ensure efficiency and reliability. Recognizing how these segments connect and work together is essential for anyone looking to utilize this device optimally.

Furthermore, having knowledge of the individual functions within the assembly can empower users to troubleshoot issues and maintain their equipment effectively. By delving into the specifics, one can appreciate the innovation that makes these flame-producing tools invaluable in various applications, from culinary arts to repair tasks.

Understanding the Butane Torch Basics

In various applications, a compact device serves as an essential tool for generating intense heat. This equipment finds its place in culinary practices, metalworking, and crafts, providing users with the ability to achieve precise and controlled flames. Grasping the fundamental components and their functionalities is crucial for maximizing efficiency and safety.

Core Components

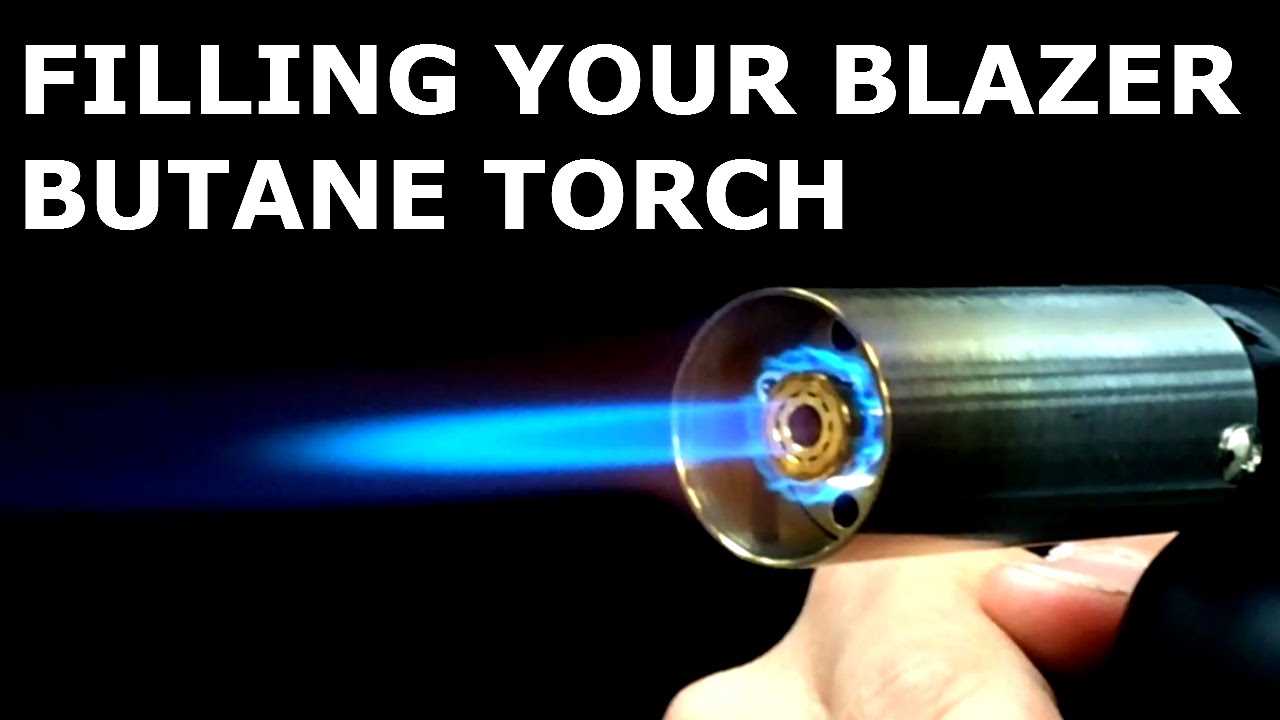

The structure comprises several key elements that work together harmoniously. A reservoir holds the fuel, which is released in a controlled manner to create a flame. An ignition mechanism is vital, allowing for easy activation while ensuring that the device can be safely operated. Additionally, the nozzle plays a critical role in directing the flow of heat, enabling users to focus the flame as needed.

Safety Considerations

While utilizing this heating device, it is imperative to prioritize safety. Always work in well-ventilated areas to prevent the buildup of harmful gases. Proper handling and storage of the fuel are also essential to mitigate risks. Familiarizing oneself with the operational guidelines can enhance user confidence and prevent accidents.

Key Components of a Butane Torch

Understanding the essential elements of a handheld flame-producing device is crucial for effective and safe operation. Each component plays a significant role in ensuring the reliability and efficiency of the tool during various tasks.

The fuel reservoir holds the flammable substance, providing the energy needed for ignition. The ignition system, often a spark or piezoelectric element, initiates combustion, creating the flame. A nozzle is designed to control the flow of gas and shape the flame for precision. Additionally, the valve system regulates pressure, allowing for consistent performance. Finally, the safety mechanisms are vital for preventing accidents, ensuring user protection during operation.

How a Butane Torch Functions

This device operates by harnessing a combustible gas, which, when ignited, produces a focused flame. The process involves several key components working in harmony to ensure efficient performance.

- Fuel Chamber: Holds the flammable gas under pressure.

- Valve Mechanism: Controls the release of gas for ignition.

- Ignition System: Creates a spark to ignite the gas.

- Air Intake: Allows oxygen to mix with the gas for combustion.

- Flame Adjustment: Lets users modify the intensity of the flame.

Understanding these components can help users maximize efficiency and safety during operation.

Safety Features in Modern Torches

In contemporary flame devices, a variety of protective mechanisms are integrated to ensure user safety and enhance operational efficiency. These innovations not only minimize risks associated with high-temperature outputs but also promote responsible usage. Understanding these features is crucial for both novices and seasoned users.

Ignition Lock Mechanisms

One of the primary advancements is the ignition lock feature, which prevents accidental activation. This ensures that the device remains inactive until the user deliberately engages the mechanism, thus reducing the chance of unintentional flare-ups.

Flame Control Adjustments

Another critical aspect is the adjustable flame control, allowing users to modify the intensity of the output. This functionality is essential for various applications, ensuring precision while maintaining a safe operating environment. Overall, these enhancements reflect a commitment to safety and efficiency in design.

Types of Butane Torches Available

In the world of portable heating tools, various models cater to different needs and preferences. Each variant is designed to provide specific functionalities, ensuring versatility for users in culinary, crafting, and industrial applications.

Culinary Devices

These instruments are tailored for food enthusiasts, offering precise flame control for tasks like caramelizing sugar or roasting peppers. The compact design makes them convenient for kitchen use, allowing for an ultimate experience in meal preparation.

Industrial Tools

Heavy-duty variants are engineered for more rigorous tasks such as soldering, brazing, or even jewelry making. With robust construction and adjustable flames, these tools ensure optimal performance in demanding environments.

Common Uses for Butane Torches

These versatile tools find their application across various fields due to their ability to produce a focused flame at high temperatures. They are essential for both professional tasks and everyday activities, providing convenience and efficiency in various processes.

Culinary Applications

In the culinary world, these instruments are invaluable for tasks such as caramelizing sugar on desserts, browning the tops of dishes, and melting cheese. Chefs often rely on them to enhance flavors and textures, making them a staple in both home kitchens and restaurants.

Crafting and Repair Work

In crafting and repair, these devices are employed for soldering metal, joining components, and even performing detailed artistic work. They are favored for their precision and control, allowing artisans to achieve intricate results while working with various materials.

Maintenance Tips for Longevity

Ensuring the durability and reliability of your ignition device requires regular attention and care. Implementing effective maintenance strategies can prevent malfunctions and extend the lifespan of your equipment, allowing for consistent performance over time.

Here are some essential practices to keep your device in optimal condition:

| Tip | Description |

|---|---|

| Regular Cleaning | Clean the exterior and any accessible components to remove debris and residues that could interfere with functionality. |

| Check Seals | Inspect seals for wear and tear; replace them if they show signs of damage to prevent leaks and ensure safety. |

| Proper Storage | Store the device in a cool, dry place away from direct sunlight and extreme temperatures to prevent degradation. |

| Fuel Management | Use the recommended fuel type and avoid overfilling the reservoir to minimize the risk of spills and ensure efficient operation. |

| Periodic Inspection | Regularly check for any signs of malfunction or wear, addressing issues promptly to prevent more significant problems. |

Adopting these maintenance tips will help ensure your ignition device remains functional and safe for years to come, ultimately enhancing your overall experience.

Replacing Parts in Your Torch

Maintaining your heating tool in optimal condition is essential for its performance and longevity. Over time, components may wear out or become damaged, necessitating their replacement. Understanding the structure of your device will aid you in identifying which elements require attention and how to effectively substitute them.

Identifying Worn Components

Before proceeding with any replacements, it’s crucial to assess which components are malfunctioning. Common signs include irregular flame output or difficulty igniting. Regular inspections can help you catch issues early, ensuring that you can replace faulty elements without compromising functionality.

Steps for Replacement

To replace a component, first, ensure the device is completely cool and disconnected from any fuel source. Refer to the manual for guidance on disassembly. Once you have access to the affected area, carefully remove the damaged part and install the new one, ensuring a secure fit. After reassembly, conduct a thorough test to verify proper operation.

Identifying Issues with Your Torch

Understanding potential malfunctions in your device can enhance its efficiency and safety. By recognizing signs of trouble, you can troubleshoot effectively and ensure optimal performance.

Common Signs of Malfunction

- Inconsistent flame output

- Unusual noise during operation

- Difficulty in ignition

- Unresponsive controls

Troubleshooting Steps

- Check fuel levels to ensure sufficient supply.

- Inspect the nozzle for blockages or damage.

- Examine connections for wear or leaks.

- Clean any dirt or residue that may affect functionality.

Optimal Butane Fuel for Performance

Choosing the right fuel is essential for achieving peak performance in any application that requires high heat output. The quality of the combustion substance can significantly influence the efficiency, burn time, and overall effectiveness of the equipment. Selecting a premium-grade option ensures reliable operation and reduces the likelihood of malfunctions or interruptions during use.

Factors to Consider

When evaluating options, consider the purity of the fuel. Higher purity levels minimize impurities that can lead to incomplete combustion and residue buildup. Additionally, the canister’s design plays a crucial role in delivering consistent pressure, which directly affects the flame’s stability and temperature. Always check for compatibility with your specific device to ensure optimal functionality.

Performance Benefits

Utilizing a high-quality combustion substance can lead to improved flame characteristics, including a more intense and controllable heat source. This results in faster heating times and better precision for various tasks. Furthermore, reliable fuel helps maintain the equipment’s longevity by reducing wear and tear associated with lower-grade alternatives. Investing in superior fuel is not only beneficial for performance but also for the overall lifespan of the device.

Differences Between Disposable and Refillable Models

When considering various options for flame-producing devices, it is essential to understand the fundamental distinctions between single-use and reusable models. Each type offers unique advantages and disadvantages that cater to different user needs, preferences, and applications.

Convenience and Usability

Single-use units are designed for quick and effortless access. They typically come pre-filled and ready to operate, making them ideal for users who prefer a hassle-free experience. Conversely, refillable variants require regular maintenance and occasional refilling, which can be seen as an inconvenience by some. However, this aspect allows for more sustainable use and can lead to cost savings over time.

Environmental Impact

The environmental implications of each model type are significant. Single-use devices contribute to waste, as they are disposed of after their contents are depleted. Refillable options, on the other hand, promote a more eco-friendly approach by reducing overall waste. Users concerned about their ecological footprint may lean towards reusable designs, knowing they can extend the life of their equipment.

DIY Repairs for Butane Torches

Engaging in maintenance of your handheld flame devices can save you both time and money. Often, minor issues can be resolved with a bit of know-how and common tools. This guide aims to empower you with practical tips for fixing common malfunctions.

Identifying Common Issues

Start by pinpointing the problem. Leaks, inconsistent flames, or ignition failures are frequent concerns. Inspect the fuel chamber and nozzle for any signs of wear or blockage. Regular checks can help prevent larger issues down the line.

Basic Repair Techniques

For leaks, consider applying a sealant specifically designed for gas appliances. If the flame is unstable, adjusting the fuel flow might be necessary. Always ensure safety precautions are in place before attempting repairs, and consult your user manual for specific instructions relevant to your model.

Choosing the Right Torch for Your Needs

When it comes to selecting a reliable source of intense flame, understanding your specific requirements is crucial. Whether you are engaged in culinary arts, metalworking, or DIY projects, the right choice can significantly enhance your experience and outcomes. This section aims to guide you through the key considerations to ensure you pick the most suitable tool for your tasks.

Assessing Your Requirements

Begin by evaluating the primary applications you have in mind. For tasks requiring precision, such as caramelizing sugar or soldering delicate components, a model with adjustable intensity may be necessary. Conversely, if your work demands a more robust heat output for tasks like brazing or welding, a heavier-duty variant will be more effective. Identifying the intensity and control you need is essential for optimal results.

Safety and Usability Features

Safety should always be a priority. Look for features such as automatic ignition, safety locks, and ergonomic designs that facilitate comfortable handling. Additionally, consider the fuel source and refillability options. A user-friendly design can make a significant difference, especially for prolonged use. Taking these factors into account will not only ensure a safer experience but also improve your efficiency and enjoyment in the activities you pursue.